With the right tracking system, companies save money, improve productivity or simply streamline their operations, ensuring maximum efficiency.

So, it’s no surprise the entire Location-based Service (LBS), and Real-Time Location Systems (RTLS) market will amount to $48.5 billion by 2026.

Even though GPS tracking has been in use for many years, it’s only after the rise of the Internet of Things that it became more widespread in the construction industry.

Basically, with GPS tracking systems, construction companies can rely on different types of data while managing their assets.

They can track machines and vehicles in real-time, and gain insights into maintenance status, utilization rates, or safety records.

All of this information is indispensable to running a successful construction company and meeting various business goals.

While most of us are familiar with GPS technology, sometimes we are unaware of how it can improve our day-to-day operations to the fullest.

So, in this article, we’re taking a deeper dive into the ways it helps you get the most out of your equipment by using GPS tracking systems.

In this article...

Easily Locating Your Equipment

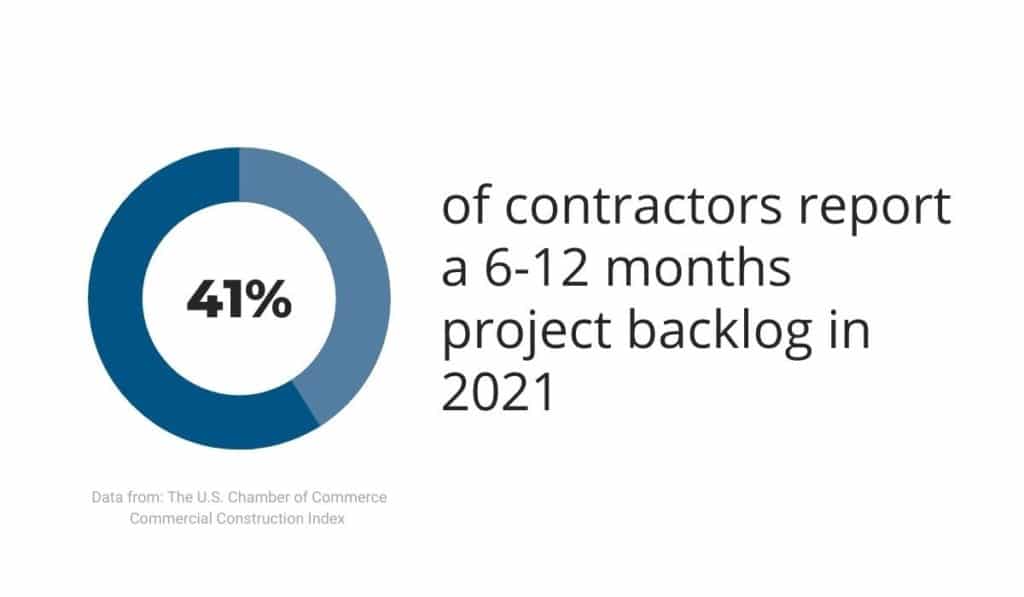

In the past two years, the construction industry has been heavily impacted by the COVID-19 pandemic, which led to a vast number of delayed or even shut-down projects.

In fact, 41% of contractors report a 6-12 months project backlog in 2021. Most of it was due to labor and material shortages, but also supply chain disruptions.

The bottom line is that many construction companies have to set new plans in motion to prevent similar issues in 2022.

So what can they do?

The key is to make the most of their current assets and maximize efficiency, which they can do with the help of a good GPS tracking system.

When a company owns a large fleet of expensive machines, it’s necessary to track them regularly and in real-time. With the right system in place, workers can easily locate equipment through a desktop or mobile app and start their daily work.

Additionally, you can efficiently allocate the right equipment to the right location to finish jobs as quickly as possible.

Let’s suppose you need a dump truck to collect excess material from a job site. You can access your GPS tracking system’s data and see which dump truck is the closest to the job site’s location.

That way, you’ll get the job done faster and save money on fuel and working hours.

But the best part is that GPS tracking doesn’t just work on expensive heavy equipment. You can put GPS trackers on any type of equipment and tool that you want to locate easily.

Like this drill with a GoCodes label and QR code which updates the tool’s GPS location with each scan.

It comes down to this: companies facing significant operational challenges can improve their processes with GPS tracking.

This will help them locate their equipment and utilize it more efficiently, which will result in a faster project turnover and improved profitability for the company.

Reducing Equipment Idle Time

Another benefit of better equipment utilization is that idle time gets reduced to a minimum.

But before we explain why this is important, let’s define idle time for construction equipment.

When the engine of the construction equipment is running, but the machine is not moving or doing any work, we call that idle time.

This can be due to three factors:

- Starting the engine

- Waiting time because of the driver’s personal reasons

- Delays due to traffic conditions (red light, heavy traffic, etc.)

This might not seem like a big problem because some idle time is even expected in construction.

However, while that may be true, if you don’t track how much your equipment is idling, it could negatively affect your equipment and business operations.

How?

First, you’ll significantly impact fuel usage for your heavy equipment.

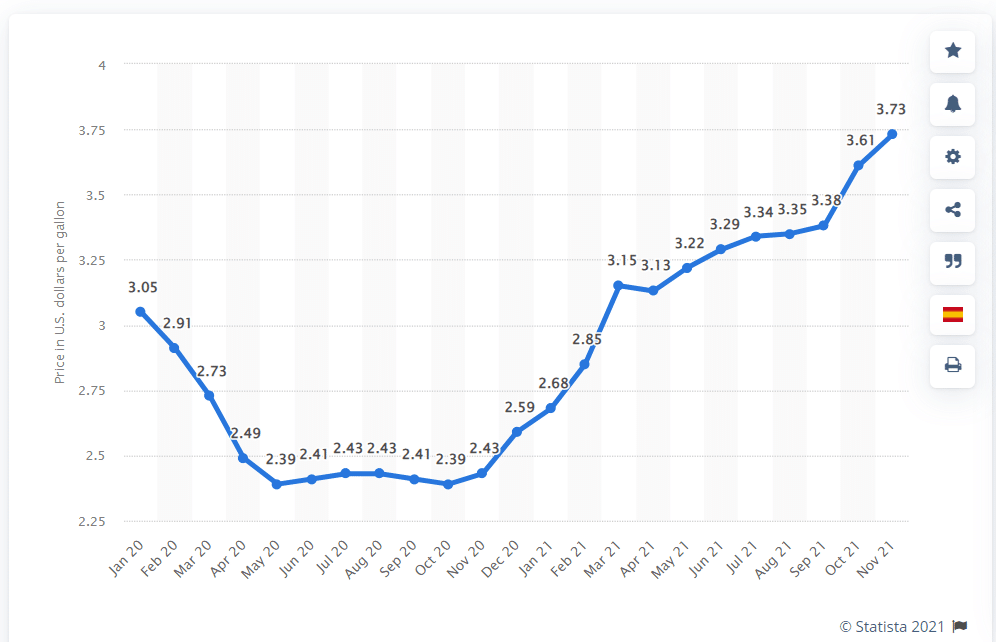

Did you know that fuel accounts for 35% of the operational costs of construction companies?

This is not surprising when you know that fuel prices are volatile and rising due to energy supply shortages year after year. For instance, compared to last year, the price of diesel increased by $1.3.

For a medium-sized excavator with a 100-gallon tank, you’ll spend $373 on a single refill!

Now, consider the fact that most construction equipment spends 30% of its time idling, which means it unnecessarily wastes fuel without doing any tasks. That’s 30% of your money going out of the exhaust that you can’t get back.

But by effectively tracking your equipment and its fuel consumption, you can find ways to reduce idle time and save money. GPS tracking can help you monitor your heavy equipment operators’ activities that might contribute to excessive idle time.

Are they leaving the engine on during their breaks? Are they taking longer routes or speeding? Having this information can help you manage your fuel costs more efficiently.

The next thing you should keep an eye on is how excessive idling affects the resale value of your equipment. One of the things that new buyers will look at is your hour-meter reading.

So, for example, let’s say your machine has 7 000 working hours, but 2 500 were spent idling, and it’s competing against a machine with 5 500 working hours and 1000 hours of idle time.

Both machines did the same amount of actual work (4 500 hours), but because your machine has more operating hours, it will be priced lower on auctions.

In the end, if you want to maximize revenue for your equipment and reduce the time spent idling on your construction site, invest in a GPS tracking system.

Improving fleet efficiency is an ongoing challenge you can combat with the right tools that will provide relevant information.

Planning Your Equipment Maintenance Schedules

Apart from tracking how your equipment is used on the field, it’s important to check the condition the equipment is in regularly.

You’re probably aware that unexpected breakdowns can complicate your daily operations and negatively impact any construction project’s performance.

For example, a single broken excavator can postpone digging the foundation and delay other related tasks, resulting in breaking budget and project deadlines. This is why regular equipment maintenance is essential.

But how can GPS tracking help you with this?

GPS tracking systems will measure different telematics indicating the right time to send your equipment for preventative maintenance. Here are some things you can monitor to maintain your equipment:

| Inspection Results | Use Daily Vehicle Inspection Reports (DVIR) to assess the overall health of your assets and find issues. You can see common inspection failures and defects to help you improve your maintenance strategies. |

| Preventative Maintenance | Having a preventative maintenance schedule can help you coordinate your assets to work on essential jobs in optimal working conditions. |

| Diagnostic Trouble Codes | You can get alerts in real-time about equipment issues. |

| Repair Turnover | Don’t let your equipment spend too much time in the repair shop, so check status updates frequently to send the equipment to the job site as soon as possible. |

| Odometer Readings | Control mileage and fuel costs with regular odometer updates. |

In a nutshell, GPS tracking systems will help you track your equipment’s maintenance needs so you can take preventive measures to get the most out of your assets.

Avoid making unnecessary mistakes and enhance your asset utilization by using great technology.

Preventing Unauthorized Equipment Use

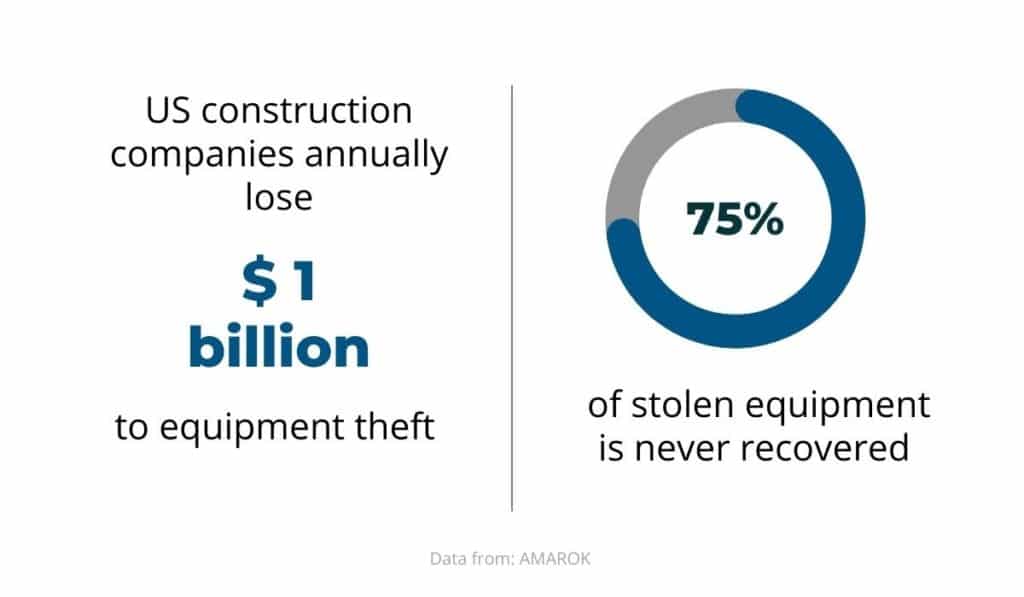

Equipment theft is a global problem.

According to recent data, tool and equipment theft cost UK construction companies £17.5 million in 2020. In 2021, the trend continued with almost £1.46 million lost due to stolen equipment each month.

The same is happening in the US. According to Amarok, the US construction companies annually lose $1 billion, and 75% of stolen equipment is never recovered.

What’s more, this problem is worsening. The prices of construction power tools are rising, making them a tempting target for anyone with bad intentions.

What can you do?

Relying on traditional anti-theft methods such as keeping equipment in locked storage facilities or using CCTV cameras is useful, but only up to a point.

By the time you can look over the security camera’s footage, the thieves could be miles away, with your chances of recovering the stolen equipment diminishing each hour.

You need a more reliable security system to protect your valuable assets. This is possible with GPS tracking.

For example, you can set a geofence around a perimeter to easily track equipment and vehicles going in and out of a location. You will get timely alerts on your desktop or mobile app and monitor the equipment.

So, if you notice a vehicle deviating from the path it’s supposed to take, you can act quickly to prevent any malicious intentions.

This also applies to cases when your workers use your equipment for side jobs or personal use.

By quickly tracking your equipment and the location history records, you can identify unauthorized use.

In the end, stolen assets can negatively impact your company in numerous ways:

- Increased insurance premium

- Damaged reputation

- Low profitability

- Project delays

To mitigate these problems and protect your assets, your solution is simple: invest in a GPS tracking system.

Conclusion

High-value assets are essential to construction companies because they’re the main drivers of productivity. So you need to ensure your assets are always in great working condition and on the right worksite.

But to get the most out of your equipment, you need to gather relevant data. This is where GPS asset tracking comes to the rescue.

With the right GPS tracking system, you’ll always get alerts of your equipment’s location and control where it goes. You’ll be better at allocating equipment and significantly reduce operating costs, like fuel consumption or maintenance.

This will also help you keep a close eye on unauthorized use or even theft. More control means better asset management, which in turn enhances productivity and profitability.

So, take advantage of the dynamic features a good GPS tracking system can provide you. Make the most out of your equipment to grow your company.