Simply put, the rapid development of technology in the construction industry opens many new possibilities but also requires construction businesses to adapt or ultimately lose their competitive advantage.

In this new construction landscape full of integrated construction management solutions, cloud-based software and mobile apps, BIM, IoT, AI, etc., one of those requirements for construction businesses is to track their construction tools, equipment, machinery, vehicles, and any other mobile or fixed assets, preferably in real time.

To achieve this and, as a result, streamline their operations and boost productivity, construction businesses need to start tracking their construction tools.

So, here’s a step-by-step process on how to establish an efficient tool tracking system.

In this article...

Build an Inventory List

Whether you’re beginning from scratch or already keeping some form of inventory, be it on paper, or in Word or Excel, the first step in tracking construction tools efficiently is building a baseline inventory list of tools, equipment, and other assets that may or may not end up on the list of assets you want to be tracked.

In other words, to be able to decide what should be tracked, you first need to know exactly what tools and equipment your business owns.

Although this can be a time-consuming process that includes different managers, supervisors, and other employees as tools and other assets move across jobsites and change hands, it’s a crucial step in creating an efficient tool tracking system.

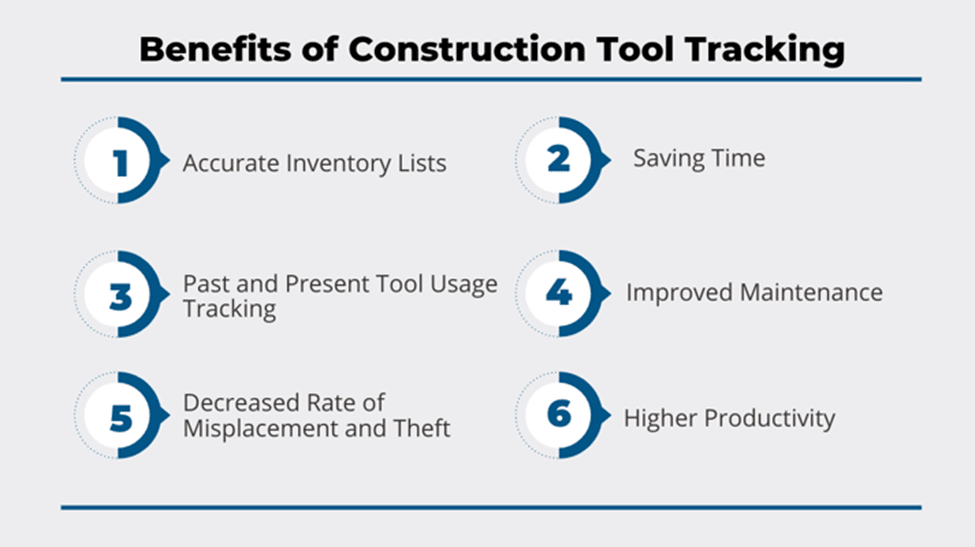

To make this first step easier, just a quick reminder of the benefits that tool tracking can provide to construction businesses:

As you can see, these advantages include accurate inventory lists, time savings, tool utilization, maintenance improvements, and higher productivity.

But, to get there, the process of compiling an initial inventory list should be carried out first, preferably with the help of inventory management software.

Your simplest and fastest option is to select a cloud-based software solution that, paired with asset trackers, provides a complete tool tracking system, from inventory setup to real-time tracking.

That option offers you ease of use, affordability, and mobility,

However, the quality of data generated by the tracking system will largely depend on how well the initial inventory captured the actual number and status of all tools, equipment, and other physical assets.

That’s why you and your managers, supervisors, and other employees need to invest time and effort in compiling the initial inventory list. This entails:

- locating all assets, inspecting and recording their current condition and use

- assigning a unique code to each of them

- deciding on what (and how) tools and equipment should be tracked

Once the tracking system is set up, it will provide a quick return on investment (ROI) on your efforts by generating the above benefits.

That said, you could try building (digitizing and integrating, or migrating) your inventory list with the help of our tool tracking solution, GoCodes.

In addition to tracking your tools and equipment using QR code tags and scanner apps on smartphones and other mobile devices, this cloud-based, fully customizable tool tracking solution can help you set up your inventory list in an easy and efficient way from the ground up.

Whatever method or software you choose, remember that the data collected by the tool tracking system will be a valuable source of information later on, making the process of building an inventory list well worth the time and effort.

Make the Inventory List Available

Once you have the initial inventory list, it’s time to share it with your employees to inform your decision-making, improve communication and collaboration, and ultimately increase productivity.

Like the first step, while the inventory list can be made available to workers in many ways, cloud-based asset tracking apps offer the most advantages when it comes to sharing, updating, modifying, and managing the list of your tools, equipment, and other assets.

Whatever the method, allowing construction teams access to the inventory list will have a two-fold effect.

First, when each member of the construction team can access the inventory list independently and see, for example, if a tool is available, that reduces confusion, saves time, and increases productivity.

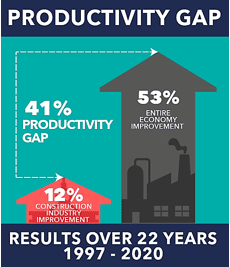

Considering that low productivity on all levels is a long-standing issue plaguing the construction industry, making the inventory list available should be seen as part of broader efforts to address inefficiencies and close the 41% productivity gap between construction and other industries:

In addition to boosting productivity, enabling employees to leave comments or report inventory-related issues will give you in-depth insight into the actual condition and usage of your tools and equipment, thus further informing your decisions on tracking requirements, stock levels, procurement, and maintenance practices, etc.

Naturally, not everyone handling tools and equipment should be able to update or change the list, but the ability to access, comment, or report a problem ensures up-to-date information, better communication, and improved decision-making at this stage and later on.

When all these features are integrated into a cloud-based asset tracking solution, employees can simply scan the item with their smartphone or another scanning device to view, add, or comment on the inventory info, at any time and from any location.

In other words, the step of making the inventory list available via a tracking app will not only inform your equipment tracking and management decisions but also allow you to streamline operations, improve team communication and collaboration, and increase productivity.

Populate Your Tool Records

The third step is to decide what information should be part of your tool tracking system and to populate your tool records.

Let’s say you have the definitive list of all assets your construction business owns, and that list has been freely circulated and updated by relevant users.

It’s safe to assume that each item on your inventory list has a name or unique code assigned to it, along with other information you found relevant while building the initial inventory list.

Moreover, as tool inventory software solutions are usually highly flexible and allow you to add custom fields, the types of metrics and information that can be tracked for a specific tool or tool category are practically endless.

Here’s just an example of what data could be part of your tool tracking system:

However, when you start populating your tool records in a tracking solution of your choice, it’s recommended to start by adding only the key information about the tools so that the initial task is not too overwhelming.

From there, you can slowly expand and add more relevant things to track going forward.

For example, a standard inventory list could include a general info tab (e.g., name and type, serial number, description), an availability tab (e.g., location, condition, usage, and maintenance schedule), and a financial info tab (e.g., purchase price and date, depreciation rate).

Naturally, once your tool records are populated, it becomes easy to access, view, and update all the relevant information, thus creating a centralized source of up-to-date information available to all users and streamlining all other tools and equipment-related processes.

Tag Your Tools

Until now, you’ve compiled the initial inventory list, made it available and editable by everyone, and decided what tools and what data will be tracked by the tool tracking software of your choice.

Thus, the step of tagging your tools is preferably done in parallel with the previous step of populating your tool records.

But, before you do that, you should select the right asset tracking labels and tags.

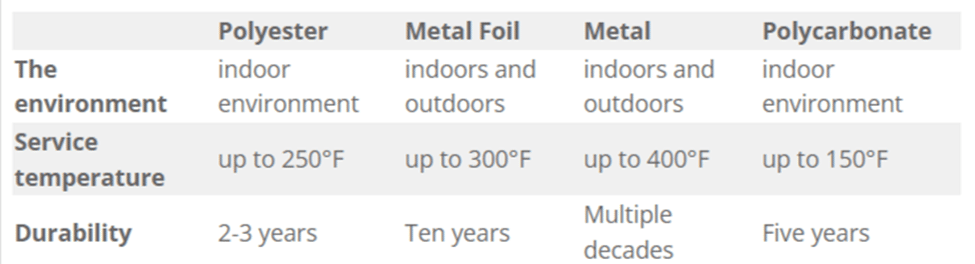

Naturally, this involves many factors to consider and even more options to choose from, but it all comes down to the tool’s frequency of use, the environment in which it’s going to be used, and the desired label durability.

Among many different label types, here’s an overview of the four most used kinds of asset tags, together with what kind of environment they are best suited for, the temperature in that environment, and the average label durability:

Of course, it’s recommended to opt for tags that are high-quality and durable so that they don’t fall off, tear or become difficult to read.

As to what these labels or tags will have printed on them, barcodes or QR codes are usually the most practical solution, together with a unique alpha-numeric identifier and selected ownership or other information, all depending on the size of labels (e.g., on small tools).

Likewise, you’ll need to decide what the asset tags will do, i.e., how they will track different tools and equipment.

For example, GoCodes offers a simple and affordable tracking solution in the form of GPS-enabled QR code labels made of different durable materials that, when an asset is scanned, update its GPS location, and show it in Google Maps.

However, if you want additional tracking and protection features for your most valuable assets, GoCodes also offers rugged Bluetooth beacons (tags) that periodically emit their GPS position.

To sum up, you should decide what asset labels or tags you’ll use to track your tools, what type of material they’ll be made from, and what information they’ll display.

After they’re ready, proceed to tag your tools, preferably while populating your records in the tool tracking software of your choice.

Assign Responsibility for Tools

Although the first four steps will enable you to actively start tracking construction tools, your last move should be to assign responsibility for tools and establish an effective check-in/check-out system.

Doing so will increase the accountability and productivity of workers, supervisors, and managers alike.

Both functions, assigning responsibility and tracking when a tool changes hands, can now easily be set up using cloud-based tool tracking software that, together with asset tags, represents a fully functional tool tracking system.

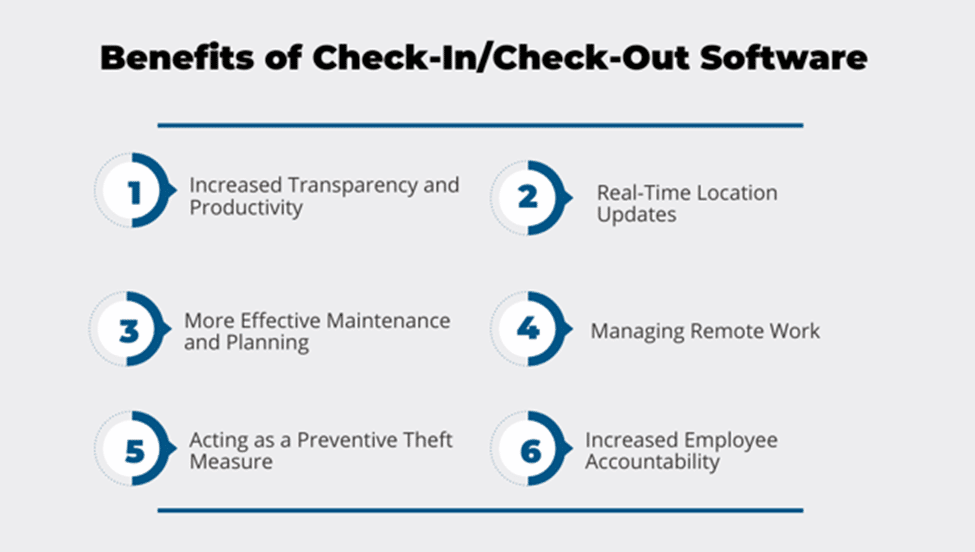

For example, a check-in/check-out system where the user, by scanning a tool, assumes responsibility for it, and does the same upon returning it or giving it to another user, can benefit your construction business in many ways:

For example, when tools are assigned and reassigned through the system, that increases employee accountability, reduces the chances for tools to be left behind, misplaced, or stolen, and makes it more likely that employees will report a problem observed while using tools.

As tools often get lost while changing hands between construction workers on-site, your tool tracking app should allow users to transfer and assign tools to each other on the jobsite while enabling supervisors and managers to easily monitor the chain of custody and address any related issues, from locating a missing tool to quickly finding a replacement.

Again, this is where having cloud-based software that allows barcode or QR code scanning comes in handy—it enables the construction team to use their mobile devices to quickly and effortlessly transfer tools between each other, update their location, or edit other relevant details.

This way, all changes are visible in real-time, ensuring that every tool is accounted for, which in turn increases accountability for tools among the team.

Overall, this step completes the process of creating a fully functional tool tracking solution by establishing an efficient tool check-in/check-out system that increases the accountability and productivity of both workers and managers.

Conclusion

Having established an efficient tool tracking system, you’re probably aware that this task can, in some cases, require considerable time and effort until the system is fully operational.

It’s also clear that no effective system can be established without the help of tool tracking software, preferably a cloud-based mobile app, that, coupled with the right type of asset tags or labels, enables employees to access and update the tool’s info and location.

As a result, managers can automate, improve, and streamline tools and equipment management workflows.

Finally, when we consider the benefits of tool tracking, it’s evident that the efficiencies gained across your construction business will outmatch all the time and effort invested in starting to track your construction tools.