Staying on top of your construction inventory—especially as your business grows—is no easy feat.

You need to make sure that your valuable tools are in the right location, your machinery is in good health, and your materials and consumables are at optimal levels.

As you might already know, trying to juggle all of that manually isn’t the best course of action.

Luckily, there are now construction inventory management solutions available that can make these complex, but important tasks a breeze.

In today’s article, we’re discussing some of the biggest benefits that such software carries, so stick around and find out why it’s worth the investment.

In this article...

Enhances the Tracking of Valuable Inventory

It goes without saying that your construction site is full of valuable inventory: from expensive tools and heavy machinery to materials and consumables.

It also goes without saying that the last thing you want is for any of it to get lost or stolen.

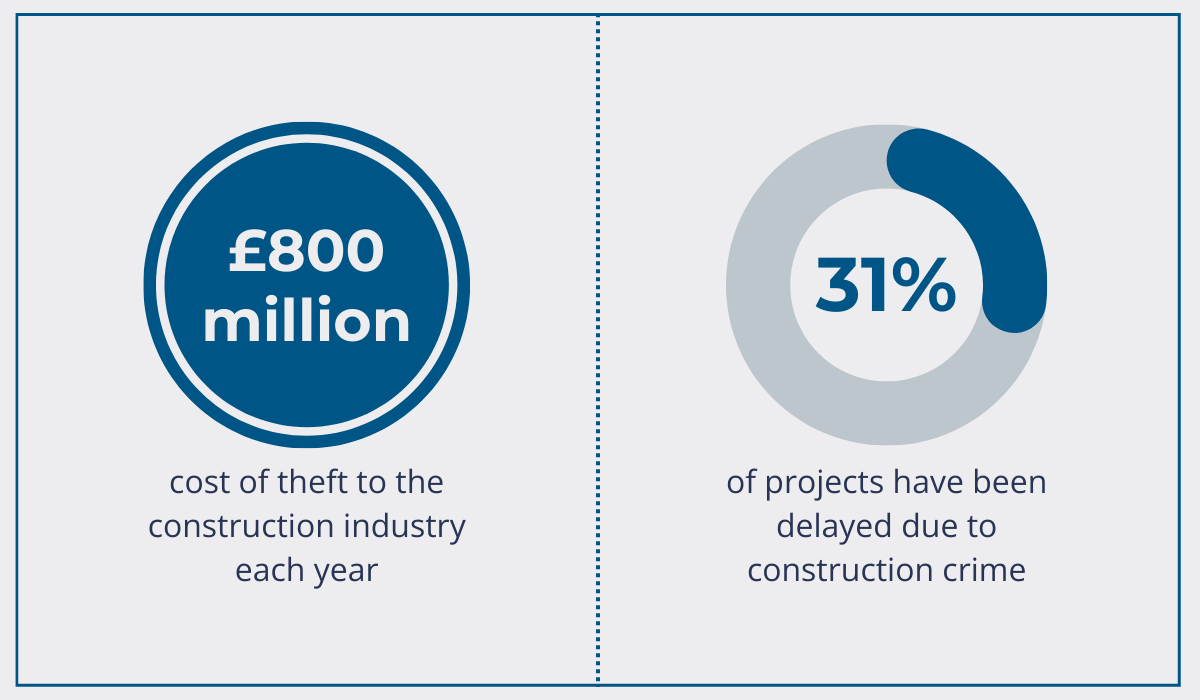

Yet, studies show that construction site theft is on the rise.

According to the BauWatch 2024 Construction Crime Index, 62% of the surveyed construction site workers stated that construction site theft has increased in 2023, and around 70% witnessed theft on the construction site at least once a year.

Therefore, it is not surprising that victims of construction site theft are suffering severe financial losses and project delays that make it difficult to meet project deadlines.

These concerning numbers probably have you wondering, “What can I do to make sure this doesn’t happen on my construction site?”

The answer is simple: you need to vigilantly keep track of your inventory.

And when we say “keep track”, we don’t mean “create an inventory list.”

Instead, consider investing in construction inventory management software.

This kind of solution comes with specialized features allowing you to track—among other things—where your inventory is and who is using it.

To illustrate how exactly this works, we’ll use our own software, GoCodes, as an example.

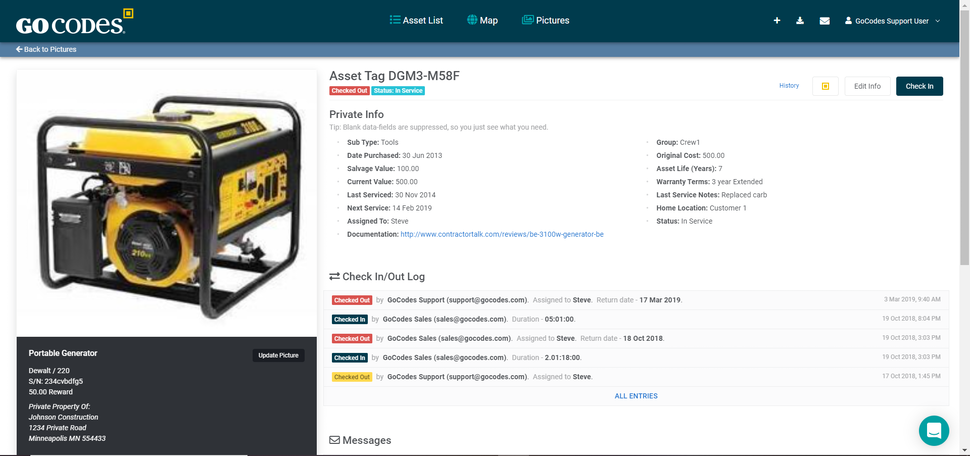

GoCodes is an asset tracking and management software that allows you to keep track of your valuable inventory using QR code technology.

The process is simple: any piece of inventory you want to track first needs to be entered into our cloud-based system.

Then, affix a QR code tag onto each one. GoCodes offers a variety of label options, making it possible for you to choose the best type depending on what kind of inventory you want to track.

From that point on, all your crew members need to do is scan the QR code using our in-app scanner each time they want to check in or check out a tagged asset, or simply pull up information about it.

Being diligent about this will create a comprehensive log of inventory movement.

Let’s say one of your handheld power tools has been misplaced.

All you have to do is access your GoCodes Asset List and look up the tool in question in order to find out when it was last used, at which location, and by whom.

This makes it infinitely easier to figure out where the tool might be.

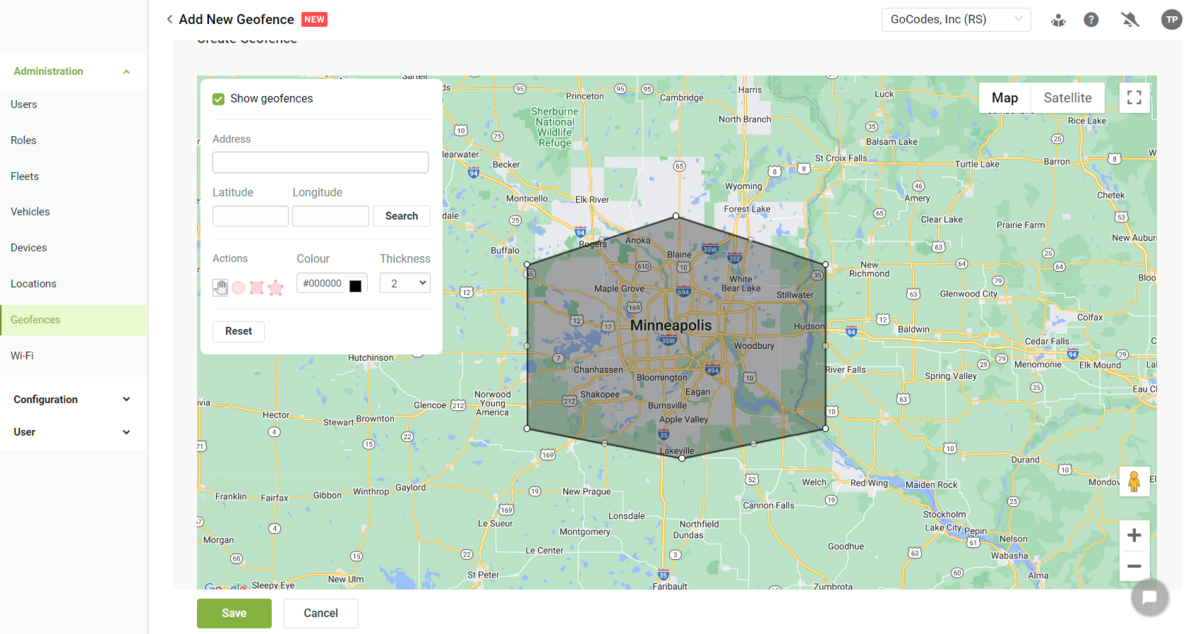

GoCodes now also offers real-time GPS trackers, making it possible for you to continuously monitor your inventory.

This new feature allows you to select an area in which inventory is expected to be for a prolonged period of time and set up a geo-fence around it.

In the event that the tracked inventory leaves the area, you will be alerted immediately, thereby increasing the odds of asset recovery.

In short, using construction inventory management software to track your inventory can make loss and theft-related issues a thing of the past.

Knowing exactly where your assets are at all times will prevent project delays and budget overruns, but also provide you with peace of mind.

Enables Inventory Management Across Multiple Job Sites

Managing your inventory on a single construction site is a complex task.

For starters, you need to tackle the material procurement process, which involves identifying potential suppliers, obtaining quotes, negotiating prices, and finally, getting the materials delivered to the site on time.

Given the constantly fluctuating prices of various materials and uncertainties regarding their availability, this can be quite stressful.

On top of that, you also need to make sure that all of the tools and equipment needed for the project are available and in good working condition.

Now, imagine having to manually coordinate all of that, but across multiple job sites.

Chances are, these tasks would quickly become impossible to juggle.

This is precisely what makes inventory management software such an indispensable tool, explains Daniel Chlad, Global Head of Logistics at MEGATECH Industries.

This kind of solution is going to facilitate a centralized approach to construction inventory management, making it easy for you to stay on top of all the moving parts involved in managing multiple construction sites at once.

Unlike manual methods, using this software will provide you with a holistic view of all your materials, tools, and equipment, which makes decision-making and inventory allocation a breeze.

Let’s say your construction company is about to take on a new project, alongside the two already in progress.

With robust inventory management software at your disposal, you can easily check where exactly your tools and machinery are, and when they’ll be available for you to assign to the new project.

You can also look into the material inventory levels at the two active sites and determine whether there is a potential overstock that you could transfer to the new site.

With an inventory management solution, coordinating all of this and communicating it to the relevant stakeholders is no longer arduous, time-consuming, and error-prone.

Once the tools, equipment, and materials are transferred to the new site, the crew simply needs to scan the attached QR code labels, indicating that the inventory has been received successfully.

This eliminates the need for manual data entry and any miscommunication regarding the inventory transfer status.

As you can see, managing inventory across multiple job sites requires a lot of alignment and many moving parts, which can quickly become overwhelming.

However, it becomes infinitely more manageable with construction inventory management software at your fingertips.

Allows You to Track Maintenance Needs

Construction inventory maintenance is a big part of inventory management, no doubt about it.

After all, only inventory that is in good mechanical health can be allocated to construction projects.

That is why it’s important to not only stay on top of your asset maintenance, but also diligently keep track of all maintenance-related activities.

So, does this mean you should invest in a separate maintenance tracking software?

Well, not necessarily.

Plenty of construction inventory management solutions can handle both inventory management and maintenance tracking.

Wayne Newitts, VP of Marketing at Logiwa WMS, an AI-powered fulfillment platform, believes that such a holistic approach is better anyway:

Having a complete overview of your inventory and its maintenance past and future all in one place carries a plethora of benefits.

For starters, it helps you optimize the way you prioritize maintenance, thereby making sure that you avoid project disruptions because a key piece of inventory is being serviced.

Let’s say that, according to inventory management software entries, an excavator is due for maintenance in 2 weeks, but is also scheduled for extensive use on an important project during the same time.

Having this information at their disposal, the manager can reschedule maintenance for an earlier date, thus ensuring that this avoidable project disruption is prevented.

Simply put, keeping track of maintenance within inventory management software will allow you to better plan and schedule the usage of tools and equipment.

That way, these key inventory types will always be available exactly when needed.

No unexpected delays, and no budget overruns.

Mika Majapuro, VP of Product Management & Strategy at Railinc Corp., says:

In short, opting for construction inventory management software that has maintenance tracking features is essential for making sure your inventory remains in good mechanical health, and your projects always stay on track.

Helps Prevent Inventory Shortages

But project delays can occur for reasons other than less-than-ideal maintenance timing.

Some, like adverse weather conditions, are out of your control.

But others are entirely preventable with the help of construction inventory management software.

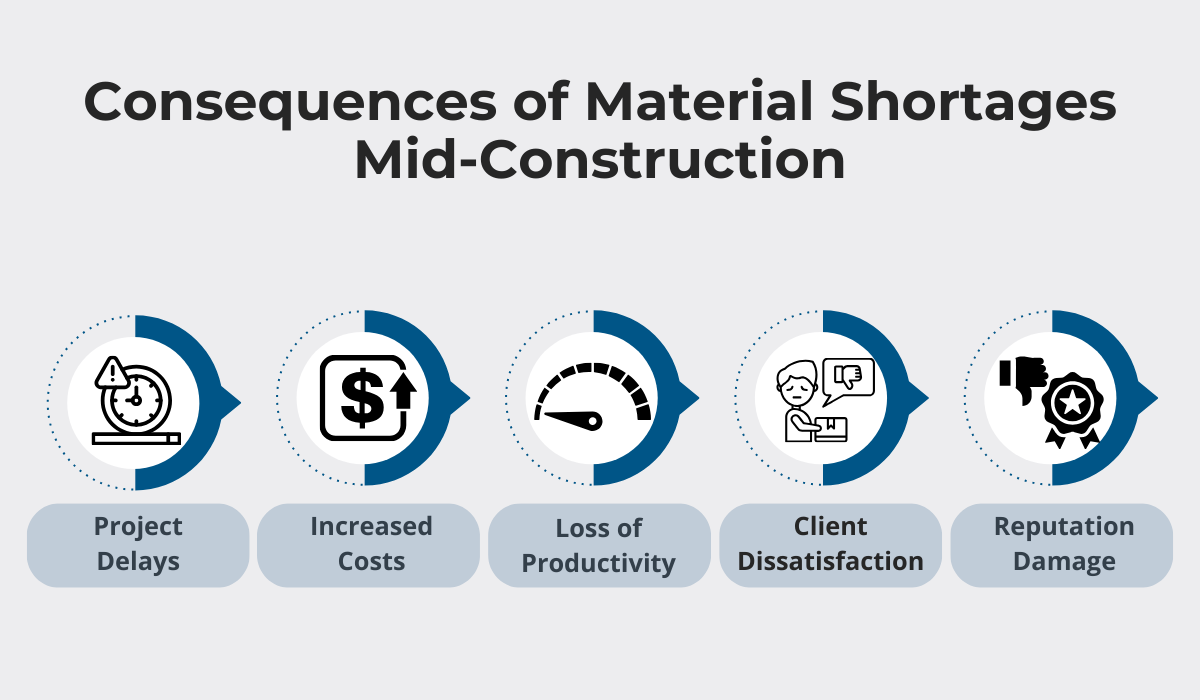

One such example would be delays caused by suboptimal inventory levels.

Picture this:

Your crew is in the middle of a project, and the project manager calls to inform you that they’ve run out of a specific material due to unexpected rework.

They’ve already gotten in touch with the supplier, but have been informed that there is a shortage of this material on the market, so it is going to take some time for it to be replenished.

Yes, you can call around and try to find an alternative supplier, but chances are, they won’t be able to provide it either.

Or they will, but at a much higher price.

Whatever the case may be, you’re sure to suffer the consequences.

The good news is, however, that experiencing unexpected material shortages mid-construction can easily be remedied by implementing an inventory management solution.

This kind of software not only provides you with real-time visibility into your inventory levels, but also often comes with a low stock alert feature.

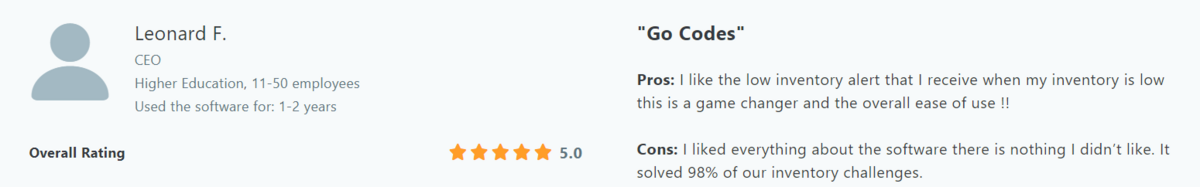

Our GoCodes is an example of such software.

Among other features—like inventory and maintenance tracking—it allows you to enable the ‘Inventory Quantity Tracking’ and ‘Low Inventory Quantity Notifications’ features.

As their names suggest, these features are there to help you track consumable inventory levels and receive notifications when a specific inventory type is low in stock.

As you can see in the screenshot below, you can enter how many pieces of specific inventory type you own, and what the acceptable minimum quantity is.

Once you hit that threshold, you’re going to receive a low-stock alert, letting you know it’s time to get in touch with your supplier and order some more.

That way, you’ll never have to worry about finding out you’re low on an important inventory type when it’s already too late.

According to our clients, this feature is truly a game-changer:

So, if you’ve been manually tracking stock levels for individual pieces of inventory, now is the time to change that.

Investing in construction inventory management software that boasts this feature is going to provide you with peace of mind and help you avoid the uncomfortable consequences that come with unexpected inventory shortages.

Supports Business Growth

As a construction company owner, we believe that one of your biggest goals is to grow your business and maintain its success.

But as your business grows, so does the number of projects you’re able to take on, and, consequently, the amount of inventory you own.

When you’re first getting started and you have fewer assets, using run-of-the-mill spreadsheets for inventory management can work just fine.

But the more tools and equipment you invest in, and the more you feel the need to stock up on basic materials and consumables, the more difficult spreadsheet tracking gets.

Why?

Because spreadsheets aren’t built to grow together with your company.

The review you can see below testifies to that.

This user experienced sudden growth that spreadsheets couldn’t follow anymore, prompting them to invest in an inventory management solution.

Unlike spreadsheets, such solutions have the ability to accommodate the needs that come with business expansion.

Let’s illustrate with an example.

Say your company is handling 2 similar-sized residential projects at the same time.

Naturally, one of each of the key assets won’t be enough if you want to meet the project deadlines, so you’ll have multiple instances of various tools and heavy equipment.

With inventory management software at your disposal, you’ll have a clear overview of exactly where each one of them is, who it’s being used by, and when it will become available again.

Simply put, you will no longer have to waste time looking through spreadsheets scattered around different folders, trying to figure out which one of your identical excavators is the one that needs maintenance.

Tony Simonsen, COO of Payapps, sums it up well:

“Spreadsheets serve their purpose and can be functional for construction companies, but they are also very limited in their ability to accurately log and track important and actionable data. In addition, using spreadsheets can lead not only to error rates but lack of visibility, lack of consolidation, lack of consistency, and lack of control.”

On top of providing you with better visibility into your inventory and easier resource allocation, using construction inventory management software also provides you with invaluable data and analytics.

Steve Cangiano, Product Manager at construction software provider CMiC, explains that it is difficult to extrapolate data that can help improve future projects when it is stored in spreadsheets.

So, the verdict is clear: inventory management software is bound to become an indispensable part of your tech stack once your construction business starts growing.

It is going to seamlessly adapt to your growing needs, so don’t underestimate its importance.

Conclusion

It is safe to say that construction inventory management solutions have the power to turn time-consuming, error-prone, and challenging tasks into easily manageable ones.

From enhancing the way you track your inventory, to keeping track of its maintenance and preventing inventory shortages that can bring about serious consequences, inventory management software is sure to become an indispensable tool for every construction company, big or small.

So, if you’re looking for a well-rounded solution that will provide you with a holistic view of your inventory’s levels, locations, and status, look no further—this is the kind of software you need.