If you’re grappling with numerous tools and equipment, entangled in a network of spreadsheets and databases, asset tracking can feel like a maze with no exit in sight.

Is there a way out of the manual tracking process, you might wonder? Where does one even start developing an efficient strategy to manage and monitor assets?

The answer might be hiding in plain sight.

Those tiny squares with black-and-white patterns that you’ve likely seen and used countless times, commonly referred to as QR codes, could be the solution.

In this article, we’ll walk you through a step-by-step process that demonstrates how QR codes can be instrumental in efficiently overcoming your asset tracking hurdles.

In this article...

Determine What Assets You Need to Track

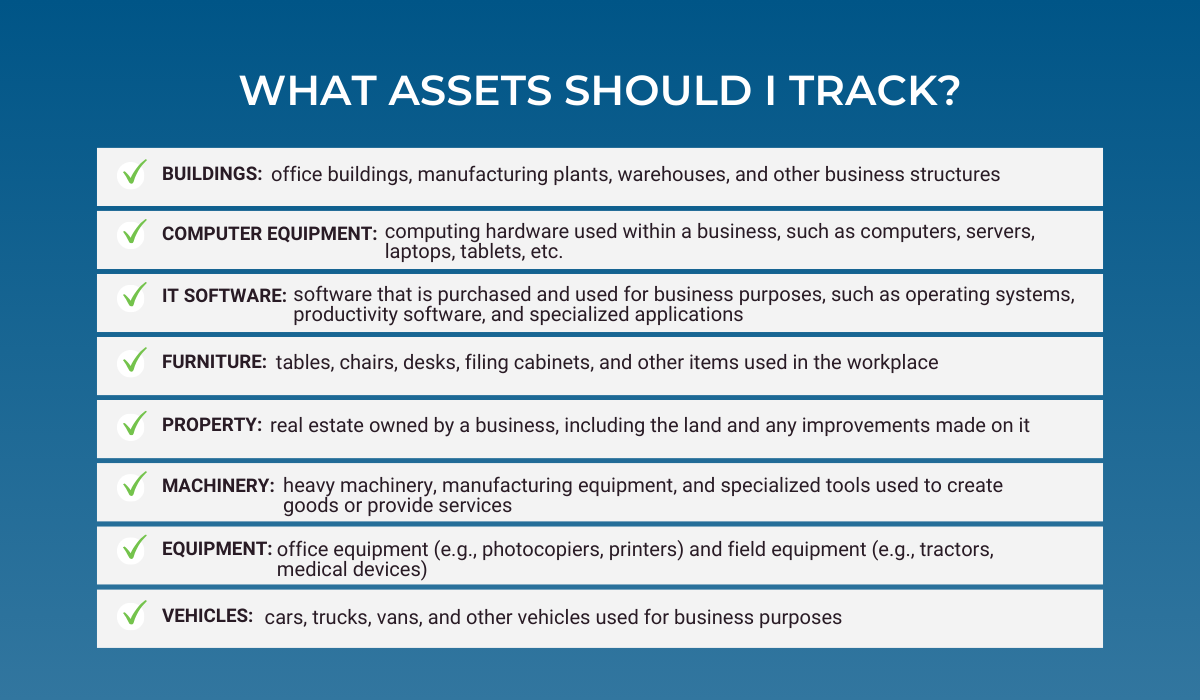

When it comes to using QR codes for asset tracking, the initial step inevitably boils down to the question—what assets should be tracked?

While this might seem simple on the surface, this essential step sets the stage for an effective asset-tracking system.

For instance, if you’re in an office environment, you may decide to track IT equipment, from computers, laptops, and printers, to specialized gear like servers or networking devices.

Conversely, if your work is rooted in the construction sector, you’ll most likely need to track assets like excavators, loaders, jackhammers, and drills.

To help you get started, take a look at the list below, which can give you a few ideas of what to track.

Anything that holds significant value, moves frequently, or is essential to your operational processes should be on your list.

At this point, you may wonder why it’s even crucial to identify assets before jumping into QR code asset tracking. There are a few key reasons.

Firstly, not all assets need to be tracked, so it will help you decide on categories of tools that you should put QR codes on.

Secondly, it will clarify what is being tracked, making it easier to monitor the movement, usage, and retrieval of the items.

And thirdly, knowing what to track will influence your choice of QR code labels and tags, as well as how they’re printed.

For example, a construction business may require more durable labels than, say, a development agency. But more about that in the next section.

Acquire Your QR Code Labels or Tags

After making the decision about what assets to track, it might occur to you that using your office printer to print QR codes on labels and tags could save some pennies.

However, in reality, this seemingly budget-friendly route is laden with potential pitfalls.

For starters, a common issue that can crop up is incorrect size settings and dimensions.

You may find the QR codes printed are blurry as a result of downloading them in incorrect formats or improper resizing.

And blurriness can significantly impede scanners from reading the codes.

Also, the quality of the labels or tags you print on QR code labels matters.

The consequence of printing your own QR codes on poor-quality material is susceptibility to water damage and abrasion.

They may also peel off quickly since they don’t have permanent adhesive at the back.

So, what’s the smart solution? Partner with a reliable supplier that specializes in QR codes.

To illustrate, let’s use our own tool, GoCodes, as an example.

As a sophisticated asset-tracking tool, it can lift the burden of picking the right QR code labels and tags off your shoulders.

With a reasonably-priced premium or professional plan, you’ll receive high-quality, thick poly labels at no extra cost.

Their resistance to water and chemicals, along with a permanent adhesive backing, ensures durability even if you operate in harsh conditions where equipment frequently goes through wear and tear.

You can also design your QR code labels and tags, and include your logo, phone number, email address, or message, which is always a nice feature as it makes them appear more professional (as you can see in the image below).

If you need different label specifications, GoCodes offers options such as premium polyester (subsurface printed), anodized aluminum metal foil, and anodized aluminum metal tags.

You can even request a sample before committing to the software, so you can be confident that you’ve chosen well.

And for those who still hold fast to printing their own labels, GoCodes is flexible enough to accommodate that as well.

The QR codes the GoCodes will generate for you will be carefully calibrated to the proper dimensions, minimizing the chances of blurriness.

As you can see from this example, while DIY labels are an option on the table, if you desire a more durable and robust solution, advanced asset-tracking tools that work on QR code principles can make all the difference.

Attach the QR Code Labels or Tags to Your Assets

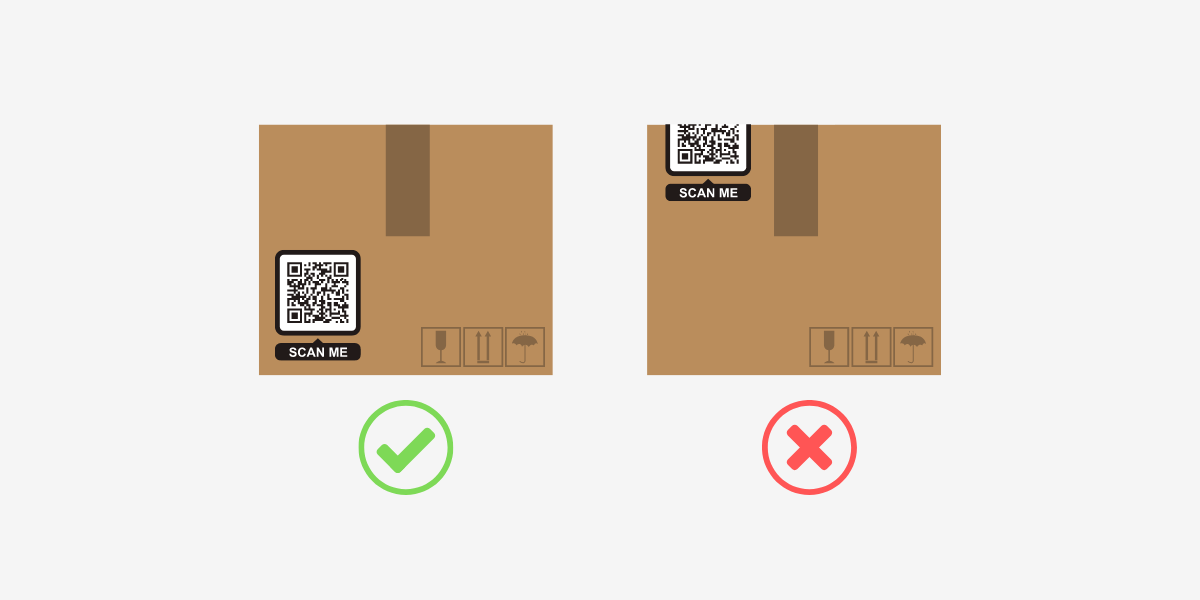

Once you’ve acquired QR code labels and tags, the next logical step is to correctly attach them to your items.

This process might appear simple at first, but it’s not always as straightforward as just affixing a sticker or tag to an item.

When attaching the QR codes, think about how your assets are typically used and handled on-site.

Placing the label or tag in an area that frequently comes into contact or gets bumped might not be the best choice.

Imagine a drill as an example. You wouldn’t place the QR code sticker at the end of the handle, where technicians grip the tool.

Nor would you put it on the drill bit where it’s likely to get scratched or chipped.

Instead, a flat, stable surface on the body of the drill would render a crisp scan and is less likely to get hampered by routine use.

Moreover, when it comes to placing the QR codes, you want to make sure they’re easy for your workers to scan.

If a label is tucked away in a hard-to-reach area or hidden under dirt and debris, scanning becomes a tiresome chore.

Also, placing it near corners should be avoided, as they could leave the code unreadable.

It’s wise to opt for flat, smooth surfaces on your asset.

This makes scanning much easier, and your QR code will remain intact and visible during its lifetime.

As you can see, attaching QR code labels and tags is paramount for creating an efficient asset-tracking system.

By placing them in accessible spots while avoiding high-contact areas, you’ll ensure your team can quickly and accurately scan QR codes.

Set Up Your QR Code-Based Asset Tracking Solution

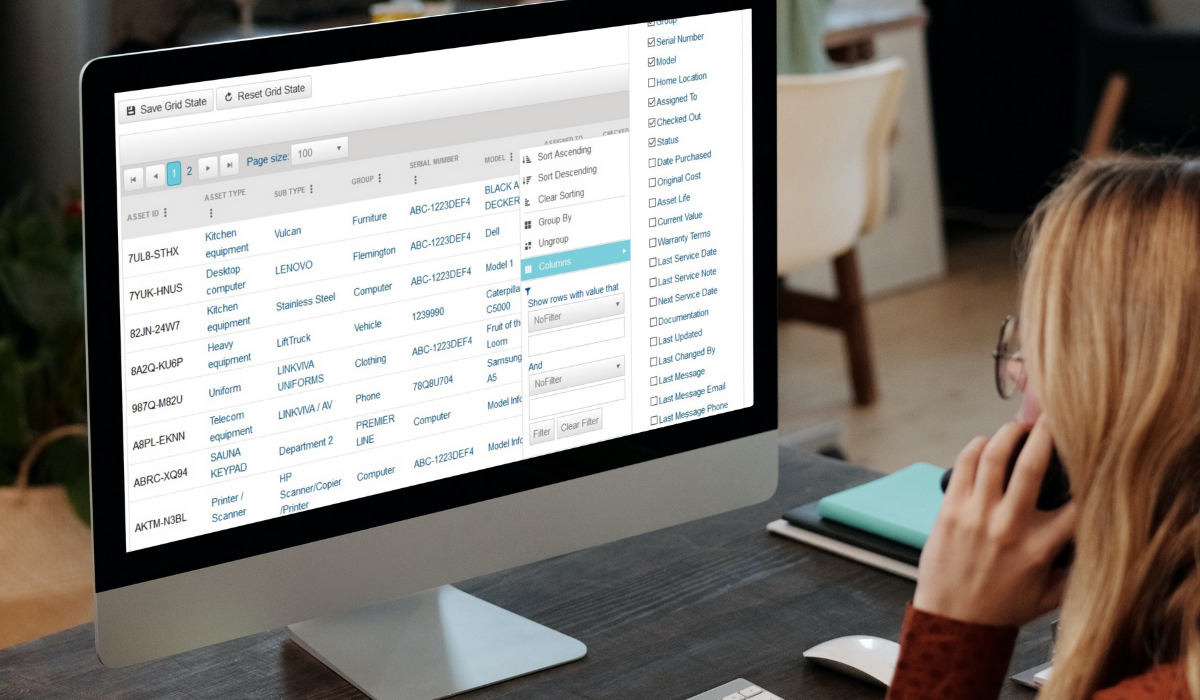

After you’ve secured your QR code labels and tags, it’s time to set up a QR code-based asset-tracking solution.

You might be tempted to think, “But I already have a generic QR code scanner on my phone. Can’t I just use that?”

Or maybe you’re pondering, “Why not create some QR codes online for free and find an app to track them?”

While these seem like logical notions, they’re fraught with drawbacks.

QR codes themselves are versatile, but a free app scanner only takes you halfway.

It gets the primary job done—scanning the code and displaying basic information.

But your goal is to build an effective asset management system, one that not only tracks items but also allows you to update asset details, generate reports, and give you real-time status at a glance.

Self-generated QR codes or generic mobile apps can’t provide this level of functionality.

Therefore, what you need is specialized software designed for this exact purpose.

Let’s use our tool, GoCodes, to demonstrate this point.

GoCodes goes beyond mere scanning. It’s a complete tool management system that provides you with the following:

- real-time asset tracking

- secure cloud-based data storage

- tool assignment capabilities

- maintenance features, and much more.

This means you won’t have to worry about losing track of who has what tool or piece of equipment, maintenance schedules slipping through the cracks, or running into blind spots in your asset tracking.

GoCodes automates and schedules this process on a cloud-based platform, so it’s less prone to human error and inconsistencies.

Also, it’s designed with exceptional user-friendliness in mind.

Even team members who might not be tech-savvy can master its features. This is pivotal in industries with workers of different levels of education or technical expertise.

Therefore, opting for a specialized asset-tracking platform is always the best solution.

It may initially come as an investment, but it pays off in the long run because it automates the whole process, stores everything in the cloud, and provides you with accurate tracking of your assets.

Start Scanning Your QR Code Labels and Tags

Having chosen your software, you’re now standing on the threshold where you put things in motion.

It’s time to roll up your sleeves and start scanning your QR code labels and tags.

At the first glimpse, it might look overwhelming, particularly with a vast array of assets lined up for scanning.

Luckily, here also you can use specialized software that’ll simplify the process.

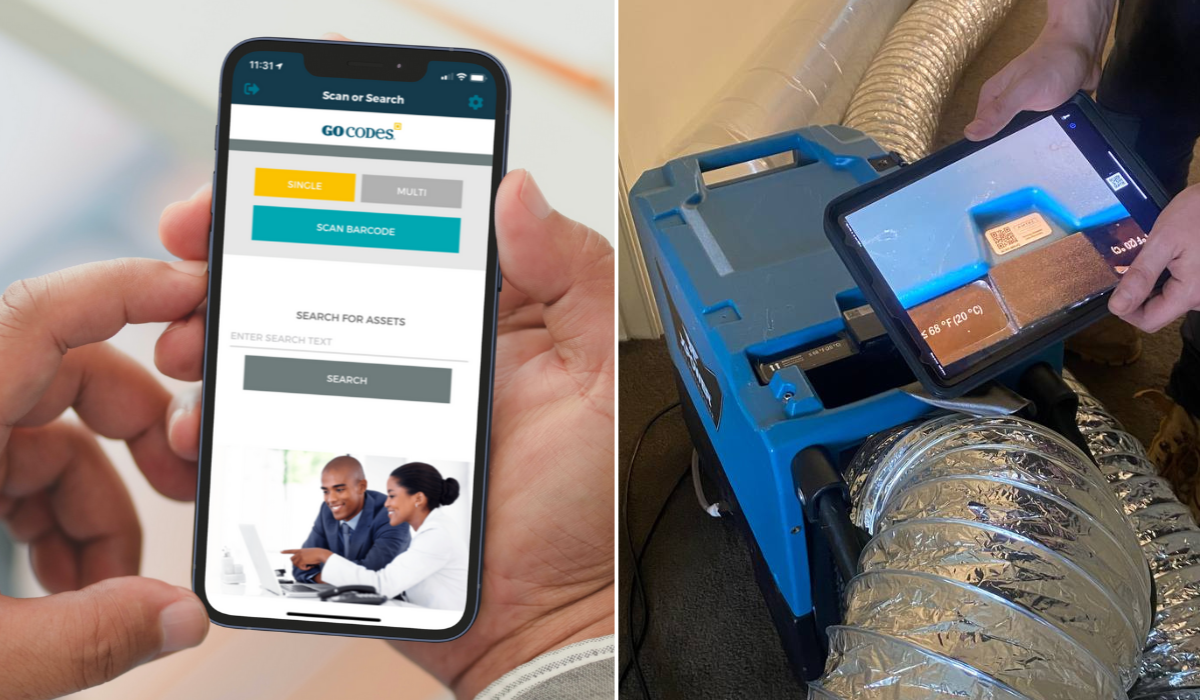

Most high-end asset tracking tools today come with apps designed to work on any mobile device, such as smartphones or tablets.

Once you install the app, you can start scanning QR codes attached to your assets.

Every scan will offer instant access to critical information about the asset–current holder, maintenance history, and even the location of the asset.

This means no more chasing after assets, wondering if they are sitting idle in storage, transferred to another team, or out for repair.

With every QR code scan, real-time asset data is just a tap away.

Let’s take schools and higher education institutions as an illustration.

They’re often faced with the challenging task of monitoring expensive IT equipment, such as tablets, laptops, reference books, and multimedia tools that are consistently reallocated amongst students and staff.

By embracing QR code scanning, they can transform their asset tracking process similar to how libraries operate.

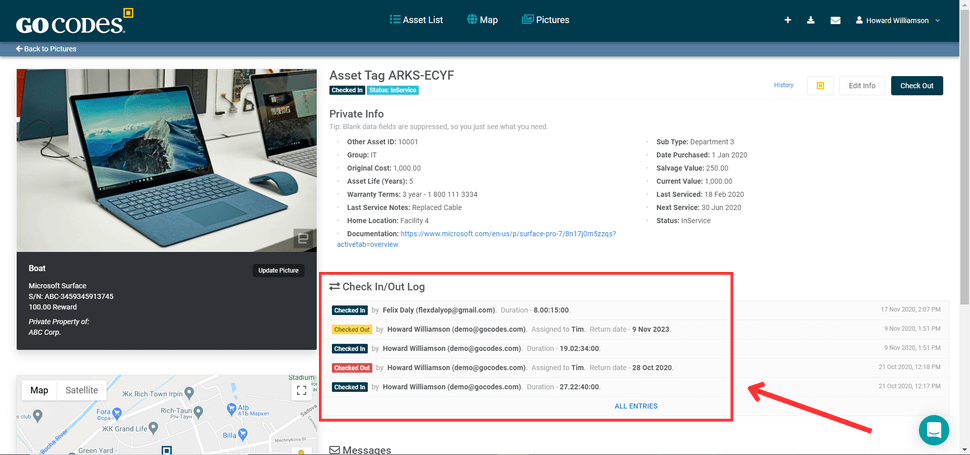

With every scan, they can monitor the movement of their assets and maintain a record of who has borrowed or returned them (check-in and check-out feature below).

This heightened level of accountability is instrumental in deterring theft and mishandling–an invaluable benefit for any organization, not merely academic institutions.

Moreover, besides accessing vital information, by scanning QR codes you can directly update data about your assets.

Just open the app, scan the code, input the changes, and they’ll be registered across the system.

This means that accurate and updated information will be available to anyone, anytime they scan the QR code.

In summary, scanning QR codes breathes life into a structured and organized asset-tracking process.

Far from burdening your team, it saves time and gives you full control over your inventory.

Conclusion

And there you have it–a comprehensive, step-by-step guide that simplifies how to use QR codes in your asset-tracking strategy.

Five straightforward steps that, when implemented systematically, can take the hassle out of your asset management and introduce a degree of simplicity and efficiency in the process.

Keep in mind that integrating QR codes into your asset tracking doesn’t have to be a formidable challenge.

With the right approach and premium asset tracking software, this technology can be implemented effortlessly and provide accurate tracking and a more organized inventory.