The seamless orchestration of heavy machinery, tools, and other construction equipment can significantly impact your project timelines, costs, and overall productivity.

For construction professionals, asking the right questions is essential to ensure that the equipment is not just operational, but working at its peak efficiency.

In this article, we delve into those critical questions.

By addressing these queries head-on, you can unlock the secret to more effective construction equipment management, leading to enhanced project outcomes, a streamlined workflow, and well-oiled job sites.

In this article...

Are We Leveraging Technology to Track Our Equipment?

Nowadays, technology and productivity truly go hand in hand.

So, if you’re not utilizing a dedicated equipment tracking system, you might be missing out on numerous benefits that could speed up your workflows and enhance the efficiency of your operations.

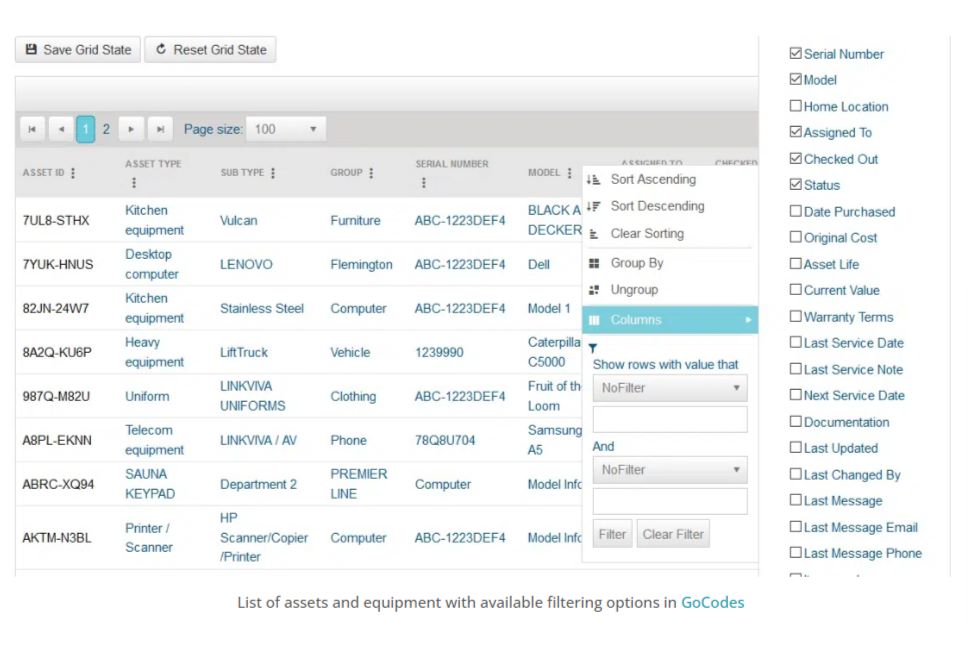

Firstly, equipment monitoring with specialized automated software is, believe it or not, much simpler and more time-efficient than with traditional methods like, for example, spreadsheets.

The system automatically updates the location, usage status, or condition of your equipment, thereby eliminating the need to enter the data manually.

This not only saves you time, but also provides you with thorough, accurate, and up-to-date asset records.

In other words, while the software takes care of its tasks, you can focus on yours, instead of worrying about mundane activities such as updating a machine’s or tool’s whereabouts every time they are moved from point A to point B.

Another efficiency-boosting aspect of asset-tracking solutions is the elimination of human error.

Let’s be realistic: when manual data input is assigned to workers, mistakes are inevitable, impacting your ability to properly manage company assets and posing risks to overall productivity.

A typo, a miscalculation or simply forgetting to enter a vital piece of data into Excel—all of these can have serious (and costly) consequences down the line.

Just imagine what happens when someone forgets to update a machine’s location.

This alone can waste a lot of valuable time, sending workers on a quest to find that key piece of equipment and diverting them from their work.

Asset tracking solutions, such as our own GoCodes Asset Tracking, circumvent such issues and offer greater reliability when it comes to equipment management.

The system itself, comprised of QR code labels, software, and a scanner app, is user-friendly, allowing your employees to get used to it quickly.

QR codes are affixed to machinery and tools and scanned via the app for information viewing and updates.

Each time QR code labels are scanned for actions like equipment check-in or check-out, the asset’s location and status are instantly updated—no room for typos, data omission, or accidental deletion.

All information is securely stored in the cloud.

You can then access the usage history at any time through your computer, phone, or tablet, leveraging the information for well-informed decision-making and better resource allocation.

Remember, these solutions are developed precisely for equipment management, so why not give them a thought?

Do We Have a Proactive Maintenance Schedule?

The significance of adopting a proactive approach when it comes to maintenance cannot be overstated, and individuals who neglect this important aspect simply can’t reach the maximum equipment management efficiency.

Those who do prioritize maintenance, on the other hand, reap a multitude of benefits, including:

- Reduced repair costs

- More predictable expenses

- Extended equipment lifespans

- Enhanced job site safety

- Minimized unplanned downtime

- Fewer project delays

While the advantages are extensive, the bottom line remains the same: proper asset upkeep is directly linked to effective equipment management, no doubt about it.

So, what’s the key to unlocking all these benefits?

Preventive maintenance and regular inspections.

Waiting until a machine reaches a critical condition is not the best course of action, every equipment manager will attest to that.

Instead, focus on developing a schedule for inspections to identify potential issues in the making, and address them while the asset is still operational in order to prevent those problems from evolving into major disruptions in the future.

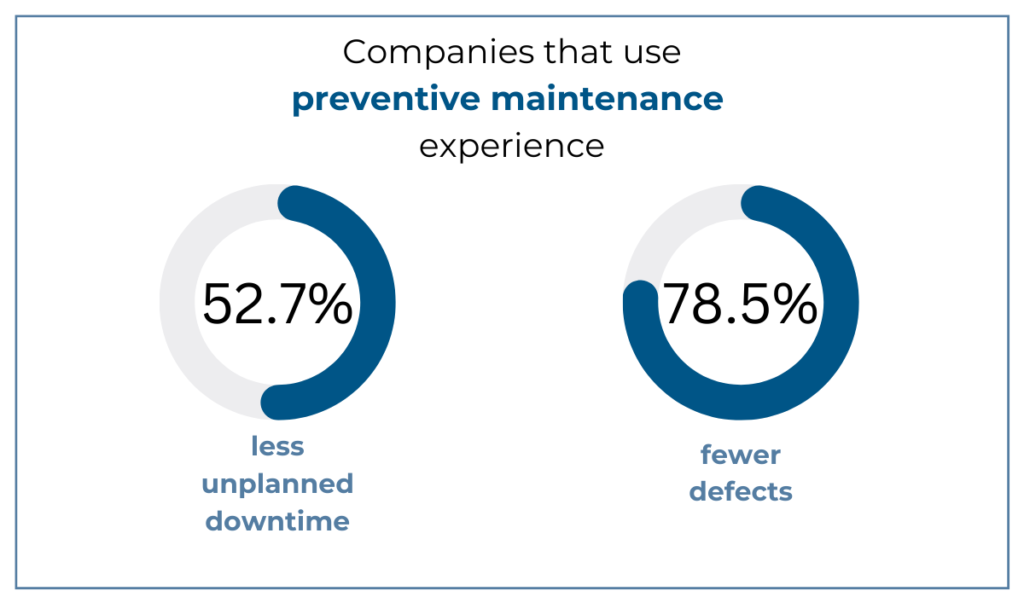

Research from the NCBI supports this approach, confirming that companies implementing preventive maintenance experience significantly less downtime and fewer defects.

Adhering to a well-structured equipment servicing schedule definitely pays off in the long run, ensuring your machinery and tools remain functional for as long as possible and perform optimally.

Overall, a proactive maintenance strategy is simply a must if you aim to make the most out of your assets, which is, ultimately, the essence of successful equipment management.

Are We Effectively Utilizing Our Equipment?

When it comes to efficient equipment management, however, it’s not only about how well you care for your machines and tools.

It’s also about how effectively you use them.

Inefficient asset utilization manifests itself in two ways, each on one side of the spectrum: overutilization and underutilization.

Underutilization is usually given much more attention, as it, essentially, involves equipment sitting unused on a job site and not contributing to revenue generation.

Those who rent their equipment are even less fond of this problem since it means they are basically paying for an asset that isn’t making them any money.

On the other side of the spectrum are overutilized assets, which are equally harmful, potentially causing safety issues, unplanned downtime, and project delays due to the increased likelihood of unexpected failures from overwork.

But, how do you put a stop to these problems and make sure your resources are properly used?

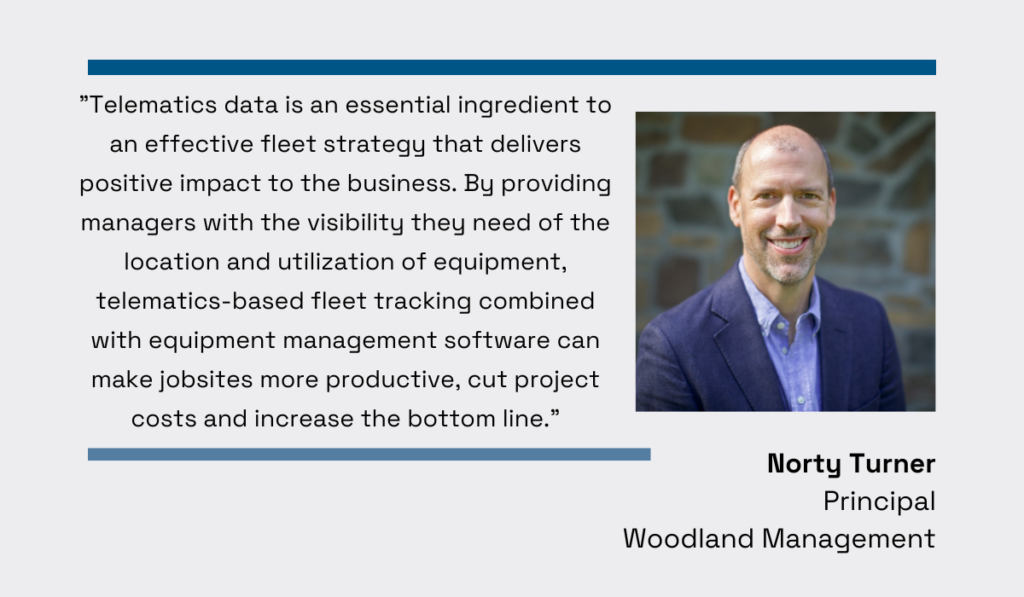

According to Norty Turner from Woodland Management, the answer lies in telematics.

Telematics, encompassing various data related to equipment usage, helps you identify areas that might need improvement, guides decision-making, and optimizes asset utilization through strategic allocation.

For instance, monitoring asset data may reveal that an excavator has been at a job site for an extended period without being used.

In response, you can either relocate it to another location or, if it’s rented, return it until needed again.

So, here are some metrics to pay attention to:

- Equipment check-in/check-out

- GPS location

- Miles

- Ignition off/on times

- Fuel use

As Turner mentioned, all of these metrics can be tracked and analyzed using equipment management software, which not only compiles data but also generates reports on asset usage, helping you make sense of the information.

Consequently, by relying on this rich data, you become much better equipped to handle resource allocation, ensuring you have the right amount of equipment in the right places.

How Do We Secure Our Equipment Against Theft?

The problem of construction equipment theft looms large over the minds of many managers as well as other industry professionals.

Given the significant financial implications involved, it’s hardly surprising that theft prevention has become a non-negotiable aspect of any robust asset management strategy.

It is widely acknowledged that the ramifications of having your equipment stolen extend well beyond mere replacement expenses, encompassing:

- Disruptive project delays

- Constrained cash flow

- Increased insurance premiums

- Reputational damage

- Decreased productivity

At the end of the day, there’s no denying that theft can significantly harm your projects as well as the very success of your business.

The question then becomes: how probable is it for you to fall victim to such an incident?

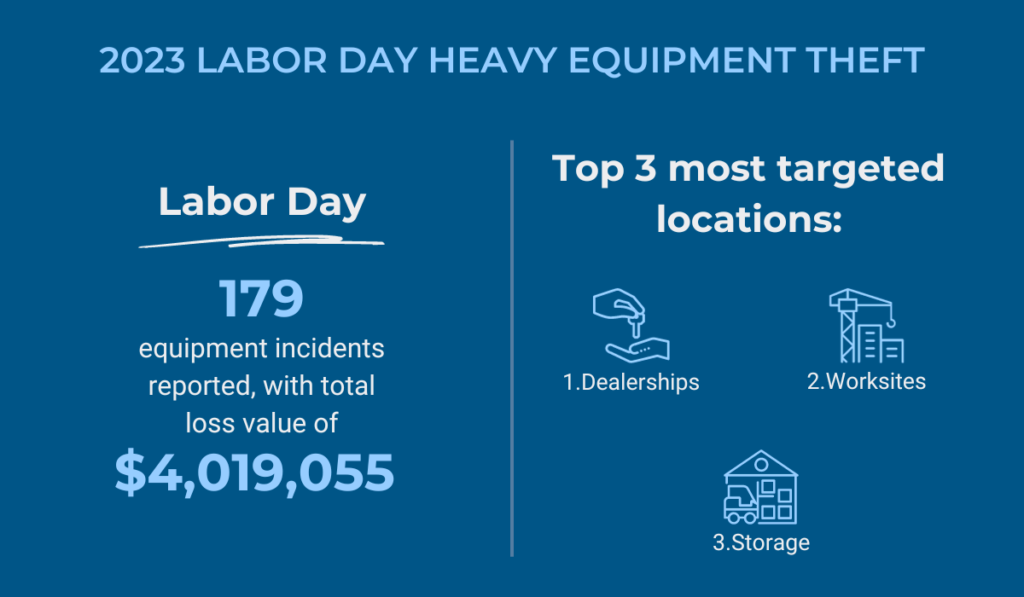

According to the National Equipment Registry, the likelihood is alarmingly high.

The report on the 2023 Labor Day heavy equipment theft reveals some staggering numbers—179 reported incidents in that single day, with a cumulative loss exceeding a mind-blowing $4 million.

These criminals spared no one, targeting dealerships, worksites, and storage facilities indiscriminately.

While Labor Day is one of the days when we see an upswing in such activities, the underlying risk of theft is, unfortunately, an ever-present reality.

When it comes to protecting your assets from crime, technology proves to be the most reliable ally.

Take, for example, Bluetooth beacons—compact tracking devices that can be seamlessly attached to your equipment.

Leveraging radio technology, these inconspicuous yet powerful beacons transmit real-time data to nearby Bluetooth-enabled devices, such as smartphones, keeping users constantly informed about the tagged asset’s whereabouts.

Some models even come equipped with an app that issues immediate notifications when the beacon strays beyond a specified range.

All in all, to seasoned equipment managers, the implementation of tracking systems is not just a recommendation—it’s a strategic imperative.

It proves to be the cornerstone of fortifying defenses against theft and vandalism, ensuring smoother operations, mitigating damage to profitability, and generally safeguarding the company’s reputation.

Do Our Operators Get Trained on Proper Equipment Usage?

Another crucial responsibility of equipment managers involves making sure that operators receive thorough (and ongoing) training in the proper use of company assets and a comprehensive understanding of relevant maintenance procedures.

Operating heavy equipment is undeniably challenging, especially with the increasing complexity of machinery brought about by technological advancements.

Therefore, continuous education is essential for all operators, regardless of experience level, as it plays a pivotal role in guaranteeing that assets are both operated and maintained correctly, thus minimizing downtime or unexpected issues, and, of course, ensuring job site safety.

Jason Turville, project manager at Trans-Jordan Cities Landfill in Utah, emphasizes the significance of adequate training for the company’s success.

He says that ensuring that the employees are not only comfortable with the machinery but also proficient in its usage is what enables them to utilize the equipment as it was meant to be utilized and make the most out of it.

So, what does successful operator training entail, anyway?

Brad Goliboski, president of Goliboski Contracting, Inc., and a trainer at Confederation College, who has trained numerous individuals on operating various types of machines, provides some valuable insights.

He explains that the training generally involves three stages: theory, familiarization, and operation.

For starters, it’s imperative for employees to thoroughly study equipment manuals until they have a complete understanding of a machine.

Then, they familiarize themselves with the machine by physically inspecting and interacting with it.

Finally, they gain practical experience by using the equipment in real-world conditions.

Of course, the specifics of training may vary slightly depending on the type of machine, but its indispensability for both new and experienced operators remains consistent.

Adept equipment managers recognize the importance of proper operator training and ensure that their team is well-educated in all aspects of machine operation and maintenance, no matter what.

Are We Planning for Equipment Replacement on Time?

Equipment management involves overseeing the assets throughout their entire lifecycle, from acquisition through operation to disposal.

However, predicting when is the right time to give up on repairs and replace a machine is an art in its own right.

Nevertheless, this is a vital part of equipment management, as it helps plan and prepare for future acquisitions, as well as decreases the likelihood of machines unexpectedly failing in the middle of a critical project.

In short, holding onto a machine for longer than necessary can result in it becoming a financial drain rather than an asset.

But, when is the right time to begin considering replacement?

Generally, it’s when the costs associated with owning that piece of equipment start approaching the revenue it generates.

Matt Lang, senior vice president at Amegy Bank, refers to this point as the break-even.

The solution for identifying the break-even and forecasting asset replacement on time involves diligent tracking of equipment data and equipment-related costs.

For that, you need to have a system, such as an asset tracking software, in place that monitors the performance, maintenance, and depreciation of the equipment in real time, enabling you to notice early indicators of potential problems.

If the issues with a particular machine start becoming more frequent and more costly, it might be an indication to you that the asset is approaching the end of its useful life.

And although this won’t change the fact that, sooner or later, every machine and tool has to be replaced, it’ll still help you navigate the inevitable need for replacement with greater preparedness, turning what might be an unforeseen challenge into a manageable and expected transition.

Conclusion

In conclusion, the role of efficient equipment managers extends beyond the mere operation of machinery; it encompasses the strategic utilization of data and the foresight to plan ahead.

It’s crucial to recognize, however, that effective equipment management is not a one-time task.

Instead, it’s an ongoing process that demands constant evaluation and adaptation.

Therefore, by regularly revisiting and addressing the questions we provided in this article, you can ensure the sustained success of your equipment management practices, fostering a dynamic and responsive environment that aligns with the ever-changing needs of your company.