Key Takeaways:

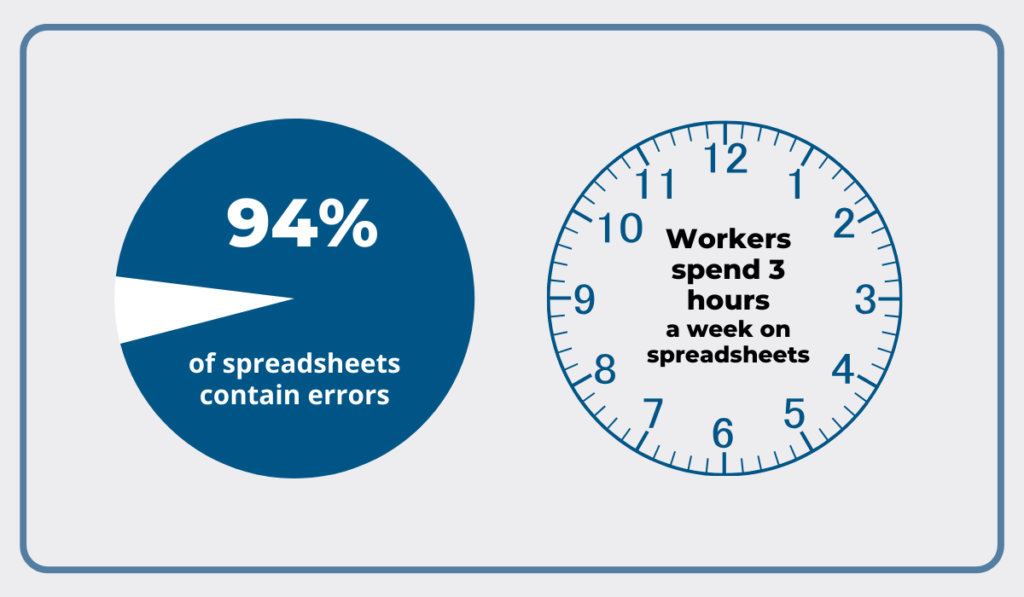

- More than 90% of spreadsheets contain errors, costing employees an average of 3 hours a week.

- Barcode systems require specialized scanners and other hardware.

- Some QR code trackers provide passive, scan-based GPS tracking.

- GPS trackers provide real-time location updates, essential for theft protection and route navigation.

There are more ways than ever to track assets—some simple, some high-tech.

From old-school pen and paper or spreadsheets to advanced tracking with QR codes, RFID, BLE, and GPS, businesses have plenty of options.

In this article, we’ll break down seven asset tracking methods, explaining how they work, their pros and cons, and which makes the most sense based on your needs and budget.

In this article...

Pen and Paper

This is the oldest and simplest asset-tracking method, still used in many businesses and low-tech environments.

Essentially, workers manually log details about assets (equipment, tools, etc.) or inventory on printed forms, checklists, and other logbooks.

In many cases, these records are later entered into a computer system through manual data input.

However, some remain solely in paper archives.

For example, a construction company’s tool and equipment check-in/out log might be digitized for tracking—or simply stored in paper form without ever being transferred to a system.

Source: Forms Direct

The upsides of tracking assets with pen and paper include:

- No technology required

- Easy for anyone to use

- Generally low cost

However, whether or not these records are later digitized, the downsides are significant.

One issue is human error—handwriting can be illegible, numbers can be misread, and manually transferring data into digital systems introduces mistakes.

Another major drawback is the time and labor inefficiency of paper-based processes.

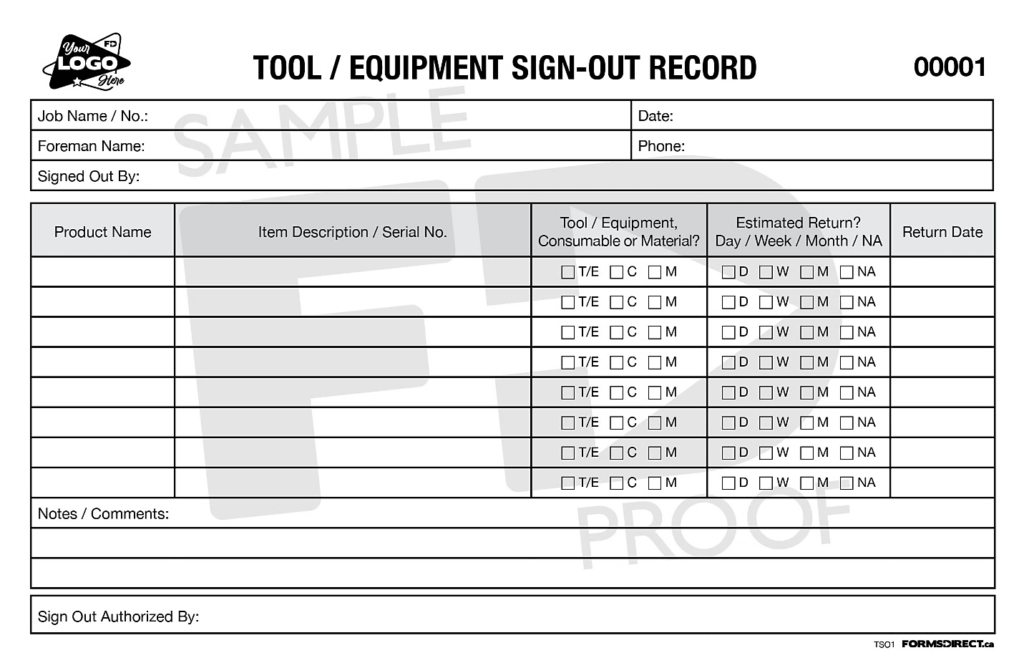

Take this heavy equipment daily inspection checklist logbook, for example:

Source: Amazon

With a paper checklist, workers must:

- Remember to bring a copy or locate one on-site

- Fill out the checklist form during inspections

- Keep it throughout the shift if issues appear

- Submit the completed form at the end of the shift

Then, administrative staff must review the forms, log reported issues, and manually enter the data into a system for tracking and analysis.

This process takes time, increases the risk of lost or misplaced records, and adds extra work for both field and office staff.

That said, when the power is out, the internet is down, or your phone battery dies, a pen and notebook can still serve as a temporary solution for later asset data entry.

Spreadsheets

Many businesses pair paper records with spreadsheets as their first step toward digitizing asset tracking.

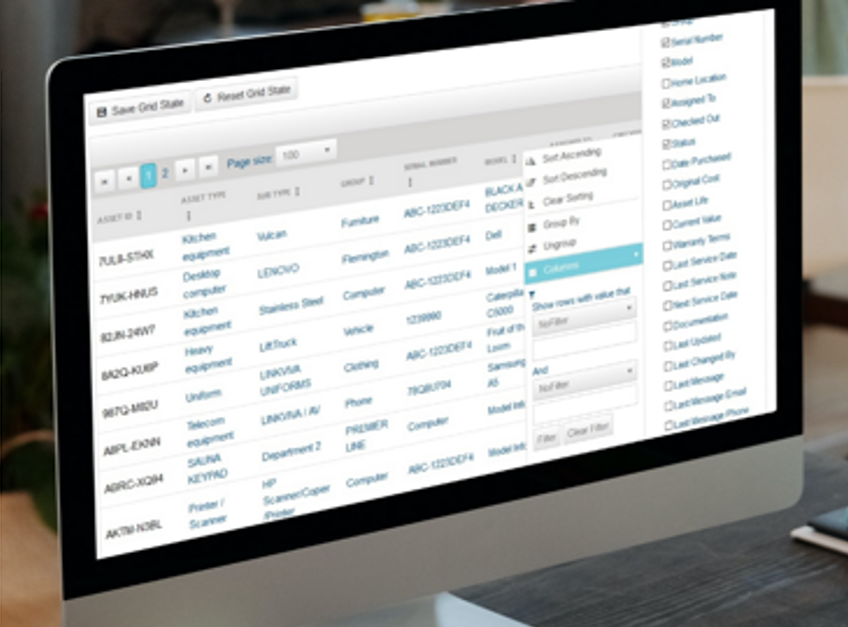

Spreadsheets—whether Excel or Google Sheets—provide a structured way to log asset details like serial numbers, maintenance dates, assigned users, and locations without requiring specialized software.

Since they’re digital, accessible, and cost-effective, spreadsheets are a step up from paper-based tracking.

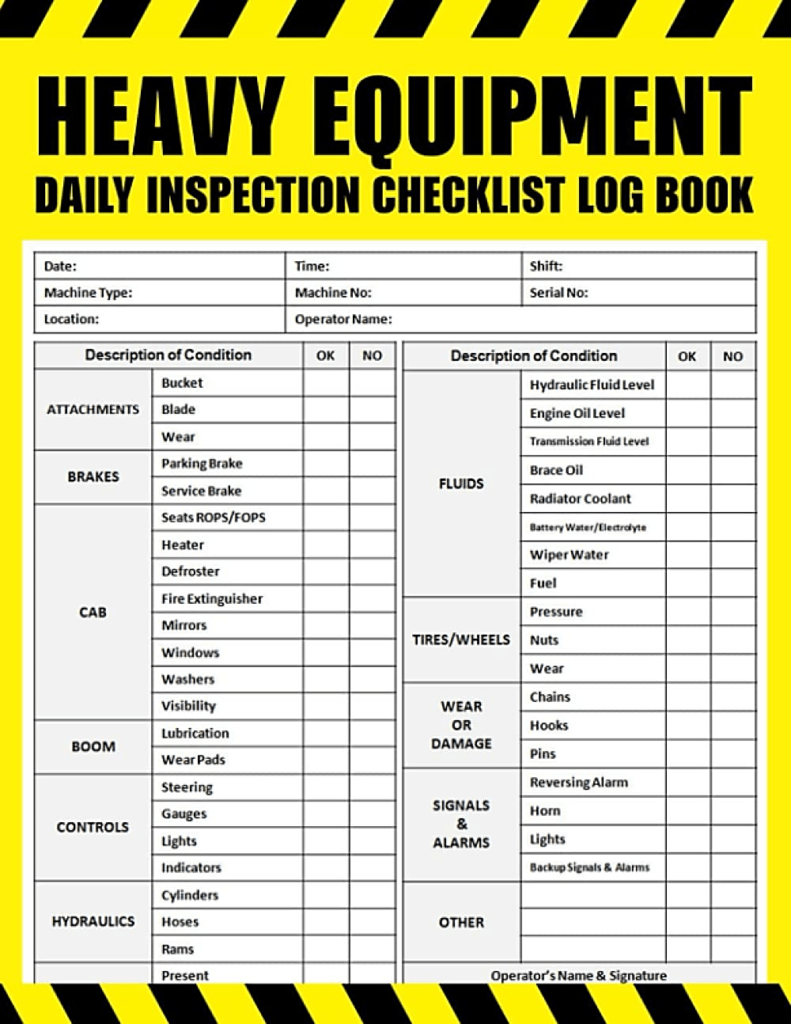

It’s no surprise that many companies, even in asset-heavy industries, still rely on this paper-to-spreadsheet combination.

A 2022 Motive survey found that 60% of fleet managers still use spreadsheets, while 52% also rely on paper documents to manage their fleets.

Illustration: GoCodes / Data: Motive

However, the continued reliance on spreadsheets often leads to inefficiencies.

After all, they were originally designed for manual accounting—not asset tracking.

While useful for basic record-keeping, spreadsheets lack:

- Automation

- Real-time updates

- Built-in error prevention

Manual data entry increases the risk of duplicate records, outdated information, and formula mistakes, making it harder to maintain accurate asset data.

In fact, research has repeatedly shown that spreadsheets are notoriously error-prone, with mistakes creeping in from both manual inputs and formula errors.

Meanwhile, a separate survey revealed that maintaining spreadsheets is also time-consuming, as shown below.

Illustration: GoCodes / Data: ProcessMaker & SpringerNature

Beyond these drawbacks, spreadsheets are also difficult to use on smartphones and tablets, limiting accessibility for field teams.

And just like paper records, they lack a direct link between digital asset data and physical assets in the real world.

That’s where the first tracking method that bridges this gap comes in—barcodes.

Barcodes

When barcodes burst onto the scene, they revolutionized asset tracking by enabling fully digital and partially automated processes.

This was a massive leap forward from paper- and spreadsheet-based methods, making asset tracking faster, more reliable, and easier to scale.

Today, barcodes remain a familiar sight, widely used in retail, logistics, and beyond.

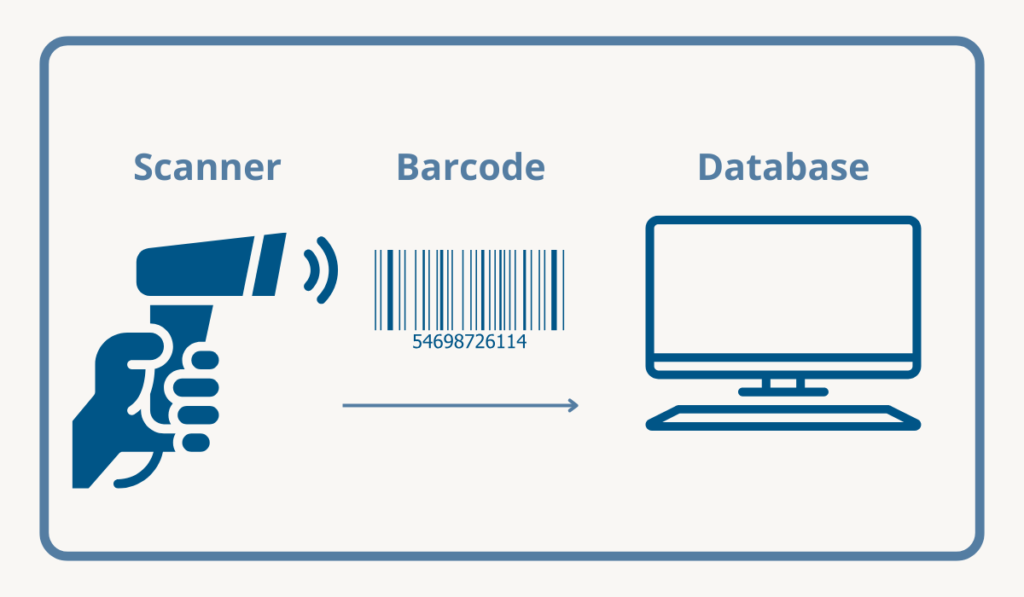

In asset and inventory tracking, each item gets a unique barcode label, which, when scanned, instantly retrieves its details from a software database.

Source: GoCodes

As shown in the illustration, barcode tracking systems traditionally rely on handheld scanners to log and track assets, particularly in warehouse environments.

However, many modern barcode-based solutions now allow scanning with a smartphone or tablet, reducing the need for dedicated scanning devices.

Regardless of the hardware used, this tracking method provides a simple and cost-effective way to store and retrieve asset information.

Scanning minimizes human errors related to data entry and enables instant database updates—allowing all authorized users to see changes in real time.

Source: GoCodes

In addition, barcodes are easy to print and cost-effective, making them a scalable solution for tracking anything from small tools and spare parts to heavy machinery.

So, what are the downsides?

First, many barcode tracking systems still require separate scanners and specialized barcode printers, increasing upfront costs.

Second, barcodes need a direct line of sight for scanning, which can be frustrating and time-consuming, especially when scanning multiple assets.

Third, barcodes are vulnerable to wear and tear in harsh environments.

If damaged, they become unreadable, requiring relabeling to maintain tracking accuracy.

Along with limited data space on barcodes, these limitations gave rise to a more advanced alternative and our next tracking method.

QR Codes

QR codes are the modern evolution of barcodes, offering enhanced functionality—including, in some cases, scan-based GPS tracking.

Unlike traditional barcodes, which store data in one dimension, Quick Response (QR) codes store information in two dimensions.

This gives them several advantages:

- They can be scanned from any angle

- They can hold more asset details than barcodes

- They remain readable even if partially damaged

QR code-based asset tracking follows the same basic principle as barcode scanning, but with one major difference—there’s no need for separate handheld scanners.

Instead, workers can simply use a smartphone or tablet with an asset-tracking app to scan asset tags and instantly access detailed information.

You can see this simple process in action here.

Source: GoCodes

Using QR codes and a mobile app with a built-in scanner for asset tracking brings many great benefits.

First, every team member with access can instantly view and update asset details based on user permissions.

This simplifies essential asset management tasks, such as monitoring asset conditions, tracking maintenance, and checking who is using an asset and where.

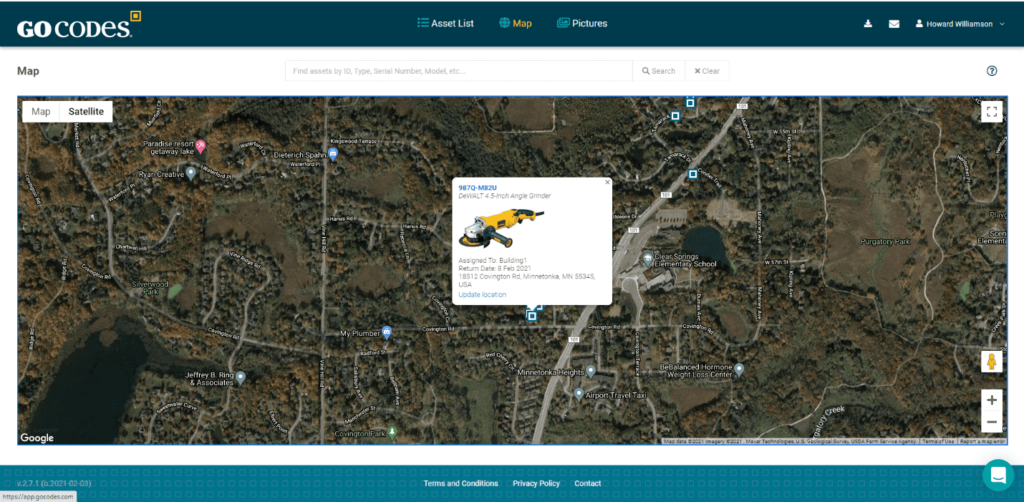

Most asset-tracking apps rely on manual location updates, but our all-in-one tracking app, GoCodes, takes it a step further.

When a worker scans an asset tag, the GoCodes app automatically captures their smartphone’s GPS location—eliminating the need for manual input.

Ultimately, this allows you to search for assets and view their last-scanned location directly on a map.

Source: GoCodes

The upsides of such automatic scan-based GPS location updates include:

- Less hassle but also more accountability for workers

- Assistance in finding misplaced, lost, or stolen assets

- Easier asset search, allocation, and maintenance

Additionally, a QR code-based tracking app enables workers to quickly check tools and equipment in and out, creating a clear record that prevents misuse and theft.

Another advantage is that QR codes of any size can be printed on a range of rugged, long-lasting materials, preventing peel-off or damage.

Source: GoCodes

Overall, QR code-based asset tracking—especially in its mobile, no-scanner-needed form—delivers a great balance of automation, convenience, and affordability.

The addition of automatic GPS location updates makes it even more powerful, acting as a passive tracker to help monitor smaller tools and inventory items effortlessly.

But what are the downsides?

QR codes still require manual scanning to access data and update locations.

Plus, the system relies on internet access, though many providers offer work offline functionality to address this.

For businesses looking for even faster, remote tracking, RFID technology offers a compelling alternative.

RFID (Radio Frequency Identification) Trackers

RFID (Radio Frequency Identification) is a wireless technology that enables asset tracking without the need for manual scanning.

Unlike barcodes and QR codes, RFID tags use radio waves to communicate with a reader, enabling automatic identification from a distance.

This means multiple assets can be tracked simultaneously and hands-free, making it ideal for warehouses, construction sites, and large-scale inventory management.

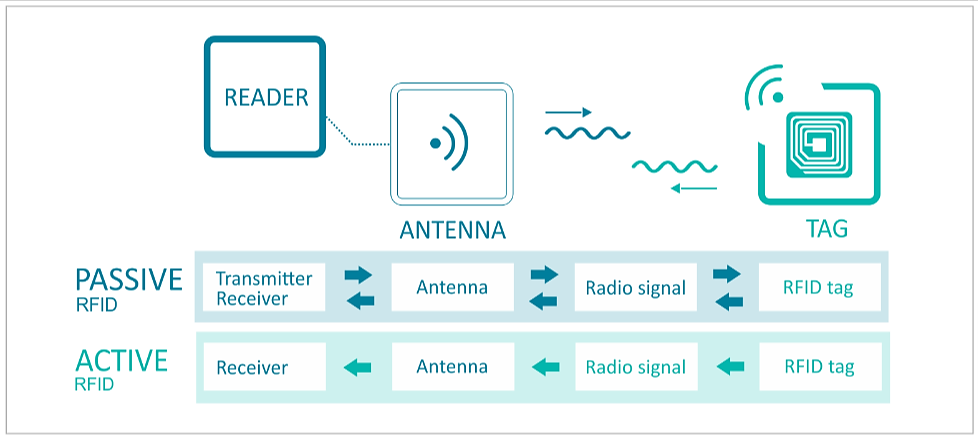

RFID technology comes in two main forms—passive and active—each with different capabilities and use cases.

Source: Aucxis

Passive RFID tags don’t have their own power source.

Instead, they rely on energy from the reader’s signal to transmit data.

Depending on the frequency, their range varies—from just a few inches (LF RFID) to about 3 feet (HF RFID) or even up to 30 feet (UHF RFID).

Since they are small and can be embedded within an asset, passive tags are well-suited for inventory management and tracking in controlled environments.

Active RFID tags, on the other hand, have built-in batteries, allowing them to continuously broadcast signals to a reader.

Although they require periodic battery replacement and are bulkier, their range is significantly greater, reaching 300 feet or more.

Source: RFID Inc

Because of their range and real-time tracking capabilities, active RFID tags are ideal for monitoring assets that move frequently within a facility.

Regardless of type, RFID eliminates the need for manual scanning, as readers automatically detect tags within range.

However, this is also one of RFID’s biggest drawbacks—it requires separate readers, increasing costs.

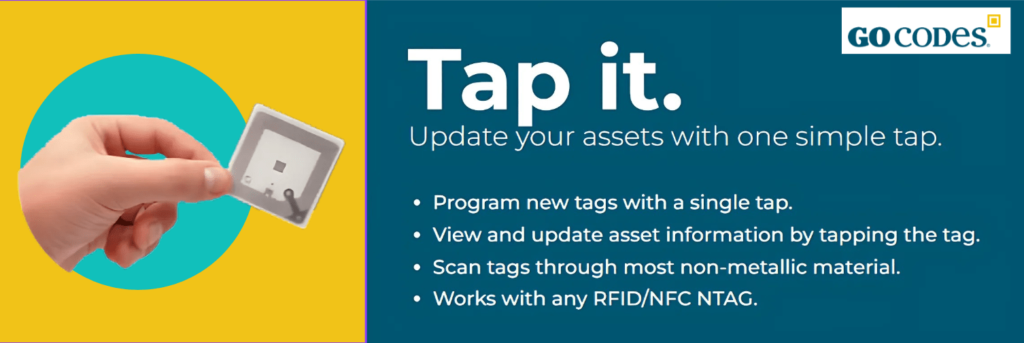

One subtype of RFID, NFC (Near Field Communication) tags, offers an alternative.

These tags can be read using most modern smartphones, eliminating the need for dedicated scanners.

Source: GoCodes

NFC tags function similarly to RFID but work at a very close range, typically between 4 and 20 inches.

Like RFID, they can be scanned through most non-metallic materials, such as plastic and wood.

While RFID automates asset tracking by eliminating manual scans—and active RFID provides short-range real-time location updates—the need for specialized readers can limit its practicality.

NFC offers a more accessible option, bridging the gap by allowing smartphones to function as scanners—but only at the tapping range.

Overall, RFID excels in controlled environments and specific asset or inventory tracking needs.

But for a simpler alternative for short-range live location tracking, let’s look at the next method.

Bluetooth Beacon Trackers

Bluetooth beacon or tag trackers provide a simple, automated way to track assets in real time within a defined area, such as a warehouse or construction site.

These small, battery-powered devices continuously broadcast signals that can be detected by smartphones, tablets, or gateway devices nearby.

Source: GoCodes

When a worker approaches an asset with a beacon, their smartphone automatically identifies it—no need for manual scanning.

Beacon trackers also support geofencing, triggering alerts if an asset is moved beyond a designated zone.

Below, you can see what a beacon looks like, along with the features we just covered—and a few more.

Source: GoCodes

While Bluetooth beacons enable hands-free tracking, their effectiveness depends on signal strength and potential interference.

Their range typically falls between 30 and 300 feet, but obstacles like walls, metal objects, and electronic signals can impact accuracy.

For more precise tracking in warehouses or construction sites, optional gateway devices can detect nearby beacons, providing real-time asset visibility.

Beyond asset tracking, BLE tags also support warehouse navigation, access control, and safety proximity alerts.

Overall, Bluetooth beacons provide a practical, cost-effective alternative to RFID for automated tracking.

At the same time, their short-range, live tracking makes them a great complement to the ultimate real-time asset-tracking method—GPS.

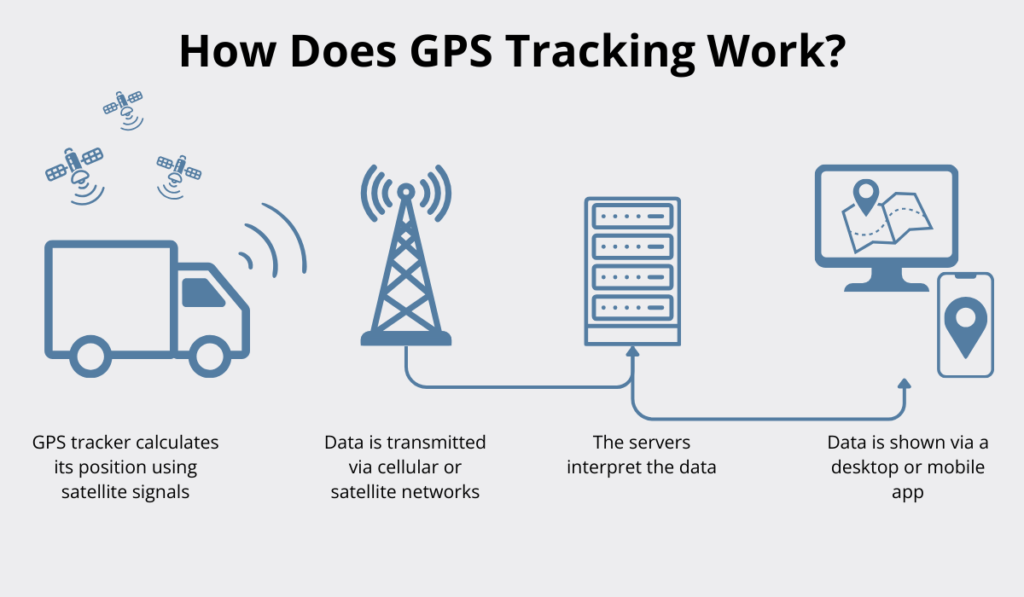

GPS Trackers

Both in movies and real life, GPS trackers are what we think of when it comes to real-time, minute-by-minute asset tracking.

A GPS tracker—whether battery-powered or wired into an asset’s power source—is installed in vehicles, heavy equipment, or other high-value assets to transmit location data at frequent intervals.

This signal is received by satellites and relayed to a tracking app, displaying the asset’s location on a map.

Source: GoCodes

GPS provides real-time location updates, making it invaluable for route navigation and theft protection.

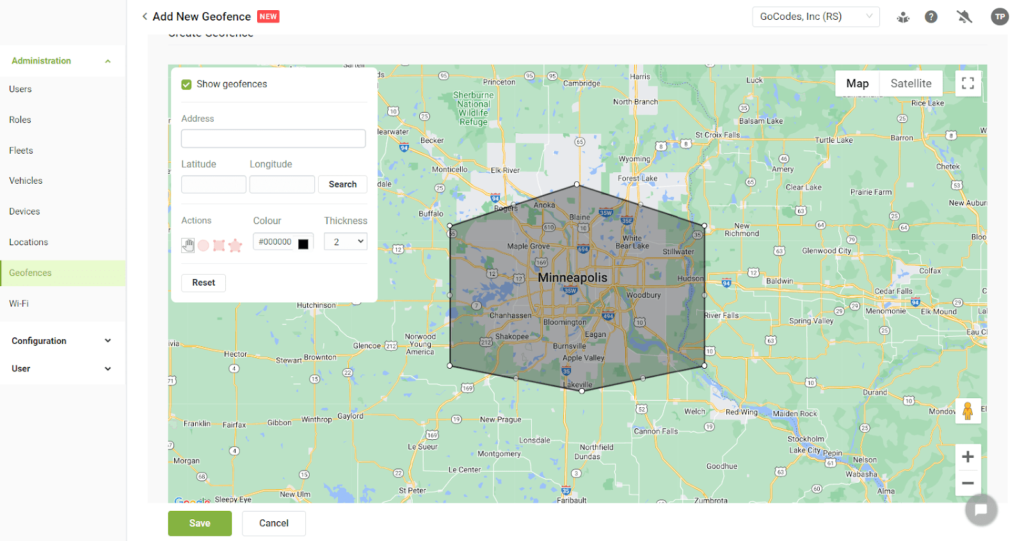

You can also set up geofences around specific areas and receive alerts if an asset moves outside the boundary—allowing for quick investigation and, if necessary, notifying authorities.

Source: GoCodes

With all these capabilities, GPS is an ideal solution for tracking fleet vehicles and valuable equipment.

But what are the limitations?

First, satellite positioning can be disrupted by obstructions like mountains, buildings, or underground locations, making GPS unreliable in some environments.

Second, cost (device + monthly service fees) and, for some assets, size constraints make GPS impractical for tracking every individual tool or item.

Lastly, while GPS trackers (with or without extra sensors) can collect various data points, they require a separate method for field data access.

For this reason, GPS tracking is often combined with barcodes or QR codes, allowing workers to quickly scan assets and retrieve additional details in the field.

Conclusion

From low-tech to high-tech solutions, no single tracking method works best for every asset.

Instead, smart businesses combine multiple tracking technologies to match their specific needs and budgets.

For example, they might use GPS for high-value, mobile assets, Bluetooth beacons for short-range real-time tracking, and QR codes for quick, scan-based asset updates.

The key is to identify the tracking features that matter most to your operations and then choose a cost-effective, user-friendly combination of technologies—ideally from a single provider for seamless integration.