As any construction company owner or manager knows, construction sites are lucrative targets for thieves attracted by the valuable equipment, tools, and materials often left unguarded.

Among these, smaller equipment and tools are particularly vulnerable due to their size, easy accessibility, and resale value.

So, if you’re faced with the problem of losing—and having to replace—a significant number of more and less expensive tools due to external/internal theft or negligence, you might be wondering what you can do.

This article will cover four effective tool-tracking methods to safeguard your assets, cut replacement costs, and streamline construction operations.

In this article...

Using Tool Tracking Software for Tool Location Tracking

For starters, you should do your research and select tool-tracking software that fits your needs and budget while enabling you to efficiently track tool locations.

This article focuses on midsized, small, and miniature construction tools and equipment whose size or market value makes it impractical or too expensive to utilize many asset-tracking methods like active GPS trackers, RFID tags, or Bluetooth beacons.

That’s why we’ll skip explaining different tracking technologies.

Instead, we’ll get right down to the simplest, most affordable, and easiest method to track tool locations, i.e., GPS-enabled QR codes.

To illustrate how QR code-based tracking works, let’s use our tool-tracking software, GoCodes, as an example.

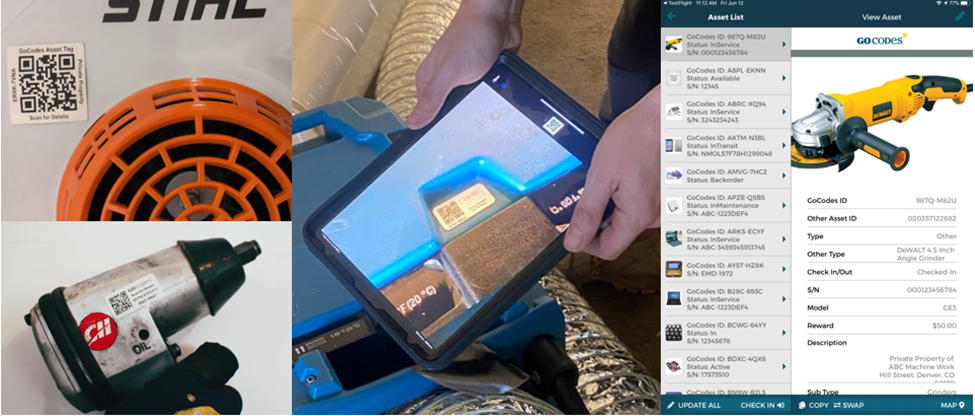

Source: GoCodes

As you can see, the GoCodes package consists of cloud-based software, an in-app scanner, and customizable QR code tags.

Note that the only “hardware” you’ll need are low-cost asset labels, as the system will run on the internet-connected devices you and your workers already have.

Naturally, this reduces upfront costs and simplifies the system’s implementation while enabling even less tech-savvy workers to easily use the tracking app with minimum training.

The tool tracking system becomes operational after customizable QR code tags are attached to tools and equipment as their unique identifiers. Each QR code is linked to the software’s database and populated with initial data.

From then on, workers can use their smartphone or tablet (with the GoCodes cloud software and in-app scanner installed) to quickly scan the tool/equipment tag and access its info page, as well as the central list of all tracked assets.

Below, you can see how the QR code tags look, how an in-app scanner is used to access the tracking app, and view and update relevant info, including the asset list.

Source: GoCodes

As we’ll see later, this simplicity of operation (just scan the tag for system access) enables many features, some of which—tool location tracking included—can have a profound effect on minimizing theft and negligence.

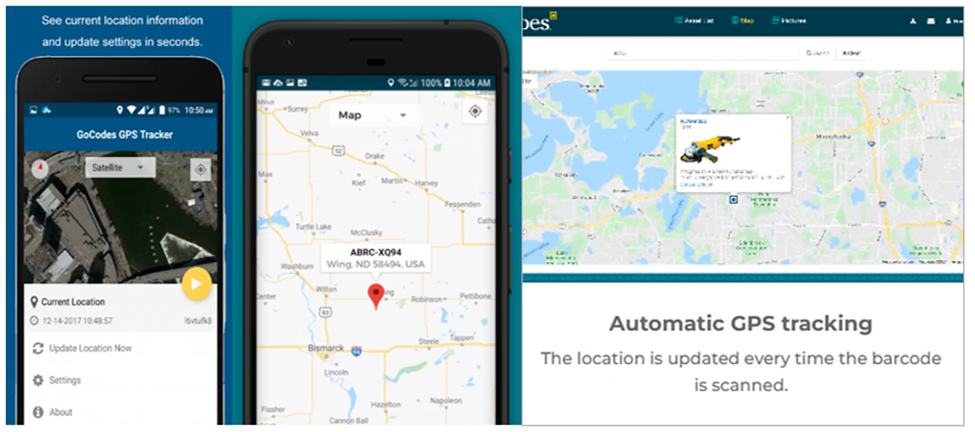

So, how does scan-based GPS location tracking of assets work?

It’s simple.

Each time a worker scans a tool QR code label, the tracking app uses the GPS function of their phone to automatically update the tool’s GPS location and show it on a map.

Source: GoCodes

When tools and equipment are regularly scanned as part of everyday construction operations, this functionality provides your managers with near real-time visibility of asset locations.

Naturally, this last scan-based location method does not provide what more expensive and complex active GPS trackers would (continuous location updates) but offers significant advantages in terms of the system’s cost, versatility, and ease of use.

For example, if a QR-tagged tool is lost or stolen, you’ll know its last-scanned location (and user) and can start your investigation from there.

Next, visible tamper-proof or hard-to-remove QR code tags on tools and equipment imply they’re being tracked in some way, which can deter some opportunistic thieves.

Additionally, such labels make reselling harder and can serve as proof of ownership when found by authorities or good Samaritans.

Overall, using QR code-based tool tracking software to get regular updates on your asset’s GPS locations is the most affordable, easy to implement, and user-friendly method for theft prevention.

Having Workers Check Tools In and Out on the Job Site

Another method for tracking where your tools are and who uses them is having workers check them in and out on the jobsite.

To do that, you can use your QR code-based tracking software’s check-in/check-out feature, enabled when tags/labels are affixed to tools and the software’s database is populated with their data.

When the system is ready, workers can quickly and easily scan a tool when taking it from the toolroom (check-out) and going to work and scan it again when returning it (check-in) at the end of the day.

Source: GoCodes

When workers are assigned tools for a longer period, managers can set up automatic reminders triggered in the tracking app that will send an email to the relevant worker and their manager when a tool is not returned on time.

As you might suspect, when workers are aware that software is keeping track of the tools and equipment assigned to them, this can significantly reduce theft and misplacement, misuse, and negligent behavior on their part.

Naturally, the check-in/out feature can be used to record tools going out and in from:

- a central storage facility/toolroom, from where workers take the tools to a jobsite and return them on a daily basis

- an on-site secure storage cabinet/container where tools are left overnight

Moreover, this feature enables workers to exchange tools directly on the jobsite and have the software record the relevant change in responsibility for that tool.

To recap, having workers check tools in and out on the jobsite is a powerful software-enabled feature that protects your assets from theft and negligence by tracking their users and holding them accountable.

Tracking Tools Stored in Vehicles Used to Transport Them

Since tools and smaller equipment are most often transported to construction sites and stored together in vehicles, tracking tools as a group instead of each one can, among other things, help you minimize theft.

To do that, you’ll need to take advantage of tool kitting, another feature typically enabled by different tool-tracking solutions.

As for how kitting works, it enables your tool tracking system to track a collection of multiple tools and equipment (kit) stored in a single smaller (e.g., toolbox) or bigger container (e.g., vehicle) instead of having to track each individual tool.

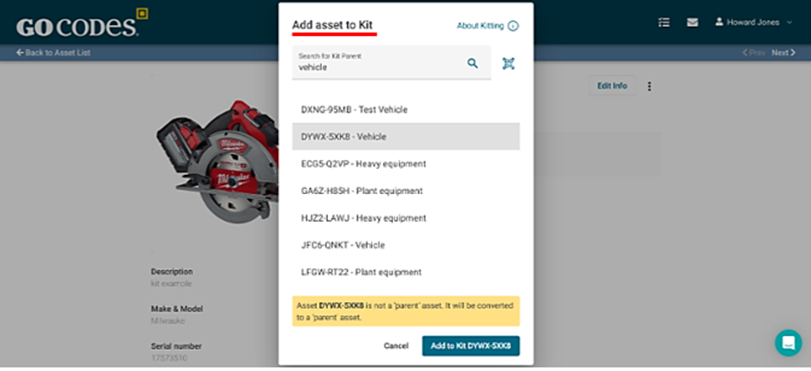

For instance, you can add this circular saw to the “kit” of tools and equipment already grouped in one vehicle going to a specific jobsite.

Source: GoCodes

From there, the assigned driver can use the tracking software to check out and assume responsibility for the entire “vehicle kit” when transporting it to the jobsite.

When the vehicle arrives, tools can be distributed to designated workers/crews and, if planned, returned to the vehicle at the end of the workday.

If tools are stored in a vehicle overnight, you can use the check-out and kitting features to ensure all the tools are accounted for before parking the vehicle in a secure storage area.

This systematic approach ensures that no tools are not left lying somewhere on-site, reducing the risk of theft or loss.

Finally, if one of your “kitted” vehicles is stolen, you’ll know exactly what was in it so you can alert the authorities and quickly find replacements to avoid work disruptions and project delays.

In essence, tool kitting is a helpful feature that allows you to group tools in specific kits, enabling easier tool tracking, scheduling, and transportation while enabling you to better protect your tools from theft.

Installing Surveillance in Facilities Where Tools Are Stored

Although tool theft prevention technologies are rapidly advancing, “old school” security measures like fences, alarms, and video surveillance shouldn’t be ignored.

In other words, regardless of the facility where your tools are stored (central warehouse, temporary storage on-site, etc.) for safekeeping, you should look for simple and cost-effective surveillance tools.

For instance, security cameras visibly installed on your jobsite can help deter less decisive thieves even when they’re not recording.

At the same time, active (constantly recording or motion-triggered) cameras, both visible and hidden, can be used to catch more persistent offenders in the act.

Due to technological advances, such surveillance systems are more practical and affordable than ever before, and you don’t even need electricity or Wi-Fi to install them.

For instance, cameras like the one below are solar or battery-powered, use cellular networks to communicate with your surveillance system, and send alerts to your smartphone in the event of intrusion.

Source: Resideo

Naturally, these and similar cameras and detectors can be installed inside and outside your permanent storage facility.

However, since most new models are designed to be easily moved from site to site, such systems can also protect your tools stored in temporary on-site facilities.

Such video surveillance can be coupled with other relatively low-cost and typically already-used construction site security measures, from warning signs, fences, and padlocks to controlling site access and fostering a culture of accountability.

Of course, using tool tracking software to keep an accurate, real-time inventory list of tools and equipment and access automatically updated asset locations, users, and other data is an integral part of preventing tool theft and retrieving your stolen assets.

In short, installing surveillance in your storage facilities is an essential ingredient in mixing old and new security methods to protect your assets from theft.

Conclusion

When the features of your affordable and easy-to-use tracking software (location tracking, check-in/out, and kitting) are combined with smart surveillance measures, their cumulative effect should considerably minimize the instances of tool theft, loss, or negligent operation.

In other words, you’ll be able to safeguard your assets better, reduce replacement costs, and streamline construction operations through software-enabled automation.

This will help you improve your company’s productivity and profitability.