Winter is here, the coldest part of the year. You are probably freezing, but did you know that your equipment is, too?

Not winterizing your machinery can have some severe consequences, which is why it’s so important to prevent lasting damage by preparing your equipment for cold weather.

The parts of your machinery that are most exposed to the elements are your coolant systems, batteries, fuel tanks, and accessories.

Luckily, each of these sensitive systems can be insulated and prepared for winter. To help you with these efforts, we have prepared some methods to protect your equipment, so keep reading.

In this article...

Consult the Equipment Manual First

Your equipment is expensive and needs special care during the winter months. You don’t want to mess it up simply because you forgot to consult your operating manual.

However, studies show that people read the manuals only 25% of the time.

Psychologists say it’s an ego thing; researchers say it’s simply due to laziness, but whatever the reason might be, you want to be in that 25% when it comes to operating heavy equipment in the wintertime.

The equipment manual has all the secrets; not only will it tell you about the machine’s parts and functions but also provide you with solutions to common malfunctions, and it will most likely have some tips for how to handle the machine in the wintertime.

Therefore, familiarize yourself with the manual to make a checklist of winter maintenance items, as well recommendations concerning oil and fluid.

For example, say you’re wondering what fuel to use in your excavator during the winter.

If you check the manual, you will find out that engine problems may occur due to the formation of wax crystals if the temperature drops below -7 °C (19.4 °F).

In this case, the manual will inform you that it’s temporarily acceptable to use a mixture of No. 1-D (S15) and No. 2-D (S15) diesel fuel.

The manual will also instruct you to consult the fuel supplier or a construction dealer if operating in severely cold weather. And that’s just one example of the solutions and answers almost any equipment manual holds.

Simply put, to find out what your machine can withstand in the cold weather, and to operate it safely, always start with checking your manual and go from there.

Double-Check the Coolant System

When it comes to protecting your equipment from freezing temperatures, it’s also important to check your coolant system.

Double-checking your coolant is essential not just as a protection from freezing but also to prevent damage, rust, and buildup in your machines.

In the past years, coolant systems were usually checked and filled before the winter months with an appropriately colored solution so that the water in the engine wouldn’t freeze.

For instance, it was customary to replace blue antifreeze with a new blue one and green antifreeze with a new green one.

However, this is not the best practice anymore. In fact, your number one concern should be the coolant mixture, not the color match.

The mixture is usually made from 50% water, 45% base fluid, and 5% additives. A 50/50 mixture is the best since it will protect your cooling system from really low temperatures.

Although mixing different coolant types can be dangerous and should be avoided, Peter Woyciesjes, worldwide RD&E manager for Prestone Products, says it’s not the end of the world:

“If you inadvertently mix red organic acid coolant and green conventional coolants, you won’t have any problems in terms of the key parameters – specifically its heat transfer properties. The product will still cool the engine and you’ll have your freeze and boil-over protection. However, you’re now starting to mix chemistries, and you won’t get optimum performance from the coolant.”

So, in a nutshell, mixing coolants is quite safe, but it may harm the performance of the coolant.

In fact, most coolant manufacturers say it’s okay to mix up to 15% of different coolant types since it won’t cause any problems.

After that, it’s a good idea to double-check the acidity levels and the freezing point.

The longer you leave your coolant unchecked, the greater the chances it will become acidic, which can cause internal erosion to the engine and the cooling system.

To avoid this, you should measure the pH levels using paper test strips. The normal pH range for a coolant is somewhere between 8.5 and 10.5.

If it’s lower than 8.5, your coolant will become acidic and if it’s higher than 10.5, it will become excessively alkaline.

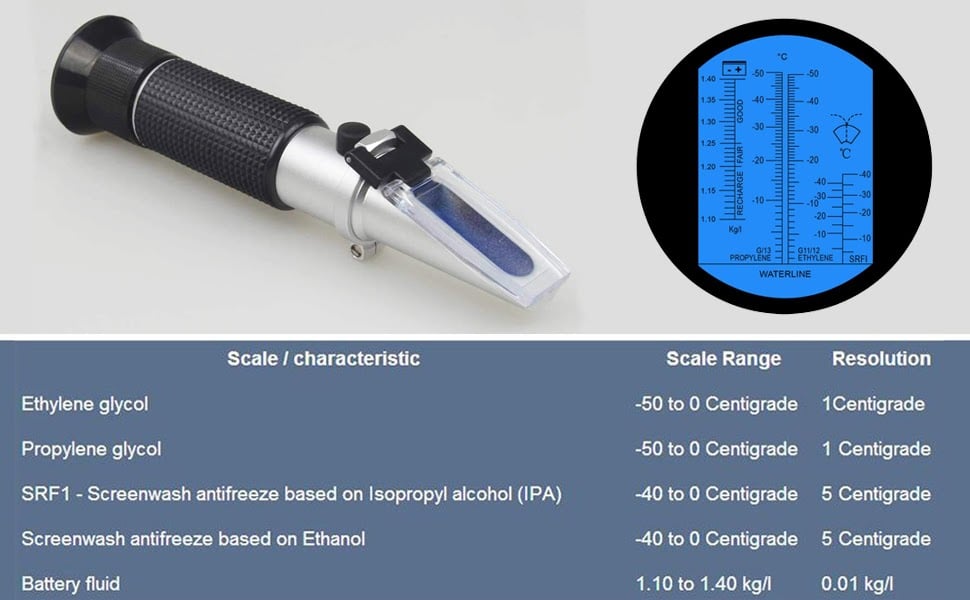

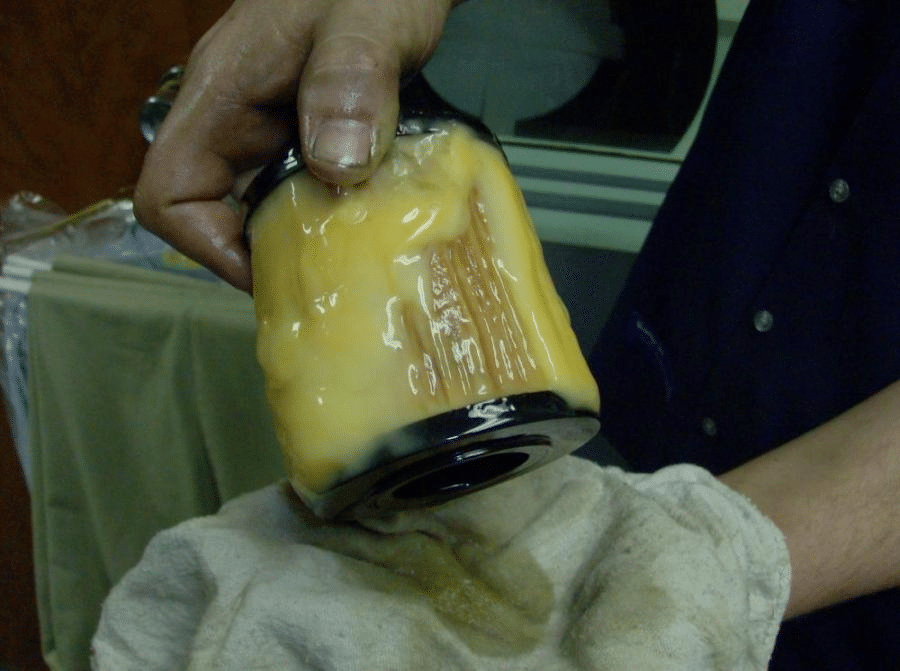

Now that you know how to measure the pH levels, let’s see how you can measure the freezing point. If you are still using a hydrometer, you should know that it’s no longer approved.

Nowadays a refractometer is used for coolant testing, such as this one from Amazon:

So, there you have it. When it comes to the coolant, the right mixture is essential to keep your machinery safe from harsh weather conditions.

Also, make sure to check up on it regularly: you know what they say—better safe than sorry.

Protect the Batteries

This might come as a surprise, but batteries are the part of your equipment that is the most sensitive to the cold.

Taking care of your batteries is essential; it will make start-up faster and reduce the stress on the engine.

For instance, your excavator may be in perfect working condition, but that won’t mean a thing if the battery is empty or weak due to freezing temperatures.

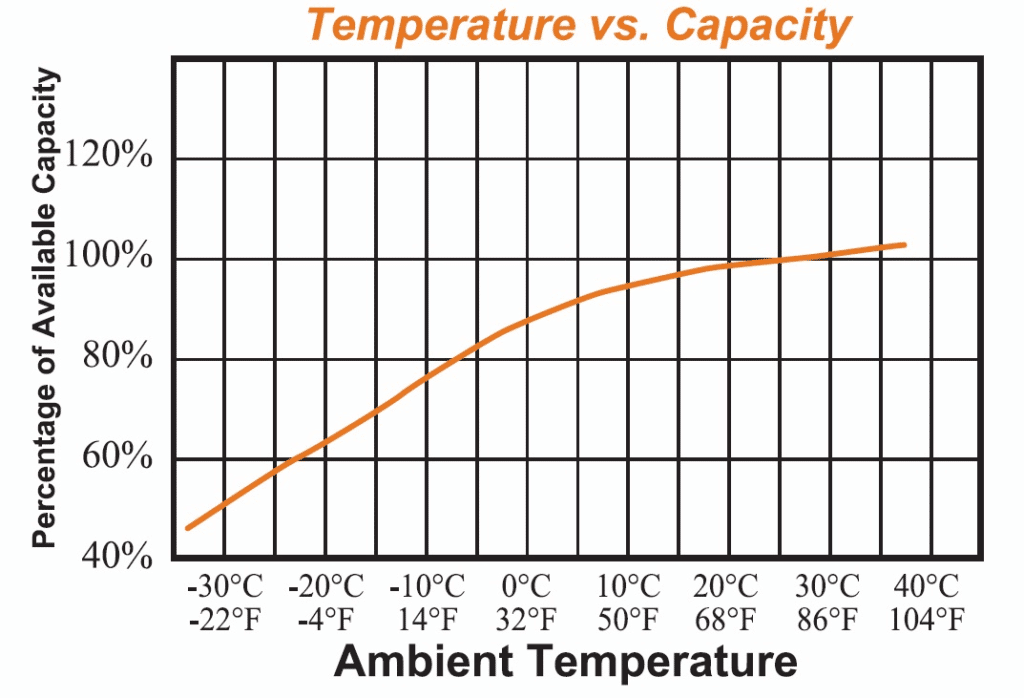

The ideal temperature for an engine battery is 80 °F (27 °C). Unfortunately, when the temperature drops, the battery efficiency decreases as well.

For example, if the temperature drops below -20 °C, your battery capacity will decrease to 35%, making the pressure on your engine nearly triple at start-up.

This is why it’s so important to keep your batteries fully charged during the winter months. But don’t take it from us; take it from the experts.

Jeffrey Muir, director of original equipment sales at East Penn, states that partially charged batteries won’t have enough energy to start a truck.

Furthermore, Larry Rambeaux, sales application engineer at Purkeys, warns that sleeper truck drivers need to be especially careful.

Due to the heavy loads they transport, sleeper trucks’ batteries will be at a lower state of charge, and parking will also pull energy from them.

Another thing worth mentioning is that it can be hazardous to warm up your battery on the road.

Rambeaux states that many trucks have caught fire while their drivers attempted to do so. Forget about using space heaters or heated blankets—the risks are simply too high.

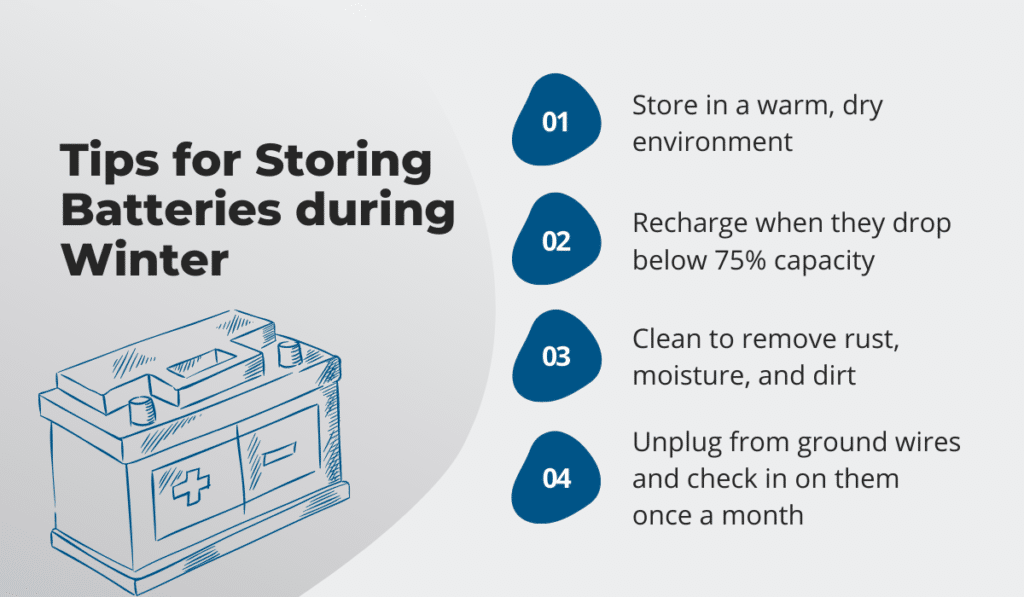

If you are not using them, the easiest way to protect your batteries from the cold is to store them properly.

The leading construction company Caterpillar suggests keeping them in a warm and dry place.

Room temperature is best; not only will a warm battery perform better than a frozen one, but you will also avoid the possibility of your battery exploding when you try to charge it or start your engine with it.

While stored, make sure to check the condition of your batteries every four to six weeks; Caterpillar recommends recharging them if their capacity drops below 75% and cleaning them to remove dirt and rust regularly.

So, to sum up, the life span of your batteries can range from months to years, depending on preventive maintenance.

It’s especially important to keep this in mind during the winter months. Make sure to keep your batteries fully charged or stored in a safe, warm place.

Perform Basic Maintenance

Regular maintenance can’t be ignored when it comes to heavy equipment, and winter months are no exception.

There are certain things you should especially keep an eye on when the temperatures start to drop.

Your machinery, and its parts and fluids are more sensitive to extreme conditions, which is why it’s important to check your fluids, filters, and more.

For example, something as simple as failing to change the fuel can seriously damage your machinery.

Most heavy equipment runs on No. 2 diesel fuel during the warmer months. However, it’s not recommended to use that kind in the wintertime since it can solidify and turn into a gel-like substance.

This is why engineers recommend switching to No. 1 in winter. This will prevent the cold from transforming your fuel into something unusable and damaging your equipment.

Also, make sure to refill the fuel tank every evening, since a full tank will help prevent ice from forming, and don’t forget to check your fuel filters. Your engine will suffer if your filters are clogged, so always keep replacement filters on hand.

However, your fuel is not the only thing that needs switching during the cold months; you’ll need to replace your oil as well.

The 2-D oil that is being used during most of the year needs to be replaced with a synthetic one.

For instance, according to the experts at the heavy machinery sales and rental company Wheeler Cat, an oil that is either fully synthetic or multi-blend will ensure that proper viscosity is maintained at lower temperatures, resulting in easier start-ups.

And if you plan to store your machines during the winter, make sure to run the engine for approximately four minutes to let the fresh oil flow.

Freezing temperatures can take a toll on your heavy machinery. To avoid that, make sure to take care of your equipment daily.

Trust us, a small amount of preventive maintenance will go a long way.

Properly Store Your Equipment

Storing your equipment without proper winterization will only have negative consequences.

Your machinery needs to be prepared and maintained before storage, or it won’t be able to return to service when the spring comes. The most important thing to do here is to shield your heavy equipment from the elements.

For instance, moisture can damage your machinery, causing it to rust and oxidize. To avoid that from happening, make sure to keep your equipment in a dry, enclosed and heated place.

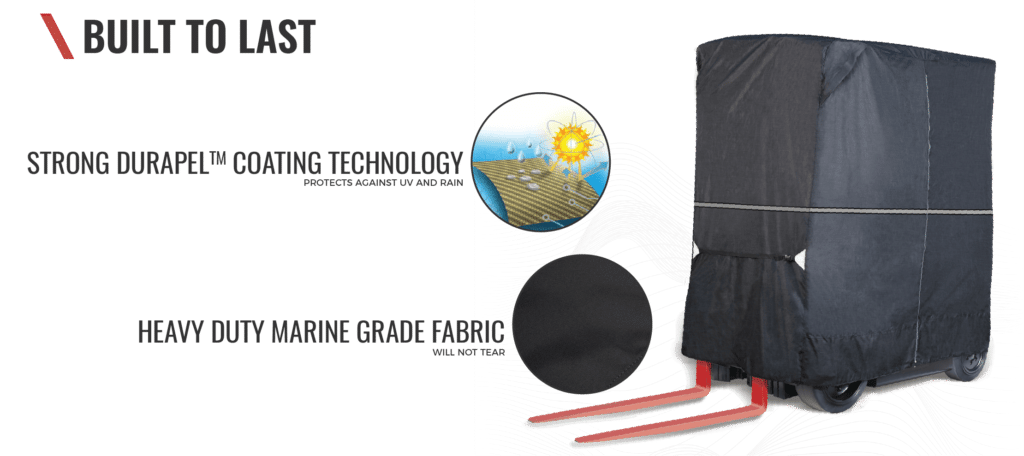

If this is not an option, and you must keep your machinery outside, make sure to park it in a dry place, sheltered from the wind and direct sun exposure. Also, try to use a tarp to cover your machines and to prevent snow and moisture from building up.

For example, you can see what a forklift storage cover looks like in the photo below.

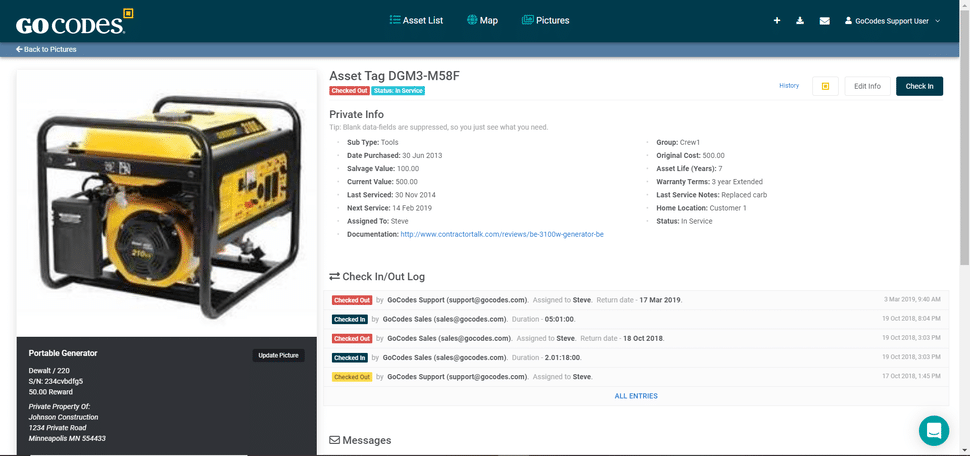

After you store your equipment, GoCodes can help you track it and provide insight into the state it is in.

For instance, thanks to GoCodes, you can find out when was the last time you used it and if the battery might need recharging.

However, before storing your machinery, it’s advisable to do some deep cleaning in order to remove any grease and debris. Don’t forget to clean your engine and cab as well, and, especially if you are storing an excavator, the undercarriage.

Also, make sure to lubricate all the components of the machines to reduce rust and moisture.

After cleaning, replace the worn or damaged parts of the machine or at least document the damage so you can do it before spring comes. Check the doors and windows for leaks and cracks and replace any burnt-out bulbs.

And last but not least, pay attention to the attachments since they often get neglected.

Perform visual checks on your wheel loader and excavator attachments and make sure you store them inside out of the elements. Another important tip is to lower them to the ground while storing.

In short, keeping your equipment clean, maintained, and out of the elements is crucial if you want to keep it in a good working condition for the springtime.

Don’t Neglect the Accessories

And we saved the best for last—protecting your accessories from the harsh weather.

When it comes to accessories, tires are always a good place to start.

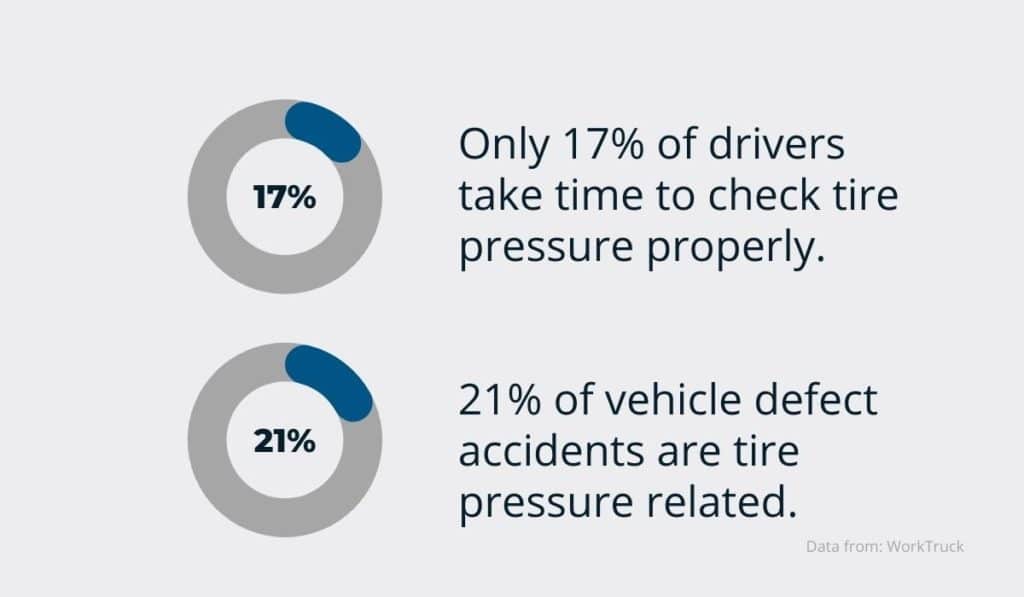

The pressure in the tires usually drops together with the temperatures. For instance, for every 10 °F (12 °C) drop in temperature, the pressure in your tires will decrease by 2-3 psi.

Unfortunately, most drivers aren’t aware of the impact of under-inflated tires on the stopping distance and the machine’s overall performance.

Even worse, statistics have shown that only 17% of drivers know how to check tire pressure properly and that 21% of vehicle defect accidents are related to tire pressure.

To avoid being a part of these statistics, make sure your drivers are fully trained to regularly maintain and inspect their tires, preferably first thing in the morning.

If the pressure drops, a good tip is to refill your tires with nitrogen gas instead of compressed air to prevent ice crystals from building up inside them.

Also, make sure that your tires have the correct tread depth since the conditions on the roads can change rapidly during the winter. Winter tires must have at least 4/32 inches of tread depth.

Tiers without sufficient tread depth won’t perform well, which can be extremely dangerous.

Another thing to keep an eye on is your hydraulic system.

Hydraulic systems are especially vulnerable to low temperatures. To keep your equipment operation safe, you must keep your hydraulic system warm enough.

Hydraulic fluid will freeze if the temperature drops below -10 °F (-23 °C), making it thick and unusable.

A great way to prevent this is by heating the hydraulic oil to maintain optimal temperature. The best way to achieve this is by using a heating blanket.

Heating blankets are designed to align the temperature with the needs of your equipment and can maintain a consistent temperature. They are also easy to set up and remove during the warmer months.

All in all, when it comes to winterizing, don’t forget your equipment attachments and accessories. Checking and preparing your hydraulic system and your tires can save you a lot of money.

Conclusion

Making sure your equipment stays protected during the winter months is a lot of work and will require some planning.

But don’t worry, if you follow the advice from this article, your equipment will be in tip-top shape all through the winter.

Remember to always start with a dry, warm place to store your machinery and other equipment and perform the needed maintenance and cleaning. These are the basics that will help you prepare for the winter and have you in top shape come spring.