QR codes have become an increasingly popular asset management solution in recent years, and for good reason.

They are cost-effective, efficient, and easy to both implement and use.

What more could you possibly need?

So, if you’ve been considering introducing QR codes to your company but don’t really know where to start, this article is for you.

In this article...

Get Buy-in From Your Team First

Before you even begin implementing QR codes in your company, it’s paramount that you get the whole team on board with this new system first.

Otherwise, to put it bluntly, you’ll be just wasting your money.

If you don’t get buy-in from the crew, the best-case scenario you’re looking at is this: they use the solution inconsistently for a couple of months before abandoning it altogether.

Unfortunately, the construction industry is still known for its if-it-isn’t-broken-don’t-fix-it attitude when it comes to embracing new technology.

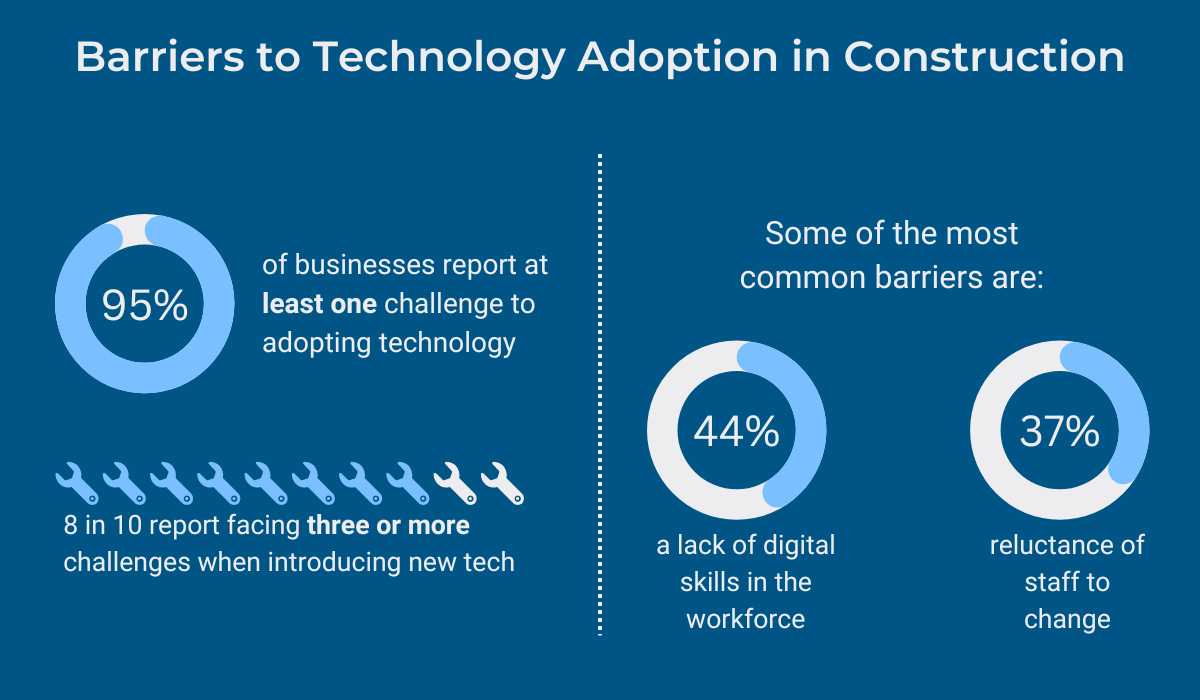

That’s why Autodesk, in tandem with Deloitte Access Economics, set out to explore the barriers that prevent businesses from looking into technological solutions when they have been proven time and time again as beneficial.

As expected, the majority of the companies reported experiencing challenges with tech adoption, mainly due to a lack of digital skills among employees, uncertainty about the required technical abilities, and reluctance of staff to change.

In essence, workers don’t know what to expect from those modern tools and therefore fear that using them will create more problems than they’re worth.

Your job is to convince them this is not the case.

Luckily, QR codes have been around for a while, so people got used to them and understand how they work, at least to some extent.

What’s more, these systems are already the asset tracking solution of choice for many businesses across different industries precisely because of their user-friendliness.

So, it should not be too difficult to persuade the team to adopt this technology.

Nevertheless, it’s essential to clearly communicate why the tool is being introduced and how it can help resolve some of the issues within the company. They need to recognize its benefits.

Once they do, you can move on to the next stage: searching for a label provider.

Partner With a QR Code Asset Tag Supplier

Yes, it might be tempting to immediately start printing out your own labels on the good old LaserJet printer.

How hard could that be anyway?

We’re here to warn you to be careful with this approach because its end result, unfortunately, may not meet your expectations.

For starters, printing and designing the labels takes time.

Do you really want to be wasting yours on such tasks?

Let somebody else take care of it instead.

More importantly, DIY QR code labels are usually lower quality, peel off over time, and are highly susceptible to abrasion and water damage, which is no good, especially for harsh environments typical for the construction industry.

On the other hand, our GoCodes labels and tags are built to last, no matter the conditions or asset type you decide to use them for.

Whether you need a light-duty poly label or a rugged tag, we have a variety of options available, all of which can be customized with your desired information, including the company name, logo, phone number, or email.

Even if you’re unsure what kind is right for you, don’t hesitate to reach out. Our team will provide a recommendation based on years of experience.

If you’re considering GoCodes labels and would like to see them for yourself before making a decision, we’d be happy to send you a complimentary sample.

Click here to learn more and order yours.

Develop an Onboarding Plan

Officially choosing a vendor means it’s time to start preparing for system utilization and create a detailed onboarding plan.

Remember, getting buy-in from the team is one thing, but ensuring the implementation procedure runs smoothly is completely different.

This is where the onboarding plan comes in.

Its role is to clearly define the expectations for this new tool as well as establish roles and responsibilities for everyone involved in the process.

Cameron Page, the CEO of Extracker, highlights setting clear objectives as the starting point in successful technology adoption.

In other words, you must first determine what an ideal system deployment would look like for you.

What goals do you wish to achieve, and by when?

Next, you need to assign a subject matter expert who will be responsible for driving the implementation process and serving as a point of contact with the label provider.

Once you have identified success metrics and appointed the internal expert, you’ll have a solid foundation for QR code implementation and be ready to move on to the first project, where you’ll actually get to see the new tool in action.

Start With a Pilot Project

It’s important to ease the employees into the whole thing and start small.

Don’t immediately introduce QR codes across entire job sites, but rather begin with a smaller pilot project involving just one crew or project team.

This will allow you to test workflows and straighten out any issues should they arise, making the transition easier for everyone involved.

Think of it as a sort of experiment in which you get to assess the effectiveness of asset labels and see if they are a good fit for your workers.

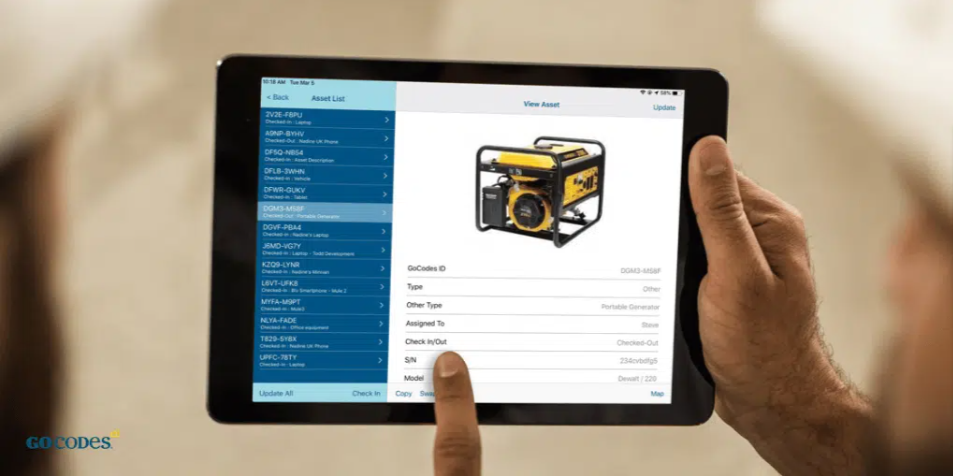

This is a perfect opportunity to let them get accustomed to using QR codes for tool check-in or check-out, updating equipment information, or simply viewing asset data and utilizing it in their daily tasks and duties.

The system is user-friendly, but it’s also quite versatile, so don’t get discouraged if you encounter some minor kinks that need ironing out along the way.

After all, that’s precisely what this phase is all about.

Once you detect and address all the potential obstacles, you can be confident that the tool can now be adopted by the rest of the team.

Train Your Team on How to Use QR Codes

No matter how uncomplicated a piece of technology seems at first glance, it’s always best to properly train your team on how to use it.

Through training, employees get to fully experience the advantages of the system, gain knowledge about all of its features and intricacies, and, ultimately, become QR code expert users.

Tim Kowalski, HAMM application support manager at Wirtgen America, believes that without proper education, adopting new technologies is impossible.

Moreover, he notes that this is often the turning point at which workers realize that the new tool can actually help them do a better job.

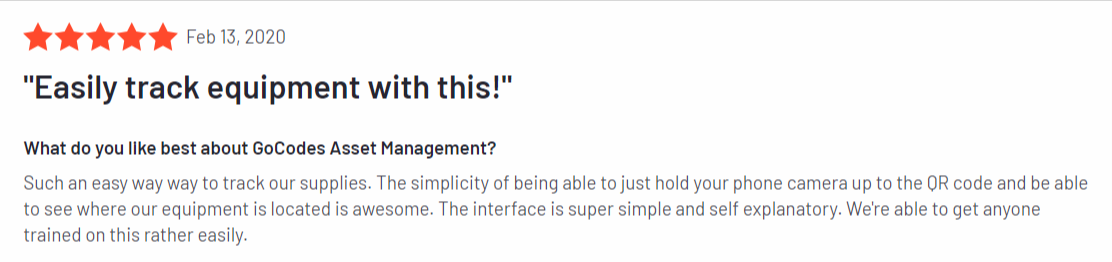

At GoCodes, we take pride in developing a solution that is easy to use, even for those who may not be tech-savvy.

This is what sets us apart from the competition.

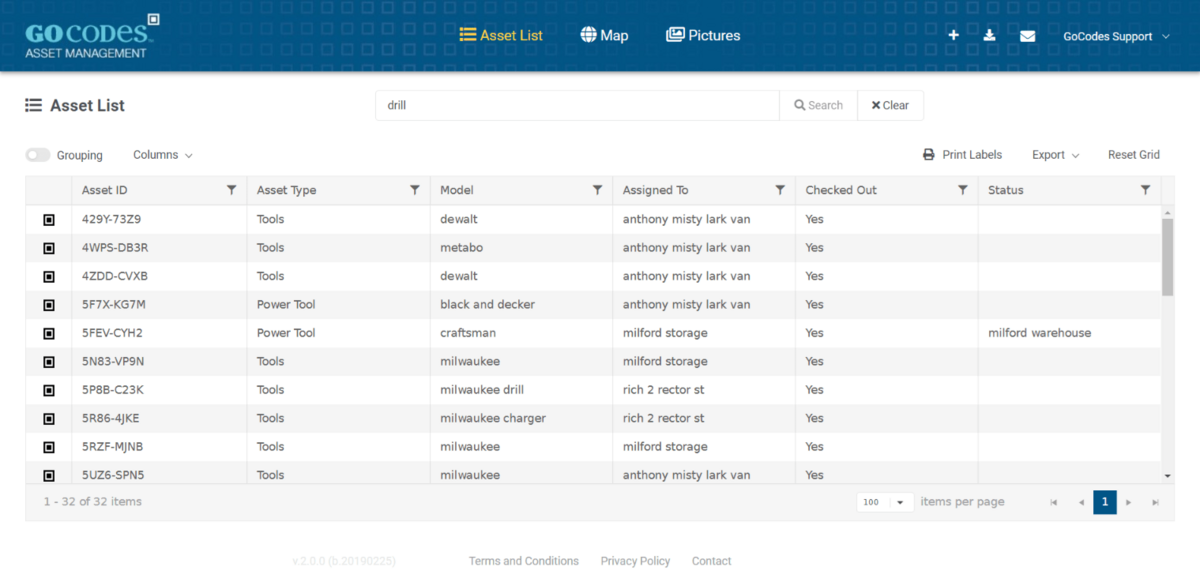

Anything from equipment checkout and safety audits to updating asset location and planning out heavy machinery maintenance can all be done quickly and easily with GoCodes QR code labels and asset tracking software.

However, we also recognize the importance of efficient training.

That’s why, on our website, you can find short video tutorials featuring step-by-step instructions with screenshots for different tasks and processes, including using our smartphone app, enterprise reporting, inventory management, and more.

Not only are these videos useful for educating new users, but they can also be valuable for workers who have been using GoCodes for a while and need to refresh their memory on some of our features.

All in all, if you make sure your team knows all the ins and outs of the QR code system, you can be sure they’ll feel more comfortable and motivated to use it, which will ultimately increase the chances of the codes’ successful implementation within your company.

Assign Responsibilities to Your Team

Every employee on the team has a role to play in the successful adoption of a QR code-based solution, but it’s up to you to assign these roles and make sure everyone’s sticking to them.

Otherwise, the system won’t work.

To elaborate on this, let’s consider a specific example.

When you tag your equipment with QR code labels and begin scanning them with a dedicated app, you get insight into a plethora of valuable asset data, such as for instance:

- Date of purchase

- Original cost

- Current value

- Warranty terms

- GPS location

But where does all that information come from?

It certainly doesn’t magically appear on its own. Someone has to input the asset list into the system first.

In other words, it’s necessary to pick a person who’s going to handle the so-called behind-the-scenes tasks and manage the asset data so that the QR codes are always up-to-date and accurate.

After the worker in charge sets up the account and adds assets to the software, it’s then up to the rest of the team to remain consistent in actually using it.

If the workers won’t use the tool checkout system routinely, or if the maintenance department won’t utilize the service scheduling features, then there’s really no point in introducing QR codes at all.

All employees must be held accountable and understand the significance of their part in making this technology effective.

As they become more accustomed to their responsibilities and to the new tool, they will gradually start to see its benefits, too.

Evaluate the Effectiveness of QR Codes

After using QR codes for some time, there should be a noticeable improvement in the overall operational efficiency within the company.

If not, the chances are you’re doing something wrong.

In any case, it’s essential to periodically evaluate the effectiveness of the system and to measure the new tool’s performance in order to see if it’s meeting all your expectations.

One way to do this is by asking the workers for feedback.

After all, they are in the best position to describe what they like and what they don’t like about using QR codes, which can then empower you to make appropriate changes and improve their experience.

Another method of evaluating the efficacy of the tool is to let it demonstrate its performance on its own.

What do we mean by that?

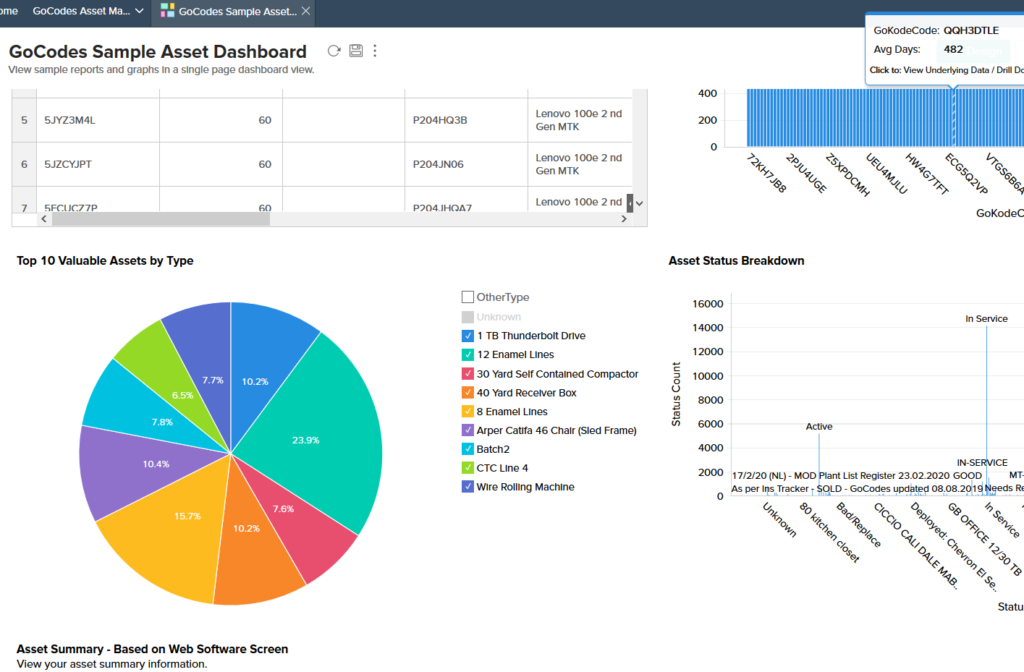

By coupling QR codes with asset tracking software, users can access a range of helpful tools designed to track key performance metrics (KPIs) like equipment utilization, maintenance costs, unplanned downtime rates, and other vital productivity indicators.

Reports and analytics features then present this data in a clear and understandable manner, providing a full and unobstructed view of the company’s operations.

This is the most efficient way to find out whether or not the system is getting you where you want to be, as it relies on objective facts and figures rather than personal opinions.

Conclusion

Overall, implementing QR code asset tracking may require some effort and convincing, but the long-term benefits are definitely worth it.

By taking a slow and steady approach, keeping your team in the loop during important decision-making, and partnering with a reliable label provider, you can seamlessly integrate QR codes into your business processes and reap the rewards.

So, why not give them a try and see how they can benefit you?