Even though Excel’s primary purpose is not asset tracking, many construction businesses still use it to keep track of their assets, such as tools and equipment.

And that’s not surprising, considering that Excel was a significant improvement compared to handwritten records back in the day, but things have changed.

Faced with the downsides of using Excel for asset tracking, most construction companies have since switched to more advanced software solutions that allow them to track their assets much more efficiently at an affordable price.

So, if your business still relies on spreadsheets and you’re considering switching to asset-tracking software, here are five reasons why you should do so.

In this article...

More Accurate Asset Records

Keeping accurate records of construction assets—from the largest pieces of heavy equipment to the smallest precision tools—is crucial for companies that want to manage their assets efficiently.

Since the data from the asset records need to be manually typed into Excel, this opens the possibility for a range of potential mistakes that can jeopardize their accuracy, particularly when multiple people use an asset tracking spreadsheet.

In other words, accidents happen, and someone can copy-paste data over the existing data, accidentally delete or modify data, set incorrect formulas, or miss the right cell, row, or column where the data should go, thus recording it in the wrong place.

In fact, due to its format and features, Excel is widely known for being especially vulnerable to the downsides of manual data entry, which has been established in various reports and surveys over the years, as discussed in the Forbes article you see below.

The above article covers some famous spreadsheet mistakes that cost companies millions of dollars, highlighting that the majority of them were caused by human error, meaning they could’ve been avoided.

In the context of asset tracking, incorrect records can lead to, for example, a construction company failing to fully utilize the equipment or tools available in storage, and purchasing new ones instead, which results in unnecessary costs.

Another big downside of using Excel for asset tracking is poor data integrity.

Spreadsheets will accept any type of asset data and won’t alert the user if they entered incorrect or inconsistent data.

All these issues are successfully addressed by asset tracking software, which automates the process of data entry into asset records, so there is far less room for human error.

Furthermore, such software typically includes built-in data validation and error-checking mechanisms, which help ensure the accuracy of asset records.

Simply put, Excel is no match for the precision ensured by the automated data collection and verification features of asset tracking software, resulting in more accurate asset records.

Up-To-Date Information

Another reason to switch to asset tracking software is that Excel can’t automatically update asset information, making it more likely that the information will not be updated on time or at all.

Consequently, you can’t rely on getting up-to-date information about your construction assets when you need them, which can lead to issues like project delays and budget overruns.

For instance, when a worker observes there’s something wrong with a tool, they should report it.

However, when that means entering data into Excel, they can rarely do that directly on-site using their smartphone (as Excel is not very mobile-friendly with all those tiny cells).

Therefore, workers will often skip this task, make a mental note, and continue with their work, which increases the likelihood that they will forget it entirely.

Consequently, the next person who wants to use that tool or plan its use can be misled by outdated information.

Conversely, tracking software typically uses asset tags affixed to tools and equipment that, when scanned, enable the automatic collection of data about asset usage, location, and condition.

Furthermore, sharing Excel spreadsheets and the changes in them with other departments or team members in real time can be difficult and result in many duplicate files, which then also leads to information being outdated or lost.

On the other hand, asset tracking software enables centralized data management, meaning that any software user can access the digital inventory of tools and equipment anytime and from any compatible device, such as their smartphone or laptop.

For example, if something is wrong with a tool, they can log into the software on their phone and immediately report it, so information is instantly updated and made available to equipment managers and other users so appropriate actions can be taken.

Therefore, if you want to automatically get up-to-date asset information and reduce human error, switching to asset-tracking software is highly recommended.

Tracking the Location of Assets

Unlike asset tracking software, Excel is not able to track the physical location of your equipment and tools as they move between storage and different job sites.

This means construction workers, supervisors, or managers need to manually record the change of location in an asset tracking spreadsheet every time an asset moves or changes hands.

Furthermore, Excel does not come with any physical asset tags—a critical component of an automated asset tracking system—that help track the location of equipment and tools in real time.

These downsides make it difficult to understand where assets actually are and who’s using them.

In turn, this opens room for all sorts of problems, such as workers losing time to find what they need on-site or assets being lost, misplaced, or stolen.

On the other hand, as the For Construction Pros article below suggests, asset-tracking software efficiently addresses these issues.

That’s because asset tracking software automatically monitors the location of assets through the use of barcode or QR code scanning, GPS tracking, or other technology.

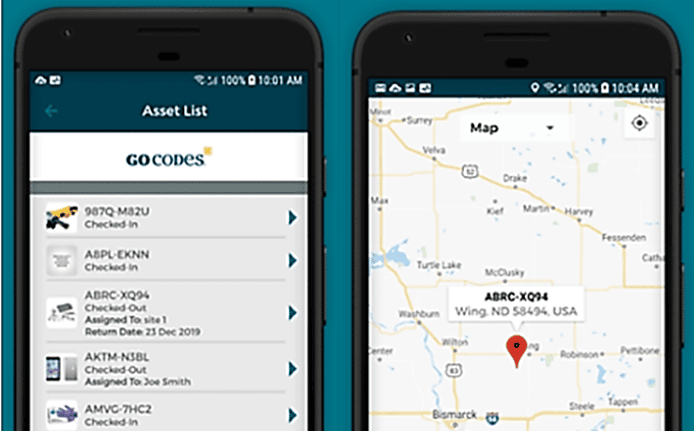

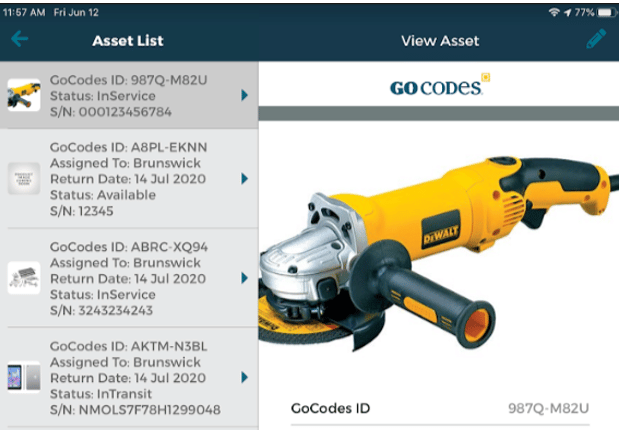

For example, our asset tracking software, GoCodes, uses GPS-enabled QR code tags that workers can scan with their smartphone, and the GoCodes app will update the GPS location of the asset they scanned and show it to the users on a map.

This means that workers can scan a tool when, for example, giving it to another worker on-site or checking it out from and back into storage.

Likewise, all GoCodes users can log into the app and access the central asset database to see the location, availability, and status of all tracked assets at any time.

Naturally, this feature is useful for efficient asset allocation and utilization and also helps when an asset is lost, misplaced, or stolen, as it provides its last known location and user.

Simply put, Excel is not intended for asset tracking and offers no practical way to track the physical location of assets.

On the other hand, asset tracking software is designed just for this purpose and automatically updates the location of assets in real time.

Improved Maintenance

Keeping up with the maintenance of your assets in Excel can be really difficult and lead to inaccurate maintenance records and schedules, which can have serious safety and financial consequences for your business.

For example, whenever any maintenance is performed on a piece of equipment, the person who serviced it must update the records manually.

Since it’s either hard or impossible to do that in Excel, especially when maintenance is done on-site, this leads to delays and potentially more errors in data entry, resulting in inconsistent records.

Additionally, Excel can’t provide automated notifications or reminders about when maintenance is due, meaning that the maintenance staff needs to regularly check the records, making it more likely they’ll miss something on their maintenance schedule.

On the other hand, asset tracking software lets you update any data on the asset’s page, allowing the employees to report maintenance actions right away, while their memory is fresh, from any location and any mobile device.

They can do so by scanning the asset tag or selecting the asset in question from the list of assets in their mobile app.

Moreover, asset tracking software enables you to schedule regular maintenance and automate service reminders, meaning that service technicians receive an automated alert when maintenance is due.

Finally, this comprehensive view of all tracked assets allows you to make informed real-time decisions when something unexpected happens, such as a machine breakdown.

Of course, maintenance practices are also enhanced by the fact that workers can use the mobile tracking app to add information about the condition and performance of the asset they’re using, as well as instantly report any issues and request maintenance.

Therefore, unlike Excel, asset tracking software automates the processes of updating maintenance records and scheduling maintenance tasks in real time, allowing you to simultaneously improve the safety of your construction assets and reduce their maintenance costs.

Performing Audits With Ease

Using Excel to perform different audits, such as asset inventory, compliance, and financial audits, often means searching through multiple spreadsheets and records to find the information you need.

Moreover, this task will likely become even more burdensome when you encounter inaccurate or outdated information in spreadsheets, which then leads to discrepancies between that record and other asset records used for auditing purposes.

On the other hand, asset tracking software keeps all asset information in a single location (cloud-based database), so the information needed for an audit is easily accessible, which saves time and reduces the chance of missing important information.

Furthermore, the software will display an audit trail, i.e., show who entered the data or made changes to asset records and when, which allows auditors to track changes and understand where any discrepancies originated.

Being able to access a complete audit history helps resolve many inconsistencies in asset records, which is much harder to do when dealing with Excel spreadsheets.

What’s more, asset tracking software usually comes with built-in reporting and analytics features, which make performing audits simpler and faster by allowing auditors to generate customized reports and perform data analysis.

For example, an accountant can generate a report with asset depreciation dates and rates for financial auditing purposes.

Overall, Excel is no match for the centralized access to up-to-date asset information, audit trails, and reporting capabilities provided by asset tracking software, which combined make audits much easier to perform.

Conclusion

So, even though Excel was great for replacing handwritten records, it’s clear that its time has passed, particularly when it comes to asset tracking.

In other words, it relies exclusively on manual data entry, it’s hard to update, it does not track the location of your assets, and makes it difficult to keep up with maintenance and perform audits.

Conversely, asset tracking software is designed for tracking the location, usage, and condition of assets; its automated data collection features ensure that asset records are accurate and information is up-to-date, and its database gives you control over maintenance and audits.

In other words, switching from Excel to asset-tracking software will streamline all asset-related processes and improve the overall productivity and profitability of your construction business at an affordable price.