Key Takeaways:

- Construction fleet tracking empowers you to optimize your equipment’s utilization, boosts your ROI, and results in less unplanned downtime and fewer project delays.

- It helps you minimize fuel, maintenance, and replacement costs.

- With the help of real-time GPS trackers and geofencing, fleet tracking aids in theft prevention.

- It helps identify risky driver behavior and helps you rectify it, which increases driver safety and ensures regulatory compliance.

What if we told you there’s a straightforward, yet highly effective way to increase the overall efficiency and profitability of your operations?

What if implementing this method could also boost safety and decrease break-ins at your job sites?

Sounds too good to be true?

Well, that’s construction fleet tracking for you.

This process revolves around monitoring your fleet and utilizing the gathered data to optimize its performance.

Don’t believe that one process can make such a difference?

Keep reading. By the end of this article, you’ll likely have a different perspective.

In this article...

Improves Asset Utilization

For starters, efficient fleet tracking gives you a full view of your machinery’s movement and performance, in turn empowering you to optimize its utilization.

It does so through telematics—a technology combining GPS systems, onboard vehicle diagnostics, and wireless telematics devices to capture and transmit real-time vehicle data.

Think, for example:

- GPS locations

- Vehicle speed

- Engine hours

- Acceleration

- Hard-braking

- Fuel consumption

According to Norty Turner, Principal at Woodland Management, such data is simply a must when it comes to boosting your fleet’s productivity:

It provides up-to-date insights into the whereabouts and usage patterns of your assets, enabling you to identify instances where machines are either misallocated or underutilized before the real damage is done.

Improving asset utilization has two major perks.

Firstly, it ensures you’re getting the most out of your equipment and boosts ROI.

Telematics instantly detects any undesirable behavior—such as underutilization or misuse that could lead to premature wear and tear—thus protecting your machines from damage and costly idle time.

For instance, by monitoring engine hours, you may discover that one of your bulldozers spends more time idle at a job site compared to similar machinery.

This information allows you to relocate it to a more productive location, where the machine would be actually making you money, instead of just wasting it.

Secondly, improved asset productivity results in less unplanned downtime and fewer project delays, leading to a healthier bottom line.

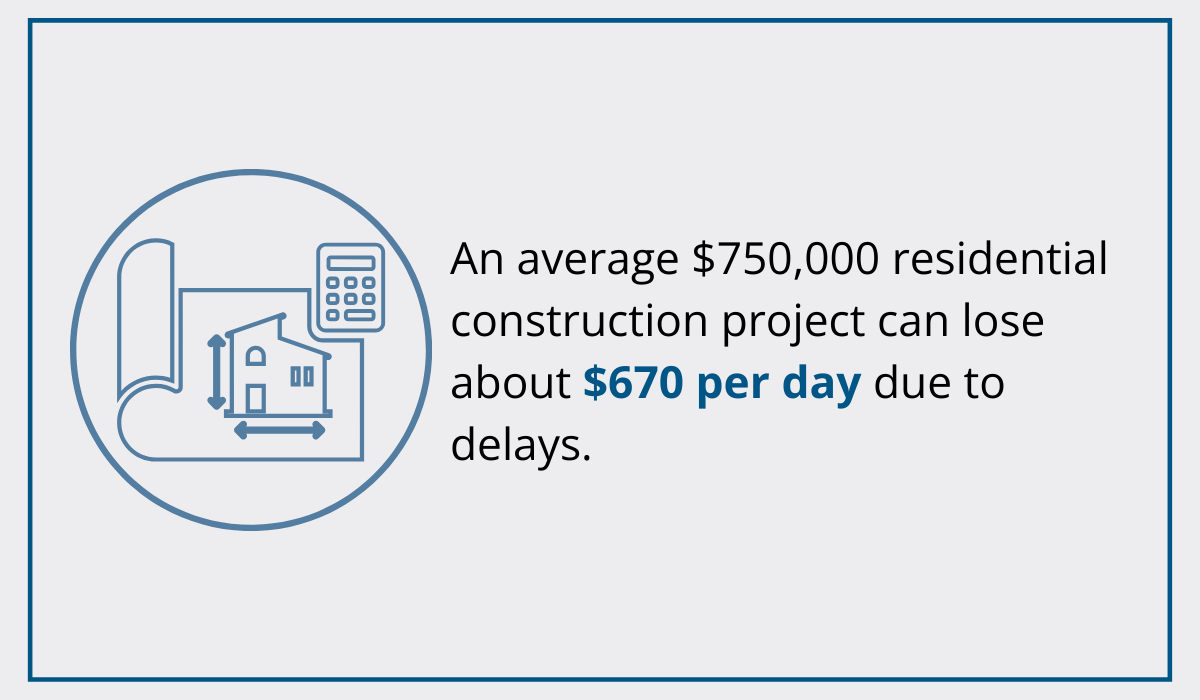

When you think about it, delays in this industry can be quite pricey.

For example, residential construction projects can lose around $670 a day due to delays, according to the estimations by the Association of Professional Builders.

Fleet tracking prevents those delays by ensuring your vehicles and machines are always where they’re needed the most, operating at peak efficiency.

No unnecessary idling, no misplaced equipment, no unexpected downtime.

Overall, integrating fleet tracking with telematics serves as a reliable means to extract maximum value from your assets, irrespective of your fleet size or the number of projects and job sites you’re managing.

It offers real-time, accurate, and comprehensive data, guiding you toward achieving optimal utilization and delivering superior project outcomes every single time.

Enables Cost Savings

By vigilantly tracking your fleet, you’re unlocking the door to substantial cost savings and boosting your profitability in the process.

The three major expenses fleet monitoring helps mitigate are:

- Fuel costs

- Maintenance costs

- Replacement costs

Fueling up heavy vehicles can hit your wallet pretty hard, even more (unnecessarily) so if you’re not keeping an eye on fuel consumption.

This can spell trouble for project budgets and your bottom line, especially with the unpredictable nature of fuel prices.

In a 2022 survey by Samsara, nearly half of the construction professionals pointed to fuel prices as their top concern.

But guess what?

Responding to this challenge, 60% of them ramped up their fleet monitoring.

This approach helps spot issues like wasteful driving habits, excessive idling, or taking longer routes than necessary, allowing you to address them immediately and slash fuel expenses before they start putting a dent in your company’s financial health.

Larry Herman Jr., Telematics Support Manager at RDO Equipment Co., warns that neglecting to track fleet activity can lead to either overutilization or underutilization—both of which can then drive up fuel expenses.

In other words, by keeping tabs on your fleet, you can prevent behaviors that result in excessive fuel consumption and its associated costs.

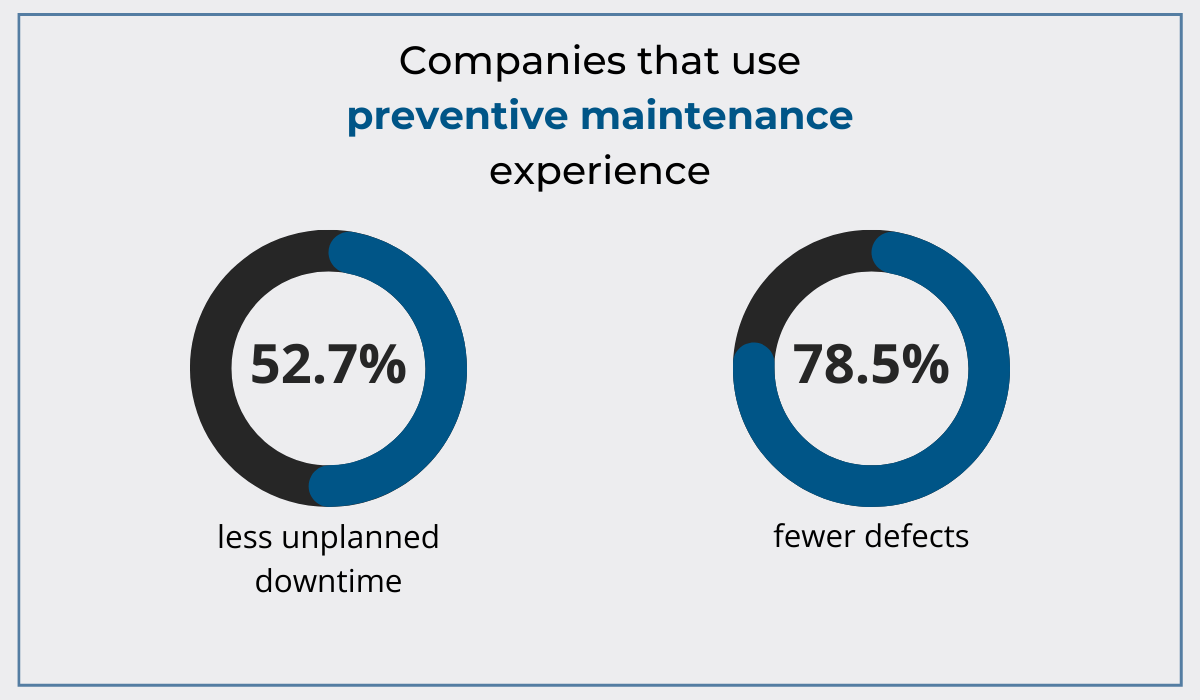

Furthermore, fleet tracking also reduces maintenance costs by overseeing the health and usage of equipment, thereby helping you identify potential issues early on.

Once the emerging problem has been spotted, you can swoop in to fix it before it escalates and starts causing trouble.

This preemptive approach, known as preventive maintenance, has been proven to significantly decrease machine defects in the long term.

And of course, fewer defects translate to reduced repairs and accompanying costs.

Plus, proper equipment upkeep goes hand in hand with longer asset lifespans, reducing the frequency of asset replacements.

Every fleet manager’s nightmare is having to shell out for a new machine sooner than expected.

But with effective fleet monitoring, you can extend the useful life of your assets, saving you from the headache of premature replacements and their hefty price tags.

All in all, efficient fleet tracking is a game-changer for the overall cost-effectiveness of your operations.

It pinpoints areas for improvement with precision and speed, empowering you to take corrective action on time and trim all those avoidable expenses before they begin jeopardizing your budget and bottom line.

Prevents Theft

Theft, unfortunately, remains a considerable issue within the construction industry.

In 2022 alone, there were 11,951 reported burglaries at American construction sites, ranking them as the seventh most targeted location when it comes to such crimes.

Media outlets frequently highlight incidents of stolen construction equipment, too, serving as stark reminders of the gravity of this issue.

And make no mistake, this is a problem all around the world.

For instance, in March 2024, a large generator and tools were taken from the job site in Guelph, Canada.

Just days prior, a break-in occurred at a job site in Ballisodare, Ireland, resulting in the theft of various equipment, including a tipper truck, heat pump, drills, and different construction materials.

These stories are only the tip of the iceberg, offering a glimpse into the extensive problem that not only disrupts the peace of mind of industry professionals but also inflicts substantial financial losses.

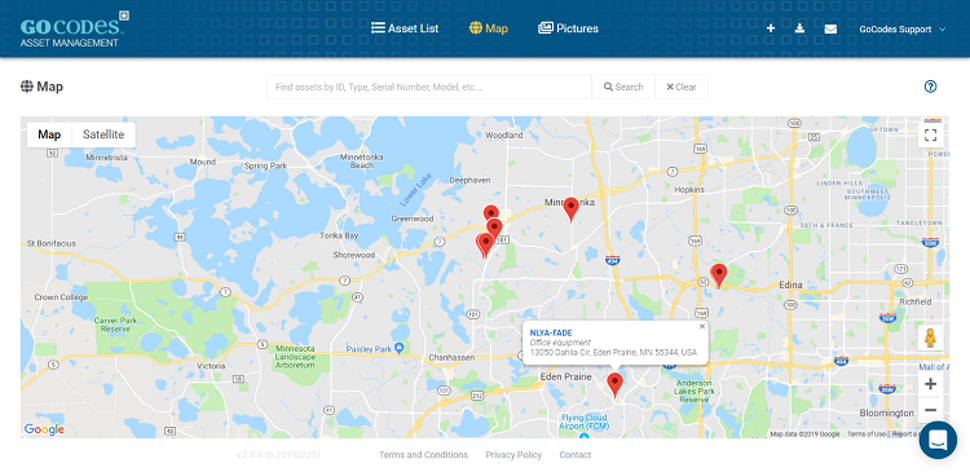

Recognizing just how serious this issue is, the GoCodes team wanted to step up its theft-prevention game.

That’s why we developed our real-time GPS trackers.

This new GoCodes technology enables minute-by-minute tracking of your assets’ whereabouts, even when they are on the go.

But our system doesn’t just passively monitor your fleet.

It also issues alerts in the event of suspicious activity, such as potential robbery.

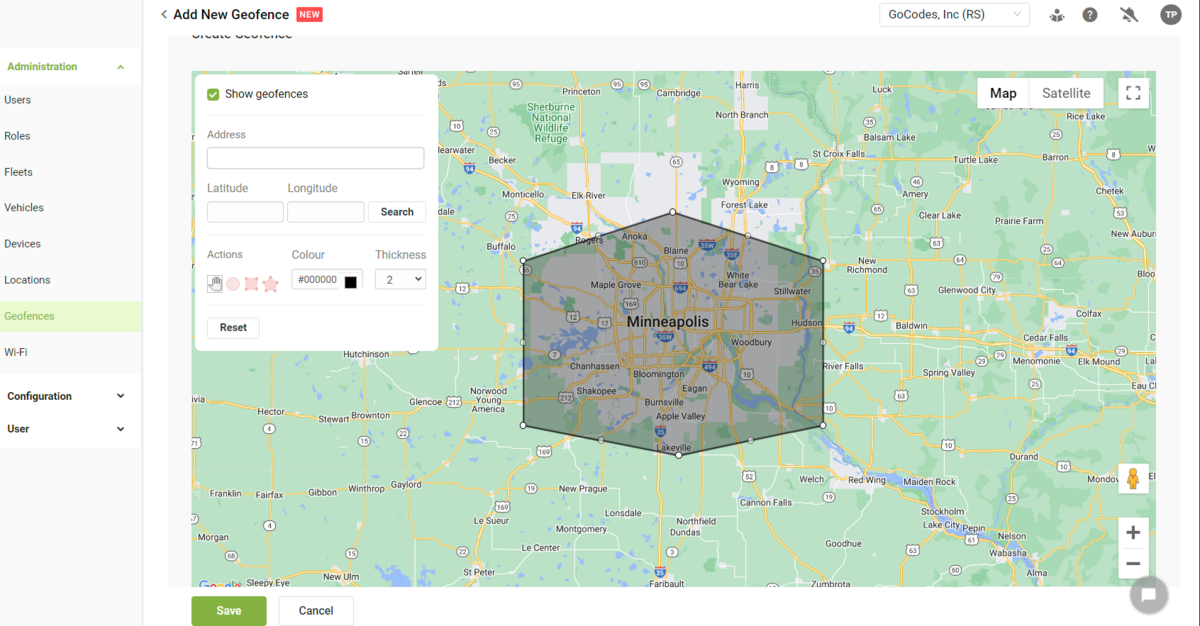

Here’s how that works: you establish a designated area for your assets on a map, such as a job site or warehouse, and create a geo-fence around it.

This ensures that equipment stays within the specified boundaries; if it crosses the geo-fence, you receive an immediate notification.

With GoCodes, no unusual and irregular behavior flies under the radar.

Plus, should a robbery occur after all, our system lets you provide law enforcement with precise location information to expedite recovery efforts.

The bottom line is this: you should never underestimate the severity of theft.

It’s a significant concern within this industry, causing major financial losses, operational disruptions, and stress.

Keeping a vigilant eye on your valuable fleet, ensuring you know where it is, how it moves, and how it’s used at all times is the only way to combat this problem.

Increases Driver Safety

Maintaining driver safety is one of the goals that are at the heart of fleet tracking.

However, achieving this goal isn’t always so easy.

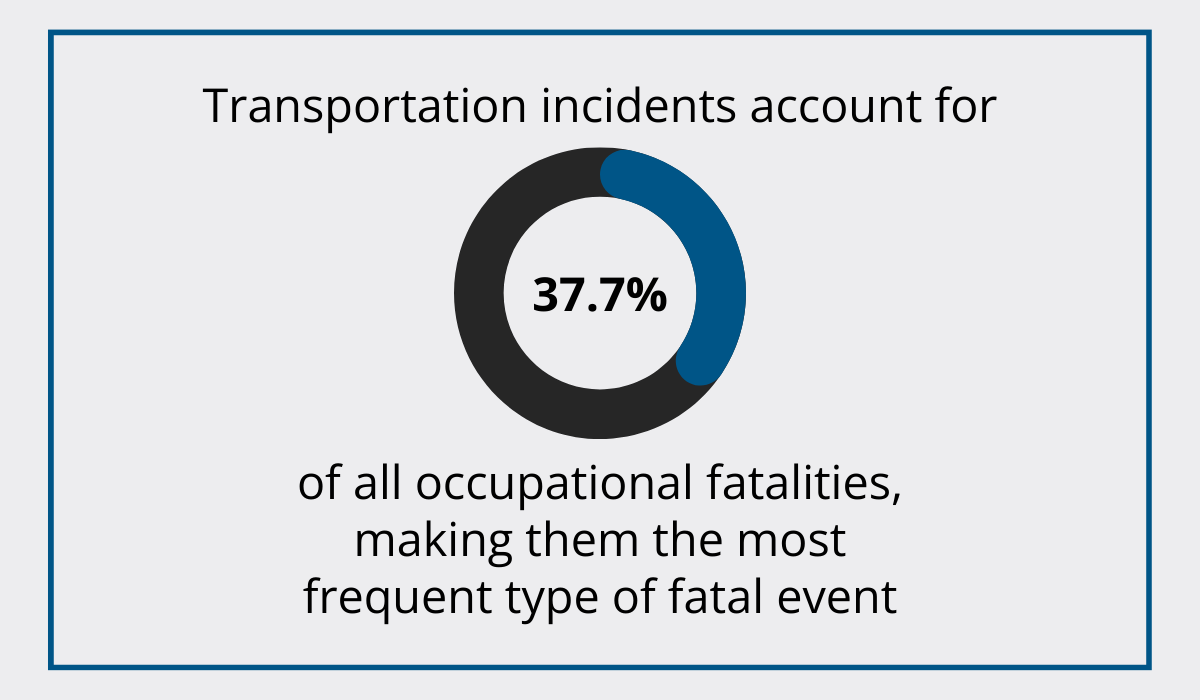

According to the Bureau of Labor Statistics, transportation incidents were the most frequent cause of fatal events in 2022, accounting for 37.7% of all occupational incidents in the US.

Now, this isn’t just a statistic.

It’s a reminder that every mile traveled comes with risks that must be managed and mitigated.

In other words, promoting driver safety doesn’t just protect company finances and project schedules but can also save numerous lives.

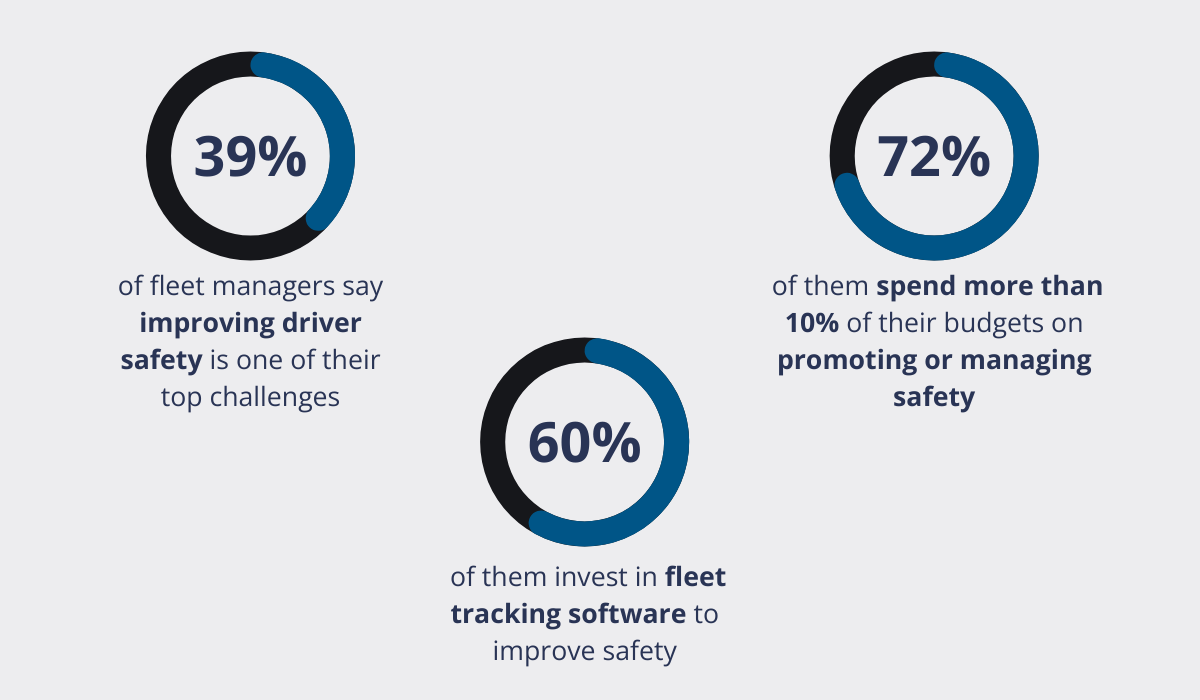

Therefore, perhaps it’s no surprise that 39% of construction fleet managers today prioritize improving driver safety above all else.

On top of that, 72% of them intend to allocate more than 10% of their budgets to boosting or managing fleet safety.

Among their top investments in these efforts is fleet management software.

This sort of technology is highly effective in monitoring driver behaviors on the road, enabling the reinforcement of safe driving practices.

It promptly identifies risky behaviors such as speeding, rapid acceleration, hard braking, or aggressive driving, empowering fleet managers to intervene and rectify the problem before it leads to injury, accidents, or worse yet, fatalities.

Plus, fleet tracking systems also assist in optimizing routes to avoid risks like traffic congestion, road construction, or hazardous weather conditions, providing drivers with safer and more efficient routes, in turn reducing the likelihood of accidents.

Remember, effective fleet monitoring isn’t just about ensuring machinery performs at its best and keeping vehicles on the road.

It’s also about making sure that every worker operating these machines is safe and sound.

With the right fleet technology, you can spot risks, take action, and foster a culture where prioritizing safety becomes second nature to everyone involved.

Ensures Regulatory Compliance

There are numerous guidelines and regulations concerning vehicle and driver safety that construction companies must follow, and ensuring compliance with these rules falls within the purview of fleet tracking.

This is particularly important because noncompliance can lead to serious legal and financial consequences.

Just take a look at the substantial fines imposed by OSHA for violations, for instance.

| Type of Violation | Penalty |

|---|---|

| Serious Other-Than-Serious Posting Requirements | $16,131 per violation |

| Failure to Abate | $16,131 per day beyond the abatement date |

| Willful or Repeated | $161,323 per violation |

Ranging from about $16,000 to a whopping $161,000, they are certainly not something to scoff at.

So, how exactly does fleet tracking help ensure regulatory compliance?

To answer that question, let’s examine a couple of specific rules related to vehicles.

For starters, according to OSHA’s Standard 1926.601(b)(1), all vehicles must:

“have a service brake system, an emergency brake system, and a parking brake system. These systems may use common components, and shall be maintained in operable condition.”

In other words, it isn’t enough to equip your machinery with the necessary components.

You also need to ensure their proper maintenance.

Fleet monitoring tracks the usage and health of these components and aids in devising efficient maintenance schedules based on operational hours, mileage, and other relevant data.

This, in turn, helps you keep your vehicles and all their parts in working order.

Next, let’s take a look at the rule from the US Department of Transportation regarding hours of service for drivers:

“[Drivers] May drive a maximum of 11 hours after 10 consecutive hours off duty. [Drivers] May not drive beyond the 14th hour after coming off duty, following 10 consecutive hours of duty.”

While it’s highly unlikely for drivers to be behind the wheel around the clock, it’s sometimes easy to lose track of time and inadvertently exceed these limits.

Fleet tracking systems mitigate this risk by monitoring driver hours and sending alerts when they approach or surpass these thresholds.

Lastly, OSHA mandates daily inspections under Standard 1926.601(b)(14), requiring all vehicles in use to be:

“checked at the beginning of each shift to assure that the following parts, equipment, and accessories are in safe operating condition and free of apparent damage that could cause failure while in use: service brakes, including trailer brake connections; parking system (hand brake); emergency stopping system (brakes); tires; horn; steering mechanism; coupling devices; seat belts; operating controls; and safety devices.”

Let’s be realistic here: organizing and coordinating all these checks every single day can be quite tricky sometimes.

Luckily, fleet tracking systems allow you to schedule such tasks and assign them to specific workers so that nothing goes overlooked ever again.

Plus, they keep records of these activities and centralize historical data on each piece of equipment, simplifying compliance verification during audits or regulatory inspections.

So, in a nutshell, with a proper fleet tracking system in place, compliance doesn’t have to be a headache anymore.

It ensures your vehicles are closely monitored, regularly serviced, and in top shape, ensuring every relevant rule is followed to the letter.

And when inspection day rolls around, it provides all the evidence you need to demonstrate compliance.

Conclusion

Are you starting to recognize the potential of fleet tracking yet?

We hope that we’ve successfully demonstrated the perks this process brings to the table.

Yet, to truly harness its power, you need to do it right.

That means keeping a close eye on your vehicle data, analyzing every bit, and using those insights to drive improvements.

And don’t forget the fleet management technology with its advanced capabilities such as GPS tracking, fuel consumption monitoring, or driver behavior management.

Blend these together, and you’ll be on the fast track to mastering fleet management and unlocking its full range of benefits.