Winter is here, the coldest part of the year. During this time, construction sites face a number of hazards, as the wind, snow, and ice can lead to injuries and even fatalities.

Is your construction site ready for the freezing temperatures this winter season?

Slick roads can be a problem for your forklifts, dump trucks, excavators, and other machines, and the cold weather presents serious health risks for your workers.

But don’t worry, in this article, we will give you some of the best winter construction safety tips, so keep reading.

In this article...

Conduct Pre-checks to Minimize Winter Hazards

During the winter season, in addition to your usual on-site safety checks, you should take some time to conduct pre-checks to minimize the risk of accidents.

The supervisor should inspect the site every day to ensure it’s safe and free of potential hazards. For example, inclines on wooden ramps can be very dangerous even with a bit of ice on them, or a tree laden with snow can fall overnight.

For this type of emergencies, always keep reserves of sand, salt, or grit ready and make sure you have a safety protocol in place.

Remember, preparation is half the work; it will save you a lot of time and keep potential injuries and increased downtime away.

Cold temperatures can take a toll on your construction machines both because of exposure to harsh conditions during working hours and since they will likely be left outside during the night.

Fluids, such as engine and hydraulic oils, are especially affected by the cold, so make sure they are rated for the low temperatures and, if not, replace them.

For example, Norty Turner, senior vice president of United Rentals, recommends blending 1D and 2D diesel fuel in winter, since one has better starting power, and the other provides more heat value per gallon.

Furthermore, cold weather can take a toll on your tires as well. It causes them to lose air, so check the pressure every day.

The world’s leading construction company Caterpillar even recommends inflating your tires with dry nitrogen gas to eliminate ice crystals.

Another thing to take into consideration is the capacity of your batteries.

When the temperatures drop below zero, the battery’s fully charged capacity will decrease by 35%.

Instead of taking the risk of your engine not starting, clean your battery from any dirt or corrosion and spray some terminal protectant on it. Also, clean the cables if needed.

Finally, this brings us to perhaps the most important preparatory activity—dewatering.

There is no dry or stable foundation without it, so investing in a good dewatering system will minimize the possibility of falls, soil erosion, ice buildup, and flooding once the snow starts melting.

So there you have it; even though freezing temperatures will make your work a lot harder, you will avoid problems, injuries, and downtime with a good pre-check routine.

Remove Snow Safely

For the safety of your workers, you must make sure your site is free of snow before the work starts.

Snow removal is an unavoidable part of ensuring construction safety in winter, and even though it seems simple and self-explanatory, you should always go about it mindfully.

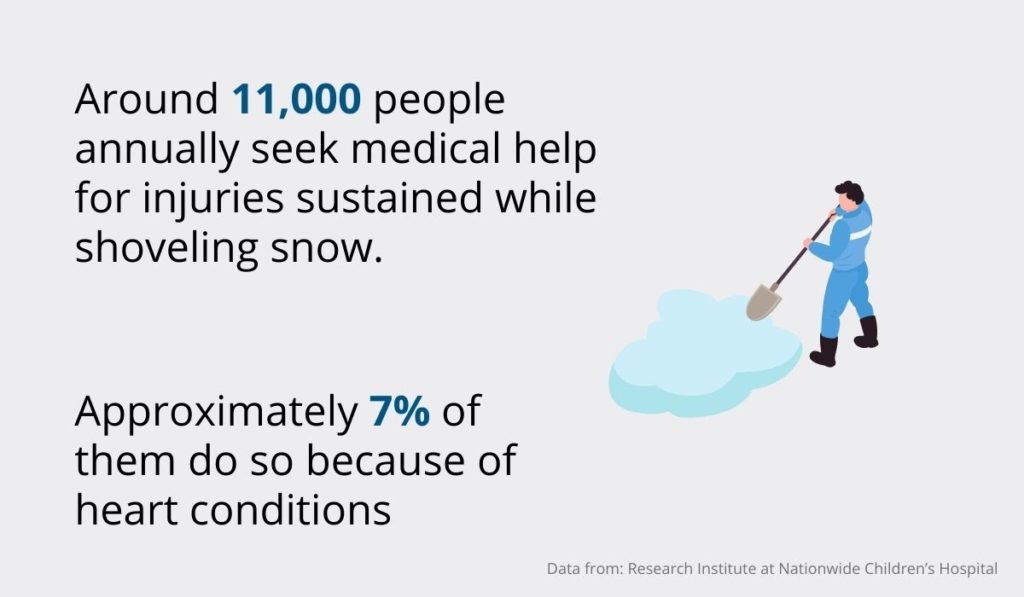

For instance, shoveling snow manually is a common mistake.

You probably don’t see much danger in this activity, but manual snow shoveling is actually a strenuous exercise which puts you at risk for muscle strain, or even worse—heart attack.

Yes, you read that correctly; studies have shown that freezing temperatures cause the vessels in your body to constrict, which can increase blood pressure and therefore cause a heart attack.

Furthermore, according to the Research Institute at Nationwide Children’s Hospital, around 11,000 people seek medical attention due to injuries obtained while snow shoveling every year.

Approximately 7% of them do so because of heart conditions.

Therefore, be especially careful to avoid assigning your workers who are at risk of cardiovascular diseases due to pre-existing conditions such as high cholesterol, diabetes, obesity, or because of advanced age, to shovel snow

Instead, use the right tools to make things easier for your workers.

For instance, consider getting a snow tarp. The workers can lay it down before snowfalls, and later simply use a crane to lift it by all four corners to remove it, together with all the fallen snow.

This tool will save you some time and money, while also protecting your workers from potential injuries.

Removing snow from the rooftops is another dangerous winter routine. Working on rooftops and decks is tricky all year round, but that’s particularly true in very cold weather.

In fact, falls during rooftop snow removal are the most common wintertime cause of fatalities and injuries.

In addition to the potential loss of life, according to the US Department of Labor, a fall can cost you up to $3,000,000 in damages.

Because it’s so easy for workers to slip and fall off roof edges, ladders, and even aerial lifts, it would be best to find ways to remove snow from rooftops without involving workers.

For instance, you could provide snow rakes that can reach the roof while the worker remains on the ground.

However, this is not always possible.

Still, when there is no other solution and your workers simply have to climb the rooftops to remove the snow there themselves, there are a few things you can do to prevent them from getting hurt.

You can prevent accidents with some planning, proper training, and adequate fall protection.

Invest in some safety equipment such as fall arrest systems, scaffolds, and protective gear.

While this type of equipment can prevent injuries, it won’t be of much help if your workers can’t use it, so remember that nothing can replace proper safety measures, particularly regular training.

During the training, your employees will learn how to use protective gear and tools and spot potential hazards.

In conclusion, to make sure the winter season goes without a hitch on your construction site, always try to remove snow without involving your workers in the process.

If that’s not an option, make sure they are fully trained to deal with hazards and implement safety protocols, and that they use protective equipment.

Reduce the Risk of Slipping on Icy Surfaces

Snow is usually accompanied by ice, which makes it even more dangerous. During the wintertime, it’s extremely important to reduce the risks of slipping on icy surfaces.

Falls and slips were responsible for 244,000 non-fatal and 880 fatal injuries at the workplace in 2019 alone. They can have broken bones, fractures, bruising, or even death as a consequence.

You definitely want to avoid your workers getting hurt, so every morning, before work, make sure to remove the ice with some salt or sand.

Keep in mind that it’s not just the ground you should be worried about; ladders, rooftops, and other elevated surfaces should also be treated.

If there is a place on your construction site where you can’t remove the ice, mark it and prevent access.

However, if you think that the danger stops there, you’re wrong. Ice on the road can also be a risk when operating or driving heavy construction equipment.

Did you know that 24% of all weather-related road accidents happen because of ice? To prevent any of your workers from becoming a part of these statistics, start by emphasizing the importance of driving slowly and carefully.

However, you must keep in mind that operating heavy machinery is not the same as driving a car. For example, a dump truck is a lot heavier than a car and therefore will slide further if it encounters ice on the road.

This is especially dangerous when that ice isn’t immediately visible.

Have you ever heard of black ice? Despite its name, it’s not really black, but transparent.

However, since it’s so thin that it blends in with the pavement of the road, it’s nearly impossible to see.

Because the drivers probably won’t be able to notice it, it’s important to keep an eye on how cold it is.

If the temperatures are below zero, you should assume there will be black ice on the road, and act accordingly.

Besides driving safely, you should also get your heavy machinery vehicles winter-ready.

Firstly, check your winter tires for any signs of wear and tear; if there is snow, get some chains or studded tires. Remember, you can never be too safe in these conditions.

Next, check your brakes, battery, and engine to ensure they’re in top condition. Also, make sure that there is enough antifreeze in your coolant reservoir.

You should never forget that ice is your equipment’s biggest enemy in wintertime. Still, these tips should help you tackle it appropriately.

Minimize Exposure to Harsh Weather

In addition to reducing the risks related to snow and ice, it is also important to minimize exposing your workers to harsh weather.

Freezing temperatures can lead to an array of issues, such as:

- cold stress

- frostbites

- trench foot

- chilblains

- hypothermia

All of these can be dangerous, which is why it’s essential to educate your staff about the symptoms.

For example, a tingling sensation, pain, swelling, blotchy skin, numbness, and a heavy feeling in the foot are all symptoms of trench foot.

However, to avoid these types of problems entirely, it’s crucial to limit your workers’ exposure to harsh temperatures and conditions.

In order to achieve that, the first thing you should do is to provide your workers with a safe place where they can warm themselves up during their breaks.

Providing a heated area on a construction site can be a challenge; however, we are sure you can equip a trailer or a tent with some adequately secured portable heaters.

Depending on the type of your construction site, you can even go the extra mile, like Brett Leconte, a manager at a Scarborough landscaping company called GCK2 Landscapes, did.

He has convinced his bosses to buy movable tents that comprise scaffolding, sheeting, and PVC electrical conduits, so that the workers can work in any kind of weather conditions.

If this isn’t doable on your construction site, another great idea is running shorter working shifts while the cold weather persists, and serving hot drinks.

However, make sure those drinks are not caffeinated since they can increase heart rates and make your workers feel a false sense of warmth. You can serve tea, hot chocolate, or hot lemonade instead.

Additionally, keeping a close eye on the weather will help you plan ahead and prevent you from sending workers into dangerous situations, such as storms or blizzards.

Follow the national weather forecast every morning and several times during the day to avoid any surprises.

In this way, you will ensure that your workers have enough time to secure construction areas, leave them and safely arrive home.

In short, to protect your workers from the cold, make sure they have a heated break area, run shorter shifts and keep an eye on the weather forecast.

Provide Workers With Personal Protection Equipment

Minimizing exposure to harsh weather isn’t enough; you should also make sure to provide your workers with personal protection equipment (PPE) to make sure they avoid winter-related injuries.

While so much is at play when choosing the right type of clothes and gear: from the temperature and the weather conditions, to the duration of work, one thing is always certain—workers must wear layers.

This includes a moisture-wicking base layer and a waterproof outer layer.

But did you know that over-protection is also a potential problem?

Winter PPE can be bulky, which will, in turn, limit the mobility of your workers. This can result in a number of problems from eyewear fogging and blocked vision, to snow glare, and even limited hearing.

To avoid all of these issues, there are certain things you have to keep in mind.

For instance, gloves have to be durable, but they also need to have the right texture, and they must be waterproof. Also, if the temperatures are extremely low, insulated mittens are a must.

The same goes for the boots; insulation will keep your staffs’ feet warm and dry even if moisture gets in. They also need to be breathable and provide traction to reduce the chance of slipping.

Another thing that will keep your workers’ feet even warmer is socks. They should be extra thick, and it’s even recommended to wear two pairs.

It’s also a good idea to always carry an extra pair since socks can easily get wet and cold feet can cause many health-related problems.

If you wear glasses, you are probably aware of how annoying it can be when your lenses fog in the wintertime. The same thing happens with the construction eyewear, so make sure you get the ones with anti-fog coating.

Finally, although many underestimate this, it’s important to keep the head warm.

Hard hats usually won’t provide enough heat for the winter temperatures, so make sure that your workers wear wool caps underneath.

So there you have it; it’s much easier to stay warm than to get warm. The easiest way to ensure that your workers maintain their body temperature is to provide them with appropriate winter PPE.

Conclusion

Winter brings a lot of challenges for your construction site; machines are freezing, workers are freezing, and there is snow and ice everywhere.

In order to keep your construction site safe during the winter, you must remove snow and ice, take care of your machines and shelter your workers from the cold by providing them with protective clothes and a heated area to spend their breaks in.

We know how scary all of this sounds, but if you follow the advice from this article, you’ll have nothing to worry about!