Key Takeaways:

- Fleet telematics streamlines fleet operations, enhances safety and security, and reduces fuel and maintenance costs, thereby creating a strong foundation for optimizing fleet operations.

- However, fleet telematics can come with drawbacks related to the price of comprehensive systems, challenges in system integration, and privacy concerns among drivers.

- Despite this, fleet telematics can provide a significant ROI, especially when integrated with an overall asset tracking and management solution like GoCodes Asset Tracking.

If you’re a construction company owner or manager operating a fleet of trucks, heavy machinery, and vehicles, you likely heard the term “fleet telematics.”

You might’ve also heard that fleet telematics offers a host of benefits resulting in increased operational efficiency, enhanced fleet safety and security, and reduced fuel and maintenance costs.

Yet, it can be difficult to understand what this technology actually does, how it works, what are its tangible benefits and potential drawbacks, and how much it costs.

In this article, we’ll try to demystify fleet telematics by addressing five questions often asked by construction professionals.

In this article...

How Does Fleet Telematics Work?

While it’s relatively easy to explain how fleet telematics works, it’s much more complex to cover the range of different hardware and software capabilities and options in the telematics arena.

Let’s start with the easier part.

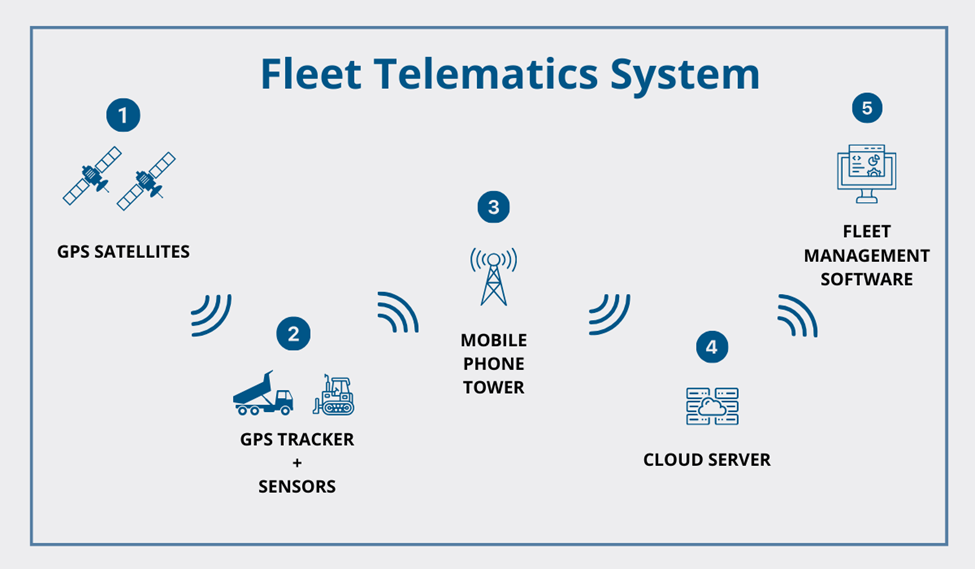

Telematics combines GPS tracking, sensors, and fleet management software into one.

As you know, GPS trackers use satellites to track the location of vehicles across the globe and use telecommunications (cellular, Wi-Fi, radio frequencies) to transmit real-time data to the central cloud server of your telematics provider.

From there, the data is relayed to your fleet management software that processes and displays the info in a user-friendly way on your smartphone, tablet, or laptop.

Here’s how this works.

While the data collection and transmission principle in telematics systems is relatively straightforward, complexity increases when we come to the sensors used to gather vehicle or equipment data.

That’s because these sensing devices can be:

- part of your vehicle/equipment (onboard diagnostics, i.e., built-in sensors),

- part of your GPS tracker (acceleration, temperature, etc.),

- other externally installed vehicle/equipment sensors.

This means that the range of vehicle data collected by your fleet telematics will depend on what combination of the above sensing capabilities you opt for, keeping in mind the system’s installation complexity and overall cost.

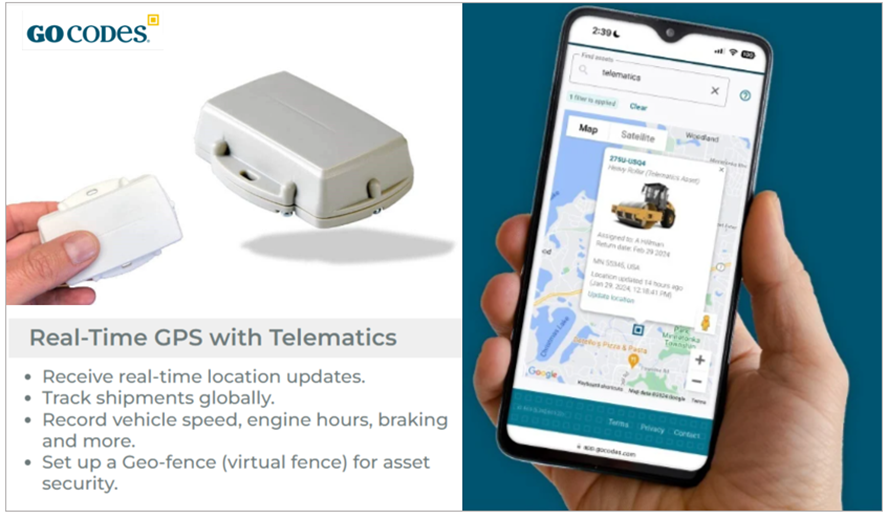

For instance, in a simpler system setup, your fleet telematics hardware can consist of easily installed, AA battery-powered GPS trackers equipped with their own basic sensors.

This telematics system allows you to:

- monitor the real-time location of your vehicles/equipment on a map,

- set virtual security perimeters/zones (geofencing) for vehicles/equipment, and

- record data such as speed, engine hours, rapid acceleration, or hard braking.

As explained, all this collected data is transmitted to the software component of your fleet telematics system, where it’s processed, interpreted, and presented in an easy-to-understand format.

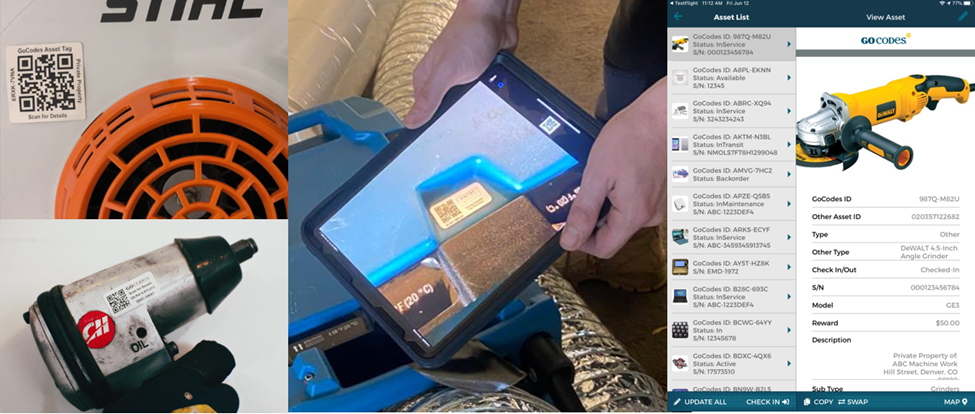

Our end-to-end asset tracking solution, GoCodes Asset Tracking, namely our mobile app (software) and our real-time GPS trackers (hardware), are a great example of such a system.

Until now, we explained how the data collected by GPS trackers and telematics sensors ends up on the screen of your smartphone and described the vast sensing capabilities offered by various tracker and in-vehicle sensors.

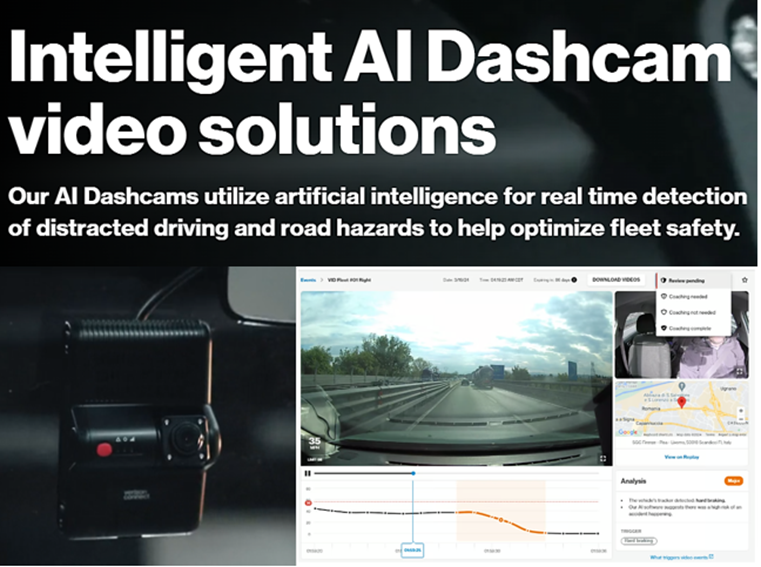

Beyond that, road-facing and driver-facing dashcams, as well as AI-driven algorithms and driver/operator assistants are also increasingly becoming part of full-blown fleet telematics solutions.

Naturally, this significantly broadens the spectrum of what such systems can do for your fleet management, along with some drawbacks like complex installation, high monthly/yearly costs, and privacy concerns.

We’ll discuss all these factors in more detail later.

However, what truly drives any fleet telematics system is not its hardware, but its software.

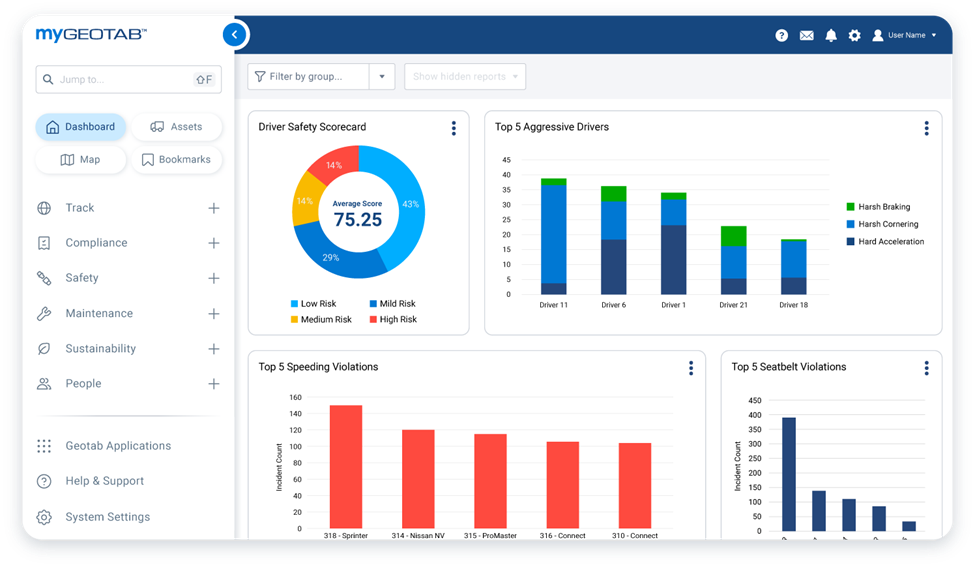

The software determines how all this data will be processed, analyzed, and presented to enable you to streamline fleet operations.

This is where things become even more nuanced because different software solutions often prioritize different aspects of fleet management, such as maintenance scheduling, fuel efficiency monitoring, or driver behavior scoring and coaching.

Therefore, although fleet telematics systems operate on the same principle and utilize similar technologies, their functionalities vary depending on the tracking and sensing capabilities of their hardware and the data presentation and analytics abilities of their software.

Together, these components determine what tangible benefits your construction fleet and your business can achieve, which leads us to the next common question.

How Can My Construction Fleet Benefit from Telematics?

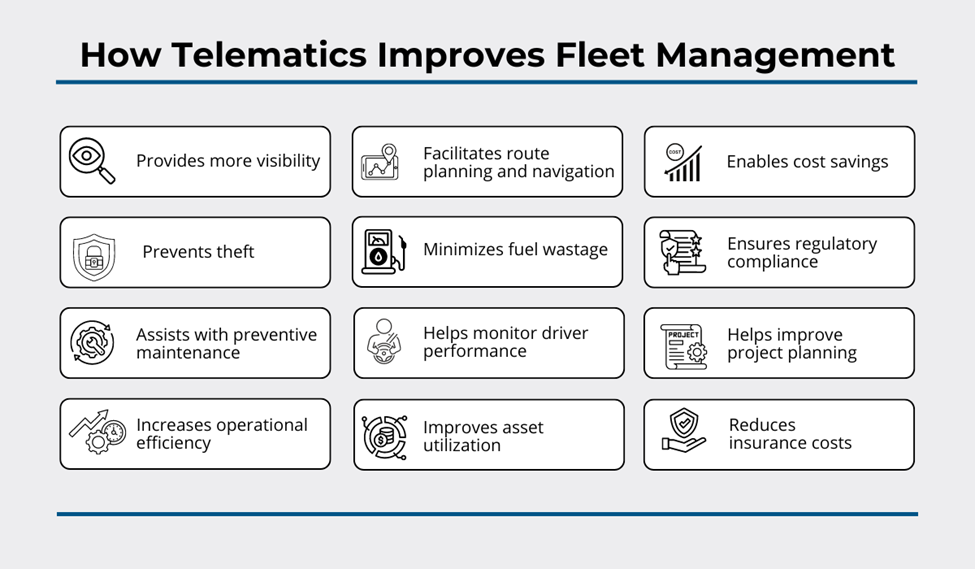

Given the diverse telematics hardware and software capabilities, the range of benefits for your construction fleet is vast, ultimately leading to streamlined fleet operations, enhanced safety and security, and reduced fuel and maintenance costs.

Naturally, these advantages extend beyond fleet management to impact other operational areas resulting in, for example:

- improved workforce, equipment, and tools allocation and utilization,

- enhanced project management, including cost estimates, planning, budgeting, scheduling, and billing,

- optimized inventory management, and

- more accurate accounting for regulatory and tax compliance purposes.

These and other improvements contribute to increased company-wide productivity, reduced costs, and enhanced profitability.

Even with the simplest telematics system setups, your construction fleet can realize numerous benefits, with additional advantages emerging as the sophistication level of both hardware and software increases.

To illustrate, here’s what benefits can be extracted when basic GPS trackers and fleet management software (mobile app) are properly used by fleet managers and drivers/operators:

Of course, some of these advantages are further amplified, data collection and analysis automated, and processes streamlined with advanced telematics systems.

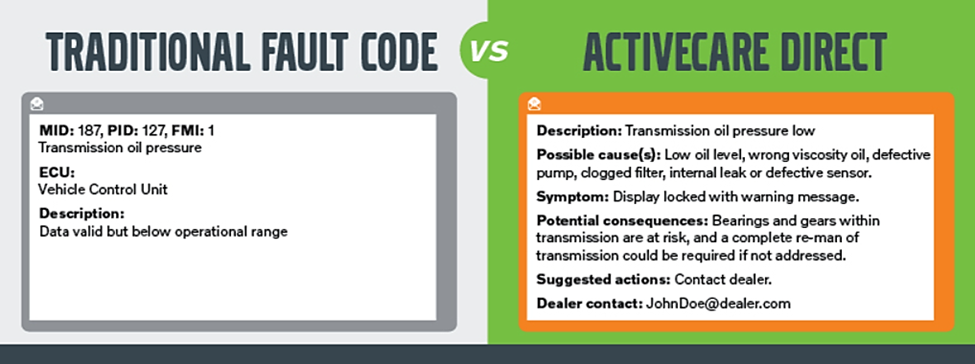

For starters, when GPS trackers are integrated with the vehicle’s internal network of sensors, such as onboard diagnostics (OBD), fleet managers and drivers gain access to a wealth of real-time vehicle diagnostics and proactive maintenance alerts.

For example, if the vehicle’s system (oil pressure sensor) detects a sudden drop, the operator and/or fleet manager will be promptly notified via the software app, enabling them to take appropriate action and prevent further engine damage.

As illustrated, some manufacturers have their own engine fault code interpretation and alert systems for their construction vehicles and equipment.

Another major advantage lies in standardly built-in (or external) fuel tank sensors linked to your telematics via the vehicle’s diagnostics system.

When combined with GPS-derived mileage and other vehicle data analyzed by fleet management software, they provide managers with valuable insights into fuel consumption patterns and driver/operator behavior trends.

Likewise, GPS tracking data can be used to improve driver safety (and fuel consumption) by identifying and addressing risky driving behaviors, such as speeding or harsh braking.

This can be further enhanced when your vehicles, trucks, and heavy equipment are equipped with road- and/or driver-facing dashcams, allowing for:

- accident prevention through real-time monitoring of road conditions (weather, upcoming stop signs, pedestrians on the road, etc.) and distracted driving behaviors (seat belt, phone use, fatigue) and

- video documentation of incidents and accidents for insurance claims and legal purposes, facilitating faster dispute resolution and reduced liability.

Again, even simpler telematics solutions provide a strong foundation for optimizing fleet operations and can be upgraded over time if necessary.

Ultimately, the range of benefits for your construction fleet will be based on telematics hardware abilities and, maybe more importantly, proper utilization of software features to analyze collected data and extract actionable insights.

Are There Any Drawbacks to Fleet Telematics?

With so many benefits, there are bound to be some drawbacks to fleet telematics.

First, there is the price of full-blown telematics solutions—discussed in the next section—and then there are drawbacks related to technology issues, installation requirements, and privacy concerns.

For instance, GPS tracking of fleet vehicles and equipment collects vast amounts of data about vehicle location, driver behavior, and operational performance.

While this data can be invaluable for improving fleet management, it can also raise privacy concerns among drivers and operators.

There may be concerns about surveillance, data misuse, and infringement of personal privacy rights.

However, GPS tracking of company-owned vehicles is generally legal (subject to local laws and regulations) and any concerns can be properly addressed before introducing the system, as Beverley Wise, director at Webfleet, advises:

In other words, companies should openly address the subject of fleet tracking, and highlight the operational benefits of telematics for drivers/operators, such as:

- less paperwork through automated reporting and logging,

- improved safety through real-time monitoring of vehicle conditions and driving behaviors,

- increased accountability and recognition through performance metrics and incentives tied to telematics data, and

- evidence in case of errors and accidents, and easier insurance claims processing.

Another common issue is the complexity of the technologies involved in creating this elaborate system.

This complexity can lead to challenges in system integration, software updates, and troubleshooting, especially if a company has limited IT expertise.

Furthermore, the installation of telematics devices may or may not require specialized knowledge, depending on the level of telematics system sophistication.

This will depend on a number of factors, such as whether the trackers are plug-and-play or hardwired, powered by a vehicle battery or its own batteries (or even solar-powered), and so on.

In any case, it’s recommended to check the telematics installation requirements and see whether the provider offers installation (assistance) as part of their pricing package or for an additional fee.

Overall, despite these drawbacks, field-tested fleet telematics solutions can provide a significant ROI in the form of streamlined operations and reduced fuel and maintenance costs.

What Costs Should I Expect?

Understanding the costs associated with adopting fleet telematics is essential for budgeting and informed decision-making.

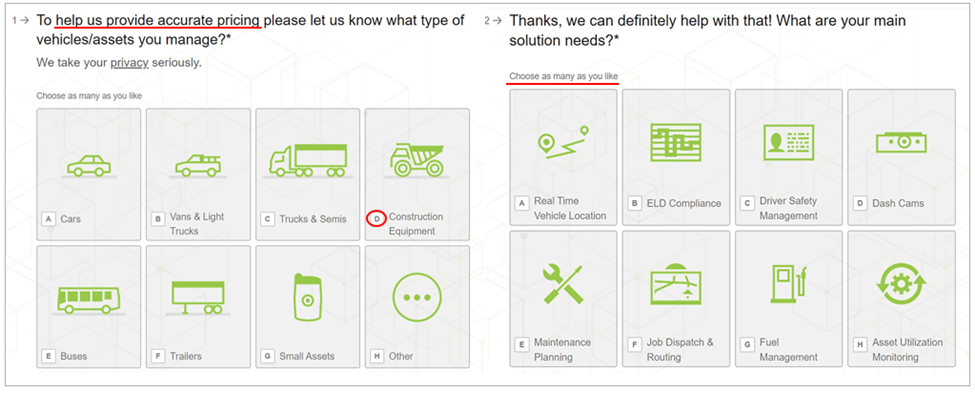

However, specific amounts are hard to come by, as most providers offer quote-based solutions tailored to your requirements.

Typically, the pricing of telematics solutions includes several components, such as:

- hardware costs (GPS trackers, sensors, dashcams),

- monthly/annual software subscription fees (usually including cellular data plans for GPS tracking) per tracker,

- installation expenses (if needed or if not included in the pricing package),

- additional charges for optional features, customization, or integration with other systems.

Very generally, the starting price of various types of telematics-enabled GPS trackers along with fleet management software use is somewhere between $23.50 and $44 per month per fleet vehicle, with varying contract duration (e.g., one, two, or three-year contracts).

Other externally installed sensors and dashcams are typically charged separately, with pricing among providers including different combinations of hardware and software features.

As mentioned, it’s very hard to be more precise because most companies do not list specific prices on their websites, but instead require owners/managers to define their fleet tracking needs, give info, and request a quote or schedule a demo.

While this approach allows for tailored solutions that meet your company’s fleet tracking requirements, it makes it difficult for time-pressed owners or fleet managers to compare cost components across many similar providers.

In such cases, the most optimal solution may be to create a shortlist of potential telematics providers based on online research and contact them via email with a long list of specific questions about different pricing options.

This way, you can assess what features you need and want to pay for, and what features are superfluous or too pricey for your budget.

At this time, it’s also good to look for alternative, simple, and more affordable asset-tracking solutions your provider offers that can complement your telematics system.

An additional bonus is that, by doing this, you’re also assessing the quality of your potential provider’s customer support, which can be essential later in case of technical difficulties during implementation.

By insisting on transparent pricing and leveraging free demos and consultations, you can get a clear idea of what costs you can expect and make informed decisions.

Can Telematics Be Integrated with Other Systems?

Yes, fleet telematics can and should be integrated with other systems if they’re not already part of a comprehensive fleet, asset, and inventory tracking and management system.

In other words, fleet telematics (trackers and sensors) focuses on trucks, vehicles, and yellow iron.

However small and affordable, such devices are generally still too large and too expensive to be fitted on all the other equipment and tools, IT devices and instruments, PPE, spare parts, and other inventory supplies a typical construction company uses in its operations.

Therefore, one of the key integrations of fleet telematics involves establishing an overall asset tracking and management solution.

This consists of using unique asset identifiers, such as barcodes, QR codes, or RFID tags, that are attached to all items you want to track regardless of their size and value.

For example, our end-to-end asset tracking solution, GoCodes Asset Tracking, relies on patented QR codes that, when scanned, instantly take the user to the software’s list of all assets (database) and that asset’s individual info page.

This tracking and management system is so simple and affordable that telematics providers are using QR codes to keep track of their trackers and other devices.

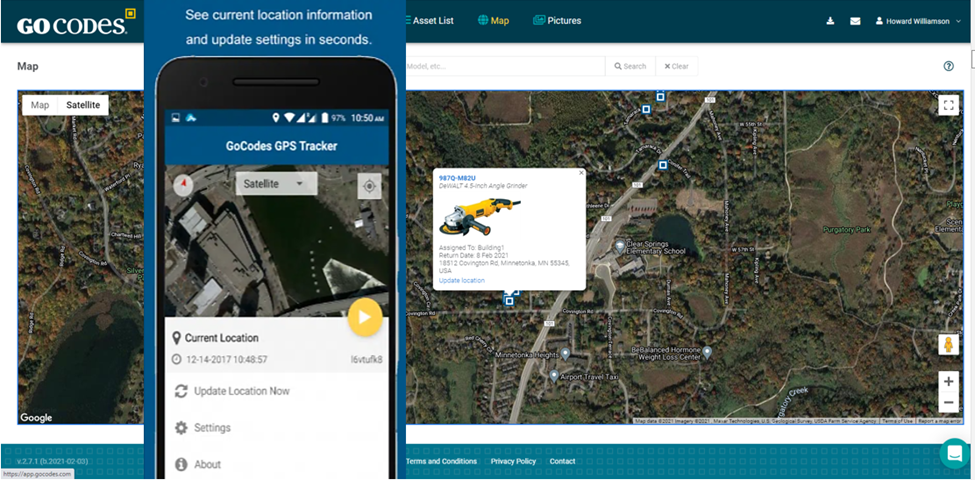

Our QR codes and tracking software also provide one telematics feature, namely scan-based GPS location tracking.

More precisely, when someone scans an asset’s QR code tag, the software will use the scanning device’s GPS location to determine and record the asset’s location.

Although this is not live GPS tracking, regular scanning of equipment and tools when checked in and out or their kitting when transported to jobsites can provide near real-time, comprehensive visibility of all your construction assets.

It also provides you with a central database of all assets, their most recent location, current and past users, and asset maintenance status.

This gives rise to many features that enhance fleet management even without real-time GPS trackers and telematics, such as:

- scan-based GPS location updates,

- automated asset check-in/check-out,

- maintenance tracking and scheduling,

- inventory tracking and management,

- alerts for scheduled maintenance, checked-out asset returns, and low inventory levels.

Other than hardware additions (tags) for asset and inventory tracking, another key area of your telematics system’s integration capabilities is its connectivity and interoperability with other software systems.

These integrations can be application programming interfaces or APIs (free or charged separately) that enable communication and data exchange between different software solutions.

Depending on your other software systems and the telematic provider’s integration options, this may require some programming expertise.

They can also come as plug-and-play integrations for popular software products, such as various construction project management and accounting software platforms.

When integrations are done right, project managers can use telematics and asset-tracking data to plan projects, estimate costs, and establish budgets and schedules.

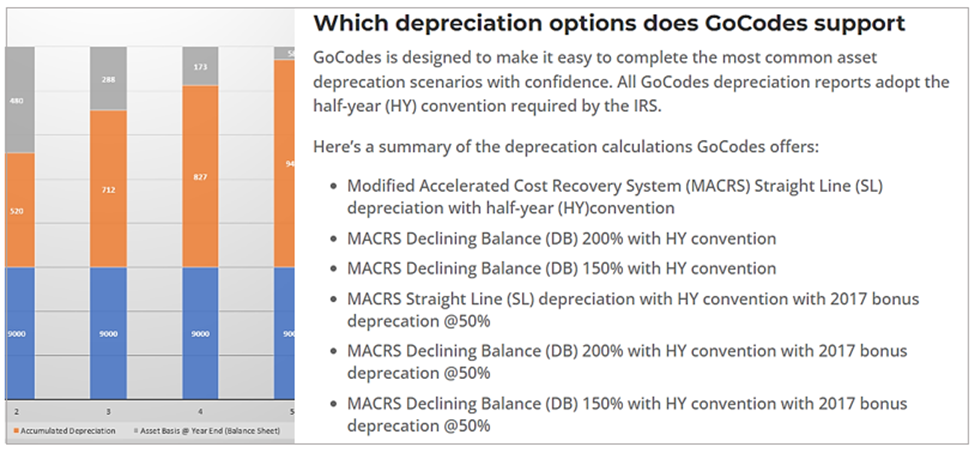

Likewise, accountants can pull updated data on fleet fuel consumption, maintenance costs, and utilization trends for regulatory compliance, depreciation, financial reporting, and tax purposes.

The best course of action with regard to fleet telematics integrations is similar to finding specific pricing and involves online research and a list of integration questions for short-listed telematics vendors.

In summary, interoperability with other systems is a prerequisite of an effective telematics system because the right hardware and software integrations can unlock the full potential of many telematics benefits we mentioned.

Conclusion

In closing, we can conclude that fleet telematics offers construction companies a powerful toolset for enhancing operational efficiency, improving security and safety, and reducing costs.

While navigating the complexities of telematics systems, from understanding various hardware options and pricing structures to integrating with other software solutions, may seem daunting, the potential benefits we outlined far outweigh the challenges.

By embracing telematics and leveraging its capabilities, construction fleet managers can propel their businesses toward greater productivity, profitability, and success in the modern digital age.