Inspired by the Morse code, the idea of barcodes was first conceived by Bernard Silver in the late 1940s. However, it wasn’t until the late 1960s that barcodes entered commercial use.

Today, everyone’s familiar with these black-and-white lines that vary in width and store valuable data.

Although old, barcode asset tracking is far from obsolete. In fact, it can still go head-to-head with many more recent asset tracking solutions.

Therefore, in this article, we explore the many benefits of barcode tracking and how it can help propel your own business forward.

In this article...

Low Cost of Implementation

An asset tracking solution should be efficient enough to help you stay ahead of the game without breaking the bank. Barcodes are exactly that. They’re extremely cost-effective.

To get started with barcode asset tracking, you’ll need three things: barcode labels, barcode scanners or readers, and asset tracking software.

Although this was not the case before, nowadays, you can get all three components from a single vendor, which makes the upfront cost of the whole system significantly lower.

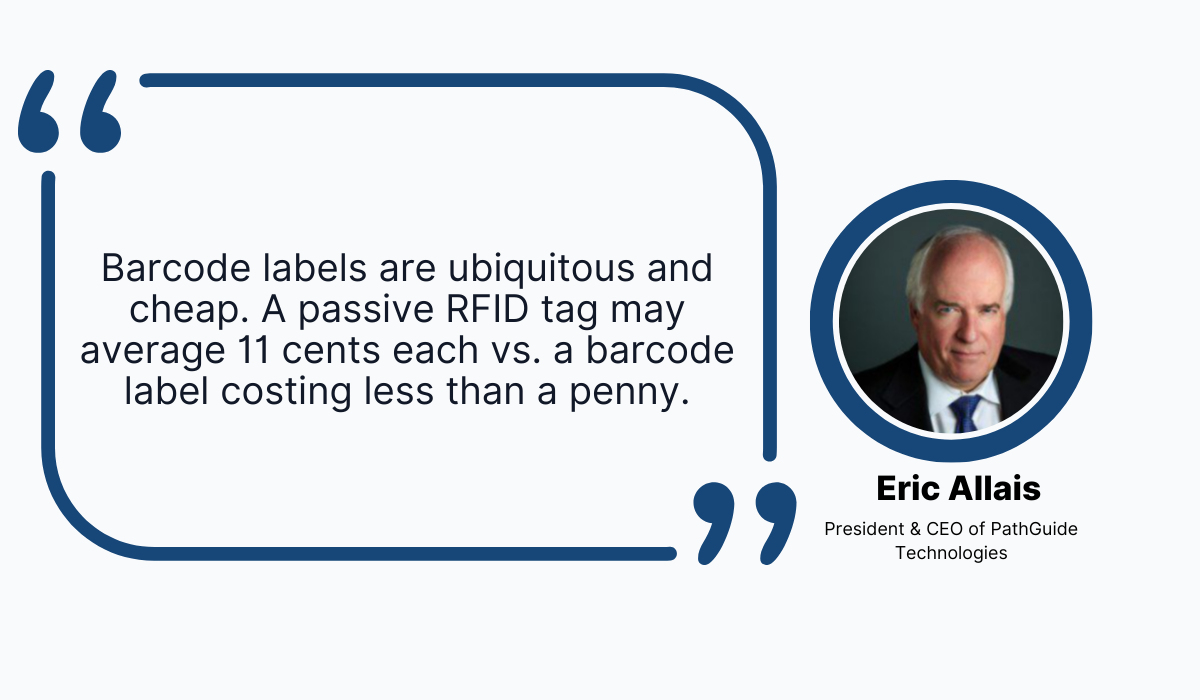

That’s why this is the asset tracking system of choice for many decision-makers across all industries today, despite the fact that there are more modern solutions available on the market. This is what Eric Allais, President and CEO of Washington-based PathGuide Technologies, says about barcode asset tracking:

Tracking your assets via barcodes is significantly cheaper than many other solutions, such as, for instance, RFID or UWB systems, but not at the expense of its efficiency.

Barcode-based systems are an extremely useful solution that’ll definitely improve your asset tracking process.

What’s more, this asset tracking solution is super easy to use, meaning you’ll save quite a bit of money on employee training.

All you have to do is print the labels, attach them to your assets, and start scanning.

Easy for Employees to Use

It’s really that easy, meaning barcode scanning already checks two important boxes: user-friendliness and cost-effectiveness.

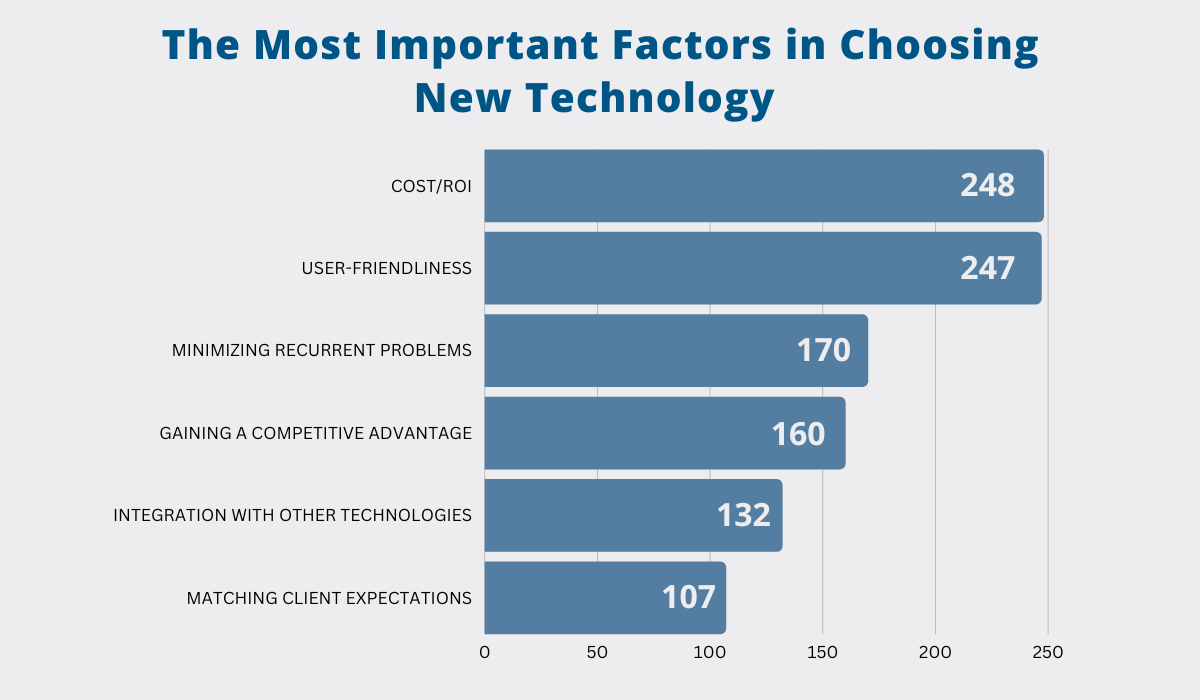

In fact, these two are the most important factors to many when considering investing in new technology, according to a 2018 report by Autodesk and FMI Capital Advisors.

They conducted a survey of 599 construction industry professionals. This is what they said about the things they look for in new software.

This really comes as no surprise because, essentially, the harder a particular technology is to use, the less likely your team is to be willing to use it.

And if they’re not on board with it, it makes no financial sense to invest in it.

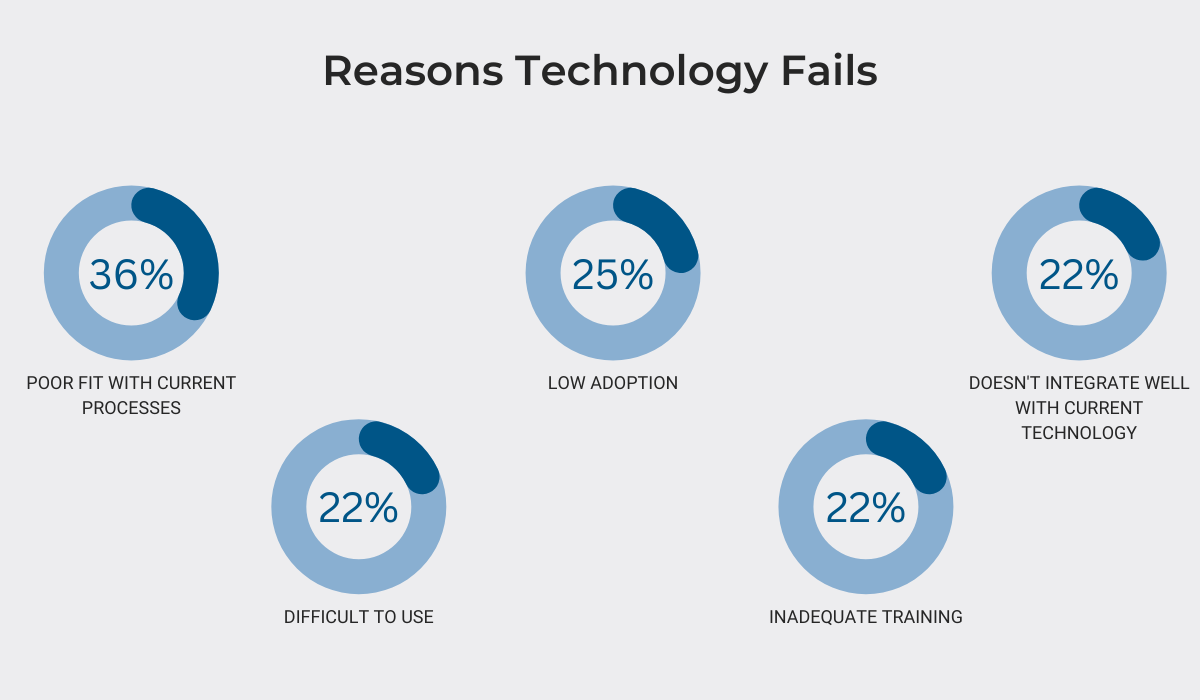

This is also corroborated by the Autodesk and FMI report.

According to the surveyed construction professionals from different facets of the industry, overly complicated systems are one of the most common reasons technology fails.

However, there’s nothing new or complicated about barcodes.

They are something everyone’s already familiar with, so the likelihood of resistance to their implementation is significantly lower than it would be with some other, less familiar asset tracking systems.

Moreover, if you’re not sure if the software will be a good match, you can always request a free trial or a demo.

Increased Operational Efficiency

With the demo, you’ll see firsthand if the software suits your needs. And if the system is a good fit, it’ll quickly reflect on your overall operational efficiency.

Asset tracking with barcodes doesn’t only save you money but time as well.

With them, asset tracking becomes quick, easy, and automated, enabling you to even scan multiple assets at once.

As a result, your workflow becomes more streamlined. You don’t have to go back and forth from a job site to the office computer to make an update.

All the changes are automatically updated on the go, and you can move on to more pressing tasks.

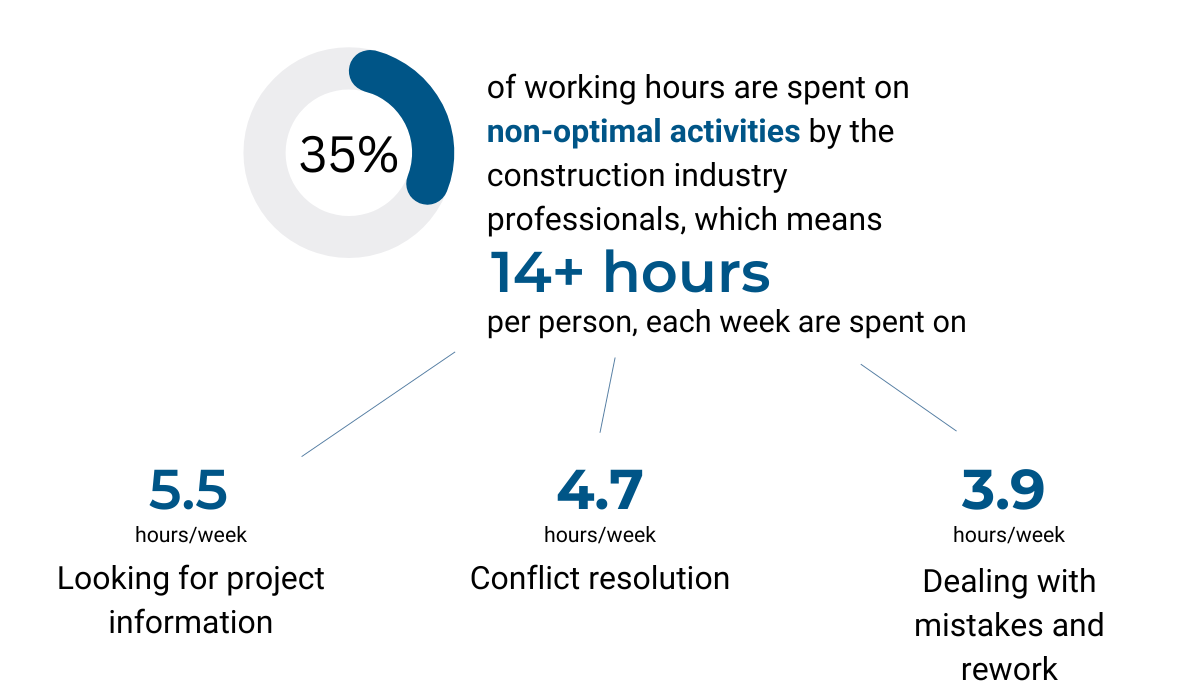

After all, there’s a lot of time wasted in the construction industry. Asset tracking doesn’t need to be another reason why it happens.

Asset tracking with barcodes eliminates the need for manual data entry, making the whole process more efficient.

Keep in mind that, unlike specialized solutions, pen and paper, as well as spreadsheets, were never developed specifically for asset tracking, anyway.

They require any change in assets’ location, quantity, or status to be entered by hand, which significantly increases the chances of errors.

Higher Data Accuracy

These errors are not without serious consequences, let there be no mistake about it.

One error might not make a huge difference to you or your business, but if the problem is systematic, you’ll soon have plenty of poor data at hand.

And what does poor data do?

It fosters poor decision-making, which directly affects your productivity, profitability, and overall success.

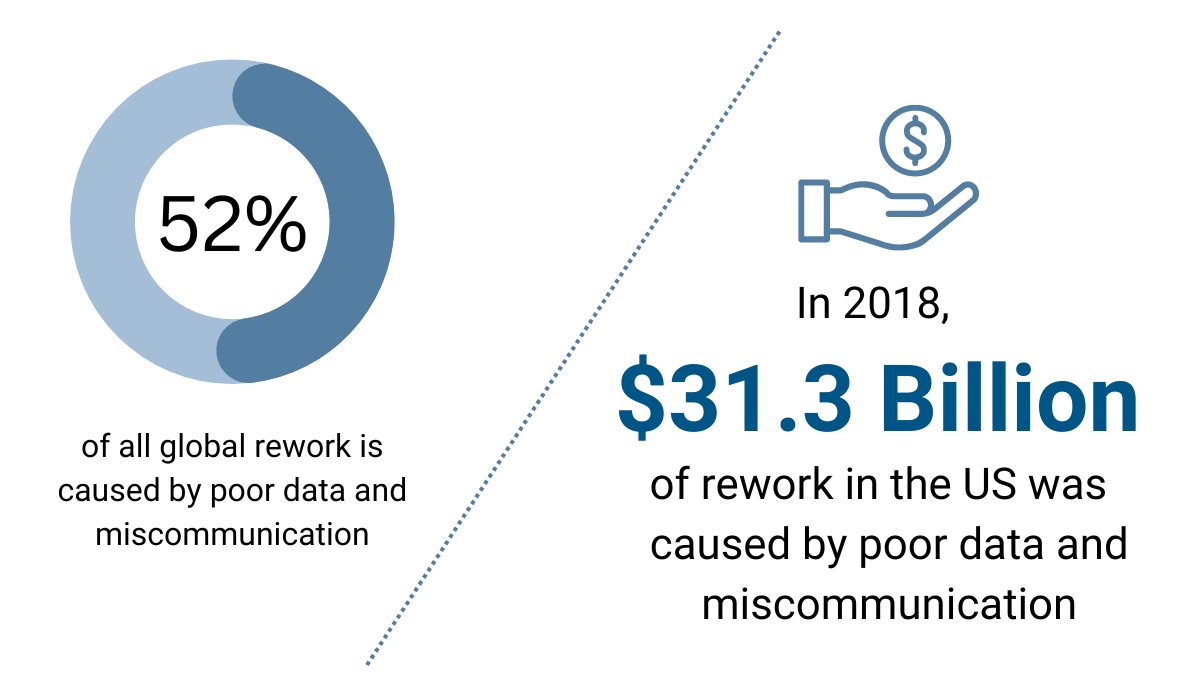

In fact, did you know that, on average, more than half of all global rework is caused by poor data and miscommunication?

And the rework is certainly not cheap. In 2018, it cost the US a staggering 31.3 billion.

Overall, you need accurate and timely data if you want your business to be profitable and well-organized.

Barcode asset tracking provides exactly that. Once you scan an asset, the update cannot be undone or altered, creating a detailed asset history record.

Moreover, if you’re using cloud-based asset tracking software, the data cannot be lost in the event of equipment failure, theft, or fire, and you can access it anytime and anywhere.

Complete Asset Visibility

Accurate, timely, and precise data create complete asset visibility.

With barcode asset tracking solutions, you can monitor where, by whom, how, and how often your assets are used and base your asset allocation on that data.

If you notice an underutilized bulldozer, for example, you can move it to another job site where it might be of more use.

Alternatively, if there’s no need for it, you can decide to sell it or rent it out.

After all, your equipment is a huge investment, so you want to increase its utilization rates and maximize the value of what you gain from it.

Asset tracking can play a major role in reducing unplanned equipment downtime and excessive engine idling.

The two can have a negative effect, not only on your productivity but on the equipment itself.

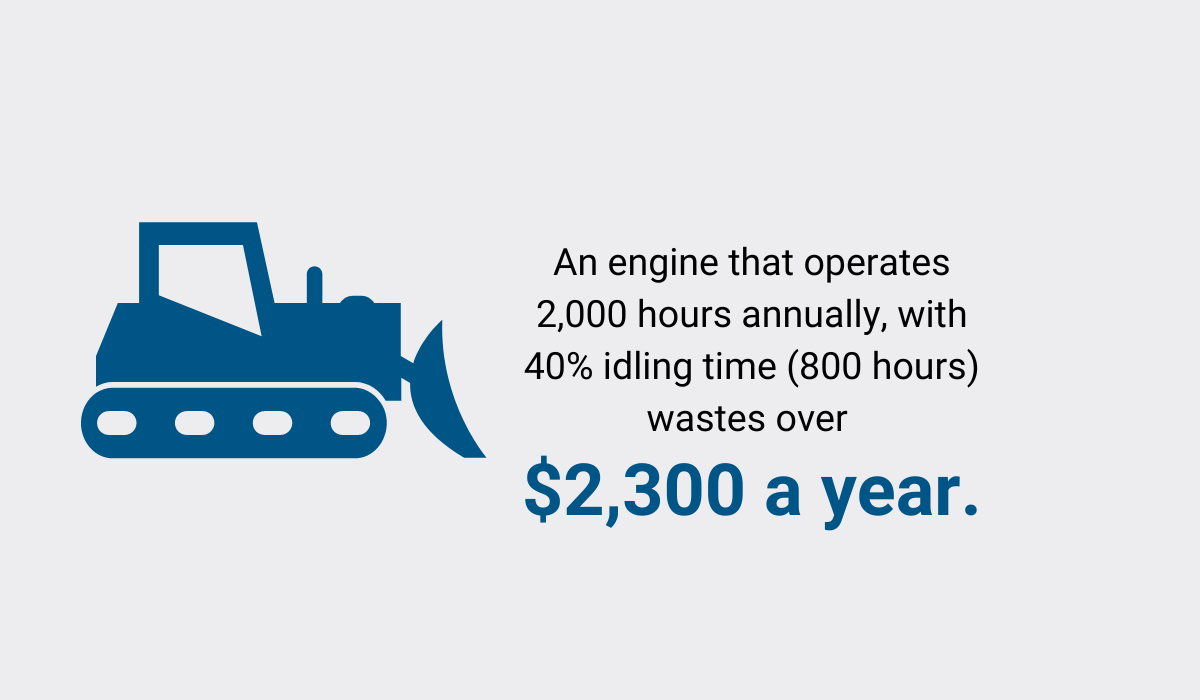

As a matter of fact, Caterpillar did the math and figured out how much idle time could cost you.

An engine that’s planned to operate 2,000h annually, with 800 idling hours, wastes $2,300 a year. But it also:

- Puts component life in jeopardy

- Accelerates Tier 4 technology wear

- Causes unplanned fluid and filter changes

- Uses warranty hours

- Drops resale value

With asset tracking, you get insight into details such as fuel use, operating hours, and all the other relevant data necessary for better-informed asset allocation.

Reduced Maintenance Costs

Your well-informed decision-making will result in a cut in a lot of unnecessary costs, including maintenance expenses.

This is because the wealth of information that comes with barcode asset tracking is extremely valuable for coming up with an effective maintenance regime.

Essentially, by monitoring your equipment, you can determine when maintenance will be needed, and then you can schedule it during planned downtime so that you avoid schedule conflicts and costly project delays.

Such planned, periodic maintenance intended to prevent rather than fix equipment failure is called preventive maintenance.

It’s known to provide a boost in productivity and to save money in the long run.

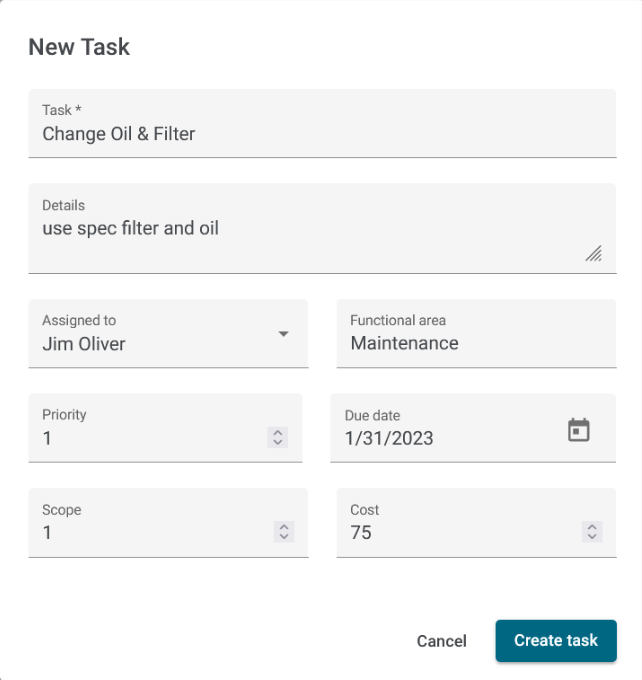

Asset tracking software will surely elevate your maintenance game, provided it has the right features.

For instance, to make sure everyone’s role is clearly defined, consider using software with a feature that enables you to set up tasks, assign them to your team members, and set due dates for task completion.

Another great feature is the notifications feature that’ll remind you via email or text message that scheduled service is due, so you and your team can always be on top of equipment maintenance.

These powerful features eliminate a lot of guesswork and make your maintenance regime much more streamlined.

As a result, you get well-maintained assets, minimize the need for future maintenance and asset replacement, as well as benefit from less costly project delays.

Decreased Risk of Asset Loss

If a broken tool can cause project delays, so can a lost one, too.

The goal for us here at GoCodes Asset Tracking is to cut down on issues such as asset theft and misplacement as much as possible, so we developed our own asset tracking solution with that goal in mind.

GoCodes Asset Tracking relies on a more advanced version of barcodes, called Quick Response (QR) codes, for asset tracking.

The QR code asset labels are attached to your assets and then scanned with our smartphone app scanner to update the asset information on the go.

So, when you need a tool, you scan the tag, and the date, time, and location of the check-out are recorded.

The GPS location of the GPS-enabled smartphone you scanned it with serves as the asset’s location.

Then when you want to return the tool, just repeat the process, and the location, along with the rest of the information, is automatically updated again.

In the event of theft or misplacement, information such as the last known location of the missing item can be indispensable for retrieval.

And when the asset is found, GoCodes Asset Tracking asset labels serve as proof of ownership.

Improved Regulatory Compliance

As you use your barcodes and asset tracking software to record maintenance, locations, check-ins, and check-outs, you create a record of your assets’ complete history, which comes in really handy for ensuring regulatory compliance.

The construction industry is among the most heavily-regulated industries out there. Construction sites are, after all, brimming with different hazards.

Electricity, fire, chemicals, confined spaces, and chances of falling and injuring yourself are an almost constant threat for construction workers.

That’s why organizations like OSHA (Occupational Safety and Health Administration) provide standards and regulations that ensure safety at job sites.

For example, in the Personal Protective and Life Saving Equipment subpart of OSHA safety regulations for construction, it’s stated that workers that face head injury at work must wear protective helmets.

Not complying with this standard would, of course, result in hefty fines and penalties for the employer, not to mention, endanger your workers.

Luckily, with asset tracking software, you can generate compliance reports and perform audits quickly and easily, so you’re always on top of all the regulations and laws.

Simply barcode your protective helmets, instruct your team to scan them when they use them, and you can then confirm the assets’ location and presence at job sites in seconds.

With barcode asset tracking, you won’t have to worry about your operations not being up to code ever again.

Conclusion

Although more than half a century has passed since they came into existence, barcodes are still a viable asset tracking solution.

They perform extremely well when it comes to increasing your productivity, generating accurate asset data, as well as decreasing the chances of asset loss, theft, failure, and non-compliance.

And, despite their many capabilities, barcodes remain cost-effective and user-friendly.

Therefore, if you’re in the market for an asset tracking solution, don’t overlook barcode tracking. Its effectiveness might pleasantly surprise you.