Keeping track of tools can be a tedious task, but in the construction industry, where nothing can be done without your equipment, this is a vital part of business operations.

Manual tool tracking may seem like the most straightforward approach, but it can be far from cost-effective in more ways than one.

That’s why, in this article, we’ll be exploring the real cost of manual tool tracking and why it’s worth considering a more efficient solution.

In this article...

Inaccurate Tool Inventory

Not having complete control over your inventory may cost you much more than you think.

Granted, one hammer that’s unaccounted for certainly won’t bring ruin to the entire company, but with manual tool tracking, you potentially face considerably bigger (and more expensive) issues.

When you monitor assets using pen and paper or spreadsheets, you don’t have the ability to update the equipment information in real time. Besides, the information you input manually is highly likely to be inaccurate or incomplete.

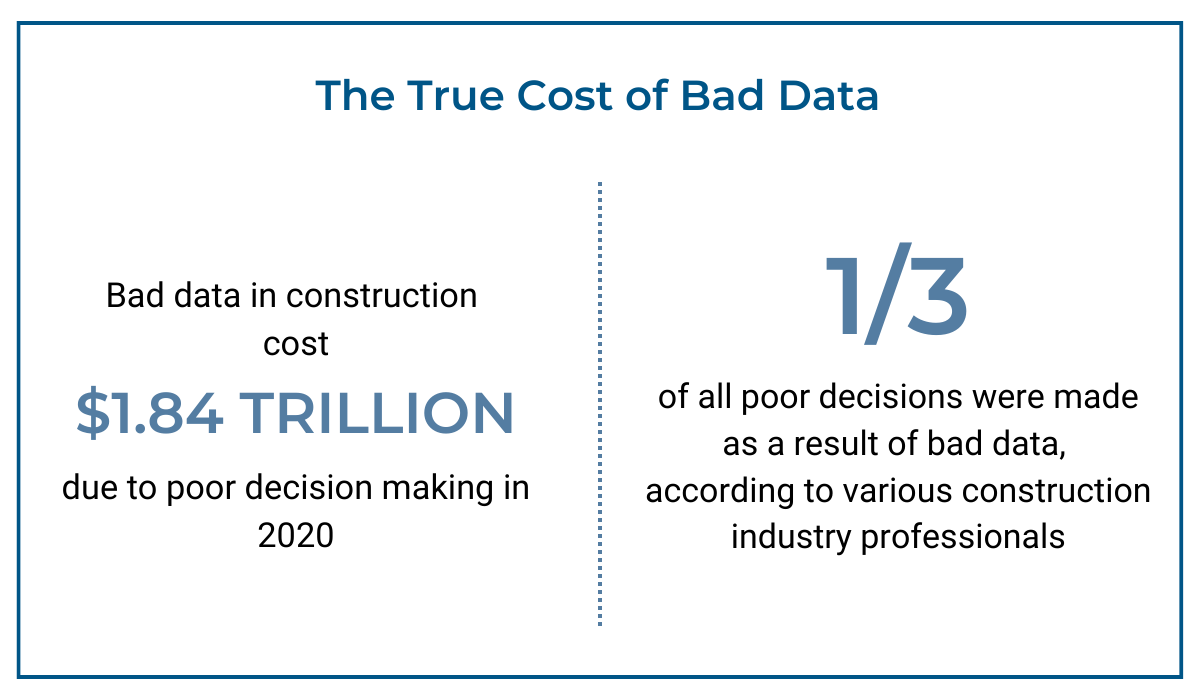

Autodesk and FMI refer to this untimely, inconsistent, or incorrect data as “bad data,” and in their 2022 report, they explored its effect on the construction industry. Take a look at the findings below.

Illustration: GoCodes Asset Tracking / Data: Autodesk

Poor data finds its way into all aspects of business operations, inventory management included.

To better understand this, let’s consider a specific example.

If, say, a grinder gets misplaced, a field worker may need to wait until the end of their shift, provided they don’t forget about it by then, to inform the project manager, who then has to type up a report in the office.

That’s a lot of steps for just one lost tool.

So what usually happens is the following: no one reports the missing equipment because it’s too much work, and in the system, the grinder is still available for use.

Such assets, which are present only on paper, are called ghost assets.

The real issue arises later when your team needs the grinder but realizes there aren’t any left.

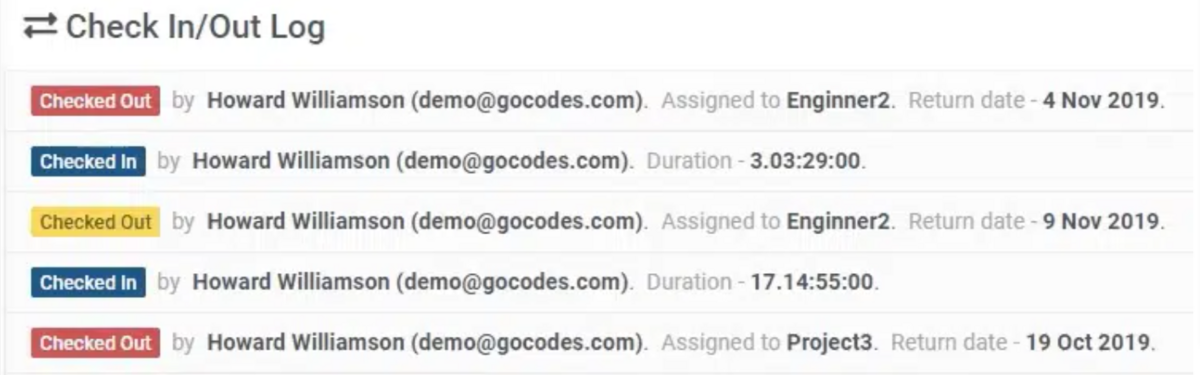

Source: GoCodes Asset Tracking

There isn’t any check-out log showing who was the last person to use the grinder, so the workers go looking for it, wasting hours and hours. On top of that, you need to order a new one as quickly as possible and wait for the delivery while the project comes to a halt.

But that’s not the only problem.

Since the asset is listed as active in the system and expensed on the income statement, it can lead to overpayment of property insurance as well as non-compliance, placing you in a jeopardous position.

In essence, you can’t know for sure what you have or don’t have unless you keep accurate and up-to-date asset records, which is hard to do if there’s no effective tracking solution in place.

Unnecessary Tool Purchases

On the flip side, it’s possible that the grinder was never lost. It’s just that nobody was aware of its existence.

If a tool isn’t in a depreciation schedule on the company’s balance sheet but is physically present on the premises, then we’re talking about zombie assets.

Although considered the opposite of ghost assets, they are the root cause of just as many problems, including increased tax liability and potential for theft, as well as asset duplication and wasted spending.

And just like the ghost assets, they stem from poor record keeping.

As a preventive measure for this type of situation, people often decide to purchase multiple tools in advance to ensure that they have backups in case some get misplaced later on.

However, this is not a practical use of the company’s resources and can significantly skyrocket your expenses.

In short, purchasing unnecessary tools is not the solution. It’s a profitability killer.

Now, monitoring the whereabouts of a signal grinder is not an issue. But what about a fleet or a whole warehouse full of equipment?

For such a large amount of resources, a centralized, automated database of all assets is necessary.

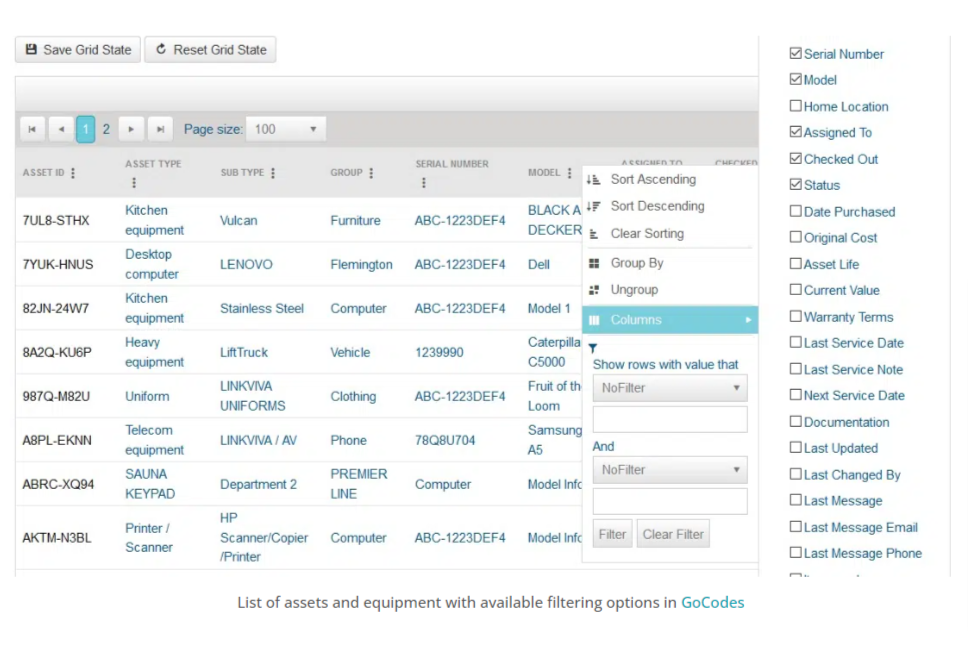

Source: GoCodes Asset Tracking

Manual tool tracking simply cannot keep up with the needs of a growing business.

Overall, it’s crucial to detect small expenses that go unnoticed at first glance. These unnecessary purchases can add up over time and accumulate into a high cost before you even realize it.

Therefore, efficient tool management involves being mindful of every expense and avoiding those that are not essential.

Lower Employee Productivity

Consequences of manual tool tracking reach far beyond just your fixed asset register and can even impact employees’ overall productivity.

When workers are responsible for inputting data, you can be sure to expect some oversights to occur. The impact of such errors was already outlined in the previous two sections.

Even with the most diligent employees, mistakes are bound to happen when a piece of information has to travel all the way from a job site to the project manager and then to the Excel sheet on the computer.

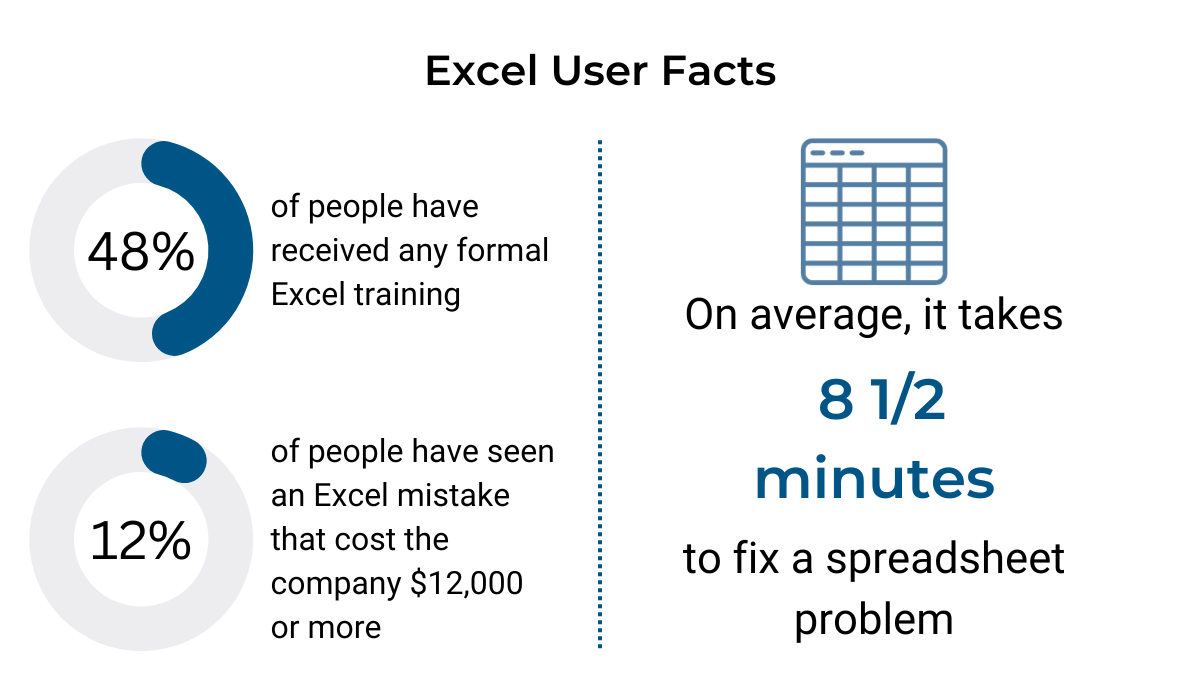

While manual asset management methods may seem less expensive at first, the time required to fix these spreadsheet errors can result in added costs.

Illustration: GoCodes Asset Tracking / Data: Acuity Training

Not to mention that formal Excel training is not a common practice, which can be problematic, especially for older workers.

Moreover, manual tool tracking and poor job site coordination go hand in hand.

Not knowing who has a piece of equipment at the moment, where it is, and when it’s going to be returned to the warehouse are all things that can seriously slow the whole team down.

After all, their time costs you money. It’s only natural you don’t want to waste it.

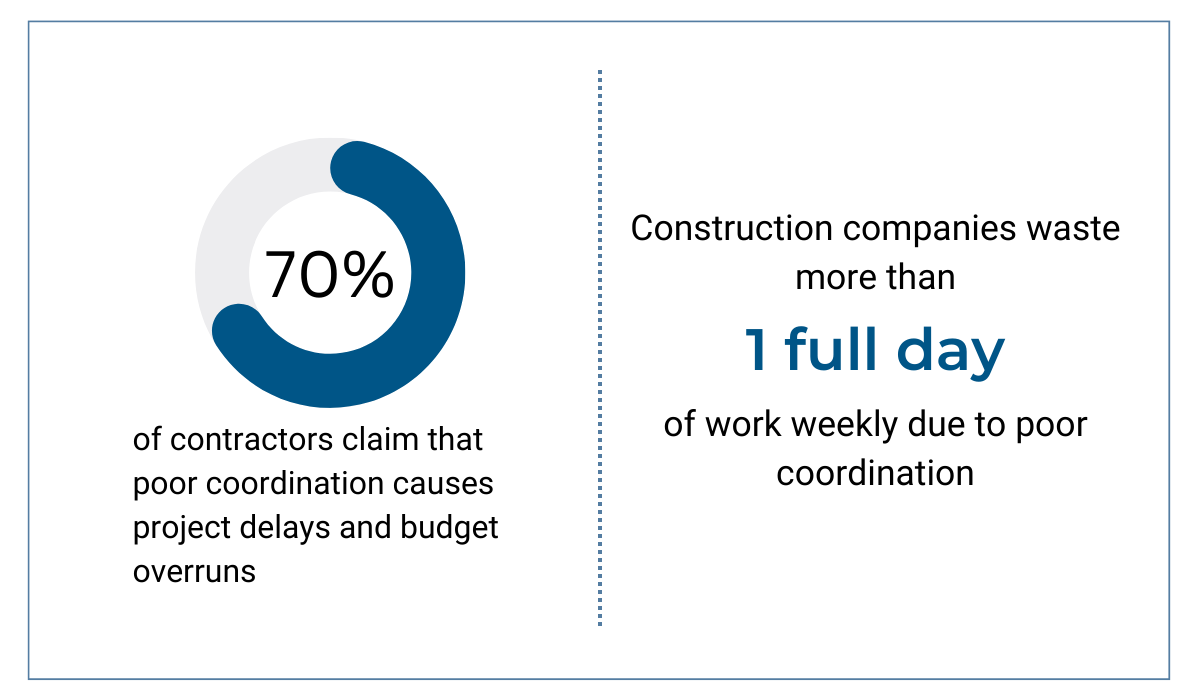

But did you know that construction companies lose up to one full day of work each week due to inefficiency?

This is certainly not something to glance over.

Illustration: GoCodes Asset Tracking / Data: Levelset

Lack of organization and communication among workers can have serious consequences for your ability to complete projects on time as well as the bottom line. In fact, nearly 70% of construction industry professionals consider poor coordination to be the main cause of budget overruns and project delays.

In summation, it’s vital to remember that every minute wasted searching for misplaced equipment affects project completion and profitability more than you even know.

Giving up on manual tool tracking methods can, therefore, be the first step in increasing your business’s productivity.

Decreased Tool Efficiency

Yes, an accurate tool inventory is important, but this alone doesn’t guarantee you’re making the most out of your assets.

Construction tools are a significant investment, and as such, they need to be well-maintained, too.

What use is knowing how many grinders you have and where they are if they aren’t in working condition?

Neglecting the upkeep of assets can result in considerable expenses over time.

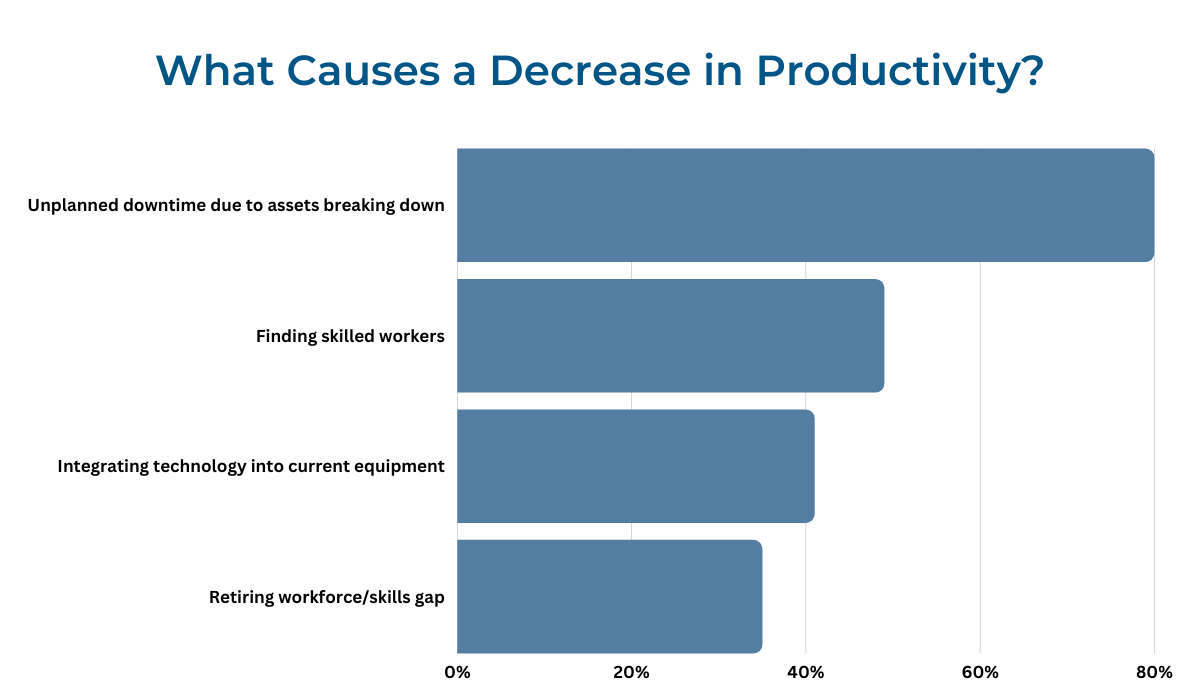

Replacement and maintenance costs, as well as unplanned downtime, project delays, and shortened equipment lifespan, are all problems you could potentially face with substandard asset care.

Illustration: GoCodes Asset Tracking / Data: ATS

To prevent such things from happening, effective team communication and maintenance strategy are necessary.

Instead of repairing the assets only when they’re already broken, you should consider scheduling frequent inspections, calibrations, and other service tasks. This will ensure any major equipment failure is avoided.

However, establishing a successful upkeep strategy is not quite possible with manual tool tracking as it has no way of properly keeping all the maintenance records.

In other words, with a lack of an automated, centralized system, it’s hard to tell when the last maintenance was performed, who performed it, and what exactly was done.

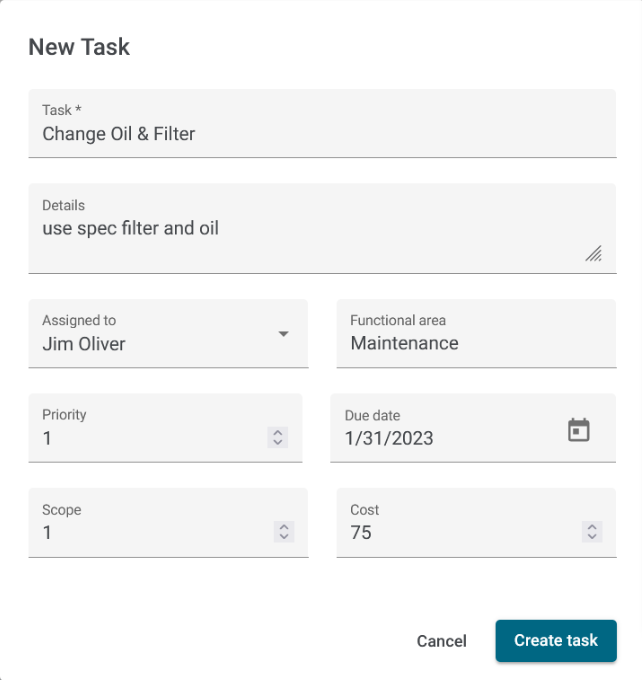

Luckily, more advanced solutions are available today, which make proper maintenance a breeze.

Source: GoCodes Asset Tracking

For instance, not only will efficient tool tracking software keep track of the maintenance history for each asset, but it’ll also enable you to set up different equipment service tasks, assign particular workers to those tasks, and even set task completion deadlines.

That way, everyone stays on top of their responsibilities, ensuring your tools are in the best possible shape.

No Way to Prevent Tool Loss

We’ve already explained how not knowing where a tool is can cause a whole avalanche of costly issues, from replacement costs to project delays.

Workers usually focus only on tasks at hand, and rarely do they bother returning equipment where they’re supposed to.

This is how most often assets get lost.

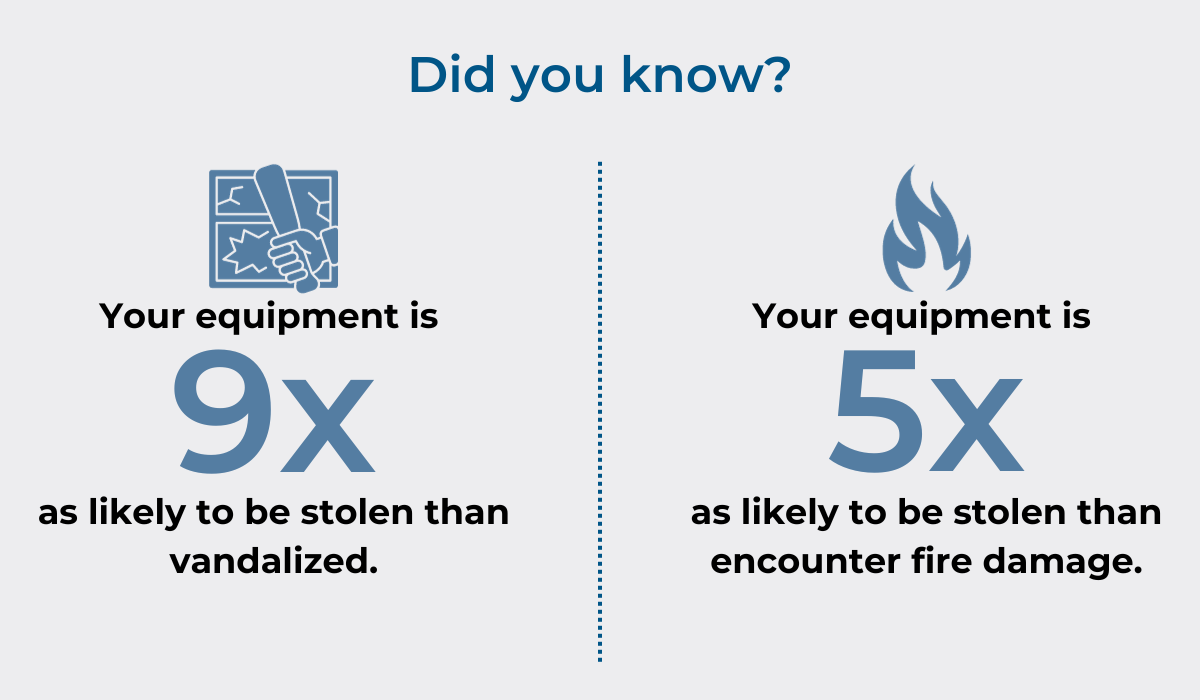

However, there’s another huge issue plaguing the construction industry, and that’s theft.

Illustration: GoCodes Asset Tracking / Data: NER

With more than 11,000 burglaries reported on US construction sites in 2021 alone, this problem is still a prevalent one in construction, wreaking havoc on businesses’ productivity and profitability.

Manual tool tracking doesn’t give you insight into the whereabouts of tools at each given moment, and in case of theft, this outdated system provides no possibility of retrieval.

That’s why using spreadsheets doesn’t make sense nowadays, especially when there are so many more advanced solutions available.

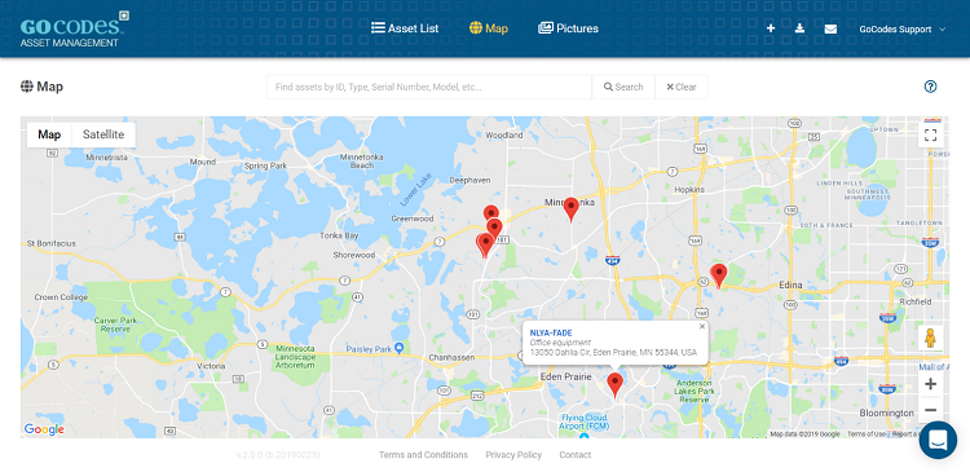

We at GoCodes Asset Tracking pride ourselves on creating an efficient and user-friendly solution that successfully prevents tool loss.

Source: GoCodes Asset Tracking

The system consists of only two components: rugged QR code labels and a tool-tracking app, which makes monitoring equipment easy, fast, and effective.

Here’s how it works.

Simply attach GoCodes Asset Tracking labels to the assets you want to track, and once you install the app on your smartphone, you’re ready to go.

Use the app to scan a tag or label for a quick check-in/check-out or an update, and each time either is done, the GPS location of the update/asset is recorded.

Source: GoCodes Asset Tracking

That way, in the event of a burglary, you’ll have the last known location of a stolen asset as well as the last person to use it.

Besides, seeing the label might indicate to the thieves that the piece of equipment is being tracked, potentially deterring them from their endeavor.

Higher Operating Costs

Are you aware that relying on manual methods to track equipment prevents you from using your assets efficiently and can actually lead to higher operating costs?

This is because systems that rely on manual data input don’t allow for tracking various metrics pertaining to equipment utilization, including:

- Asset check-in/check-out

- GPS location of a tool

- Machine part action

- Weight

- Ignition running time

- Engine hours

- Miles

In other words, with these outdated solutions, there’s no way of knowing, for instance, the fleet’s idling behavior, which could potentially negatively affect the fleet’s fuel and maintenance costs.

Therefore, by implementing technology that tracks utilization metrics, also known as telematics, you can save money in the long run.

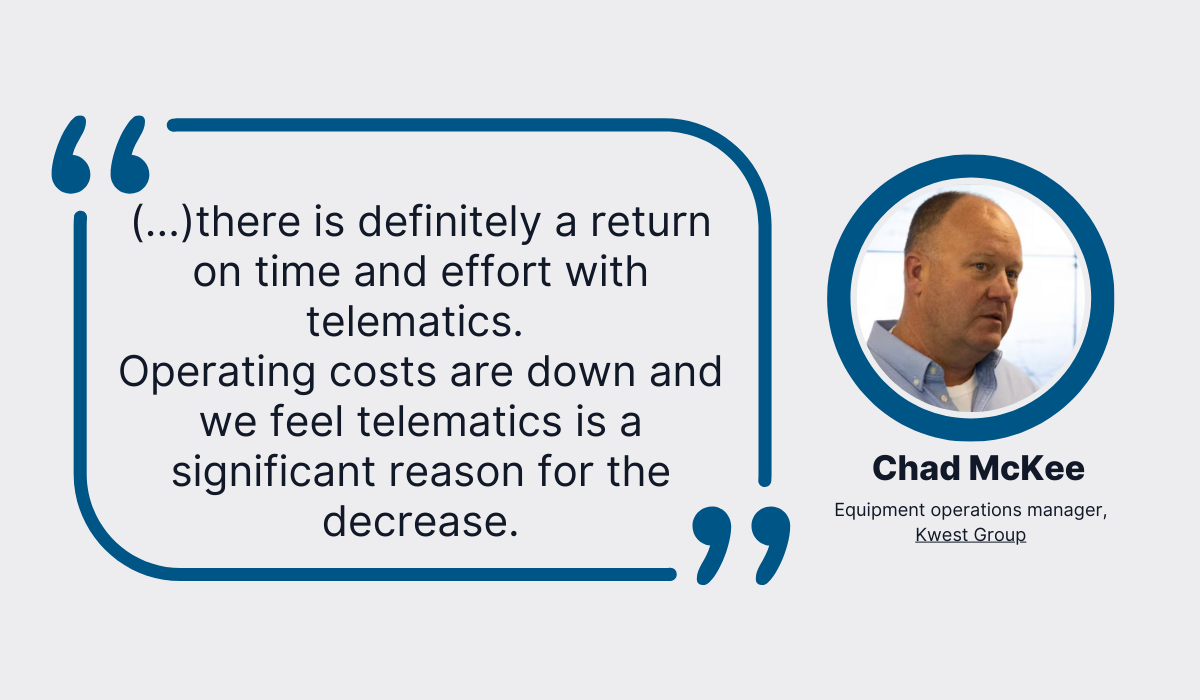

Chad McKee, equipment operations manager at Kwest Group, agrees.

Kwest started off with monitoring telematics of 20% of their assets and graduated to 100% within less than a year.

According to McKee, it paid off.

Illustration: GoCodes Asset Tracking / Source: CON/AGG

Before the system, they used to rely on manual data entry. As expected, this was a flawed solution, and since the company made a switch to automated telematics and tool tracking, its resource utilization significantly improved.

Automated tracking allows you to monitor and analyze usage trends, tool allocation, and operator performance to make better, data-driven decisions about asset use coordination.

This, in turn, improves the overall effectiveness of your equipment and ensures that you are making the most out of it.

Conclusion

Taking everything into account, it’s clear as day that manual tool tracking can be quite a labor-intensive, costly, and time-consuming process, which, more often than not, results in errors that can harm a company’s profitability.

By investing in an automated asset tracking system, you avoid all these pricey issues effortlessly.

Don’t let manual tool tracking hold your business back – consider upgrading to a more cost-effective solution today.