One of the most demanding challenges construction company owners and managers face is increasing the productivity of their operations.

That’s not surprising since construction projects and related workflows involve many complex factors beyond their control, from last-minute project changes to labor and material shortages or poor weather conditions.

However, many issues that lower efficiency are within the control of construction companies, meaning they can be successfully addressed, leading to increased productivity and hence profitability.

So, if you’re wondering what you can do to boost the efficiency of your construction operations, here are five best practices that can help you do so.

In this article...

Go Digital

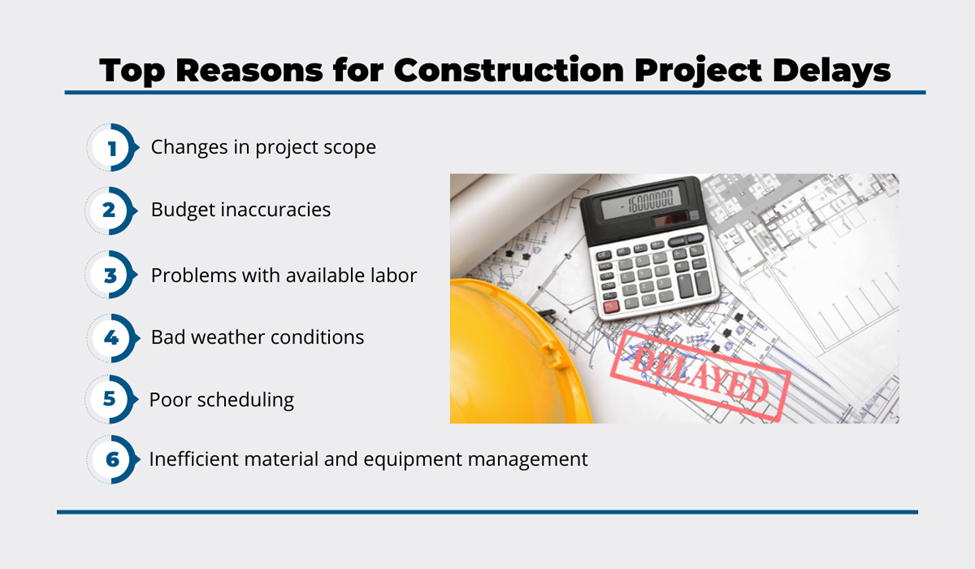

If you haven’t already, it’s time to go digital.

In other words, you need to replace inefficient paper or spreadsheet-based processes with fully digital, interactive, cloud-based software tools.

Why?

Because they can enable your construction team (workers, managers, office staff) and other stakeholders (client, architects, engineers, subcontractors) to:

- collaborate in real-time

- access accurate project data and other relevant info from anywhere at any time

- automate various administrative, construction-related processes

Mind you, these are just a few general examples, and the productivity-boosting power of software solutions spans much further, all depending on their purpose and your specific needs.

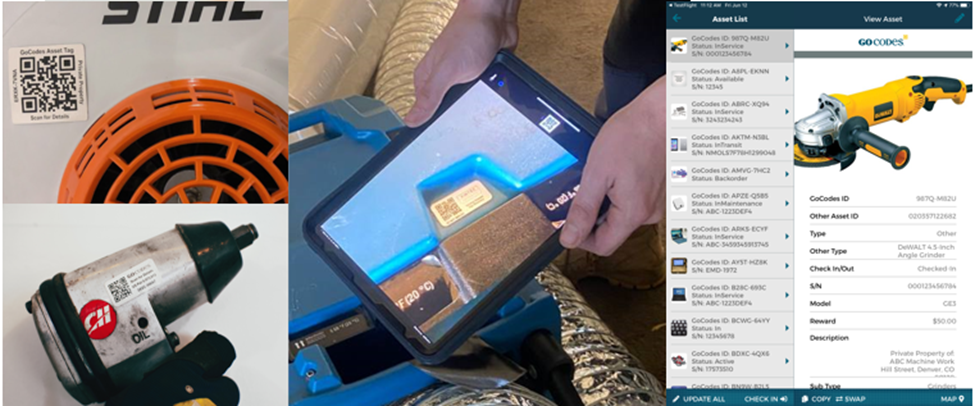

For instance, when QR code labels or tags are attached to tools and equipment, workers can use a mobile app to scan them and access digital versions of many previously paper-based documents, such as equipment manuals, safety guidelines, and maintenance records.

Naturally, this simple “scan-to-access-information” process saves workers a lot of time they would otherwise spend on finding and filling out the right documents (whether they’re available on-site or back in the office).

At the same time, administrative staff will no longer have to deal with time-consuming and error-prone manual data entry when turning paper-based data into a digital form.

Likewise, managers will have access to real-time updates of equipment users and locations, their availability, and maintenance status, thus ensuring that jobsite productivity doesn’t suffer.

Again, this is just one example of why digital transformation is essential for construction companies looking to improve their operational efficiency.

Given the variety of available construction management software solutions, nowadays there’s almost no aspect of construction operations that can’t be digitized and automated to reduce manual paperwork and enhance overall productivity.

In summary, the practice of adopting digital, cloud-based software tools will enable your company to minimize errors, establish real-time collaboration, and increase the efficiency of construction workflows.

Create a Structured Project Development Process

Going hand in hand with utilizing appropriate digital tools, this next best practice involves creating a structured project development process.

Simply put, despite potentially big differences between construction projects, your company should have a single roadmap that ensures that every phase of the project, from conception to completion, is well-defined and streamlined.

For starters, such a structured process implies comprehensive and standardized project planning, from defining project objectives and milestones to establishing a realistic timeline and identifying potential risks.

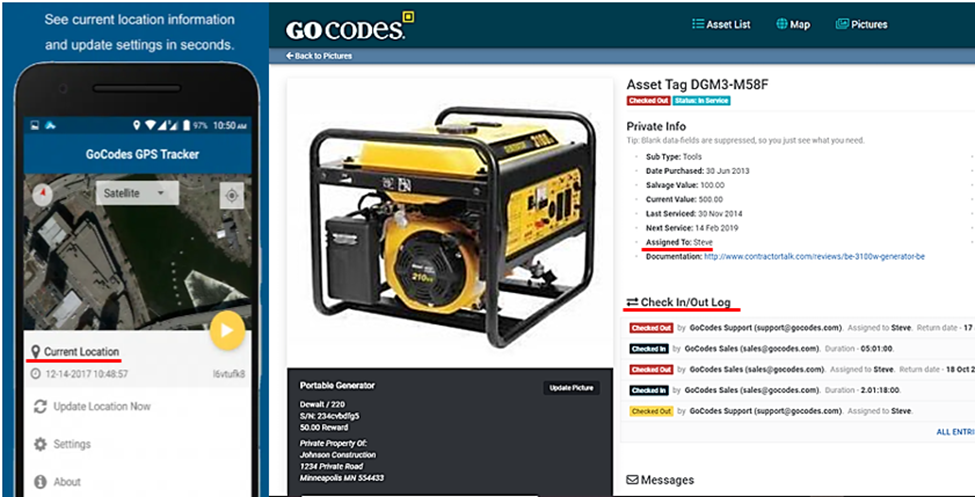

Again, this is where the first best practice we covered comes in, meaning that the most efficient way to do structured planning is using project management software.

Since the market offers a vast number of such solutions, here’s just one example.

In a nutshell, project management software should cover all the processes needed for structured project development, such as planning, scheduling, budgeting, risk assessment, coordination, and oversight.

Naturally, it should also help you standardize workflows to ensure consistency across your projects.

This involves creating templates and standard operating procedures (SOPs) for common construction processes, such as procurement, quality control, and safety checks.

Lastly, such software should allow you to assign clear roles and responsibilities to team members and facilitate real-time communication between all project stakeholders.

By creating a structured project development process that encompasses all these elements using appropriate digital tools, your company can create detailed plans, allocate resources efficiently, and track progress in real time.

Therefore, this best practice ensures that each project follows a standardized, efficient path from inception to completion, thus increasing the productivity of construction operations.

Make the Workflow Flexible

Considering the complexity of construction projects and all the factors that can affect their smooth completion, you should ensure that workflows are flexible.

For instance, since many construction tasks depend on preceding tasks being done on time, any unexpected delays can cause havoc in the project schedule, forcing managers to act quickly to prevent further issues and keep the project on track.

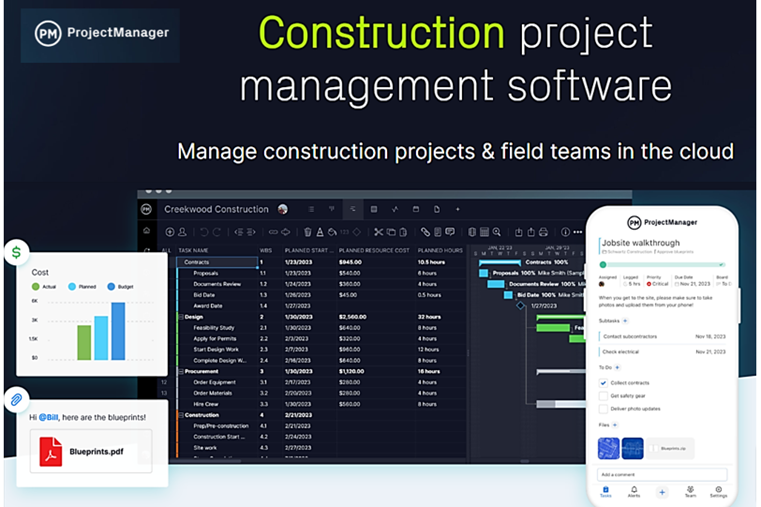

To illustrate the importance of workflow flexibility, here are the top reasons for project delays.

In all the above cases, managers need to have tools that give them the flexibility required to reallocate resources, revise timelines, or make necessary adjustments without causing major project disruptions.

Aside from solid planning, budgeting, and scheduling, one of the most important factors contributing to workflow flexibility is having a bird-eye view of all project-related operations.

Naturally, this is where project management and collaboration software solutions play a key role.

They allow for real-time communication and document sharing among team members, which enables quick decision-making and adjustments when issues arise.

Another flexibility-increasing aspect concerns resource allocation, i.e., maintaining a clear view of the company’s resources, their status, and availability.

This ensures that backup resources (e.g., the equipment available to replace any items that broke down) can be quickly identified and allocated in case of emergencies or delays.

You can also consider cross-training your team members so that they can step in for one another when necessary.

That way, if a key member of your construction crew falls ill, you have someone to replace them without disrupting the whole schedule.

Long story short, these and other flexibility-boosting practices enable companies to create workflows that are not only efficient but also adaptable to changing circumstances, ultimately enhancing productivity.

Analyze Construction Operations

The ability to efficiently analyze construction operations is another key best practice for maximizing jobsite productivity.

In other words, when crucial project data is stored in one place (cloud database), it can be easily analyzed to provide valuable insights into workflow efficiency, resource allocation, potential bottlenecks, and areas for improvement.

For example, common issues or recurring problems with specific equipment that could go unnoticed can be caught by analyzing the historical maintenance and repair data connected to that piece of equipment.

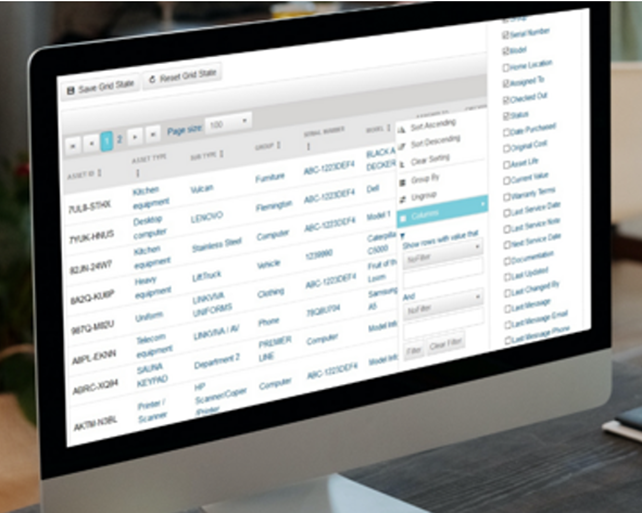

To do that, you can utilize our asset tracking and management software, GoCodes, which has a powerful and easy-to-use reporting and analytics module.

As you can see, managers can design custom reports that help them analyze different aspects of asset management, such as maintenance scheduling, inventory management, cost structure, and usage optimization.

For example, such reports enable construction companies to analyze the obtained data and gain insights that allow them to:

- identify when routine maintenance tasks, such as oil changes and inspections, should be performed and whether to repair or replace equipment

- ensure that consumable inventory items like spare parts and supplies required for maintenance and repairs are in stock when needed

- improve budgeting for maintenance expenses and determine the equipment lifecycle costs

- determine whether certain equipment is being over- or underutilized and whether the equipment can be more efficiently allocated

Similarly, other construction-related software solutions and their reporting and analytics features can be used to improve the efficiency of other construction workflows, such as project scheduling, subcontractor management, or safety compliance monitoring.

Overall, the best practice of analyzing your construction operations using digital tools allows you to leverage the collected data to maximize productivity.

Keep the Client Involved

Last but not least, the practice of keeping the client involved in their construction project can help you increase operational productivity, i.e., avoid misunderstandings or omissions that could cause delays and budget overruns.

Simply put, the client is paying for the project, and they should be kept in the loop from start to finish.

This approach should be applied from the moment a potential client contacts you, i.e., even before you engage in any business with them.

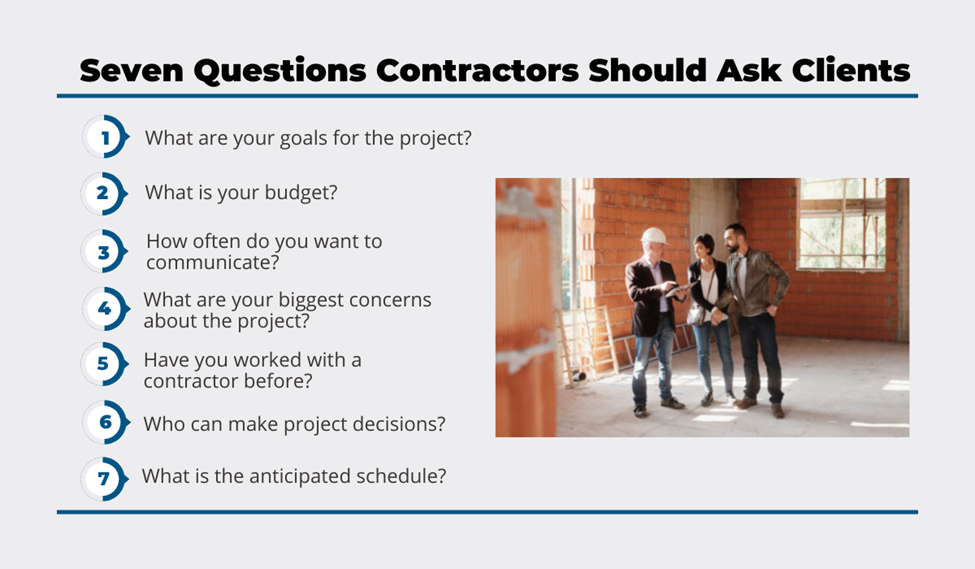

Here are seven questions any contractor should ask in their initial meeting with prospective clients, courtesy of PlanHub:

These and other questions will project your professionalism, invoke the client’s trust, and manage their expectations, all of which can prevent problems down the line, ultimately leading to more efficient construction operations.

From there, you should ensure the client receives regular project updates in the form of progress reports, preferably garnered with photos or even videos of the ongoing construction.

Naturally, they should be informed of any project changes or increased costs along with an explanation of why they are needed and alternative options, so they can decide what best fits their needs and budget.

Like with other best practices described here, digital tools can help you keep the client involved.

For instance, the tools allow them to monitor project progress and give approvals through your project management software.

To recap, transparent and frequent communication with your client can increase the productivity of your construction operations by preventing most client-instigated changes or delays, ensuring their satisfaction, and enhancing your company’s reputation.

Conclusion

So, what would be the key takeaway from these five best productivity-boosting practices?

Clearly, it’s technology, i.e., various software solutions that can help you digitize, automate, and streamline your construction operations, allowing you to increase the productivity of your workers, equipment, and other resources.

Naturally, when selecting such solutions, you should research what software apps can yield the best efficiency improvements while being user-friendly and affordable.

That way, you’ll be able to keep the related expenses down and boost the productivity of your construction operations, leading to time and cost savings and enhanced profitability.