Construction projects are becoming more complex, their budgets and schedules tighter, and the associated risks and challenges more significant.

Simultaneously, the rapid development of construction technology and software solutions has enabled construction companies of all sizes to collect, store, analyze and use various data streams to improve all their workflows.

One of the key components that data-driven construction companies utilize is an asset tracking system that enables active tracking of the location and usage of tools, equipment, and machinery that the company owns or rents.

When such a tracking system is carefully applied in conjunction with other tech solutions, construction company owners and managers can enjoy multiple benefits, of which we’ve selected the five most important ones.

In this article...

Streamlined Workflows

As other construction technologies are leaping forward, construction businesses realize the advantages of actively tracking the location and usage of tools and equipment.

Effective tracking helps them streamline their operations and increase productivity.

Moreover, when an asset tracking system is integrated with other construction management solutions, that further improves and optimizes workflows vital to project success.

In simplest terms, when the tools, equipment, machinery, vehicles, and any other physical assets a construction company uses are equipped with trackers, and their location, condition, and usage are monitored, this improves operational efficiency across all related company workflows and results in streamlined construction project management.

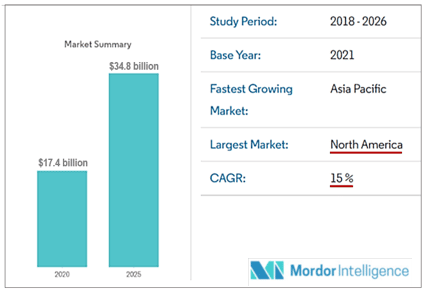

Aware of this, construction businesses are increasingly adopting various tracking solutions. As a result, the global asset tracking market is expected to double by 2026, compared to 2020.

And this is good news for contractors worldwide, as asset tracking hardware and software solutions are becoming more affordable and easy to use, while providing many advantages in day-to-day operations.

For example, let’s say that a specific piece of equipment breaks down and needs to be replaced as soon as possible to avoid downtime and delays.

Construction managers can now take their smartphone out and see precisely where another such piece of equipment is, who’s using it, and when it will be available in a few clicks.

From there, they can ensure that it quickly travels from one construction site to the next and keeps the construction crew productive.

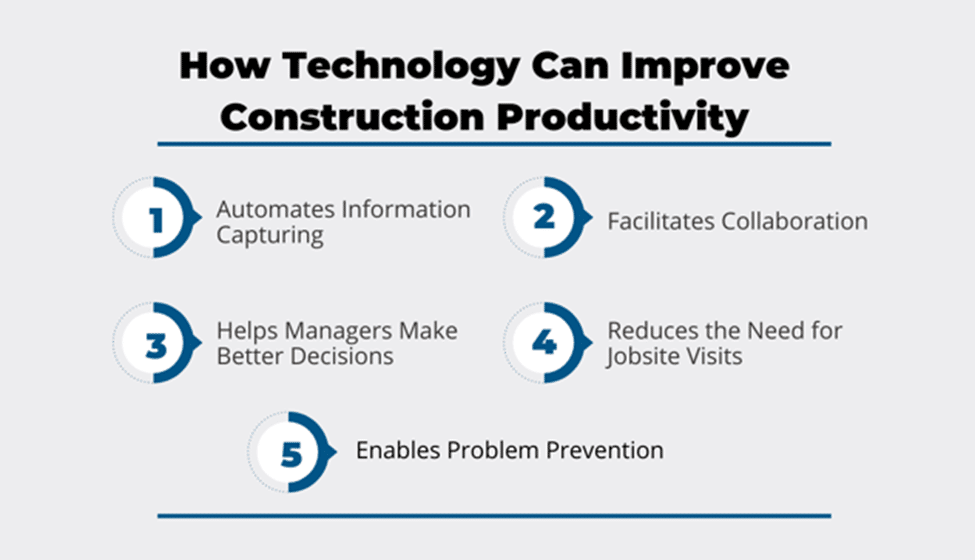

Taking a broader view, we could say that actively tracking the usage and location of your tools and equipment, whether big or small, can streamline vital workflows in the same way as other technology can improve construction productivity, namely:

From the above example, it’s clear that the asset tracking system used by the manager located a replacement quickly, automated information capturing, improved decision-making, and enabled the problem to be addressed.

Overall, asset tracking, paired with other construction management solutions, allows you to improve and optimize company workflows, cut costs, and boost productivity, thus keeping your business and projects on track.

Locating Stolen Equipment

Naturally, when you have a clear view of where all tools and equipment are, locating missing or stolen assets becomes much easier.

In case theft occurs, different asset trackers and labels can be used to track down the stolen equipment, or at least provide its last known location, prove ownership, and make reselling harder or even impossible.

If you’re in construction, you’re well aware that perpetrators have long been treating construction sites as great places to get their hands on valuable equipment and materials.

Naturally, recent supply chain disruptions and price spikes have exacerbated this issue.

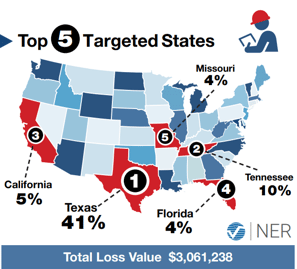

For example, you can see below that construction businesses “lost” heavy equipment worth over $3 million in just one week in July 2021.

The top five states with the most reported thefts are also listed:

These stats also indicate that large equipment is usually the target of thieves thanks to its high resale value.

In this regard, the market offers a variety of active and passive GPS trackers (they should be small and hard to find or remove) or GPS-enabled asset tags and labels.

They can help prevent theft or at least help you track down the stolen equipment by providing its current or last known location.

For example, if a stolen piece of equipment were tagged with a GPS-enabled QR code label made of tamper-proof material, that would accomplish the following:

- provide the last GPS location where the equipment tag was scanned, allowing you to establish a chain of custody and inform the authorities

- enable you to easily prove ownership when the stolen equipment is found

- make reselling harder (as tamper-proof labels leave a permanent mark when removed)

One such simple and cost-effective solution is our patented tool tracking system, GoCodes Asset Tracking.

Overall, asset tracking is essential for locating missing or stolen equipment and, coupled with other security measures, can efficiently prevent theft by both internal and external offenders.

Simpler Reporting

When construction businesses implement an asset tracking solution, it allows them to get reports on the movement, condition, utilization rate, quantity, etc., of their tools and equipment.

Moreover, with the help of cloud-based software, they can access those reports and all other relevant information in real-time, from any location and device, all of which leads to productivity gains.

When assets are tracked, the resulting status updates and reports can be used to monitor and manage any related workflows, from equipment maintenance and utilization to financial management and regulatory compliance.

For example, asset utilization reports generated by asset tracking software can be used to determine how often and how long a piece of equipment is used, thus improving their allocation and informing future “buy or rent” decisions.

Advanced GPS asset tracking solutions, with the help of internal and external sensors paired with the tracking device, can generate real-time usage reports that include engine diagnostics, operator behavior, and outside operating conditions, thus enabling many efficiency gains to be achieved and issues solved on-the-go.

Furthermore, most tool and equipment tracking systems allow users to add different info about the tracked asset via their cloud-based software solution that can be accessed from any device like a smartphone, tablet, or laptop.

Thus, the up-to-date data they provide can be utilized in different daily construction reports, as well as in the areas of regulatory compliance, insurance, and cost reporting.

For instance, such solutions can allow you to monitor depreciation and account for other financial data.

Overall, actively tracking the usage and location of your tools and equipment results in simpler (automated and digital) reporting, thus enabling construction businesses to better manage various aspects of their operations.

More Regular Equipment Maintenance

Another significant benefit of tracking construction tools, equipment, and machinery is that it helps ensure regular maintenance.

On top of that, asset tracking can ensure that relevant asset data is collected and analyzed, thus opening room for preventive and predictive maintenance practices.

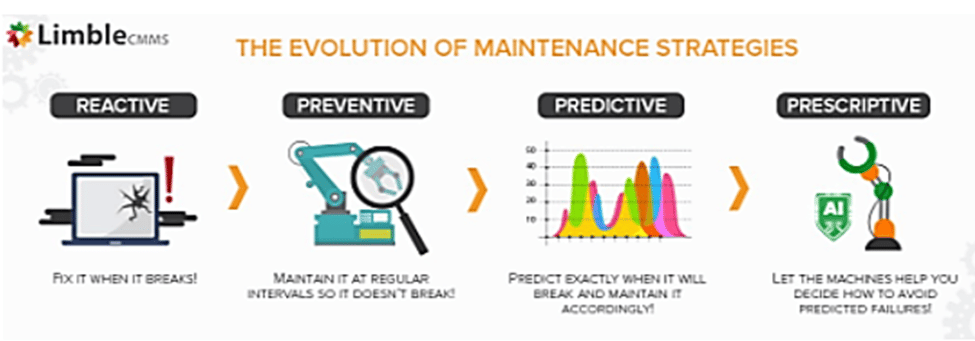

When coupled with other technologies (sensors, IoT, machine learning), such integrated solutions can and are already redefining the meaning of regular maintenance and causing maintenance strategies to evolve.

Asset tracking systems are an integral part of that evolution.

For starters, most tracking apps enable field service technicians and other maintenance staff to quickly see when a piece of equipment was last serviced and by whom.

They also provide insight into what was done, what problems the piece experienced before, when the next maintenance will be, and what the manual suggests.

Consequently, tracked assets are maintained more regularly, accurately, and efficiently, as such apps can send alerts when maintenance is due.

Managers can easily check the maintenance status of all tools and equipment in one place, allowing them to better plan, schedule, and manage equipment maintenance operations.

Naturally, this opens room for preventive, predictive, and even prescriptive maintenance.

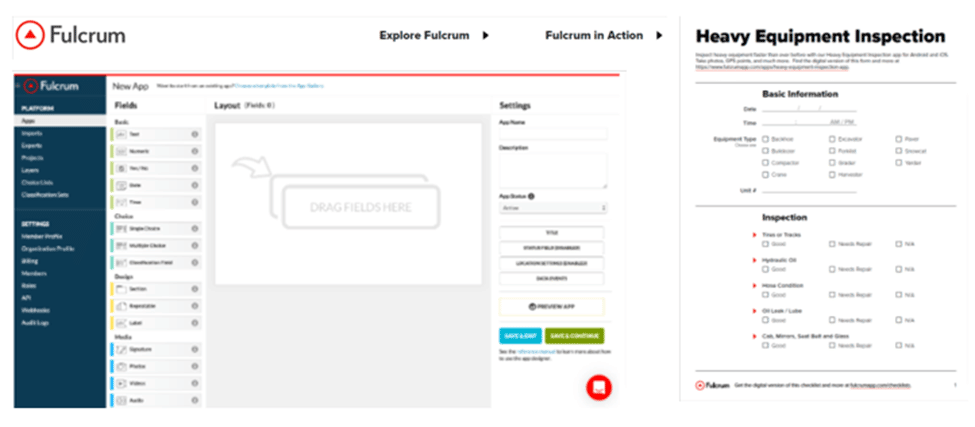

In addition, some asset tracking solutions, alone or paired with other construction management software, allow maintenance staff to perform paperless inspections, send maintenance reports, attach documents, photos, or videos, and leave comments for their colleagues.

For example, the mobile app Fulcrum lets your construction business create customized digital equipment inspection reports and maintenance checklists.

This and similar apps can be easily integrated with asset tracking solutions to further streamline equipment maintenance operations, making them more accurate and efficient.

When asset trackers are connected with smart internal and external equipment sensors and all collected data goes through one central hub where they are processed by predictive AI algorithms, it gives you a holistic view of all maintenance practices.

You can, for instance, get alerts when a machine is about to break down, or a part needs to be replaced.

In other words, tools and equipment tracking systems not only ensure more regular, accurate, and efficient upkeep but can help propel equipment maintenance into the future.

Preventing Unnecessary Downtime

Considering the other benefits of asset tracking solutions described in previous sections, it’s clear that actively tracking tools and equipment is essential for minimizing different types of unnecessary labor and equipment downtime.

For example, when the location and usage of specific tools are tracked in (near) real-time, you know, among other things, exactly how many tools you have and how many are used at the moment.

That allows you to compare your current and future construction needs and plan their allocation and procurement accordingly.

Making sure your workers always have the right tools at their disposal helps prevent downtime and minimizes delays.

In short, tracking allows you to monitor inventory levels, so you can ensure there is no shortage.

Conversely, you can also ensure that equipment and tools are not overstocked, which means you can avoid the costs arising from their underuse.

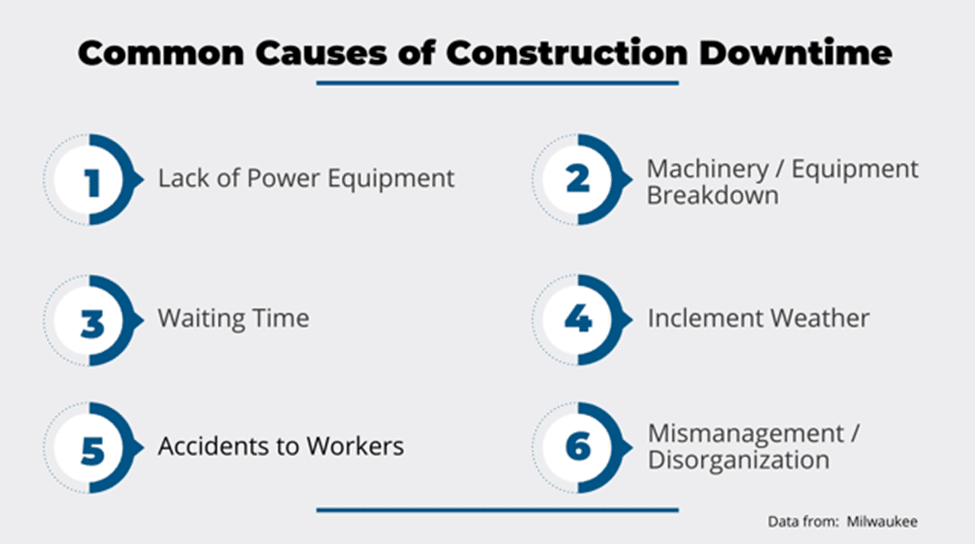

In general, we could say that asset tracking can help eliminate or minimize all but one of the most common causes of construction downtime identified in one Milwaukee study:

We’ve just seen how tracking can help address a lack of equipment (1).

It can also improve worker safety (5) through, for instance, more regular equipment servicing, and cut down labor and equipment downtime (3) caused by, for example, equipment breakdown (2) or inefficient management and disorganization (6).

All that remains is inclement weather (4) that can’t be controlled.

However, even at such times, knowing where your tools and equipment are helps in many ways, including having an accurate inventory for insurance purposes.

To sum up, actively tracking tools and equipment helps eliminate or at least minimize all kinds of unnecessary equipment and labor downtime stemming from not having a clear picture of where assets are and how they’re used.

Conclusion

Having covered the five key benefits that active tracking of tools and equipment brings to construction businesses, it’s safe to say that various asset tracking solutions are an essential part of an integrated and interconnected construction management system.

Data-driven companies utilize such solutions to streamline their operations, thus gaining competitive advantages over their peers.

Considering their availability, ease of use, and affordable prices, asset tracking solutions should be utilized by all construction businesses, helping them propel their operations into the future.