Key Takeaways:

- Asset tracking monitors tools, vehicles, and machinery to prevent loss, ensure maintenance, and boost efficiency.

- Technologies like QR codes, GPS, and RFID provide real-time visibility and cut costs.

- Streamlined tracking enhances security, optimizes resources, and drives savings across industries.

For any business that relies on physical assets, whether they’re tools, vehicles, or machinery, asset tracking is essential.

It’s how companies keep track of where their equipment is, how it’s being used, and its condition at any given moment.

This not only helps them prevent loss and theft but also ensures assets are properly handled, regularly maintained, and used as efficiently as possible.

But, how do you start with asset tracking? Who really benefits from it? And how do you set up a system that actually works?

Well, in this guide, you’ll find all the answers.

From basics and technologies to understanding benefits and the steps to get it right, we’ll cover everything you need to know about asset tracking.

Ready to see how easy it can be to keep track of your assets?

Let’s get into it.

In this article...

What Is Asset Tracking?

Asset tracking is the process of monitoring physical items that a business relies on to operate.

It’s the ongoing oversight of their location, condition, and usage across their entire lifecycles, from the moment they’re acquired to the day they’re disposed of or replaced.

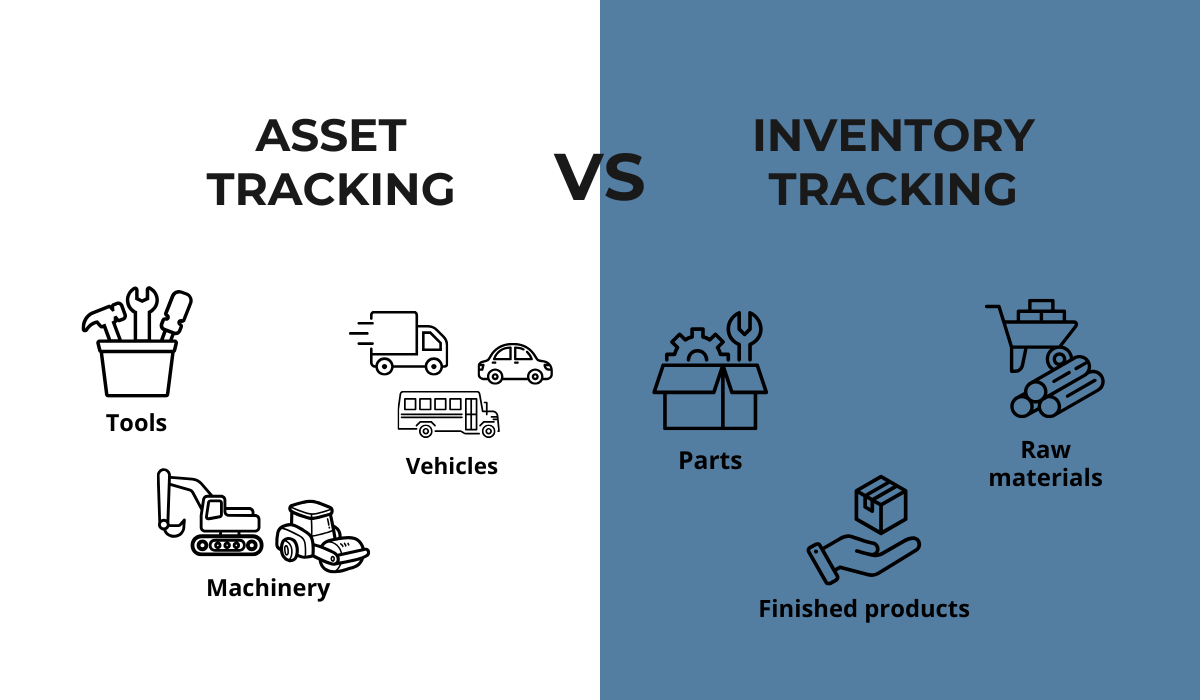

As asset tracking often gets confused with inventory tracking, it’s important to clear this common mix-up before going any further.

While both involve monitoring items, inventory tracking focuses on products a company plans to sell or consume, like parts and raw materials needed to make the products, as well as the finished products.

Asset tracking, on the other hand, deals with items (i.e., assets) like tools, vehicles, or machinery that business uses to operate effectively, whether that’s for producing a product or delivering a service.

Commonly Tracked Assets

Now, let’s take a look at the types of assets businesses typically track:

- Fleet: Trucks, vans, cars, and other vehicles used for transport and logistics.

- Machinery: Heavy machinery like excavators, forklifts, and loaders.

- Tools: Power tools, hand tools, and specialized equipment

- Furniture and Fixtures: Office furniture, storage solutions, or anything that supports infrastructure.

- IT Hardware: Computers, servers, printers, mobile devices, and network equipment.

Asset Tracking Technologies

To track these assets, companies use different asset tracking technologies, each suited to different needs and budgets:

QR Code Scanning

Quick and easy to use, QR codes are a budget-friendly way to track assets.

Each code stores data about the asset and can be easily scanned with a smartphone or handheld scanner to view details like its status, location, condition, or usage history.

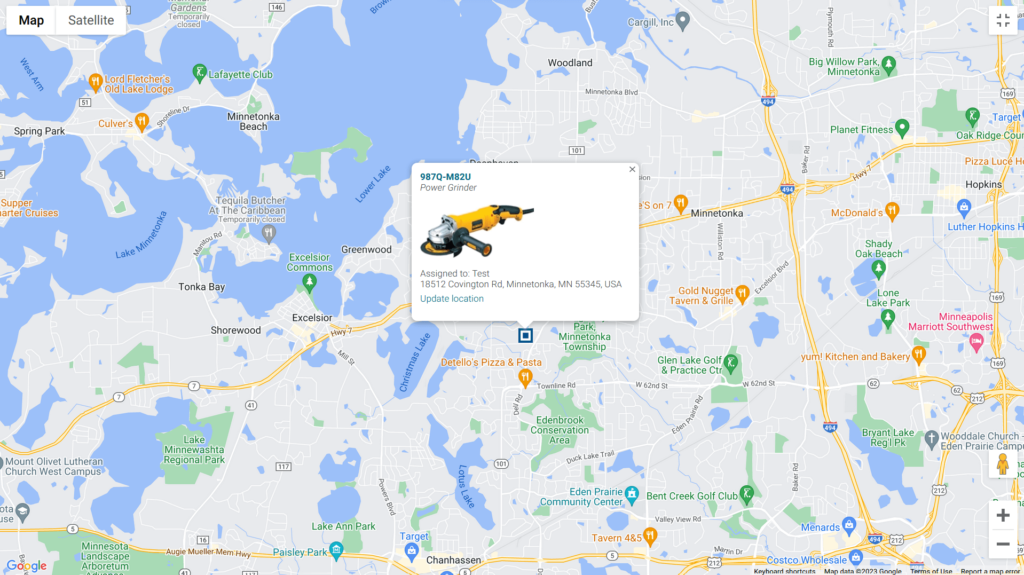

GPS-Enabled Trackers

They are ideal for large, mobile assets like vehicles and heavy machinery.

GPS trackers provide real-time location updates, minimizing the risk of theft or loss and ensuring accountability at all times.

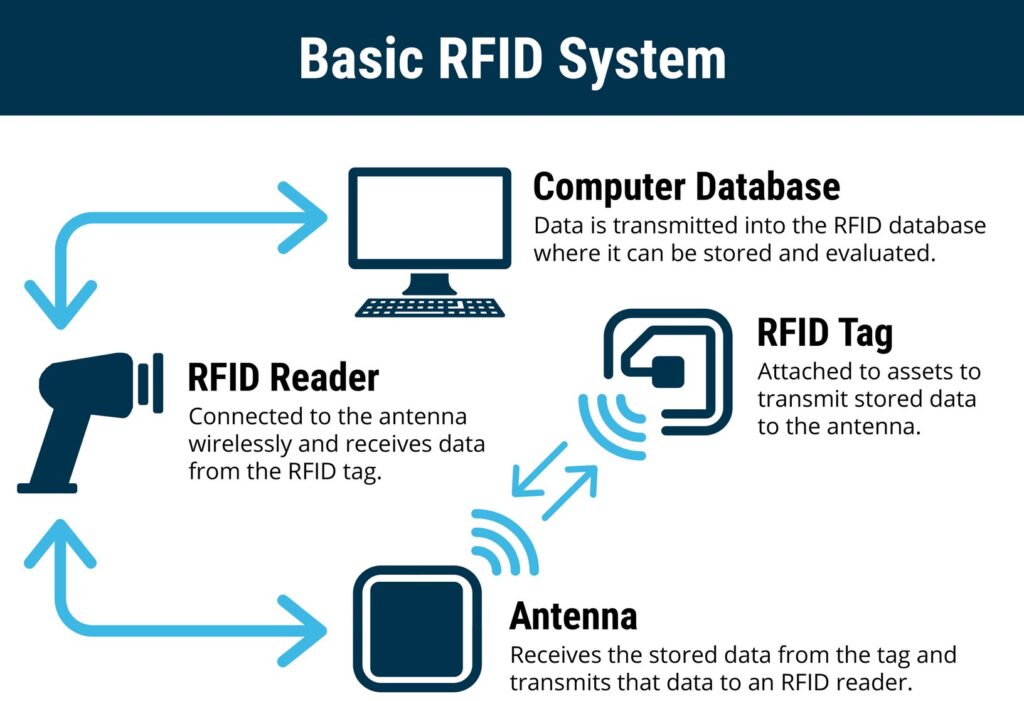

RFID Tags

RFID tags use radio waves to track assets and are particularly useful in environments with multiple assets in close proximity.

Unlike QR codes, which require line-of-sight scanning, RFID tags can be read remotely.

As such, they allow for rapid, bulk scanning, helping businesses streamline asset counts and checks.

Barcodes

Barcodes share some similarities with QR codes, but they have less data storage.

Barcodes are often used for simpler tracking needs, where fewer details are required.

Bluetooth Beacons

Bluetooth beacons are excellent for tracking assets within a set range, like in warehouses or on construction sites.

These devices emit a Bluetooth signal that nearby receivers pick up, allowing for accurate location tracking within a defined area.

This makes them great for monitoring items that don’t leave the site but move around frequently.

As you can see, each of these asset tracking technologies offers different levels of detail and automation.

So, choosing the right one depends on what assets need tracking, the information required, and your budget.

Often, however, businesses combine multiple technologies to cover all their tracking needs.

This hybrid approach ensures nothing gets overlooked, whether it’s a fleet vehicle out on the road or a power tool in the warehouse.

Who Needs Asset Tracking?

Every business where physical assets are central to operations needs asset tracking.

But, let’s get a bit more specific than that.

Here’s an overview of the major industry groups where asset tracking is essential:

| Industry Group | Why Asset Tracking Is Essential |

|---|---|

| Construction | Keeping track of equipment across job sites isn’t easy. Theft, misplacement, inefficiencies like idle time and downtime, and delayed maintenance can throw entire projects off schedule and hurt profits. |

| Manufacturing and Production | Machinery breakdowns and lost tools can halt production. Tracking ensures everything stays where it should and runs when it’s needed. |

| Healthcare and Medical Facilities | When lives depend on it, there’s no room for ‘missing equipment.’ Critical items must always be ready and functional. |

| Transportation and Logistics | Cargo and vehicles are vulnerable to theft, delays, and mismanagement during transit, causing disruptions and financial loss. |

| Utilities and Energy | When your infrastructure spans miles, like power lines or wind turbines, tracking assets ensures nothing is overlooked and maintenance happens on time. |

| Public Sector and Government | Public resources are often wasted or underutilized without proper tracking, affecting cost efficiency and service readiness. |

| Education and Research Institutions | From lab equipment to laptops, losing track of valuable assets can disrupt education and derail research progress. |

| Hospitality and Events | With constant turnover of assets like AV equipment or furniture, it’s easy to lose items or miss opportunities to improve guest experiences. |

No matter the industry, asset tracking covers several elementary use cases, each addressing a specific operational challenge:

- Fleet tracking

- Equipment maintenance

- Resource allocation

- Theft and loss prevention

Let’s break these down.

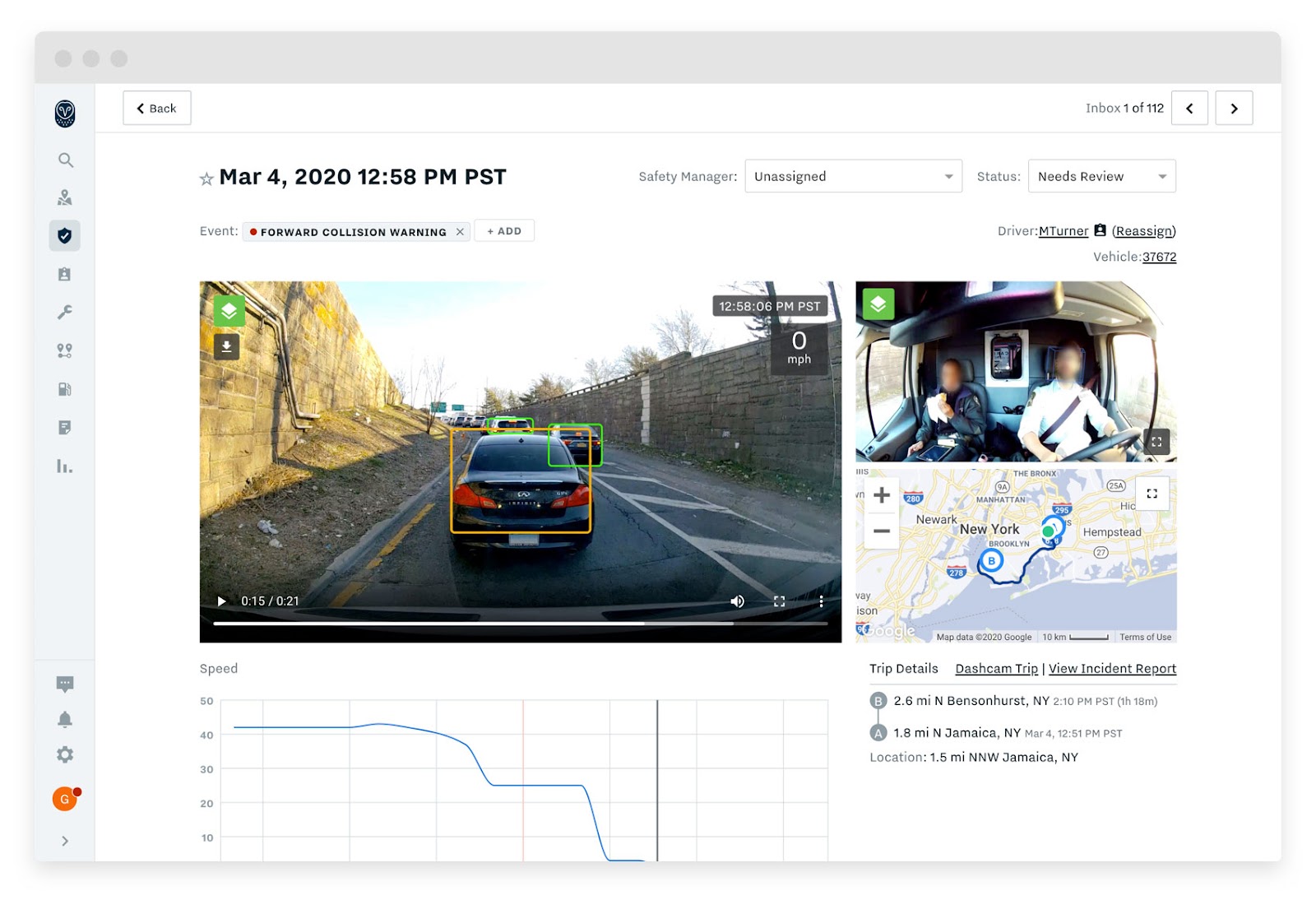

Fleet tracking is one of the most common applications.

Companies that use cars, trucks, or other vehicles to transport goods, employees, or customers use asset tracking to monitor their usage, availability, and condition.

This helps them optimize routes, reduce fuel consumption, schedule maintenance and even improve driver safety.

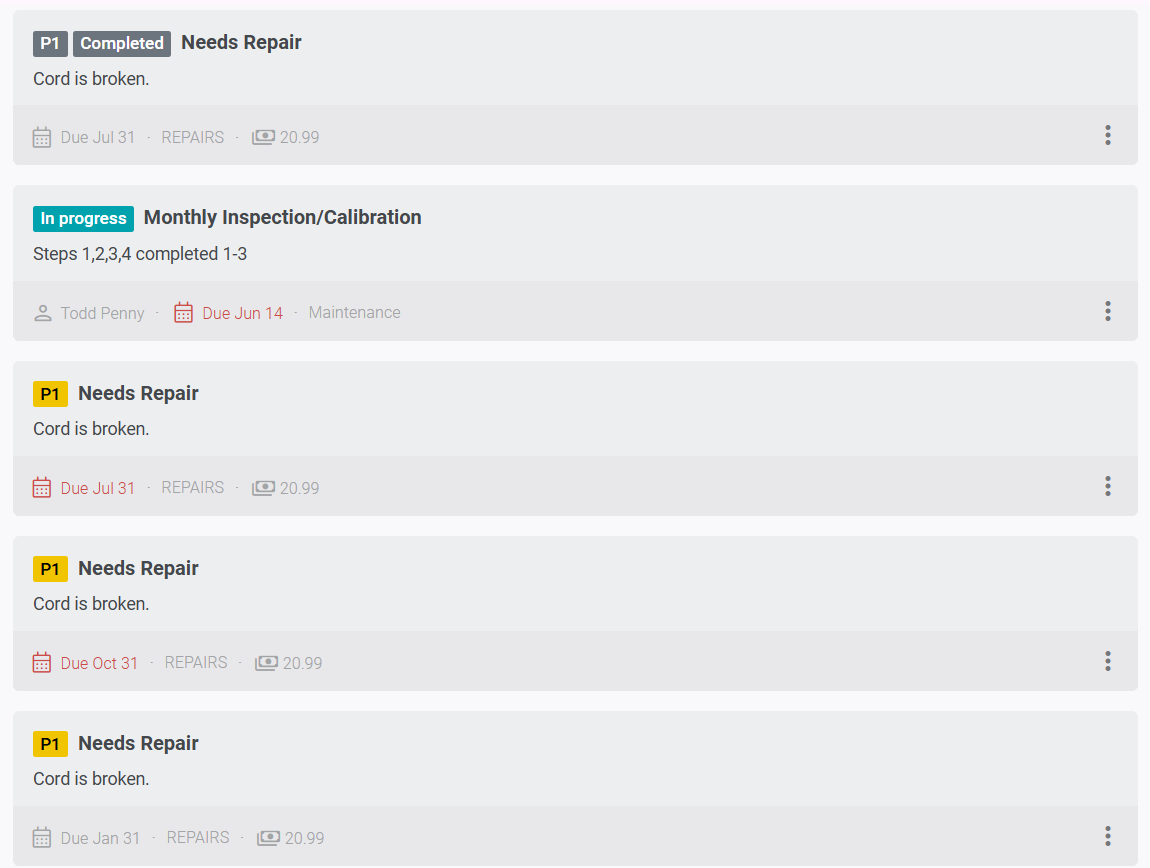

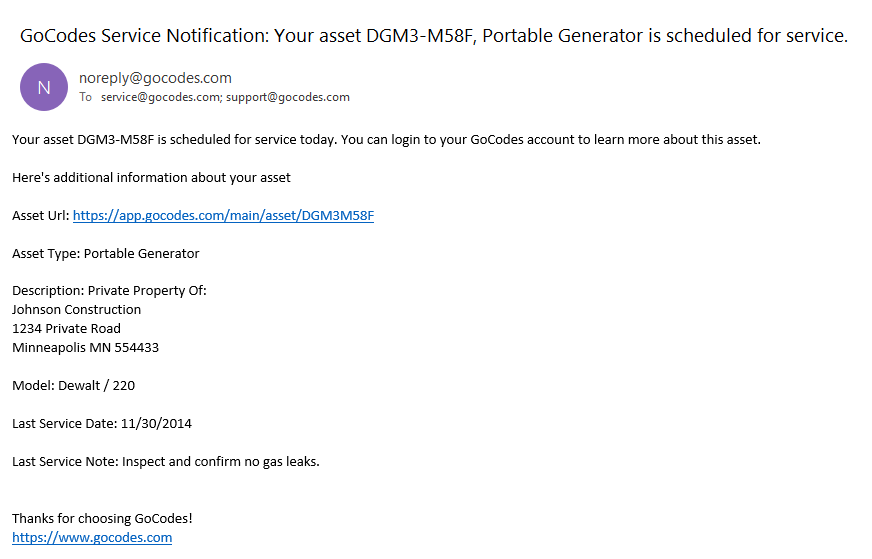

Speaking of maintenance, asset tracking ensures that machines, tools, and devices are regularly inspected and serviced on time.

Instead of scrambling to fix breakdowns, businesses rely on automated maintenance schedules and inspection reminders, keeping operations running smoothly.

Resource allocation is another crucial use case.

By knowing exactly where tools, vehicles, and machinery are, companies can assign them where they’re needed the most.

This helps avoid underutilization, prevents overbooking, and keeps projects on schedule.

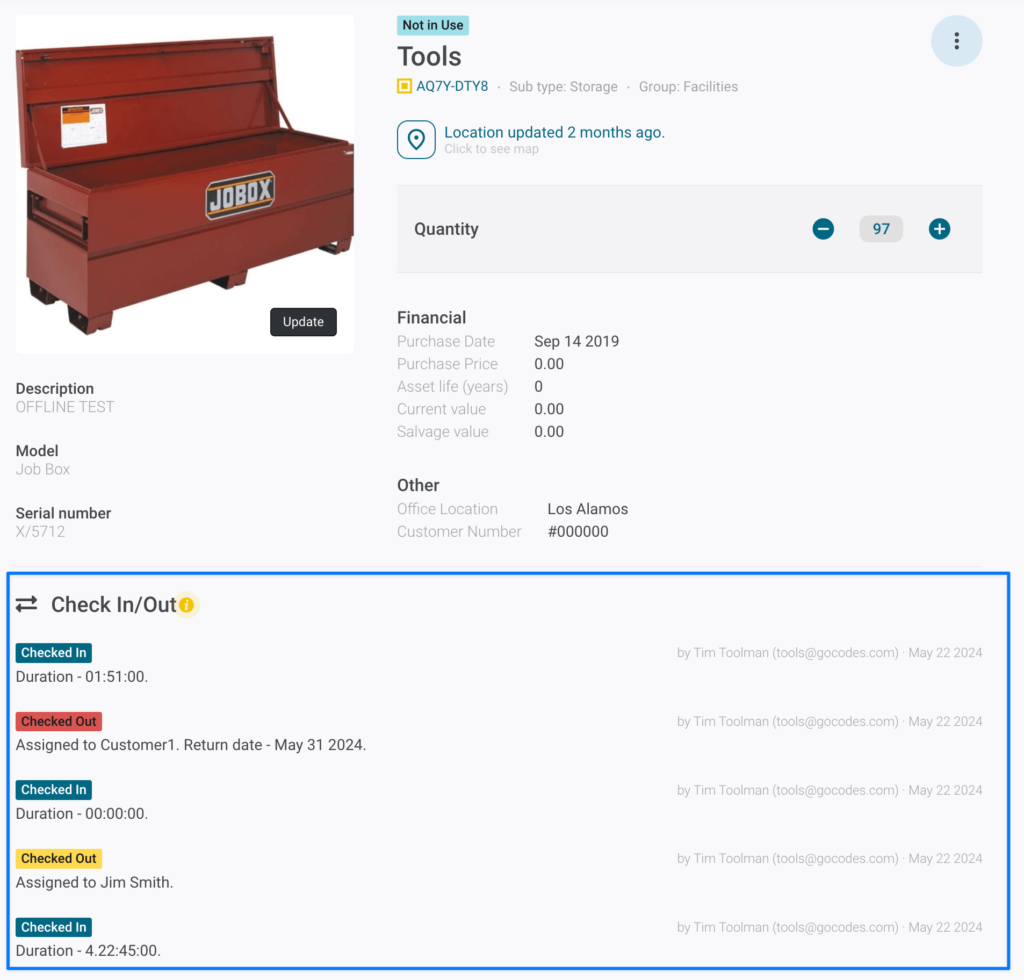

And let’s not forget theft and loss prevention.

Misplaced or stolen assets don’t just disappear—they take profits with them, too.

Asset tracking adds an extra layer of security, logging every check-in, check-out, and movement, and alerting teams of unauthorized use or removal.

Every one of these use cases adds up to one thing: having full control and visibility over your assets so you can run your business more efficiently and profitably.

Benefits of Asset Tracking

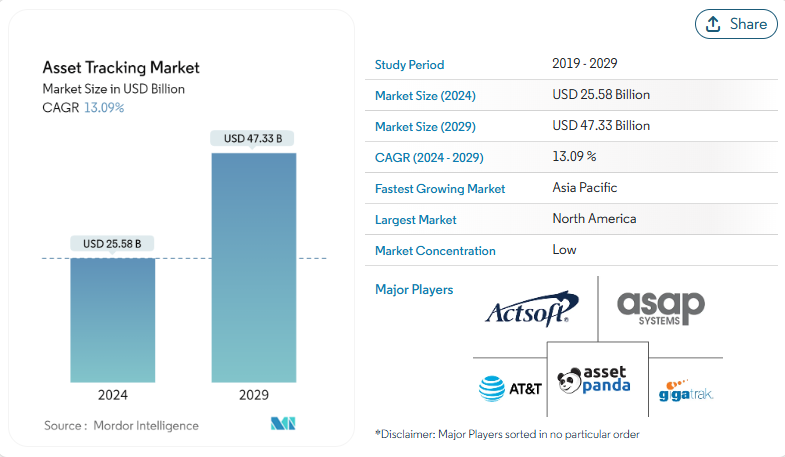

According to Mordor Intelligence, the global asset tracking market size is estimated at $25.58 billion in 2024 and is expected to grow at a 13.09% CAGR, reaching $47.33 billion by 2029.

The reason for this massive demand and growth projection?

The benefits it offers.

By now, you probably have a good sense of what asset tracking can do for your business, but let’s dig deeper and explore these benefits in more detail.

Enhanced Efficiency

Efficiency is all about getting the most out of your resources: time, tools, and people.

This means achieving better results with the same resources or achieving the same results with fewer resources.

Now, consider how many workflows are involved in managing assets.

From tracking down missing tools to scheduling maintenance and coordinating assets across teams, each one of these processes takes time.

But when they aren’t streamlined, they take even more time, which leads to delays, frustration, and unnecessary costs.

Asset tracking changes that by automating repetitive tasks and providing instant access to critical information.

Need to locate a tool or vehicle?

Instead of making calls or digging through paperwork, a quick scan or GPS lookup shows you exactly where it is.

Want to check an asset’s condition?

Tracking system logs maintenance history flags anything requiring attention, and sends alerts for inspections or repairs before problems arise.

Need to know how an asset is being used?

Usage data shows whether tools and machines are overworked, underutilized, or misused, helping you plan better and avoid inefficiencies.

In short, asset tracking takes the guesswork and manual effort out of your workflows, so your team can focus on what really matters: getting the job done.

Cost Savings

Business is all about profit, and one of the fastest ways to boost it is through cutting costs.

Now, think about all the hidden costs that pile up when tools go missing, maintenance is delayed, or equipment is underutilized.

If your team loses an asset, that’s an immediate hit to your bottom line.

You’ll either have to replace the item or face project delays because it’s not available when you need it.

On top of that, repairs get more expensive the longer problems go unnoticed, and the risk of total failure skyrockets.

And every idle or underused piece of equipment?

That’s money wasted too, because resources are sitting around collecting dust instead of delivering value.

Surprisingly, this can also lead to over-purchasing.

After all, without a clear picture of asset usage, it’s easy to buy equipment you don’t actually need.

When you add it all up, it’s a lot of money slipping through the cracks, right?

Well, asset tracking fixes these money pits by giving you real-time visibility into your operations.

A robust asset tracking solution tracks every piece of equipment, its condition, and its usage.

Thanks to it, you no longer lose tools, maintenance happens on time, and equipment is properly allocated, all of which helps prevent overbuying and underusing.

Wondering how much money this can really save?

Here’s a real-world example.

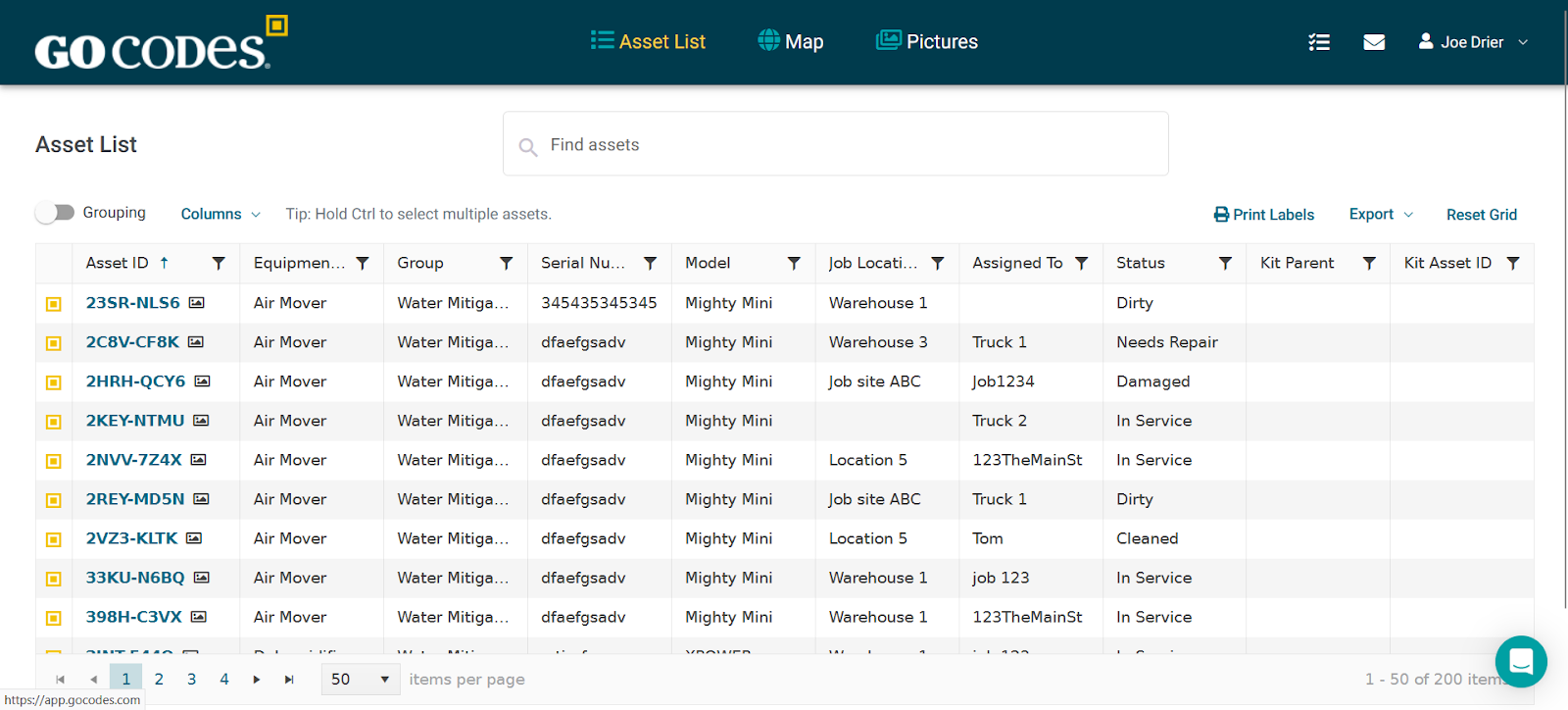

J&M Keystone, Inc., a construction restoration company (acquired by API in 2022), used to lose about $30,000 worth of equipment every year.

After implementing asset tracking software—specifically GoCodes Asset Tracking—they slashed equipment losses by 95%, bringing it down to just $1,500 annually.

All it took was a simple implementation of QR codes for equipment check-in and check-out, and GPS tagging for real-time tracking.

You can read the full case study here: Asset Tracking for Flood and Damage Restoration at J&M Keystone

Isn’t it almost unbelievable how one relatively small change can lead to astonishing savings?

Now imagine what asset tracking could do for your bottom line.

Improved Security

When it comes to physical assets, theft is a constant threat.

Whether it’s internal or external, it can cost businesses thousands of dollars every year.

In fact, according to the National Equipment Register (NER), the construction industry alone faces massive losses, with equipment and material theft estimated between $300 million and $1 billion annually.

That’s a staggering number, isn’t it?

And when assets go missing, it’s not just the replacement costs you’re dealing with.

It’s the ripple effect, too: project delays, downtime, and lost productivity, making the real cost of theft even higher.

But here’s the thing: theft thrives on opportunity.

Without a system in place to monitor your tools, vehicles, and machinery, it’s easy for items to “disappear” without anyone noticing right away.

And by the time you do, the trail is usually cold.

However, asset tracking changes that.

By allowing you to keep a digital eye on your assets, it adds a layer of security that manual systems simply can’t match.

With check-in and check-out logs, you always know who used what, when, and where.

GPS-enabled trackers let you monitor the location of your equipment in real-time, while alerts notify you of unauthorized movements or access.

And if something does go missing, asset tracking systems help you trace its last known location, improving the chances of recovery.

The result?

Fewer losses, fewer headaches, and more peace of mind knowing your valuable assets are safe.

Data Insights for Decision-Making

Better decisions come from better data, and asset tracking gives you plenty of it.

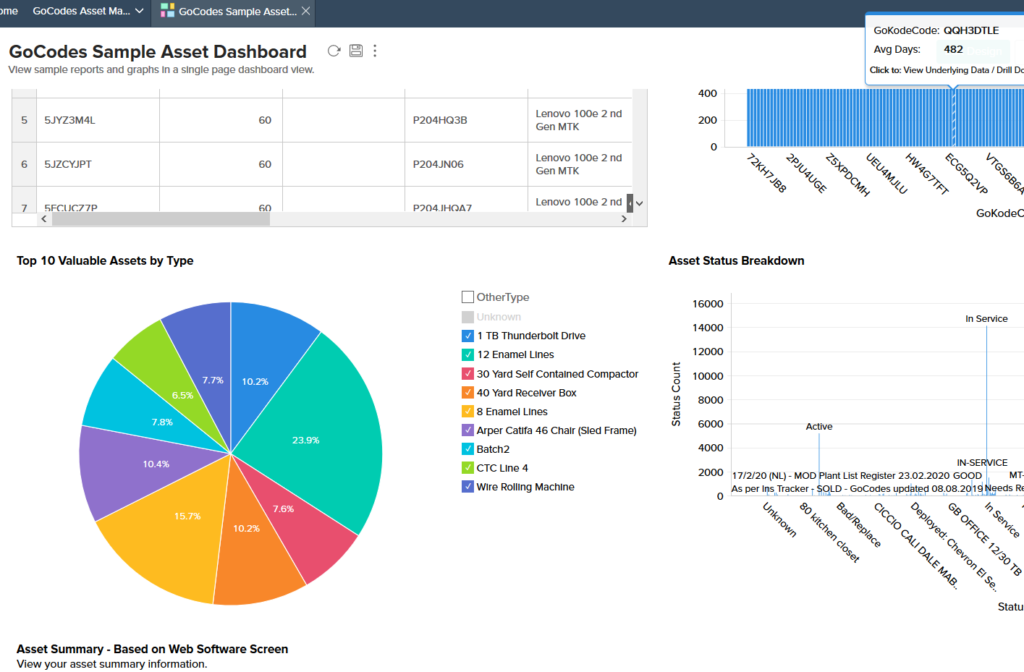

Every time an asset is scanned, logged, or monitored, it generates valuable information about its location, condition, and usage.

Asset tracking systems collect this data and present it in a way that’s easy to interpret, giving you a bird’s-eye view of your operations.

For example, trends in asset usage can reveal patterns that might not be obvious otherwise.

Are certain tools or vehicles being used more than expected?

That could indicate higher demand or the need for an extra unit to avoid overuse.

On the flip side, tracking underused assets can help you identify items that could be sold, repurposed, or relocated to save costs.

Maintenance data is another goldmine.

By analyzing repair histories and service trends, you can predict when equipment might fail and budget for replacements before emergencies arise.

And it doesn’t stop there.

Asset tracking also highlights inefficiencies you’d overlook without accurate data.

Are certain tools always being checked out by the same team? Maybe they need their own set to reduce wait times.

Is equipment frequently moved between job sites? You might consider repositioning resources for better access.

In short, asset tracking doesn’t just tell you what’s happening. It helps you understand why.

And that understanding leads to smarter, better decisions for your business.

Tips for Successfully Implementing Asset Tracking

Now that you understand what asset tracking is, who needs it, and the great benefits it brings, it’s time to talk about how to successfully put it into action.

A first glance, it might seem like a complicated process.

However, it’s actually simpler and far less stressful than you’d expect.

Sure, there’s a bit of effort involved in setting it up, but once it’s in place, the system does most of the heavy lifting for you.

Here are some practical tips to help you implement asset tracking effectively and get the most out of it.

1. Choosing the Right Technology

Picking the right asset tracking technology is like choosing the right tool for the job: it all depends on what you need and how you plan to use it.

Start by asking yourself a few key questions:

- What types of assets do you need to track?

- How often will you need to check their status or location?

- Do you need real-time updates or just periodic snapshots?

- What’s your budget for setup and maintenance?

Answers to these questions will guide you to the best solution.

For instance, QR codes and barcodes are great for businesses with simpler tracking needs.

They’re affordable, easy to use, and perfect for logging check-ins, check-outs, and maintenance updates.

If your operations involve large, mobile assets like vehicles or heavy machinery, GPS-enabled trackers might be a better fit.

They provide real-time location updates, which are especially useful for ensuring accountability and preventing theft.

On the other hand, RFID tags or Bluetooth beacons shine in environments with many assets close together, like warehouses or production facilities.

These technologies can track multiple items simultaneously, streamlining bulk scans and audits.

And remember, you don’t have to stick to just one method.

Many businesses use a mix of technologies to cover all their tracking needs, creating a system that’s as versatile as their operations.

When it comes to placement, make sure trackers are positioned where they’re easy to access but not likely to be damaged.

For tools and equipment, this might mean attaching QR codes to handles or sturdy surfaces.

For vehicles and machinery, place GPS trackers in concealed but accessible locations to protect them from tampering.

Proper placement ensures the technology works seamlessly while staying protected from wear and tear.

A little extra thought here can save a lot of headaches later.

2. Training and Adoption

The truth is, any new tool or process is only as good as the people using it.

After all, if your team doesn’t understand how to use it—or worse, avoids it altogether—even the best asset tracking system won’t do much.

That’s why proper training and getting your team on board are so important.

The best way to start training is by explaining the “why.”

When employees understand how asset tracking makes their jobs easier, whether it’s finding tools faster, avoiding project delays, or cutting down on manual paperwork, they’re more likely to embrace the change.

Next, focus on making the training process simple and practical.

No one wants to sit through hours of complicated instructions.

Instead, break it down into easy-to-follow steps.

Show employees exactly how to use the system, from scanning a QR code to checking asset logs or updating maintenance records.

Hands-on sessions work best here.

Let your team try out the tools and ask questions in real time.

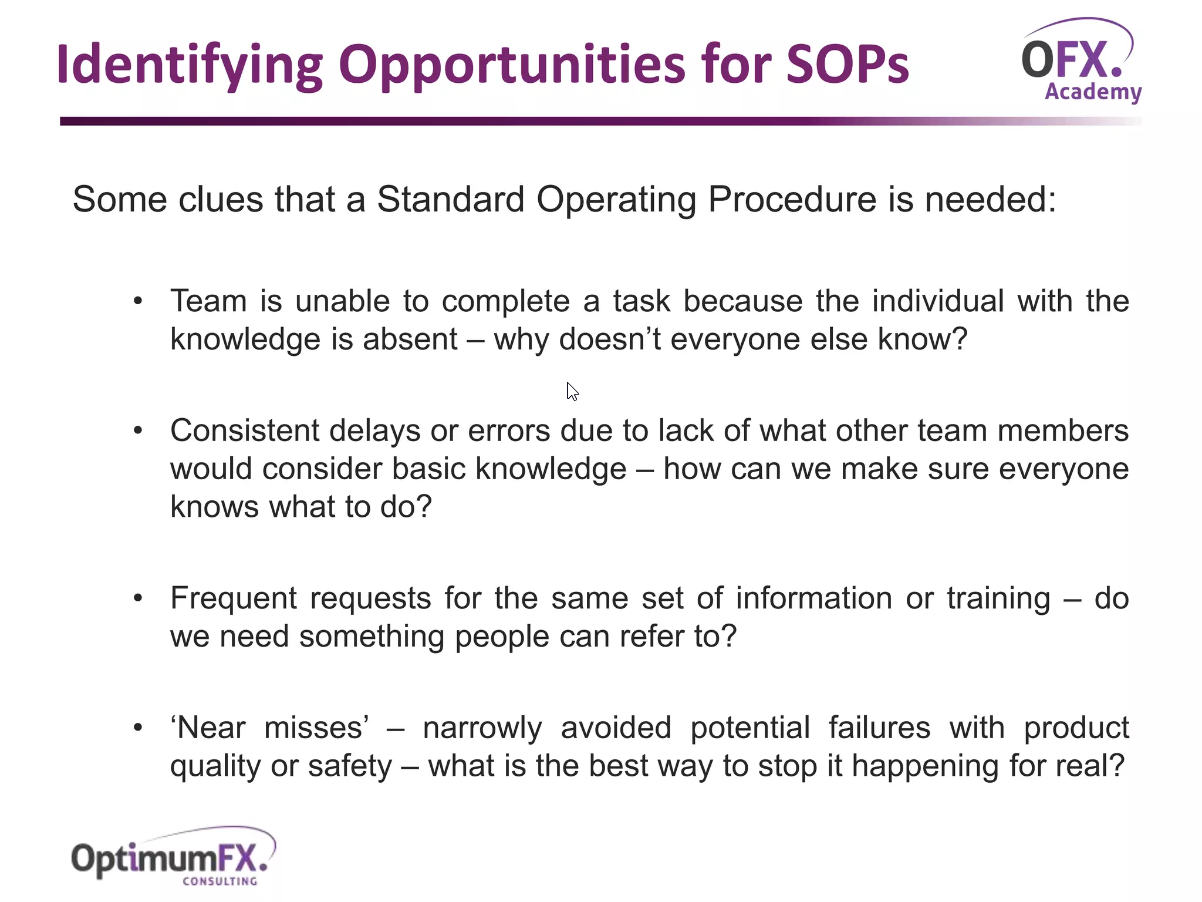

It’s also a good idea to create SOPs they can use when needed.

Finally, set up a support system and have someone available to answer questions and troubleshoot issues.

This is especially important during the first few weeks and can make a huge difference in getting everyone up to speed.

Remember, the goal isn’t just to teach them the system.

It’s to make sure it becomes a natural part of their daily workflows.

3. Data Management & Analysis

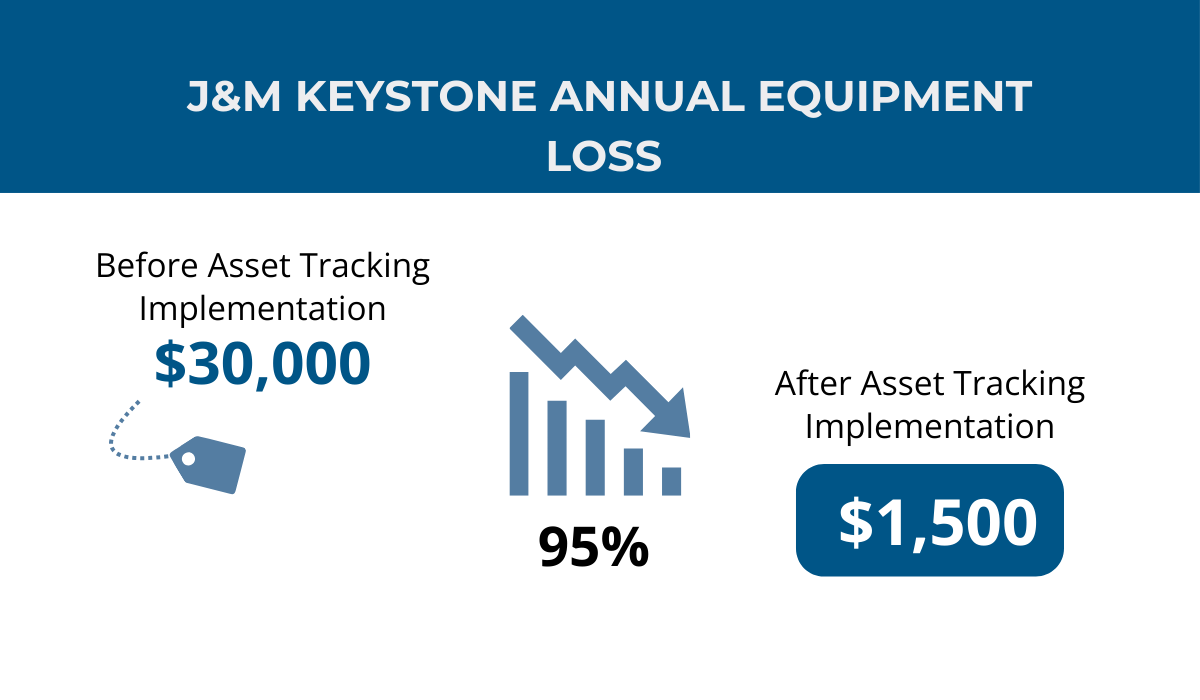

Having an asset tracking system in place is great, but the real value comes from how you manage and analyze the data it collects.

Asset tracking systems generate a wealth of information: locations, usage logs, maintenance histories, and more.

And if that data isn’t well-organized, it can quickly become overwhelming and lose its value.

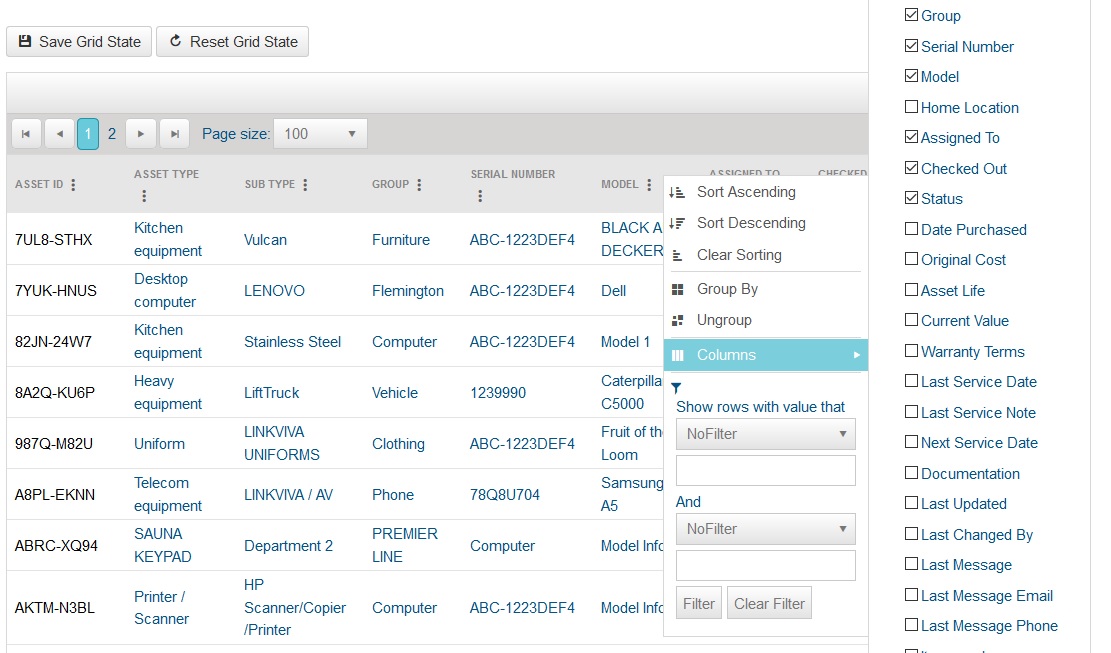

To be able to manage and analyze data effectively, you first need to make sure the system you’re using allows you to categorize and tag data in ways that make sense for your business.

The best asset tracking systems will allow you to group assets by type, location, department, or custom tags, making it easy to filter and find exactly what you’re looking for.

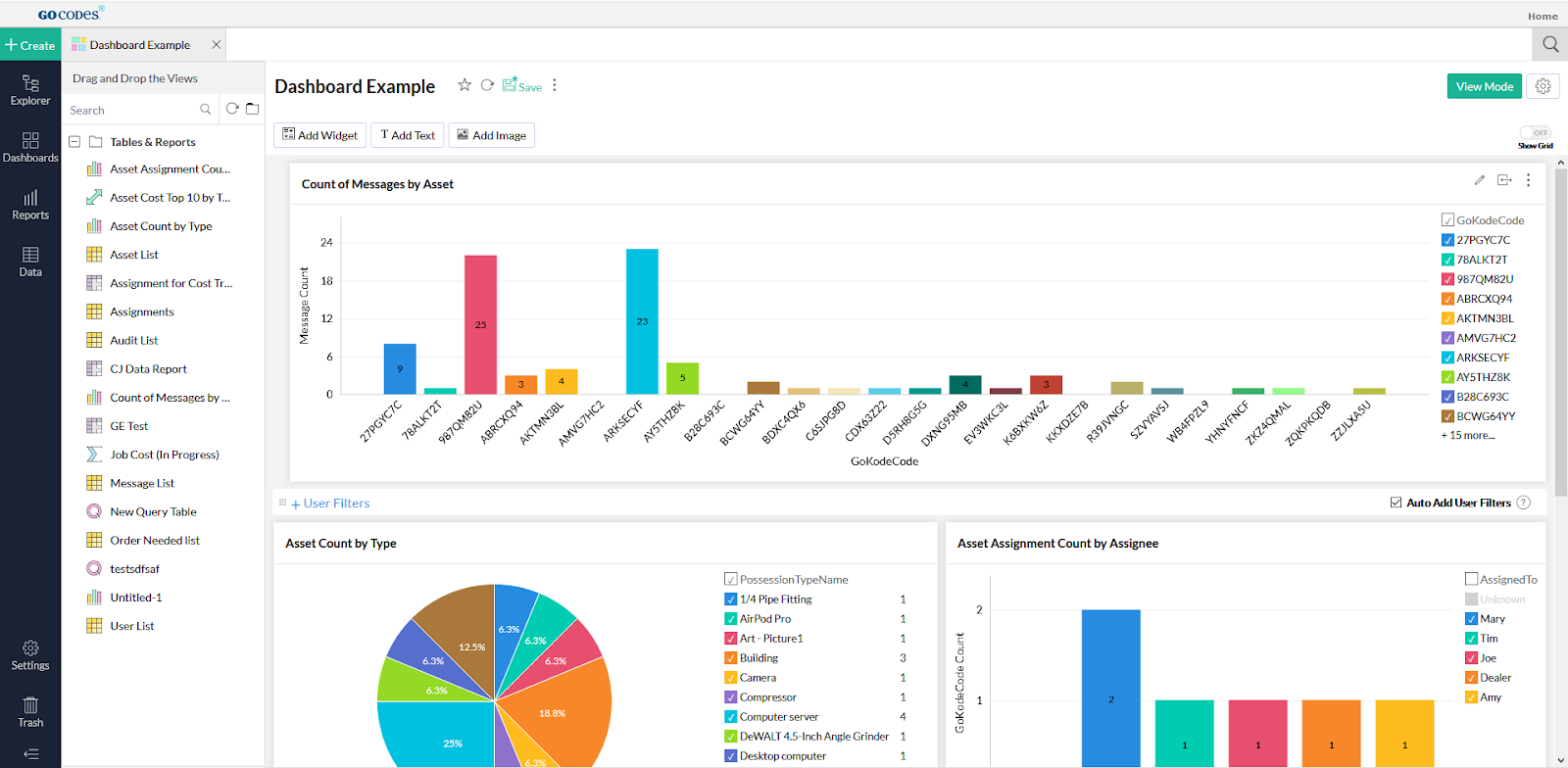

With GoCodes Asset Tracking, this process is straightforward.

The platform lets you customize categories and tags to align with your workflows, so everything stays organized and accessible.

Once the data is organized, set up a regular schedule to review and analyze it.

Whether it’s weekly, monthly, or quarterly, look for patterns that can guide decisions.

Are certain assets always in high demand? Are some sitting unused for long periods?

These patterns can help you redistribute resources, prioritize maintenance, or even adjust your purchasing strategy.

And don’t forget to use the system’s reporting tools.

Most asset tracking platforms offer built-in reports that make it easy to track metrics like idle and downtime, maintenance schedules, or asset utilization.

Take advantage of these features to get a clear picture of your operations without spending hours crunching numbers.

Automation can also save you time.

Many systems, including GoCodes Asset Tracking, let you set up custom alerts for overdue maintenance, underused equipment, or other critical issues.

These notifications keep you proactive, saving time and preventing problems before they occur.

Finally, don’t let data sit idle.

Share key findings with your team or leadership to keep everyone on the same page and drive better decisions across the board.

With the right approach and the right tool, you can turn raw data into smarter strategies that drive better results for your business.

Conclusion

Managing physical assets doesn’t have to be a constant battle of tracking down tools, fixing unexpected breakdowns, or wondering where your equipment disappeared.

With asset tracking, you can stop guessing where your equipment is, how it’s being used, or when it needs maintenance.

Instead, you’ll have everything you need, organized and at your fingertips, to keep your operations running smoothly.

And the best part?

Once the system is up and running, it does most of the hard work for you.

Ready to take control of your assets and see the difference it makes?

Let’s make it happen.