The construction industry has always had a reputation for being slow to embrace new technology. However, recent developments within the so-called Fourth Industrial Revolution, especially the Internet of Things (IoT), promise some genuine change.

To help you successfully navigate the recent trends in construction technology, we will show you how you can make use of IoT for improving construction safety.

Remember, there is no such thing as being too careful at construction sites. Even if you’re already compliant with OSHA safety regulations, you can go a step further and use IoT to minimize health and safety risks.

So, let’s see how technology can make construction a safer profession.

In this article...

Avoiding Hazards With Remote-Operated Machinery

With the highest number of fatal workplace accidents of all industries, construction is a risky line of work even when your contractors are following all the safety regulations.

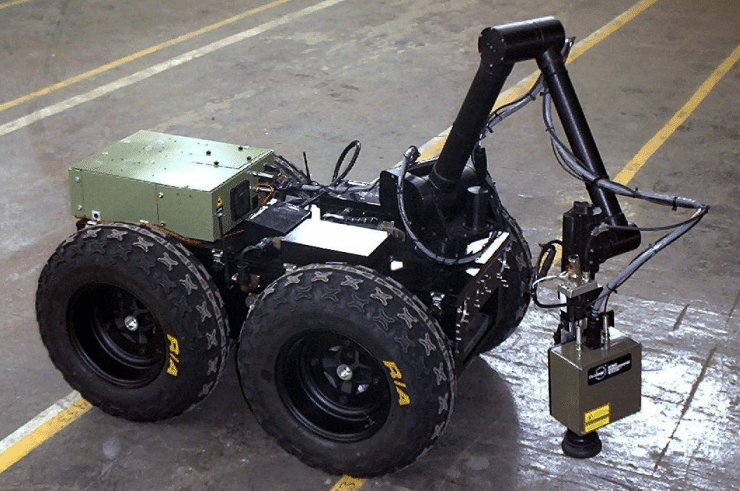

One possible method of preserving worker safety is to utilize remote-operated machinery.

In fact, OSHA states that 5,333 American workers died on the job in 2019, with the most frequently cited violations being that of the Hazard Communication Standard and Control of Hazardous Energy.

This data shows that the current practices for the detection of chemical, biological, and explosive hazards still have room for improvement.

Here is a list of industries where workers are most likely to be exposed to such dangers:

- Mining

- Underground mining

- Chemical industries

- Energy (oil, gas, nuclear)

- Logistics

- Construction

Instead of sending a person donned in protective gear to, for instance, take a sample and package it for analysis manually before you allow other workers on site, a safer practice would be to utilize remote-operated machinery.

There is now viable technology for such operations.

For example, a group of scientists has designed a robot-based Raman detector, which was able to detect the presence of explosives and other toxins in 10 minutes or less.

The robot, arm, and detector were remotely operated via a single operator control unit.

Buying new machinery can be expensive, so there are options to upgrade your construction equipment to include remote control.

For example, this Canadian company specializing in mining offers remote control systems designed for harsh environments. The systems can be installed on already existing machines.

Still, not all terrains are accessible to machines. For such situations, you can equip your workers with IoT wearables, such as a smart helmet.

Smart helmets or glasses don’t weigh more than the regular ones, yet they could improve your worker’s safety by monitoring the environmental hazards (such as carbon monoxide levels, temperature, or noise levels).

If your workers often work in challenging environments, it may be time to leave tradition behind and embrace modern solutions to reduce their exposure to hazards.

Exoskeletons Minimizing Injuries and Strains

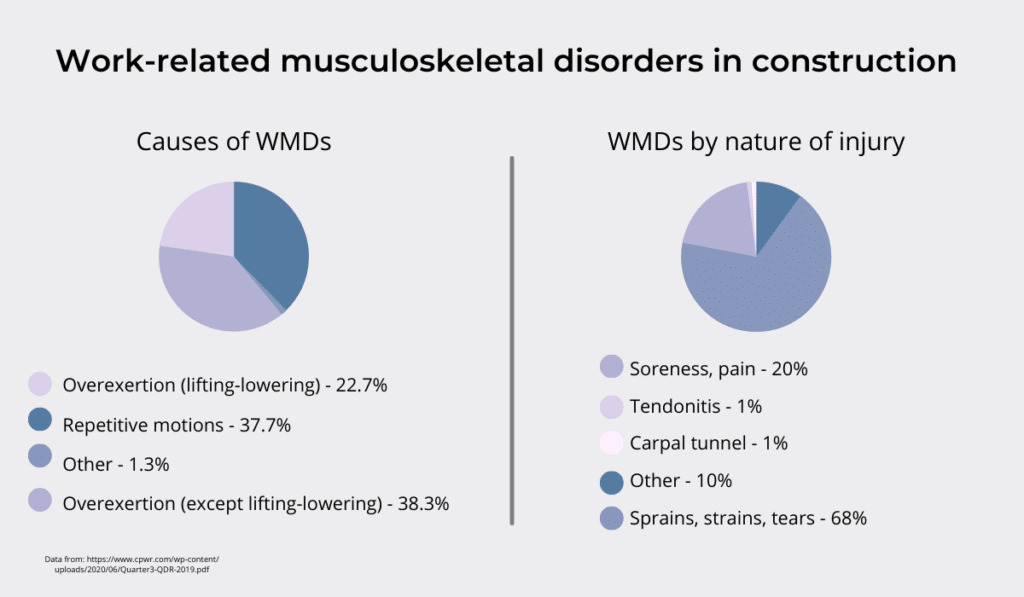

To see how exoskeletons can protect workers, we first need to take a closer look at some common construction injuries. Specifically, let’s focus on work-related musculoskeletal disorders (WMDs).

Due to increased worker health and safety awareness, the incidence of construction-related WMDS has dropped since the 1990s, but they remain more common in construction than in other industries.

Working at a construction site is physically demanding.

Repetitive motions and overexertion result in strains, tears, and other traumatic injuries, leaving your employees unable to work for days.

The following graphs show a more detailed overview of the causes and symptoms of WMDs in construction.

As you can see, the most frequent injuries in construction are sprains, strains, and tears. This is where exoskeletons come in handy.

Exoskeletons are metal frameworks equipped with motors that workers wear on top of their uniforms. They help alleviate the strain caused by the prolonged repetition of particular movements or tasks.

By using the power of motors to lift heavy loads, your workers can protect their joints, shoulders, knees, and spine. With machine learning, these IoT tools can learn each worker’s movements and adjust as required.

BigRentz, a construction rental company, has compiled a list of exoskeleton types workers can use to strengthen their grip and redistribute weight:

- Power gloves

- Arm and shoulder support

- Back support

- Standing and crouching support

- Whole-body suit

Despite potentially minimizing injuries, exoskeletons are still not widely used. Social resistance towards wearables in industrial work is still high, slowing the adoption of wearable devices.

As the robotic exoskeleton industry grows, the prices will go down over time, making worker safety protection through wearables more accessible.

Drones for Remote Worksite Surveying

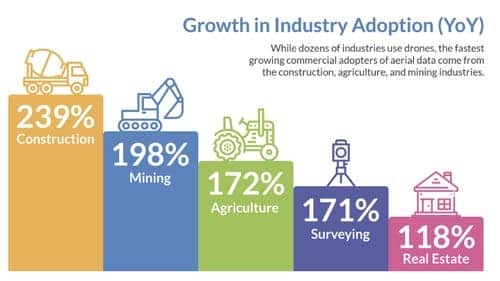

Along with remote-operated machinery, you can also use drones to inspect inaccessible or dangerous areas and thus protect your workers.

The trend of using drones on construction sites is skyrocketing, with a growth of a staggering 239% noted in 2018.

Construction is not the only industry taking advantage of drones in its operations. Mining, agriculture, surveying, real estate, conservation, and filmmaking industries also rely on this new technology.

So, how can you use drones to promote safety on the construction site?

Falling is the leading cause of work-related deaths in construction, accounting for 36,4% of all fatalities in the industry. For instance, workers often climb unsteady structures to take measurements, which puts them at risk.

To avoid that, you can deploy a drone to make hard-to-reach measurements instead. That way, you’ve eliminated the need for workers to climb dangerous heights.

Similarly, you can use drones to inspect the stability of scaffolding or other structures before a person climbs them.

Drones have come a long way since they were first introduced. Now they are equipped with HD cameras, so they can replace inspectors who would otherwise have to go through dangerous terrains to inspect a site or document the progress of a project.

Since some drones feature thermal imaging, you can also use them to detect hazardous leaks without potentially exposing workers to them.

Moreover, thermal imaging can do more than protect your workers; it can prevent unauthorized individuals from entering your site as well. You can program the drone to alert you if it detects someone going where they shouldn’t.

Finally, you can use drones to inspect the structural integrity of skyscrapers, roads, bridges, or other large structures to make sure they do not pose a threat to people using them.

Tracking Equipment and Supplies

Those who work on larger projects that include moving machinery across multiple sites can benefit from using IoT-based technology to track their equipment.

A construction site has to be properly laid out, and connecting your equipment to the internet of things, as well as logging in GPS coordinates, can help you with that.

Using GPS for tracking vehicles is not a novelty; it has been used for decades, and its reliability has improved over time. So, what do you get when you combine GPS (or, as some call it, the Grandfather of IoT) with modern technologies?

You get a way to integrate telematics into your equipment and enhance not only your business’s productivity but also safety.

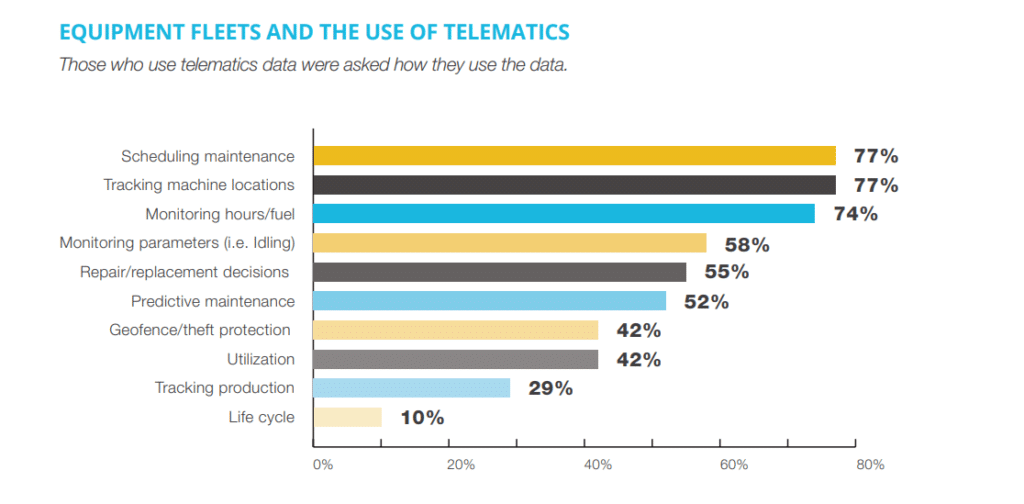

Let’s take a look at how telematics is usually implemented in construction.

When asked about the use of telematics, respondents who work in construction listed easier maintenance scheduling and tracking machine locations as their top two reasons for using telematics.

Other popular reasons for using data from telematics included predictive maintenance and data-based repair/replacement decisions.

We’ll get to maintenance in a bit, but let’s look at location tracking first.

By using a location tracking system, you can tell where each piece of equipment is even if you aren’t on the site. Location monitoring also gives you insight into how the vehicles move around the site–an element essential for employee safety.

If there are large vehicles on your site, GPS can inform you about their:

- Driving speed

- Acceleration and braking rates

- Vehicle turns

- Fuel usage

- Idle times

Keeping track of such information helps you create a safe operating environment with minimized risks for your workers.

If you’re working on a large site, equipping your assets with tracking technology allows you to plan optimal routes for delivering materials and supplies.

Finally, if an accident does occur, having the data on the movements of your equipment establishes the sequence of events so that any damages claims and other similar issues can be resolved quickly.

Enabling Better Maintenance Through Equipment Status Monitoring

In addition to using technology to avoid dangerous situations, you can also improve construction safety by tracking and monitoring your equipment status.

Tracking large machines, attachments, and tools is becoming standard practice in the construction industry. By automating the process, you reap even more benefits, one of which is eliminating human error.

Since human error is among the leading causes of injuries and accidents in construction, you should consider investing in automated asset tracking software to keep your operations running smoothly and your workers safe.

A good tracking solution will tell you more than the location of a machine.

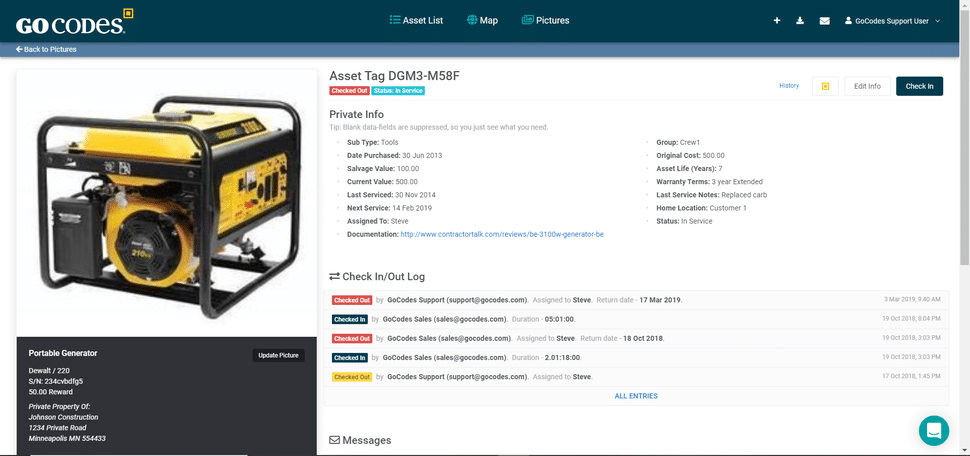

In the following picture, you can see the details about a portable generator.

The listed details include:

- type

- value

- original cost

- warranty terms

- location

- which employee used it when

- the date when it was last serviced

- service notes

- the next scheduled service

- the operating status of the equipment

As you can see, apart from identifying features, there are also details crucial for operating a machine safely.

When you know all this information, you can guarantee that your employees only work with serviced, functioning equipment.

Keeping records and monitoring the state of your tools enables you to act in advance by predicting possible future problems and servicing the tools as needed.

Still, anticipating more extensive repairs is not the only time an asset management tool comes in handy.

Heavy machines used in construction require daily or weekly lubrication to work properly. You shouldn’t risk skipping that step in machine maintenance because it can result in damaged equipment or injured workers.

To keep your site organized, you can use the database of your equipment and note down when a machine was last lubricated. With GoCodes, you can do that quickly by scanning a QR code on your machine and logging the data instantly.

Alerts on Poor Employee Performance

After you’ve implemented all safety measures to your site, it’s up to the workers to do their jobs safely and efficiently. You can use IoT to check on their performance and ensure they’re always compliant with safety regulations.

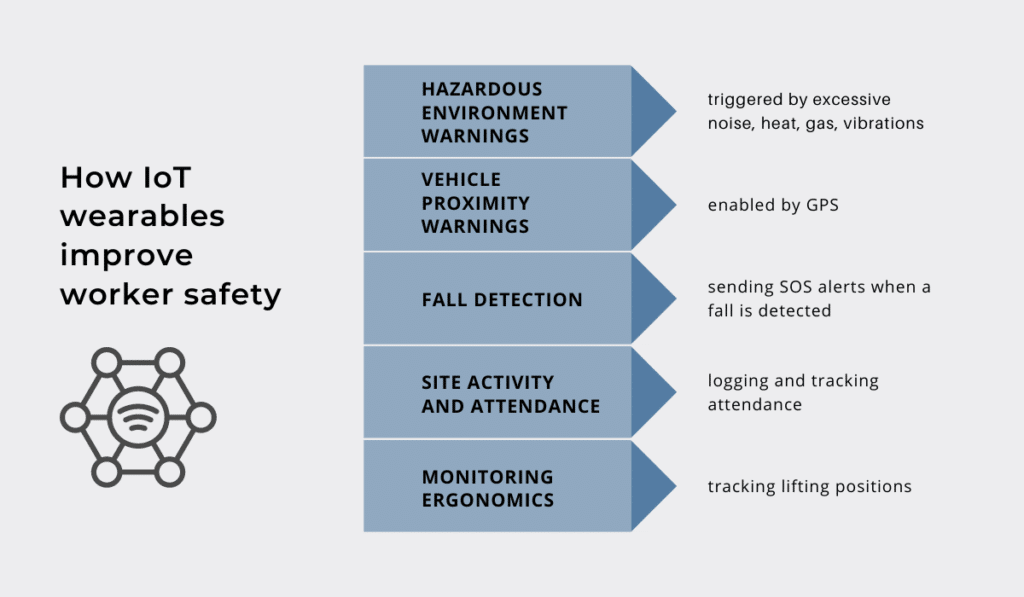

There are multiple solutions that can give you data on employee performance, from regular smartphones or GPS systems to more advanced tech items such as wearables: smart caps, eyewear, vests, boots, or watches.

For example, smart helmets could be equipped with EEG brain wave tracing bands, which would alert the worker if fatigue or microsleep are detected.

Construction is dangerous work, and you need your employees to be alert at all times.

Similarly, SolePower boots can improve situational awareness by tracking the wearer’s real-time location, sensing temperature, and allowing two-way communication and alerts.

Depending on the garment, IoT wearables can use sensors to alert workers of hazardous events and send a report to the manager.

Whichever performance tracking method you choose, you should be able to analyze the data sent from the IoT devices.

If you receive an alert that a worker is lifting material relying on their back muscles instead of legs, you could create materials on proper lifting techniques. Further monitoring will enable you to see if workers have started implementing the new practices.

Using the same methods, IoT solutions can help you see if your workers ignore high temperature warnings or spend too much time near loud machinery.

In other words, IoT offers you the possibility to collect data on unsafe practices at the job site using different sensors. You can then use predictive analytics models to decide on the best practices you can incorporate into your workers’ training. Closing the loop, you can monitor how the new changes shape the construction site as a safe work environment.

Conclusion

From the regular ones you’re already using, such as GPS, to the more futuristic ones, such as exoskeletons, there are now many IoT-based technologies you can use to increase the safety of your workers.

If you often work with rough, inaccessible terrains, consider deploying remote-operated machinery or drones to replace your workers for specific tasks. For situations where that’s not possible, there are still ways to preserve your workers’ safety.

Equipping workers with wearable devices enables them to receive notifications on hazardous situations, and helps you monitor their performance.

When it comes to making notes on the state of your equipment, a tracking solution can help you make sure everything is working properly.

The GoCodes tracking system is a straightforward, easy-to-use solution for keeping records of your equipment. Give it a try to see how easily your job site safety can be improved.