Do you feel like asset record keeping and organization are getting harder each day? Does the mere thought of the audit season give you a headache?

It doesn’t have to be that way. In fact, there’s a simple solution for all your asset monitoring issues. It’s called asset tracking software.

The software, with its check-out/check-in feature, does so much for your company’s efficiency and overall success, while also being easy to use.

If this sounds like something that could be helpful to you, keep on reading, and you’ll find out exactly how asset tracking software can improve and bring value to your business.

In this article...

Can Be Used on the Move

When we think of construction, our minds don’t usually go to an image of a quiet office setting.

No, we think of construction sites—hectic, action-packed places, where workers are always on the move.

The tools used for construction work need to reflect that. You need to be able to use them on the go.

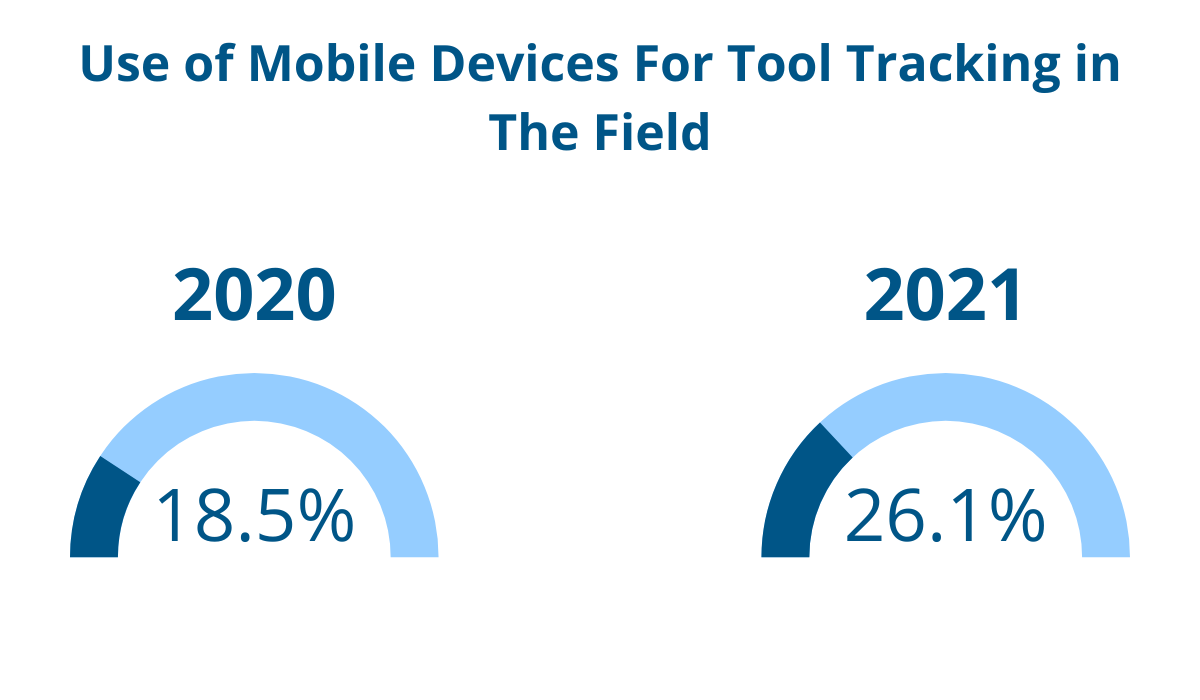

This also pertains to digital tools, including your asset tracking system. That’s why we see a rise in different automated asset tracking solutions.

Manual asset tracking simply isn’t as efficient in this regard.

Paper forms and spreadsheets were not designed for asset tracking, especially in the construction industry, where everything is subject to sudden change.

And failing to report that change can cause all sorts of issues.

Let’s say that during their shift, workers notice that a particular tool is broken. Ideally, this would be reported immediately.

However, without a mobile asset tracking solution in place, any change in assets’ data cannot be reported or recorded momentarily.

Instead, the worker will probably need to wait until the end of the shift to do so.

However, it’s highly likely that the worker who was supposed to use it will forget to report the issue, and the rest of the team will continue operating based on the assumption that the tool is available, which could potentially cause significant project delays and a decrease in productivity.

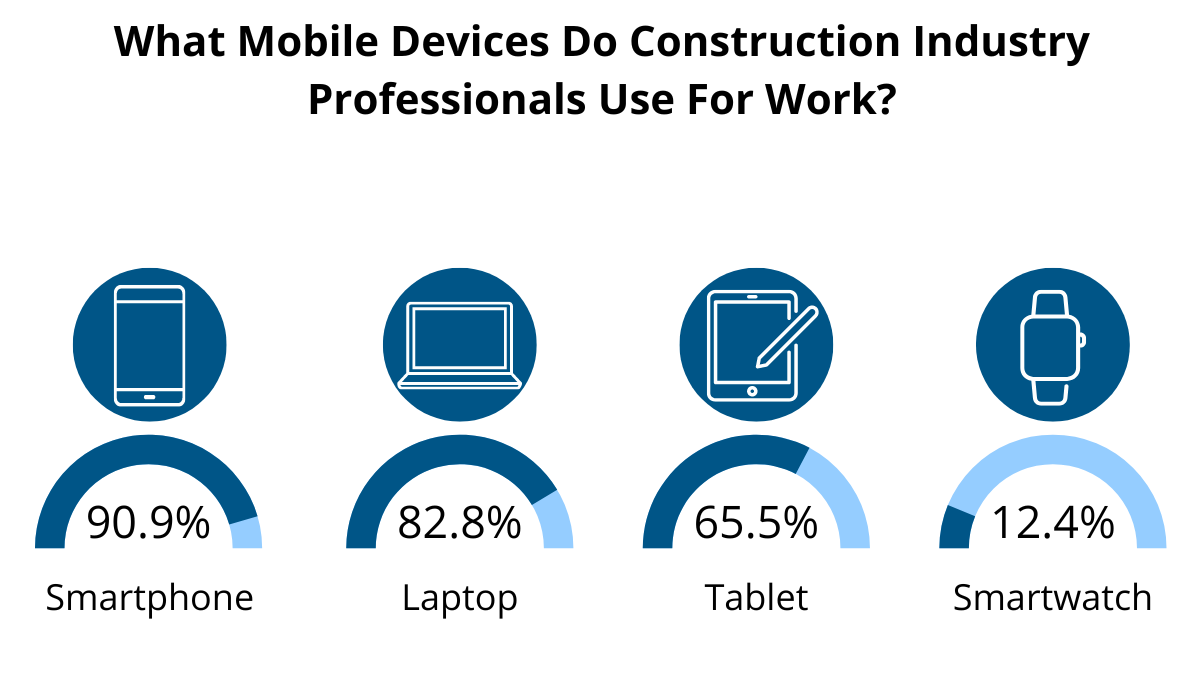

Luckily, construction professionals are realizing the importance of mobile devices and the positive impact they have on the overall workflow.

According to JBKnowledge 2021 Construction Technology Report, over 90% of respondents from all facets of the industry reported using smartphones for work purposes on a daily basis.

Asset tracking software is designed with the construction industry’s growing appreciation for new technology in mind and is available as apps on both Android and iOS that can be downloaded on mobile devices, such as smartphones and tablets, and used to check an asset in or out on the go.

Conducting equipment check-in and check-out is easy and flexible with asset tracking software, so it comes as no surprise that we see a rise in the application of this technology in construction.

It truly does wonders for job site productivity and coordination.

Provides Up-To-Date Asset Locations

Since asset tracking software can be used on the go, it provides you with real-time asset location data.

And asset location tracking is a must, especially for asset rich-companies.

The more tools, materials, and equipment you own, the easier it becomes to lose track of it all.

And not being able to keep track of your assets’ whereabouts directly translates to a whole myriad of negative consequences, such as unproductivity, project delays, revenue loss, and potential reputational damage.

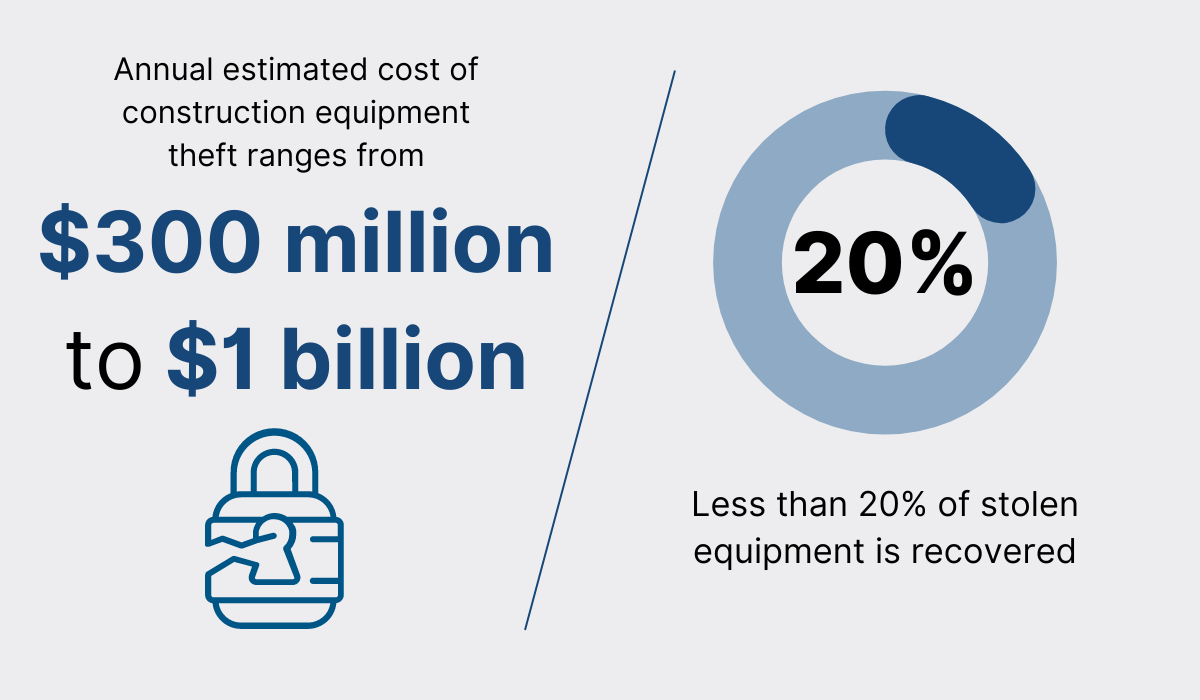

Ineffective or lacking location tracking also translates to an increased risk of equipment theft, which is already a major issue in the construction industry.

And if you think it won’t happen to you, think again.

Your equipment is nine times more likely to be stolen than vandalized and five times more likely to be stolen than damaged in a fire, according to the National Equipment Register (NER).

Asset tracking software, such as our own GoCodes Asset Tracking, is a perfect remedy for these issues precisely because it provides up-to-date information on where the asset is.

GoCodes Asset Tracking shows you the last known location on a map and updates this information each time an asset is scanned for check-out or check-in.

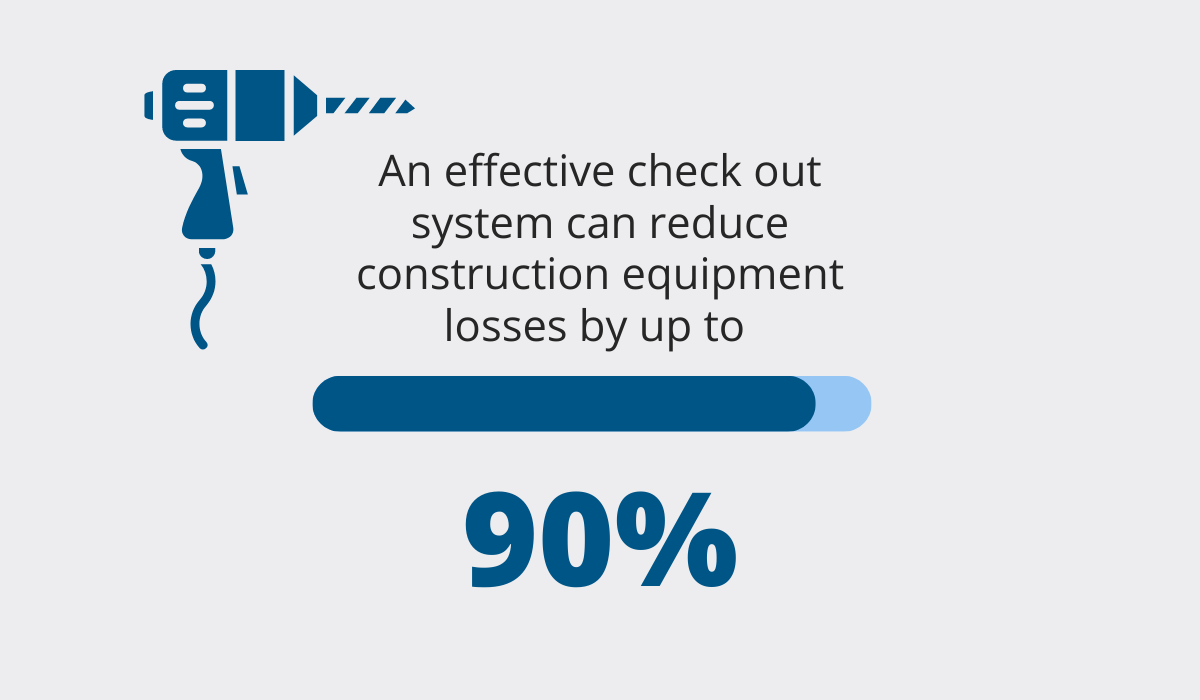

This is very effective in preventing tool loss. In fact, did you know that implementing a check-out system can reduce tool losses by 90%?

This alone is reason enough to start using asset tracking software today.

Increases Employee Productivity

The transparency that comes with the check-out system causes a significant increase in employee productivity.

This is a huge benefit, considering how much time and money is wasted in the construction industry.

According to a report by Autodesk and consultancy FMI Corp, the cost of unproductive labor in 2018 was around $177.5 billion.

In the report, it was concluded that industry professionals spend 35% of their working hours on non-optimal activities.

That’s 14+ hours per person and per week that could be spent on more pressing tasks.

What’s more, out of those 14 hours, almost 4 hours are spent on dealing with mistakes, and 5.5 hours are wasted looking for data and information, asset location information included.

All things considered, if you’re aiming to improve job site productivity, you absolutely need accurate data.

And that’s exactly what you get when you use asset tracking software for equipment check-out and check-in.

With the software, you have all the relevant data, such as asset location and availability, at your fingertips.

As a result, non-optimal activities like unproductive walking, searching for tools, or waiting for equipment to be available are significantly reduced.

Instead, you and your team can focus on doing more meaningful tasks.

Makes Employees More Accountable

The capabilities of an automated asset check-out system reach far beyond just showing you where your assets are located.

The software also provides insight into who’s using which asset at any given moment.

Naturally, this has a considerable role in increasing your employees’ accountability.

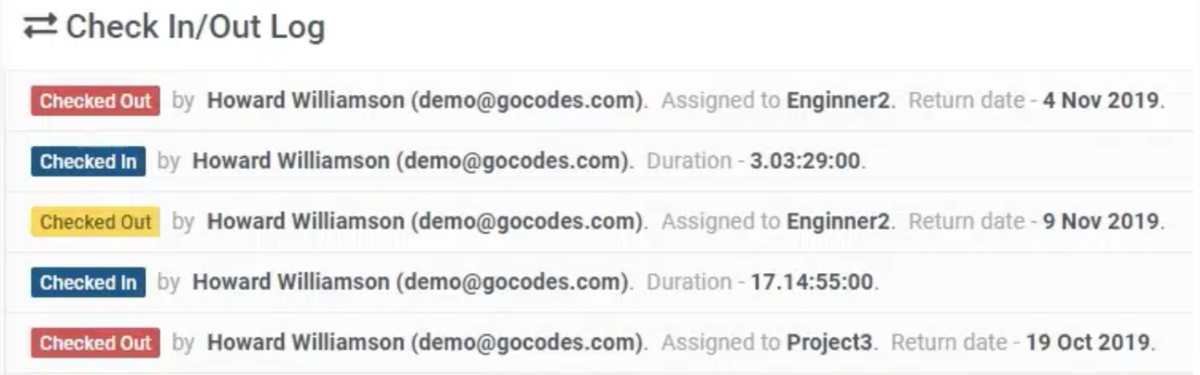

Once the update is made, it can no longer be altered or lost, meaning you always have accurate information about who the last person was to use a tool, and the condition the tool was in when it was returned.

You can also go back and look at the check-in/check-out log to see the history of an asset’s usage.

Another great thing about asset tracking software is that it allows you to choose an employee and assign a particular asset to them.

That way, everybody knows who’s responsible for that item.

Then, you can also add a return date, letting your team know when that particular piece of equipment will be available for use again.

Some solutions will also send you email notifications for overdue asset check-out if the asset isn’t returned on time, which increases employee accountability even further.

No more assets being left at a job site. Instead, you can be sure you’ll find them where they’re supposed to be, just when you need them.

Naturally, the purpose of all of this isn’t to simply control your team or make their job harder.

Greater employee accountability is a prerequisite for safer and more productive job sites. It decreases the risk of theft and loss as well as prolongs assets’ lifecycles.

Maintains an Accurate Asset Record

Using the check-out system consistently over time generates an accurate, up-to-date asset portfolio.

Each time somebody checks out an asset, the location, time, and date of the update, as well as the person who made the update, are all recorded in the asset’s history record.

This is something a manual asset tracking system simply cannot do. It’s extremely inefficient, labor-intensive, and, not to mention, highly susceptible to human error.

As a result, it produces inaccurate asset records.

Using such an unreliable system, especially during audits, would make anyone’s head hurt.

Automated asset tracking systems, on the other hand, make audits a breeze. You can rely on them during asset or internal audits to quickly confirm an asset’s location.

You’ll get precise data in a couple of seconds.

The software helps with compliance audits, too.

Just to illustrate, one of the most frequently cited OSHA standards for the fiscal year 2022 is the eye and face protection standard, which states that each employee exposed to hazards, such as flying particles, molten metal, liquid chemicals, chemical gasses, or vapors, needs to wear appropriate eye and face protection.

With asset tracking software, you can quickly confirm the presence of protective gear at a job site, confirming you’re compliant with the standard and avoiding penalties and fines.

And all of this can be done remotely, without driving from site to site.

The value of accurate asset records cannot be overstated.

Not only does precise and real-time data make for increased productivity, as we mentioned in previous sections, but it can be a major contributor to ensuring compliance with industry standards and, therefore, creating a safer work environment.

Facilitates Effective Planning

The beauty of asset tracking software lies not only in the insights it gives you into your current operations at any given moment, but it also shows what you’re going to need in the future.

In other words, the software facilitates more effective planning.

This is particularly useful for anticipating maintenance needs and formulating efficient maintenance regimes.

With preventive, or scheduled, maintenance, you save money in the long run, so it is not a bad idea to allocate some time to come up with a good maintenance schedule.

But how exactly does the check-out system contribute to efficient maintenance planning?

The answer is twofold.

First, the check-out system helps with scheduling because it gives insight into when a particular asset is being used so you can avoid work conflicts by planning maintenance during downtime.

Moreover, the system provides a wide variety of valuable data that enable you to track an asset during its whole life cycle.

For instance, you can track mileage or work hours, conclude how often or how heavily equipment is used, and schedule maintenance based on that information.

Overall, a well-run organization relies on a great deal of planning to ensure its success.

However, planning is just simple guesswork if you don’t rely on accurate data.

You’ll definitely find a source of reliable data in asset tracking software, so consider using it and take your planning to another level.

Conclusion

All in all, using an asset tracking system that facilitates checking assets in and out will generate a goldmine of valuable data that is sure to improve your business operations in so many different ways.

From protecting your equipment from theft and misplacement through increasing productivity and team coordination, all the way to ensuring compliance with laws and regulations and making job sites safer, asset tracking software does it all.

So why not try it out?