Nowadays, it seems there are countless ways to track the location, movement, usage, and operating conditions of your construction assets, like tools, equipment, vehicles, and heavy machinery.

Among these multiple options, Bluetooth beacons have emerged as one of the more popular asset-tracking methods due to their versatility and cost-effectiveness.

However, that doesn’t mean that beacons are necessarily the go-to solution for your construction company’s specific tracking needs and budget.

That’s why we’ll first explain how Bluetooth-based asset tracking works and then compare that system with other common asset-tracking technologies.

Finally, we’ll discuss the advantages of Bluetooth beacons and how you can use them to prevent asset theft and increase staff productivity.

In this article...

How Bluetooth Beacons Are Used for Asset Tracking

First, let’s cover the basics.

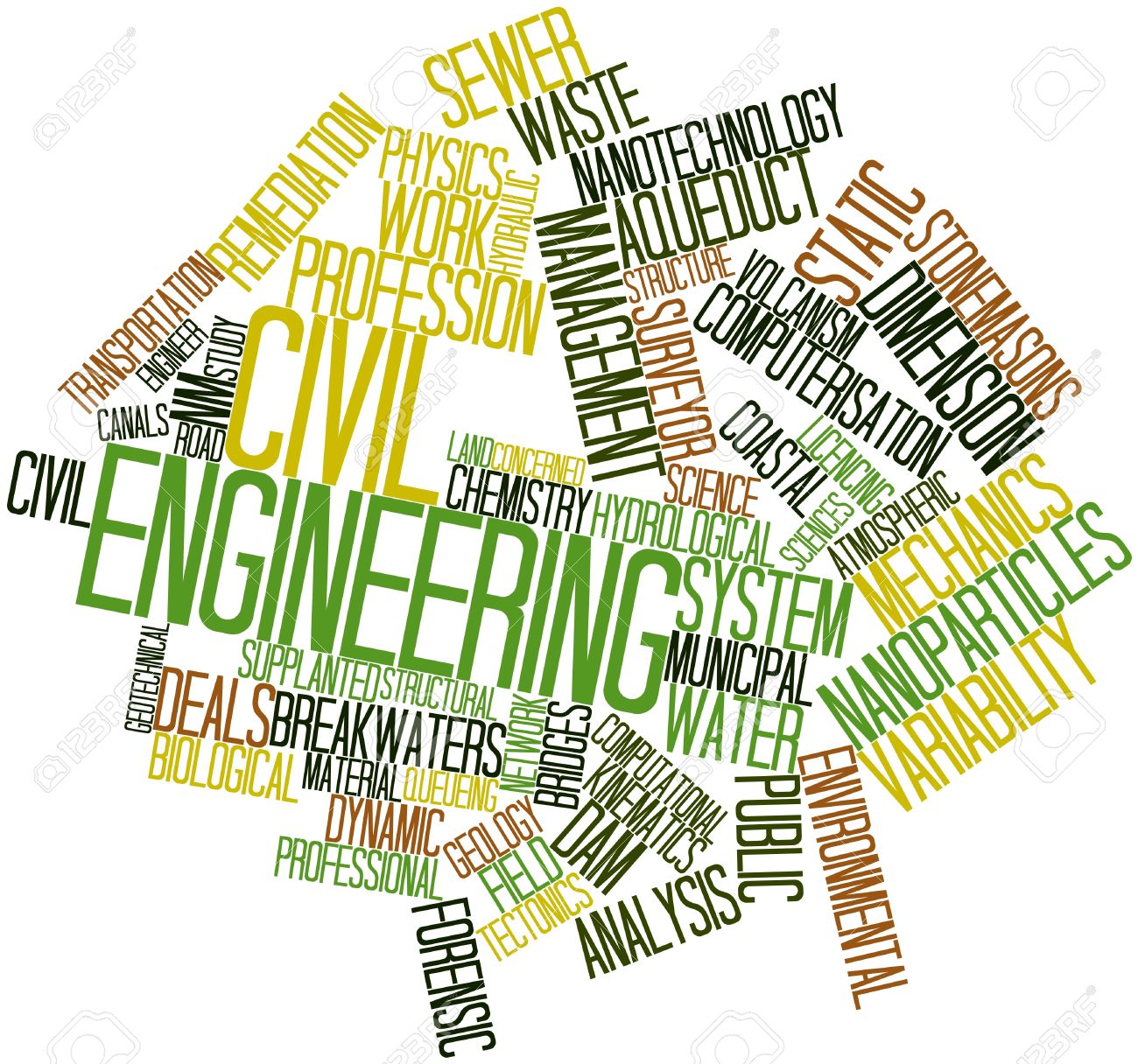

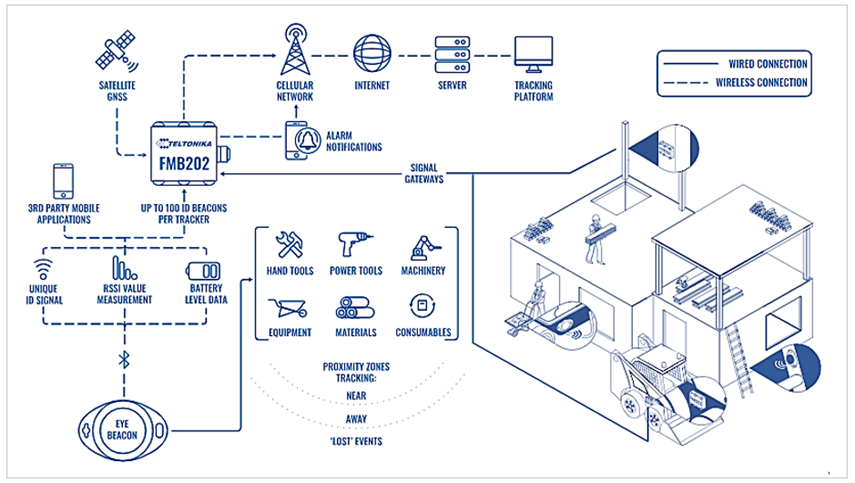

Bluetooth beacons (or tags) are small, battery-powered devices that emit short-range radio waves using Bluetooth Low Energy (BLE) technology (often called Bluetooth Smart).

BLE technology focuses on low-energy periodic exchange of data between beacons and various mobile or fixed devices (BLE receivers) within a limited range (typically up to 300 ft or about 100 m).

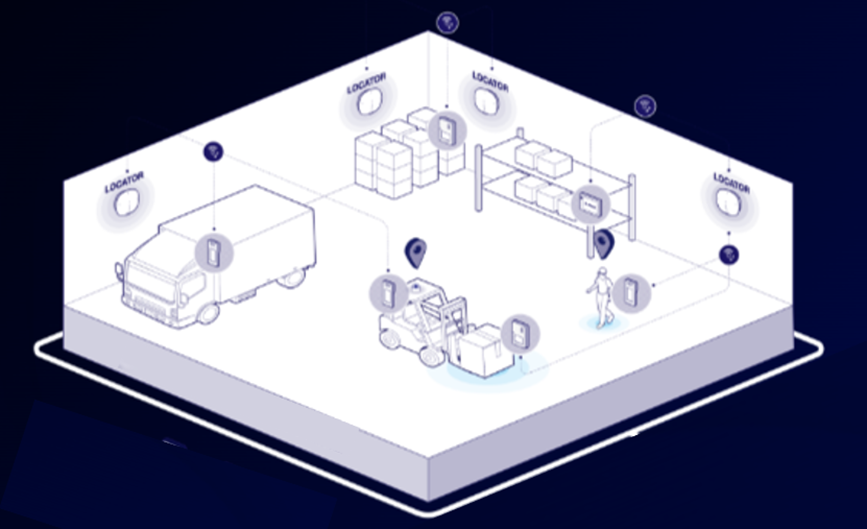

These receivers (smartphones, tablets, fixed BLE gateways/hubs) automatically detect beacons attached to assets in their range.

Then, they transmit the data to asset-tracking software that processes beacon-generated signals and shows the asset’s location on a map.

Therefore, the most basic BLE tracking system can consist of just one or two smartphones that track the movement of beacon-tagged assets within their range and can trigger alerts if an asset is moved out of range.

Conversely, more complex beacon tracking systems can have only fixed BLE hubs strategically positioned and installed around the site or combine multiple mobile and fixed BLE receivers to enable comprehensive real-time tracking of assets.

Moreover, BLE beacons can be equipped with various sensors (temperature, humidity, acceleration, vibration, etc.).

Such sensors expand the beacon’s functionality beyond automatically tracking the asset’s location to monitoring different internal (machine-related) and external (environmental) conditions.

Regardless of the specific beacon functions and system setup, these signal-detecting devices send data to a cloud-based tracking software.

The software calculates the asset’s position (and processes other data, if sensor-enabled) and presents it in a user-friendly format.

In short, Bluetooth beacons are small, versatile devices that enable construction companies to monitor the location (and conditions) of their assets in real time within a limited area, such as a construction site or warehouse.

Bluetooth Beacons vs. Barcodes for Asset Tracking

Now that we know how BLE beacons work, let’s see how they compare with other asset-tracking methods, starting with barcodes and QR codes.

As said, a beacon-based tracking system monitors the location of assets in real time without requiring any human intervention.

In other words, beacons provide automatic, remote, no-line-of-sight detection of assets within the tracking system’s range, which depends on factors like battery capacity, signal strength, and environmental barriers.

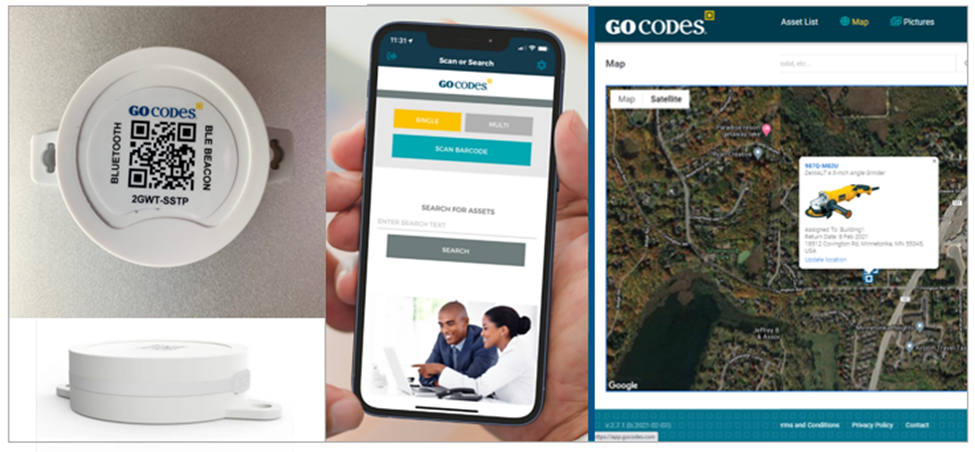

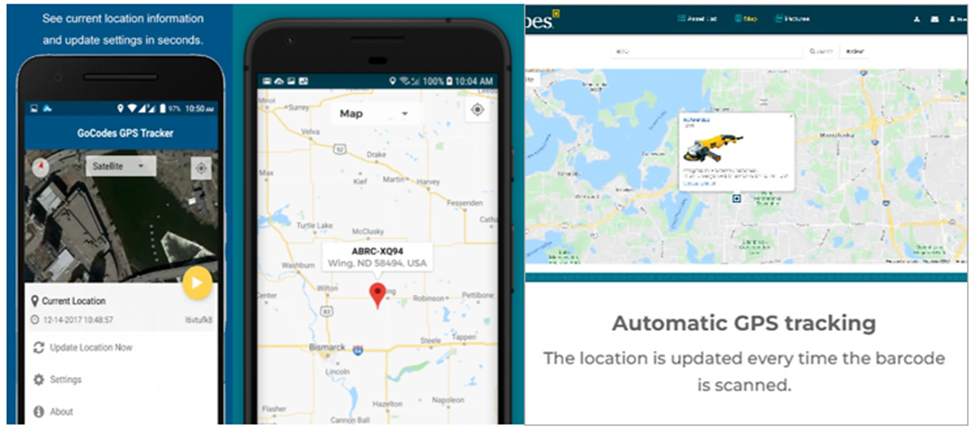

Conversely, barcode and QR code labels attached to assets require manual scanning from a short distance, which can be done with special barcode readers or in-app scanners on smartphones and tablets.

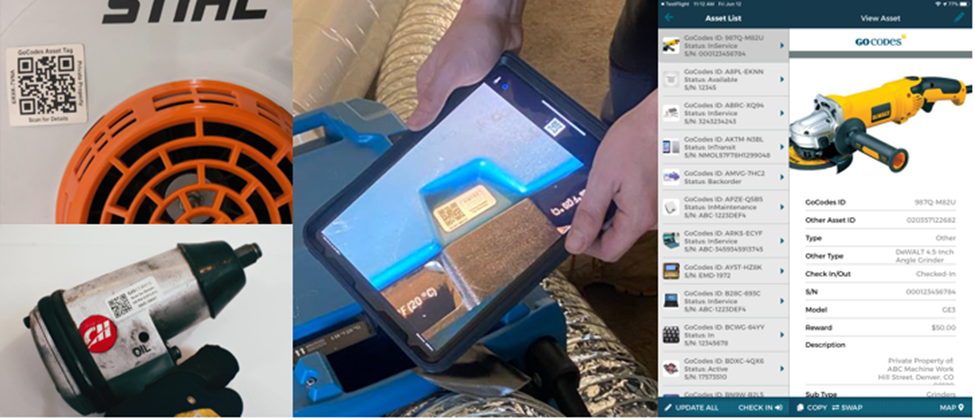

With the help of cloud-based tracking software, workers can simply scan the asset barcode tag/label to access the asset’s info page and the central list of tracked assets.

Since barcodes and QR codes require no batteries and emit no signals, a barcode-based tracking system is impervious to BLE-related challenges like signal loss or interference that can minimize the accuracy and coverage of Bluetooth asset tracking.

Although barcodes do not provide real-time location tracking, they allow contractors to achieve near real-time asset visibility through workers regularly scanning assets.

For example, QR codes attached to assets enable construction companies to control where their tools and equipment are and who is using them.

More precisely, managers can adopt an automated asset check-in/check-out system, where workers are required to scan a tool when taking it from a toolroom and when returning it or exchanging tools on-site.

Naturally, the fact that software records asset users increases worker accountability, thus preventing internal theft, misplacement, and negligent handling of tools and equipment.

Moreover, the tracking app usually includes the ability to set automated alerts sent when assets are due to return.

Another difference between beacons and barcodes is their range: as explained, beacons and receivers have limited coverage.

In comparison, barcodes can be scanned wherever an asset is found, and the software will either prompt the user to enter the asset’s location or will—using the scanning device’s GPS function—automatically record it.

The point is that—compared to beacons and all other tracking options mentioned here—barcodes are the most affordable and simplest way to track a vast number of construction assets.

This makes them an ideal primary tracking method, often combined with other asset-tracking methods covered in this article.

For instance, you might’ve noticed that all the beacons shown until now have QR codes, which proves our point and underlines their advantages over classic barcodes.

Overall, BLE beacons and barcodes are two technologies that construction companies can successfully combine to create an efficient, cost-effective, and multi-layered asset-tracking system.

Bluetooth Beacons vs. GPS for Asset Tracking

Like beacons and QR codes, BLE and GPS-based asset tracking are two distinct but essentially complementary technologies.

More precisely, construction companies can use the Global Positioning System (GPS) for global outdoor tracking and BLE for local indoor tracking of asset locations in real time.

To explain, let’s consider how GPS works.

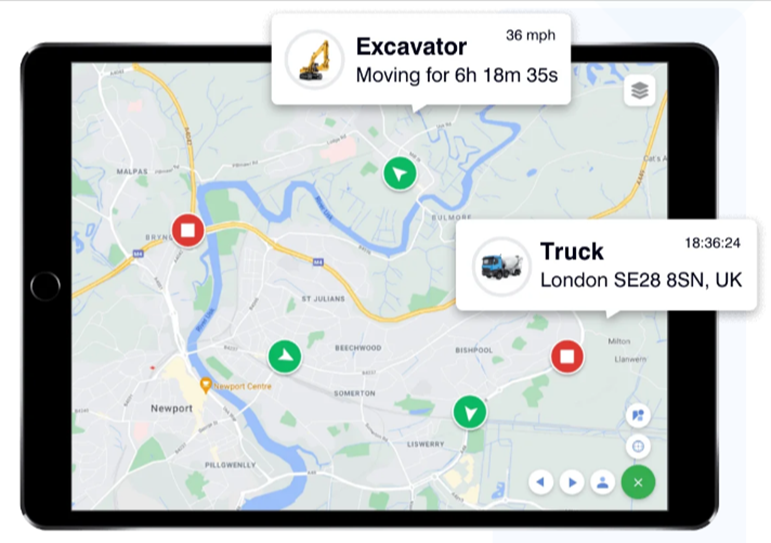

A GPS-based tracking system consists of relatively small GPS trackers (built-in or installed later, battery-powered or using the asset’s power source) and asset-tracking software.

Trackers receive satellite-generated radio signals to calculate their position anywhere on Earth and send this data to the tracking app that shows their location on a map.

Therefore, active GPS tracking provides construction companies with global real-time tracking capabilities as long as the tracker has an unobstructed view of the sky.

In other words, while ideal for outdoor navigation and other tracking purposes, GPS trackers are less practical in indoor environments, underground areas, or high-rise urban surroundings.

Conversely, although Bluetooth technology has some similar signal loss and interference issues, beacons emit short radio signals, which means they don’t need satellites and can work well in the above-listed environments.

All this means GPS trackers and BLE beacons can complement each other to provide unprecedented real-time asset visibility, both globally and locally.

However, such solutions are typically expensive, so companies often choose to track vehicles and heavy equipment with active GPS trackers, other high-value assets with BLE beacons, and all of them with QR codes.

In terms of price, GPS-based tracking solutions lead the way due to required cellular connectivity and more complex system components, particularly when sensor-enabled trackers are involved.

To recap, GPS and BLE are real-time asset tracking methods, each with advantages and flaws, best utilized in different situations (global vs. localized tracking) but for the same purpose: preventing theft and improving operations.

Bluetooth Beacons vs. RFID for Asset Tracking

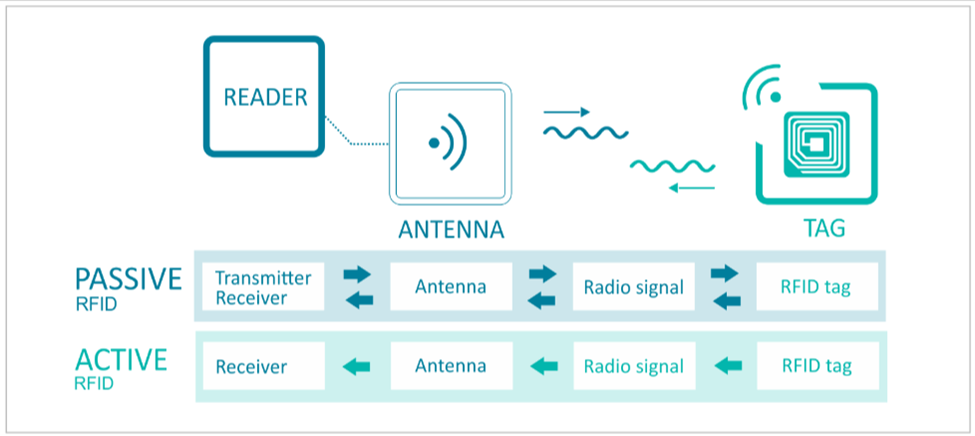

RFID (radio-frequency identification) technology is relatively similar to BLE, but RFID asset tracking requires dedicated (mobile or fixed) RFID readers.

In other words, the tracking systems we have covered until now (BLE, QR codes, and GPS) all involve the option of using mobile devices (smartphones, tablets) to detect the trackers, which is not possible with RFID.

Therefore, an RFID asset-tracking system consists of RFID tags (passive or active) and specialized RFID readers that detect them remotely (no direct line of sight required).

Passive RFID tags have no power source and are triggered by a signal sent by an RFID reader.

To do that, a reader needs to be close to the passive asset tag (from several inches to about three feet), which will depend on factors like the reader’s power output, antenna design, and the surrounding environment.

Conversely, active tags are battery-powered, which can expand their detection range up to a few hundred feet.

One advantage of RFID tags over BLE beacons is that they’re smaller and more affordable, but that’s offset by the fact you need to purchase separate readers.

According to RFID Journal, most RFID readers:

…cost from $500 to $2,000, depending on the features in the device. Companies may also have to buy each antenna separately, along with cables. Antennae are about $200 and up.

In conclusion, although comparable with BLE in terms of technology, RFID asset tracking requires a more complex system setup and infrastructure than Bluetooth beacons, which also raises the RFID system’s overall cost.

Bluetooth Beacons vs. NFC for Asset Tracking

NFC (near-field communication) is a subset of RFID technology created to support the exchange of radio signals at very short distances (about 4 inches or 10 centimeters).

As such, NFC readers are typically a standard part of smartphones and are widely used for contactless payments.

This means that, similarly to BLE beacons, you can use NFC-enabled smartphones and tablets instead of special readers, which lowers the cost and complexity of setting up an NFC-based asset tracking system.

When a smartphone is placed near the tracked asset, the tracking app allows users to access the asset’s info page and can also use the phone’s GPS function to record the asset’s location (similar to how GPS-enabled QR codes work).

Likewise, NFC tags are tiny and can be pre-installed during production or added later.

Also, such tags require no batteries or other power sources, which makes them more affordable than BLE beacons.

Coupled with the prevalence of NFC-enabled smartphones, this means that NFC-based asset tracking has lower upfront costs, but BLE beacon-based tracking offers more versatility in terms of the tracking range.

Bluetooth Beacons vs. Ultra-Wideband for Asset Tracking

Ultra-wideband (UWB) technology is used for precise indoor positioning and real-time tracking of assets with high accuracy.

Compared to other radio-based tracking technologies covered here (all except barcodes/QR codes), UWB utilizes a broad spectrum of frequencies at a very low power level.

However, to enable the detection of UWB tags, you’ll need to install at least three fixed UWB receivers (locators) around a jobsite or warehouse.

Together with the UWB gateway/hub and asset-tracking software, these locators enable real-time asset location monitoring in two dimensions (2D).

For even more precise 3D positioning (and to account for signal reflections and other interferences), a high number of locator anchors is recommended (four to six for enhanced accuracy and coverage).

Compared to BLE-based asset tracking, UWB systems require more careful planning of where locators will be placed, which also implies a more intricate system setup and higher initial costs.

In other words, BLE beacons are generally easier to deploy and more cost-effective, especially in asset-tracking applications where accuracy within a reasonable range is sufficient and budget considerations are important.

Why You Should Use Bluetooth Beacons for Asset Tracking

Having covered Bluetooth compared to five other tracking technologies, let’s focus on why and when you should use beacons for asset tracking.

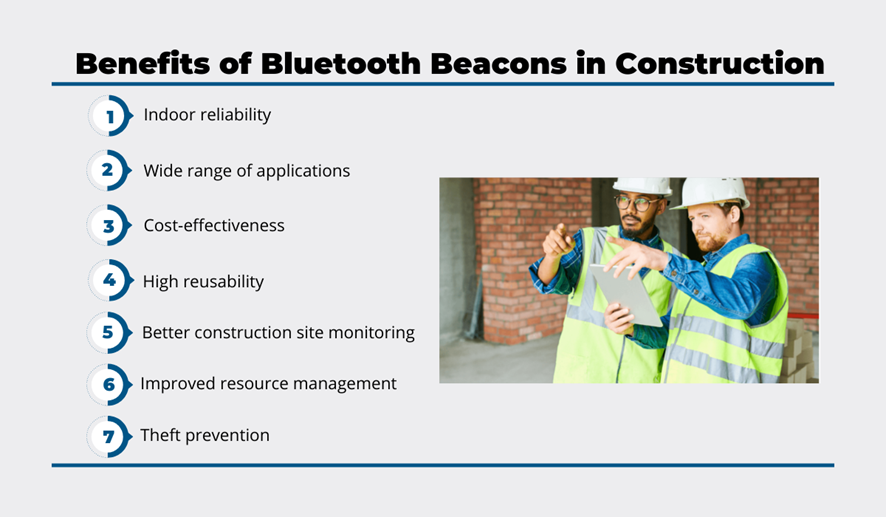

Among tracking systems that use short-range radio communication (all but QR codes and GPS), BLE beacons stand out as the most affordable and versatile solution for effective real-time tracking of assets.

Here are the benefits of using Bluetooth beacons in construction (and other industries):

BLE beacons provide indoor tracking reliability in buildings and other areas where GPS signals are weak or non-existent.

As for BLE applications, beacons can be utilized in many construction use cases other than asset tracking, such as employee monitoring, site/warehouse navigation, access control, and safety proximity alerts (when an asset or worker gets too close to a dangerous zone).

Moreover, beacons can be reused, meaning that one asset’s beacon can be relocated to another with little or no reprogramming.

The same applies to any other BLE-related infrastructure (i.e., when fixed receivers are used) that can be easily transferred from site to site.

Regarding theft prevention, Bluetooth beacons and tracking software allow you to establish an invisible fence (geofence) around your jobsite or specific zones.

In this setup, one or more smartphones can be used to track assets and alert you if any assets leave their range.

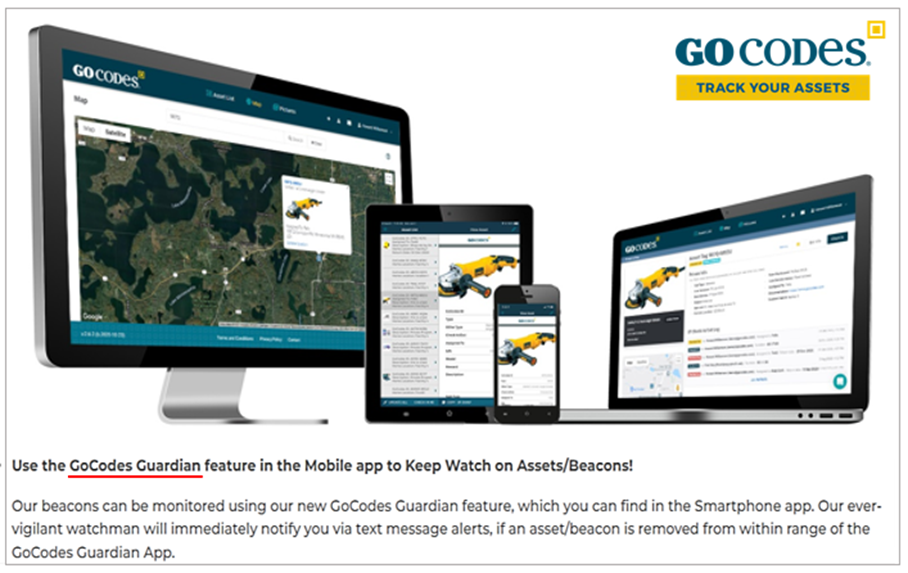

For example, our asset-tracking solution, GoCodes, provides site managers and other staff with the Guardian feature that turns their mobile devices into moving (or stationary) watchdogs that will immediately notify you in case of asset theft or unauthorized movement.

In addition to this anti-theft feature, GoCodes also provides construction companies with customized GPS-enabled QR code labels as the primary way to track the location and usage of their assets.

Combined, these two tracking methods (BLE beacons and QR codes) create a comprehensive, easy-to-use, and low-cost asset-tracking system that can significantly minimize asset theft and loss, poor maintenance, and misuse.

By itself, Bluetooth-based asset tracking is a versatile, reusable, and cost-effective method for real-time monitoring of asset locations and users, thus improving site safety and security and enhancing overall operational efficiency.

Conclusion

At the end, just a few closing thoughts.

First, your choice of asset-tracking technology will depend on your company’s specific tracking needs, asset management processes you want to improve, and budgetary restrictions.

Second, when considering your options, explore whether you can optimally combine low-cost tracking methods like QR codes and BLE beacons with higher-priced solutions like GPS trackers.