Power tools are a common sight in any construction work zone. Unfortunately, injuries and fatalities caused by improper use of such tools are also common.

Falling objects, electrical shocks, burns, or punctures are just some of the hazards you can expect when employees don’t know safety procedures when using power tools.

The following tips should help you keep yourself and your workers safe and minimize trips to the emergency room.

In this article...

Consult the Manual Before Use

Most people skip this step because they think they’re familiar with the general use of any construction equipment, but that’s where problems arise, since they often don’t abide by the manufacturer’s recommendations.

Manuals provide ample advice on how to use your tools safely, which attachments are suitable, and the specific applications and limitations of the tools.

Not all tools are created equal, and each of them has specific requirements for safe handling and usage. You should be aware of all the dangers to your physical safety when you’re operating a new power tool.

Therefore, spend some extra time reading the manual and familiarizing yourself with the proper use and maintenance of your power tools.

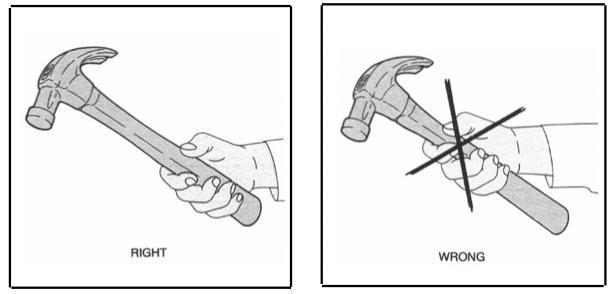

Use the Tool the Way It’s Intended

Some of the most unsafe practices at any construction site include using tools incorrectly or using them for the wrong job. You can see an example of the former in the image below.

As for the latter, using wrong attachments or wrong tools for a particular task could create mechanical or electrical stress, making them unsafe. Not only could you damage the tool, but you’re also risking a severe injury.

So, it might not be a good idea to use a wrench where a hammer would be more effective to finish the job.

Basically, do not use tools for tasks they’re not designed for. If you don’t have the right tool, wait for it to become available or buy what you need.

Never Skip Maintenance

To keep your power tools in peak performance, you should schedule regular maintenance.

Clean them regularly, and follow the manual’s instructions on proper lubricating. This should help keep them in good condition and extend their durability.

Moreover, with regular maintenance, you can detect damage on time and replace faulty parts, so the tools don’t pose a threat during the next use.

Regularly check for the following:

- Cracks

- Breakage

- Damaged plugs

- Exposed wires

Regular checks should also extend to the power tool’s accessories. Keep them sharp and replace damaged materials regularly. Even better, create a maintenance schedule and log information after each inspection of your power tools.

All in all, with regular visual inspections and maintenance, your power tools will be in top condition to finish construction tasks safely and efficiently.

Train Your Team on Safe Power Tools Use

According to experts, human error is the leading cause of workplace injuries across industries. In construction, this often means that untrained people were instructed to use power tools and injured either themselves or their coworkers.

To properly use their tools, all employees need adequate training and knowledge to be able to detect potential hazards.

The first step is reading the manual, but if that’s not enough, ensure your employees get hands-on experience and training in a controlled environment.

A training session is helpful for new employees, but experienced workers can also benefit from refreshing their knowledge on the safe handling of power tools.

Do not allow your workers to become complacent with safety procedures because power tools are not to be trifled with.

Some of them are heavy, with sharp accessories, so they need to be focused when operating any power tool. Any lapse in concentration can lead to injury.

This is also why employees shouldn’t use tools when they’re tired or taking medication.

To sum up, conduct regular training for your employees to use power tools safely and correctly.

Lock Out/Tag Out Damaged Tools

During your inspections, you might come across damaged tools. But you shouldn’t just leave them where you’ve found them.

Someone else might start using them without knowing they were damaged and injure themselves.

Hence, if you find any damaged tools, use a lock-out device and tag them with a clear label that says “Do Not Use.” You can also keep them in a dedicated locker until they can be taken for repairs.

Simply put, it’s necessary to warn your coworkers about defective tools to prevent workplace accidents.

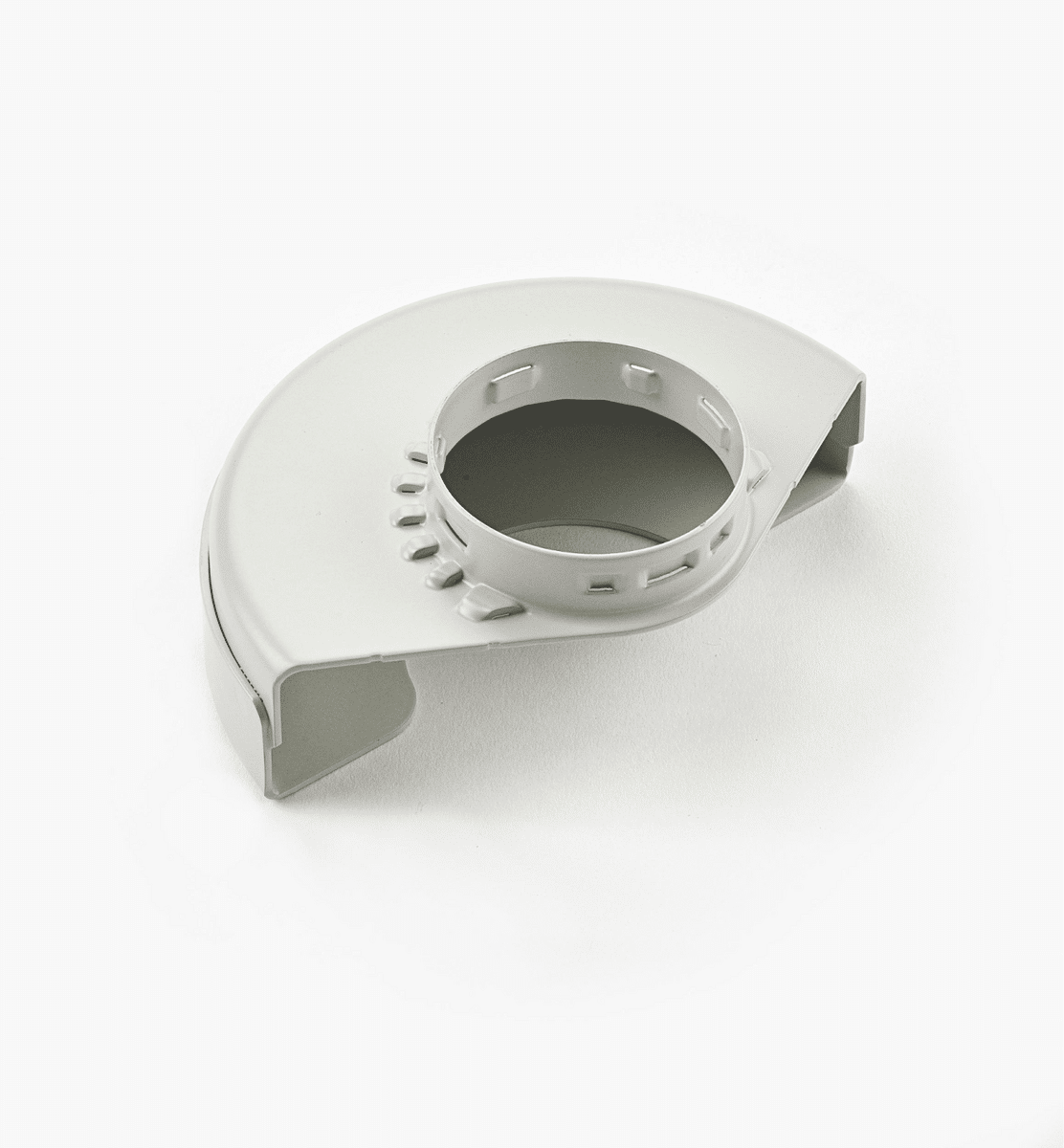

Don’t Ignore Safety Guards

Safety guards on power tools exist for a reason. Some of them protect you from being struck by moving parts like belts, gears, flywheels, or chains. Others shield you from flying chips and sparks.

Therefore, if you notice a power tool is missing a safety guard, avoid using it. In fact, the only time you should remove a safety guard is when the power tool is being cleaned or repaired. Otherwise, do not tamper or reposition safety guards.

Most of all, make sure that all guards and safety devices are put in place according to the manual’s instructions.

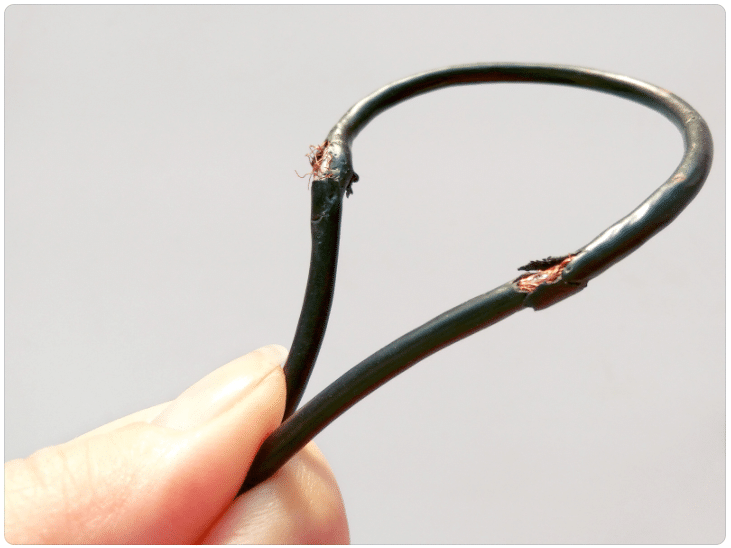

Pay Attention to Cord Damage

As you’re using a power tool, the cord often gets dragged along various surfaces, and it can easily fray even when it’s covered with a protective layer. Heat, sharp edges, or people stepping on it frequently can cause damage.

In light of that, inspect cords and cables before using a power tool. Ensure that they are intact and that there’s no exposed wiring.

So, if you’re using a tool for a long time, checking the power tool cord should be an essential part of your daily visual inspection.

Avoid Excessively Long Cords

While we’re on the topic of cords, avoid using ones that are overly long.

Long cords are a huge tripping hazard in workplaces. The general recommendation is not to use power tools with extension cords longer than 100 feet.

In case you do need to use a long cord, take advice from Ron Hazelton, a DIY and home improvement professional. Install a screen door spring and two ‘’S’’ hooks to keep your cords visible and away from busy areas. Hang the hooks on either end and attach one side to a convenient place above your work area.

Then place the cord on the other hook and suspend it in the air, away from your feet and the working part of the power tool.

All in all, use cords of standard length whenever possible, so you don’t create unnecessary tripping hazards.

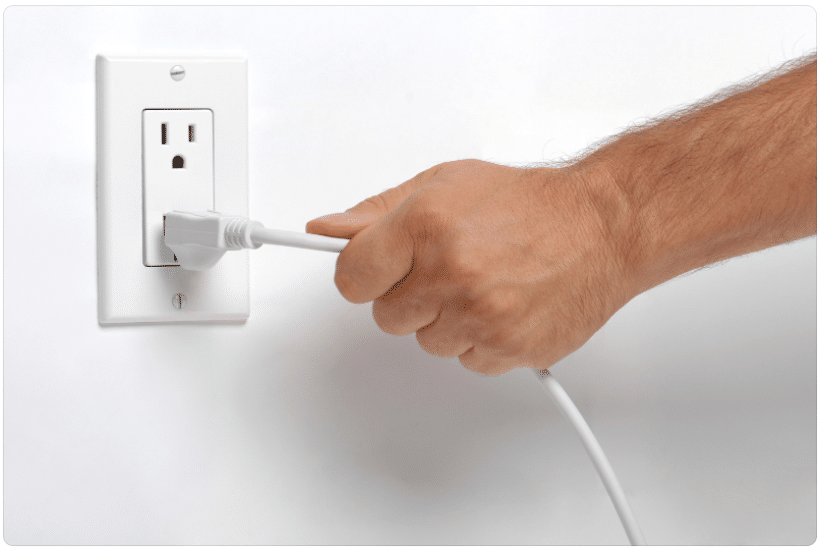

Safely Remove the Cord From the Receptacles

Safely disconnecting electrical tools once you finish working is also important, but often overlooked in a hurry.

Still, no matter how much you might want to skip walking over to the power plug, try to avoid pulling the cord to turn off the machine in a misguided attempt to save time.

First, switch off the equipment, then the main power switch. Finally, you can remove the cord plug from the socket.

Keep in mind to pull the plug, not the cord itself, when you’re unplugging power tools. This is to avoid additional wear and tear, and damage to the wiring.

Carry the Power Tools Properly

People often carry power tools in their utility belts and safety jackets out of convenience. But what if the tool unexpectedly starts?

Tools have sharp edges and pointed ends, so carrying them on your person can cause injuries.

Be aware of where your tools are at all times and avoid holding them very close to unprotected parts of your body.

Additionally, avoid holding heavy power tools by the cord when you carry them. This is yet another way to damage the wiring and increase your chances of getting electrocuted. So, always use the handles or grips.

Remember that convenience is the lazy person’s path to trouble.

Operate the Tool With Both Hands

Maneuvering heavy power tools can be tricky, so always use both hands to hold them.

Essentially, you want the most control of your power tool to ensure precision and prevent injuries. This means that you’ll need to use clamps or a vise to hold the piece you’re working on.

Having a firm grip will ensure you don’t drop your tool or hurt yourself if the tool gets stuck in the workpiece.

Ensure Good Balance While Operating Power Tools

Just as their name suggests, power tools are powerful, so you have to maintain a good posture and balance at all times when you’re handling them. Keeping a good balance is especially paramount when you’re working at heights.

Imagine dropping a power drill on your coworker from a two-story height!

So, when using a power tool, plant your feet on a stable and flat surface, or ask for help if you’re working on a ladder.

For better control of the tool, hold it close to the body. Following that, comfortable non-slip shoes will be of great help.

Mind Your Apparel

Being fashionable might not matter on the construction site, but that doesn’t mean you shouldn’t be mindful of what you wear while working with power tools.

Standard OSHA guidelines for handling power tools require wearing protective equipment such as protective eyewear and tight-fitting gloves. In some cases, you also might need a face shield, ear protectors, and a welding helmet.

But there are other things you need to know about appropriate clothing. Avoid loose clothes and loose-fitting gloves because they might get tangled in a rotating power tool.

It’s also best to put away any jewelry or watches because they might also get caught in moving parts.

If you have long hair, keep it away from your face and wear protective hair covering. Whenever possible, roll your sleeves above the elbow, so they don’t get in the way of your work.

In the end, how you dress can be a significant factor in protecting yourself when handling power tools.

Disconnect Tools When Out of Use

Always disconnect your tools when you’re done using them.

Even if you’re going for a short break, never leave power tools in a stand-by mode and plugged in. You could cause severe problems for people who don’t know the tool is powered.

Before leaving the tool unattended, shut it down, wait for it to stop working completely, and unplug it. For extra protection, you can place it somewhere out of reach for other people or store it.

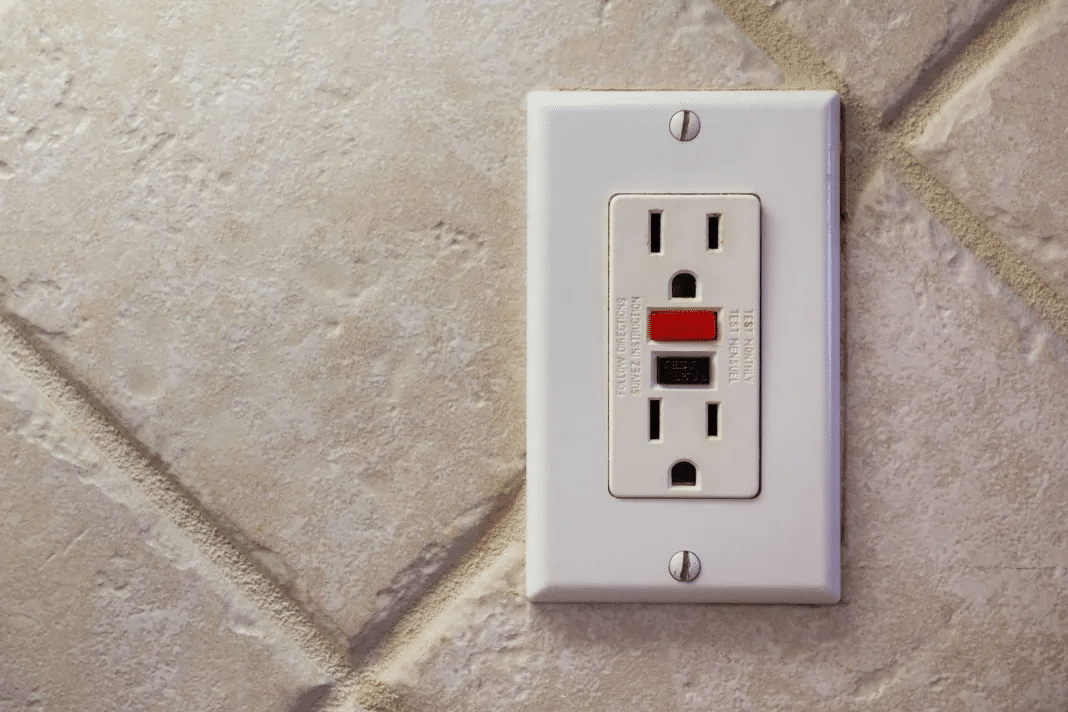

Use Ground Fault Circuit Interrupters

Electrical hazards are a serious concern for most industries because they result in many injuries and fatalities.

In 2019, 43% of electrical fatalities occurred in the construction industry, so take the necessary precautions if you’re often working with electrical power tools.

One of them is using a ground-fault circuit-interrupter (GFCI) with every power tool. They protect workers by monitoring current flow into a circuit.

Once GFCI senses any current loss, even by five milliamperes, it will shut off the power to prevent an electric shock.

The good news is that GFCIs can be found on any construction site, and they can also protect against fires, wire overheating, and the destruction of wire insulation.

To protect yourself from electric shock and burns, ensure you have proper protective equipment when working with electrical power tools.

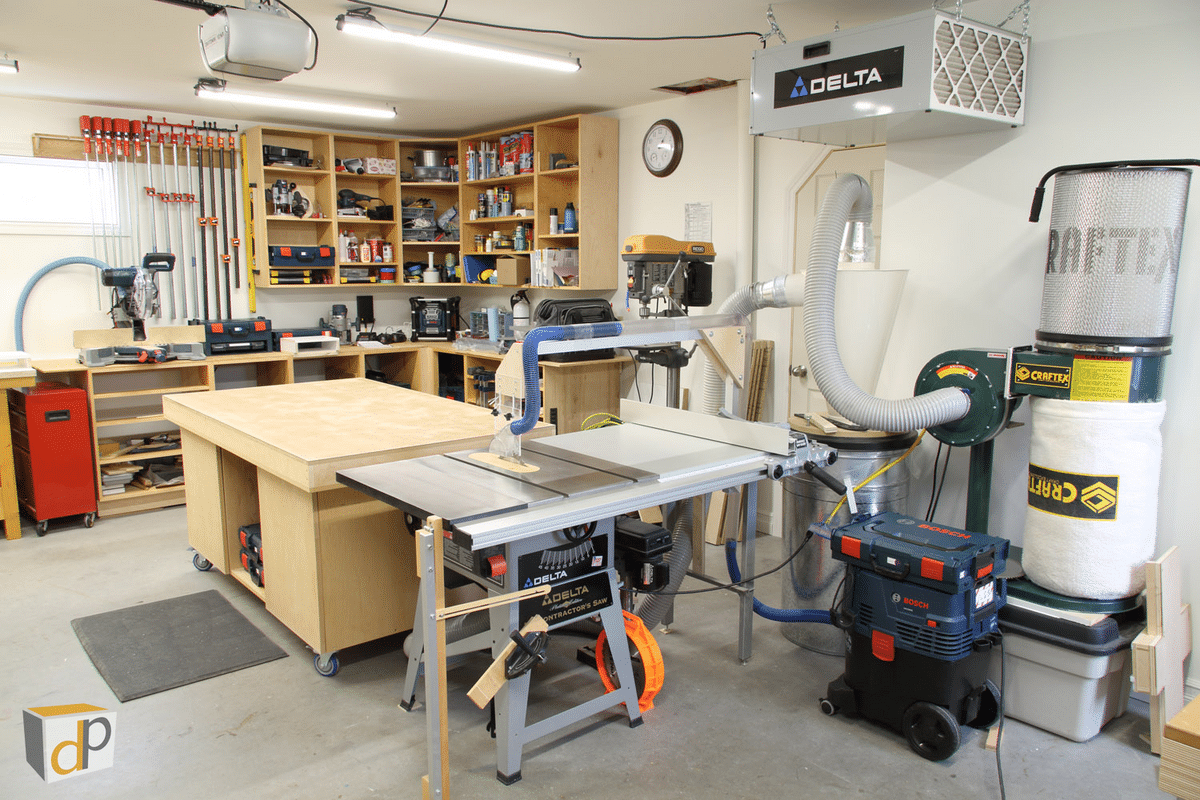

Pay Attention to the Work Environment

Is your working space clean and well-lit? Is there any liquid or debris on the floor?

A clean and dry workspace makes a world of difference for safety. Floors can become slippery if they accumulate too much sawdust or water, for instance.

If your tools are not designed to work in damp areas, avoid using them around wet spots.

Additionally, wood chips can cause fire when exposed to the heat from power tools, so be careful if they are present in your working environment.

Another thing to keep in mind is to ensure that the space is well-lit when you’re working. After all, if you can’t see what you’re doing, you’re more likely to make mistakes or injure yourself.

Remember that cluttered and damp working spaces are a hazard, so keep yours clean and dry.

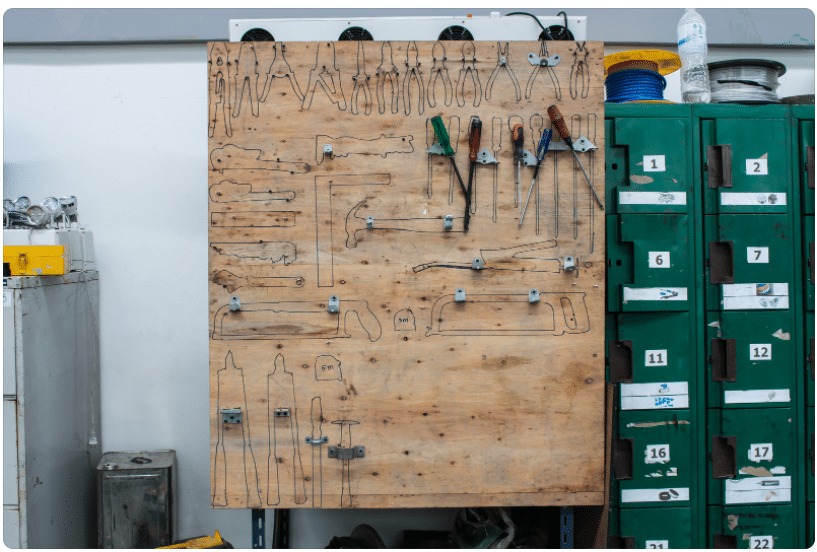

Store Your Tools Properly

You’re probably aware of how expensive power tools are. Therefore, you have to store them properly to ensure they don’t deteriorate and break, which can drive up costs for repairs or replacement.

Create a specific location where you’ll store all your power tools and allow easy access for your employees. Keep them in a toolbox or cabinet with anti-rust liners. Another good solution is to hang them on pegboards.

Otherwise, pack them in their original case with silica gel packs (to absorb moisture) when you’re not using them for a long time.

Additionally, to keep an eye on your power tools, consider investing in an asset tracking software like GoCodes so you’ll never lose a valuable machine.

When it comes to storage, the most important thing is to protect your tools and not leave them lying around on the job site.

Conclusion

Power tools make any construction work quicker and more efficient, but they also come with risks. When accidents happen, they can have far-reaching consequences.

Remember that following basic safety procedures when using power tools can mean the difference between life and death on a job site.