As extreme weather events spurred by climate change keep endangering and disrupting the lives of millions of people around the world, they also expose construction workers to a wide array of safety hazards.

Thus, protecting construction workers during such events should be a priority for contractors who want to ensure a safe and healthy workplace for their workers—and pass OSHA inspections in the process.

Naturally, contractors also want to protect the materials, equipment, and tools on the construction site from weather effects and, if possible, avoid work stoppages and delays without jeopardizing the safety of workers.

So, we’ll walk you through six extreme weather conditions, the challenges they pose for construction site safety, and potential solutions that can help you protect both your workers and your business.

In this article...

Extreme Heat

Extremely high temperatures affect construction site safety by exposing workers to risks such as sunstroke, dehydration, and fatigue, which can lead to accidents, injuries, and even fatalities.

Extreme heat also causes other site safety hazards like workers not wearing protective equipment, machinery overheating, or hazardous substances catching fire.

Before we go further, it’s worth noting that good planning, suitable preventive measures, and solid emergency action plans are great ways to avoid or minimize the effects of all severe weather conditions covered in this article.

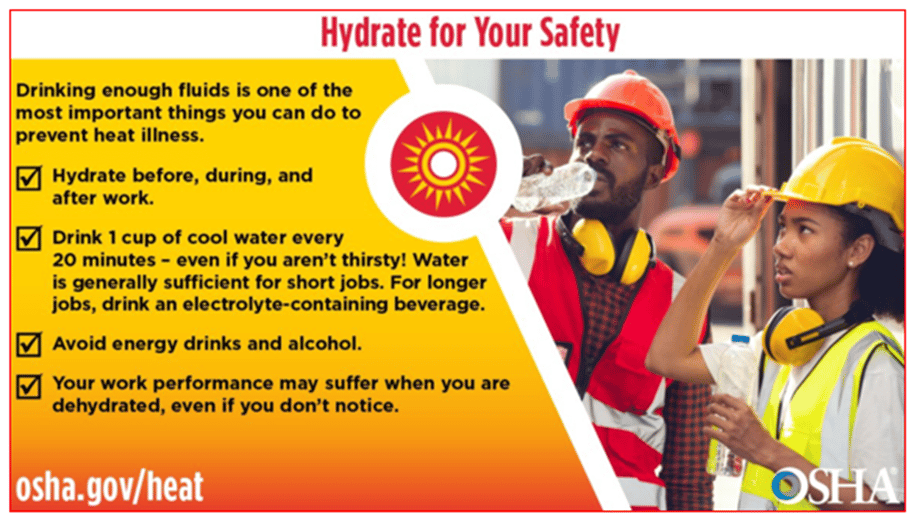

As for working in hot temperatures, one preventive measure is making sure that workers drink plenty of water.

Sounds simple, right?

However, this implies ensuring workers have easy access to drinking water (tap and/or bottled) on-site and are aware that frequent hydration is one of the best ways to prevent heat exhaustion and maintain productivity.

On top of that, they should know the symptoms of heat stress and watch for signs of it, both in themselves and their fellow workers.

In addition to staying well-hydrated, workers should be allowed to take breaks in the shade more often, which might require some careful re-scheduling of project tasks to avoid delays.

The same can be said for machinery prone to overheating in hot weather, which may need more frequent cool-off periods.

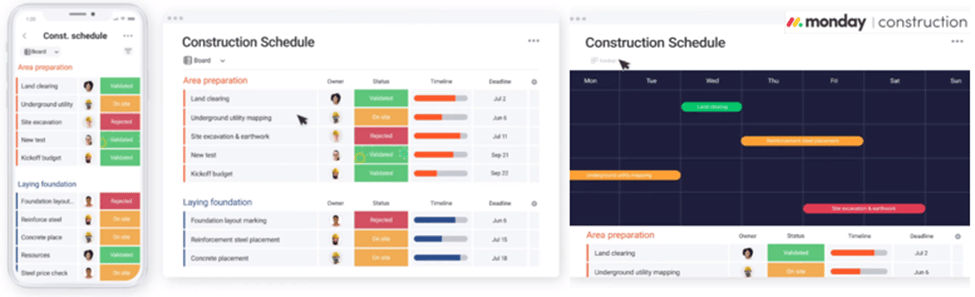

Likewise, a good construction schedule can, in some cases, allow workers to switch between different indoor and outdoor jobsite tasks depending on the outside temperature, thus protecting them from the sun and heat.

Another preventive action is to ensure that workers wear their personal protective equipment (PPE) despite the heat, which will accomplish two things.

First, it will protect workers from other common construction site hazards; next, it will protect workers from the sun (along with sunscreen).

As for hazardous substances and flammable materials, ensuring their safe on-site storage in a cool place away from sunlight is vital for preventing fires, explosions, and other accidents.

In conclusion, although extreme heat can seriously affect construction site safety, good planning and scheduling supported with appropriate preventive actions can help avoid or minimize the adverse impacts of high temperatures.

Strong Winds

Strong winds can be particularly dangerous for construction workers working at heights, such as on towers, cranes, and scaffoldings, but they also present multiple construction site hazards on the ground, such as flying materials, tools, hazardous substances, and dust.

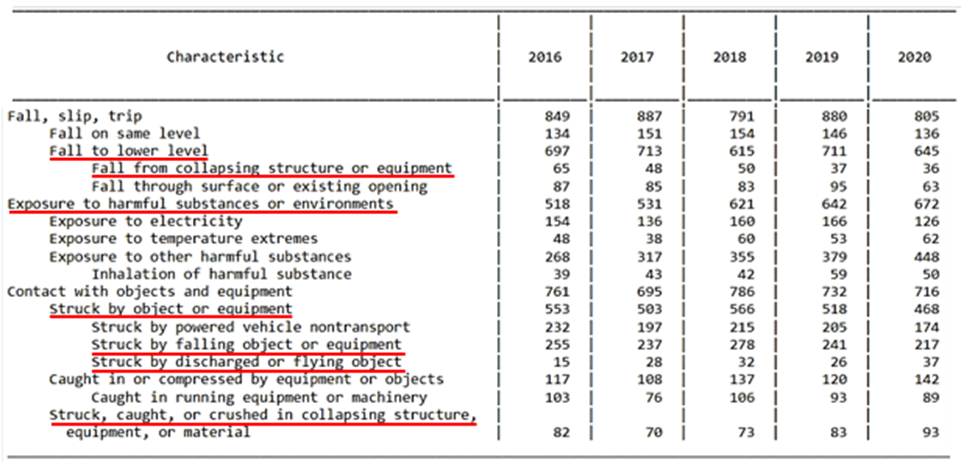

Considering that falls from height and being struck by objects or equipment are among the four leading causes of fatal construction injuries, it’s safe to say that strong winds can pose serious challenges to the lives and health of your construction workers.

Simply put, strong winds increase the likelihood of many potentially deadly construction site accidents, some of which we highlighted using the U.S. Bureau of Labor Statistics (BLS) 2020 census of fatal occupational injuries.

Moreover, according to the Occupational Safety and Health Administration (OSHA), falls and struck-by-object injuries (together with being caught in or compressed by equipment or objects and electrocution) accounted for over 60% of construction fatalities in 2020, which makes them part of OSHA’s Fatal Four.

So, what can be done to avoid or mitigate the effects of high winds on construction site safety?

Well, in case of extreme winds, the obvious answer is to suspend any operations involving cranes and towers and any works on scaffolds or stop all outdoor construction works.

However, you might also opt for innovative construction envelope systems that will cover your entire construction site and protect it from winds over 100mph (160km/h) and other severe weather events, such as RWES.

This reusable weather enclosure system is expected to last up to seven years, so the return on investment (ROI) of such systems should be carefully considered.

As for other potential solutions, windscreens and personal fall restraint systems can and should be used to protect workers working on scaffolds.

However, it should be noted that OSHA’s scaffolding standard prescribes that workers should not perform work on scaffolds in high wind conditions (and wet weather).

There is some leeway when workers are protected with the described measures, and the competent safety officer/site manager has deemed it safe.

Finally, ensuring that any loose materials and objects on the jobsite are securely fastened down, no debris is left lying around, and harmful substances are safely stored will also help you protect the lives and health of your construction workers.

Heavy Rain

Depending on its severity, heavy rain can cause construction site accidents such as slips and falls on wet surfaces, collisions between vehicles, heavy equipment, and people due to reduced visibility, electrocution, flooding, or collapsing excavations.

Heavy rain, just like other severe weather conditions, increases the already existing construction site hazards by several orders of magnitude and creates some new ones.

For instance, sudden heavy rain can create flash floods that come quickly and have deadly consequences, like the tragic event in Oman when six construction workers were trapped in rainwater and mud while laying down water pipes.

So, other than ensuring that the construction site is protected by suitable drainage trenches and channels, in many cases, it’s not recommended to continue outdoor works in heavy rain as doing so poses too many risks.

Thus, when heavy or torrential rain sets in, it’s better to wait it out, provided that workers have dry, sheltered areas available.

Again, a good construction schedule can allow you to reorganize outdoor and indoor work so that workers are protected until the weather improves.

Other preventive measures include ensuring that workers use suitable PPE like anti-slip shoes or boots, reflective raincoats, anti-fogging eye protection, and wipes.

Another is properly maintaining your power tools, electrical cords, connections, and outlets to avoid electrical hazards.

In fact, Senior Safety Advisor at HIA Safety Services, Rick Little, says:

“Using power tools in the rain or wet conditions after the rain can result in electrocution.”

To sum up, although heavy rain will negatively impact the safety and productivity of your construction workers, there are actions you can take to prevent dangerous construction site accidents, or at least minimize their effect.

Extreme Cold

Like other weather effects, working on construction sites in extremely low temperatures directly and indirectly affects jobsite safety by increasing the probability of accidents that can have fatal or non-fatal consequences.

In other words, the potential for on-site incidents rises as the temperature drops.

For instance, it can be heavy snow that threatens to fall on workers, ice on inclined or elevated surfaces, resulting in slip-and-fall hazards or frozen windshields that reduce visibility.

Furthermore, working in extreme cold for prolonged periods can cause health issues like frostbite, hypothermia, and other cold injuries.

Naturally, many safety tips can help you avoid or minimize these types of problems brought on by snow and freezing temperatures, including these:

For instance, it’s wise to carry out additional safety checks of construction vehicles, equipment, and power tools as they, their parts, and electrical components may malfunction due to extremely low temperatures.

In addition, the site supervisor should inspect the jobsite for potential hazards, such as inclined and elevated icy surfaces and roofs or trees with heavy snow that could endanger workers.

These issues are easily addressed by keeping bags of salt, sand or grit, and other suitable equipment like snow blowers on-site.

As for minimizing your workers’ exposure to extreme cold, it’s crucial to provide them with a heated space where they can warm themselves up.

While this can be challenging to provide on some jobsites, tents or trailers equipped with portable heaters are practical and cost-effective solutions in most cases.

Overall, even though freezing temperatures increase safety and health hazards for your construction team and slow down both people and equipment, these issues can be prevented or mitigated by diligent planning and timely preparation.

Heavy Fog

The biggest issue heavy fog causes on construction sites is reduced visibility for construction vehicle drivers, heavy equipment operators, and ground workers, resulting in a greater risk of vehicular accidents and workers getting hurt by tools and equipment.

Moreover, just like in the case of heavy rain and extreme cold, fog can make surfaces wet and slippery, which, combined with impaired visibility, can be particularly dangerous when using steps, ladders, and scaffolds.

When it comes to people, vehicles, and machinery working in foggy weather, making them visible should be a priority.

For workers, this means reflective jackets or raincoats and hard hat lights.

For vehicles and heavy equipment, using fog lights or low-beam headlights will ensure better visibility.

Of course, proper safety training should address working in foggy conditions for both vehicle/machine operators and ground workers.

Needless to say, heavy fog will slow down your construction operations, among other things, by making it harder for workers to find the right piece of equipment or a tool left somewhere on-site when they need it.

To address this (and many other fog-related equipment management issues), you could utilize asset tracking technology that will allow your construction workers to see where tools and equipment are located by simply logging into a cloud-based app on their smartphone.

One such tracking solution, both simple and affordable, is GoCodes Asset Tracking.

So, although heavy fog presents risks for construction workers and slows down construction works, accidents and injuries can be prevented and productivity maintained by using proper PPE and training and some innovative tech solutions.

Lightning Storms

Although lightning storms can expose construction workers to significant dangers, lightning safety is probably the most overlooked aspect of construction site safety.

According to the National Oceanic and Atmospheric Administration (NOAA), around 20-25 million lightning strikes occur annually in the U.S. that, on average, strike about 300 people and kill about 50 of them.

As per OSHA, 26% of lightning fatalities over ten years occurred in construction (15% roofing, 11% other construction activities).

For instance, lightning is likely to strike the tallest object in a specific area. Often, these objects are cranes, towers, and scaffolds.

Since they’re made of or contain metal, they can act as conductors, which can result in electrocution or fire.

Thus, it’s logical to immediately suspend all operations at heights when a thunderstorm is coming.

Furthermore, all activities that involve or occur near flammable substances or explosives, conductive materials, and water should also be stopped.

Finally, workers should unplug all corded tools and equipment and find shelter.

According to OSHA’s Fact Sheet, the best shelters during a lightning storm are fully enclosed buildings with wiring and plumbing, followed by hard-topped vehicles with windows rolled up.

The recommendation is to stay in the shelter for at least 30 minutes after hearing the last thunder.

Naturally, lightning storms are often accompanied by heavy rain and strong winds, both with their own risks.

Thus, it’s clear that actively monitoring weather reports and having a flexible construction schedule to switch to indoor works or suspend outdoor operations without causing a delay is probably your best bet for preventing many worksite accidents, including lightning fatalities.

Conclusion

We’ve described what severe weather conditions can do, alone or combined, to a construction site.

It’s clear that the best way to keep your workers safe and your projects on track is a combination of sound project planning and scheduling, proper training and PPE, suitable preventive measures, and solid emergency action plans.