Key Takeaways:

- Geofencing helps prevent construction theft by allowing you to create virtual boundaries around desired areas and providing you with alerts if any tracked vehicles or equipment exit these boundaries.

- It also provides real-time monitoring and enables proactive risk management. This helps construction companies ensure safer work environments, lower accident risks, and safeguard their workers’ well-being.

- Using geofencing in construction can improve efficiency by streamlining processes and providing construction managers with valuable data on the movement of equipment, resulting in a more effective work environment.

- This technology lets construction managers plan the best routes for vehicles and equipment in specific zones. By analyzing historical data and real-time updates, they can find the best routes to sites, thereby cutting down on fuel use.

If you’re interested in how your construction company can benefit from geofencing, you’ve landed at the right spot.

These virtual boundaries, created by software using GPS and other tracking technologies, allow for real-time monitoring and management of construction resources within defined areas.

Moreover, the hardware and software that enable geofencing offer many more features.

They provide a comprehensive solution for enhancing security and safety, optimizing operations, reducing costs, and maximizing productivity across your construction projects.

In this article, we’ll explore how geofencing can contribute to achieving success in these critical aspects of your construction management operations.

In this article...

Helps Prevent Theft

One of the primary functions of geofencing is theft prevention.

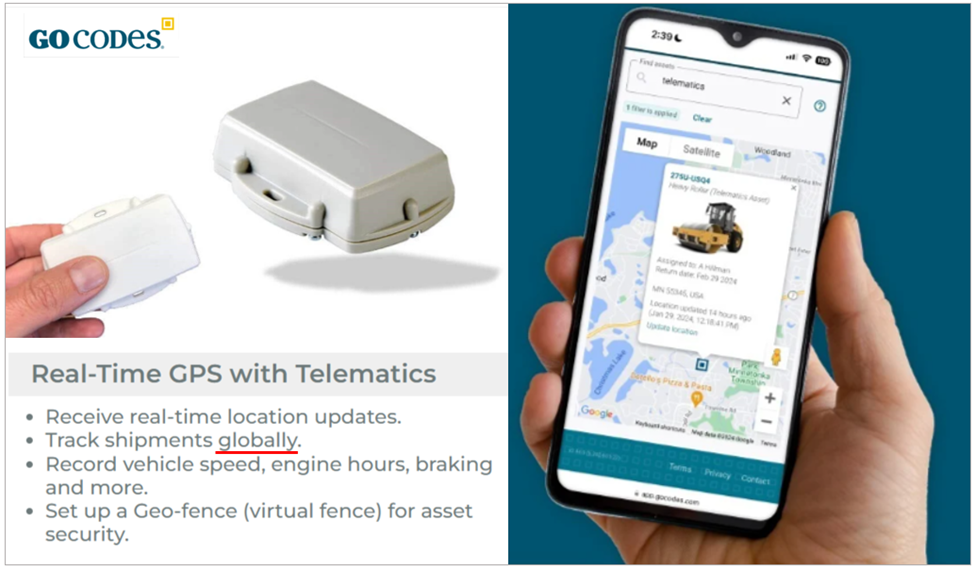

Moreover, when it comes to preventing theft and unauthorized use of construction trucks, vehicles, and yellow iron, geofencing is typically just one feature of a wider GPS fleet tracking system.

In other words, geofencing is enabled by the components of such systems, namely:

- active GPS trackers installed in your fleet vehicles, and

- tracking software installed on your smartphone and other internet-connected devices.

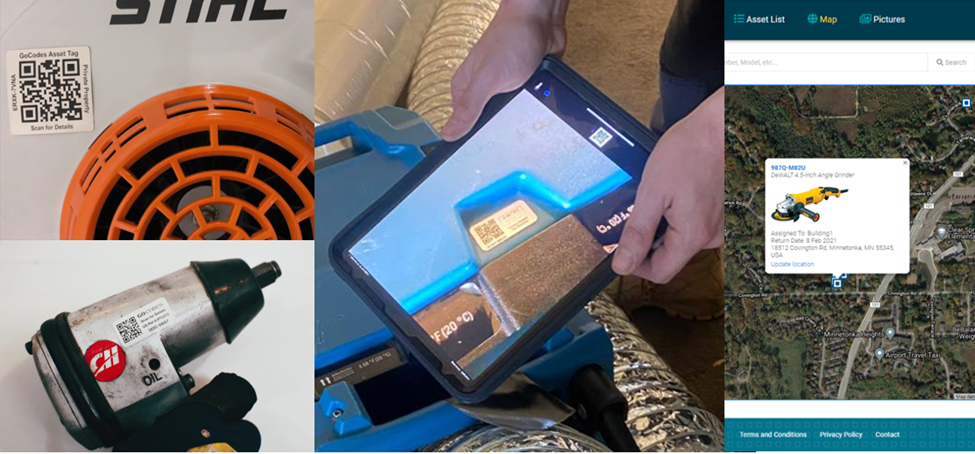

When combined, they create a real-time tracking system, such as our GoCodes, capable of tracking your vehicles and equipment anywhere in the world and showing their location on a map.

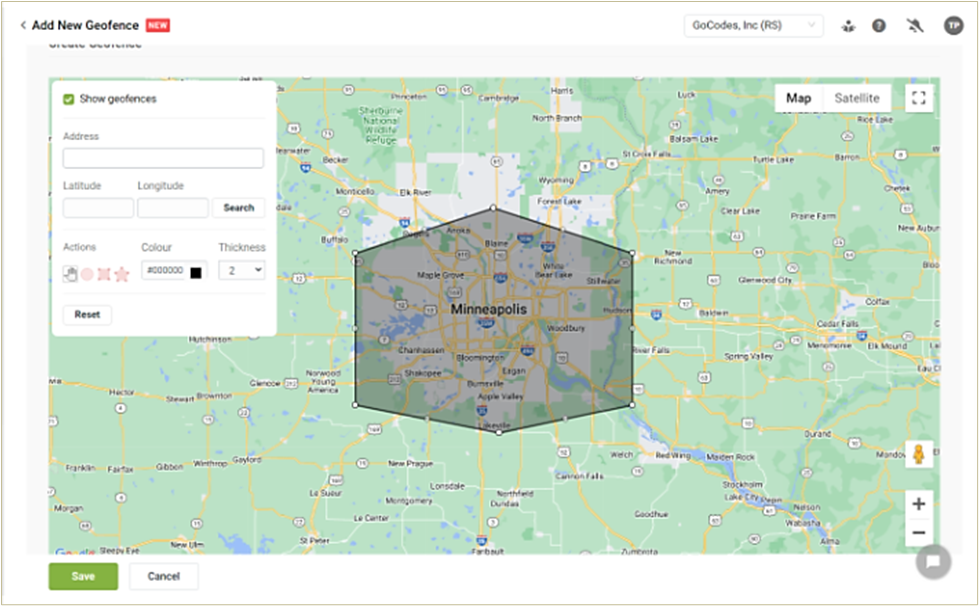

This also means you can select any geographic area (jobsite, storage yard, town, etc.) where your valuable equipment will be located and set up a geofence around it.

Using the software app, you can set up multiple geofences, make them as big or small as you want, and modify their shape and functions.

This means you can set up virtual boundaries around one or more construction sites, storage yards, or even transport routes, and get immediate alerts if one of your tracked vehicles or heavy equipment leaves the geofenced area.

For instance, if you get an alert that one of your trucks left the designated perimeter around the jobsite and it’s not scheduled to do so, you can swiftly investigate whether:

- one of your employees made an honest mistake,

- one of your employees intended to use it without authorization,

- someone else stole it.

From there, you can take appropriate action and, if necessary, alert the authorities.

However, if you get an alert from the geofence set around a storage yard during the night, theft is the most likely option and quick reaction is often critical for equipment recovery.

In any case, if the GPS tracker on your stolen equipment is well-hidden and tamper-proof, you’ll be able to track it globally and assist law enforcement in recovering it.

So, that’s how GPS trackers and software enable real-time location tracking and perimeter breach monitoring for your vehicles and equipment, thereby preventing theft.

But what about safeguarding other smaller, but still valuable equipment, tools, and other assets?

In theory, they could all be equipped with real-time GPS trackers, so the geofence would detect if they’re taken from the designated location.

However, due to GPS tracker size and price issues, construction companies often opt for more affordable and practical tracking methods for these assets, such as:

- RFID tags,

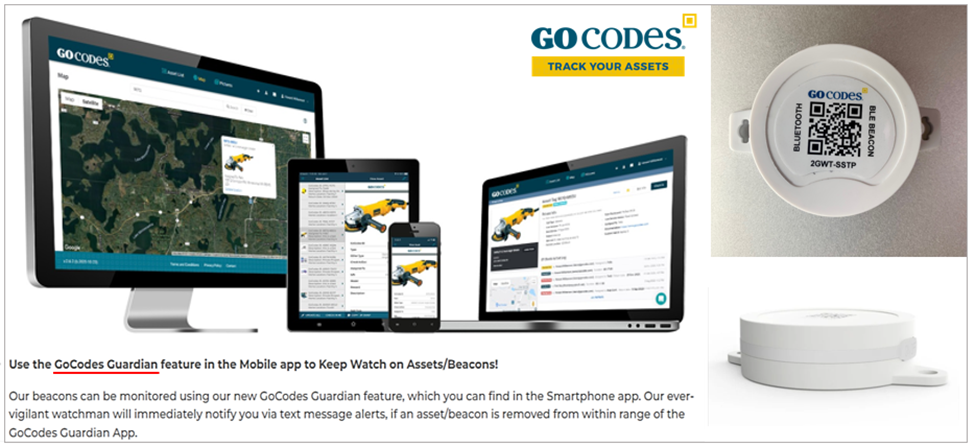

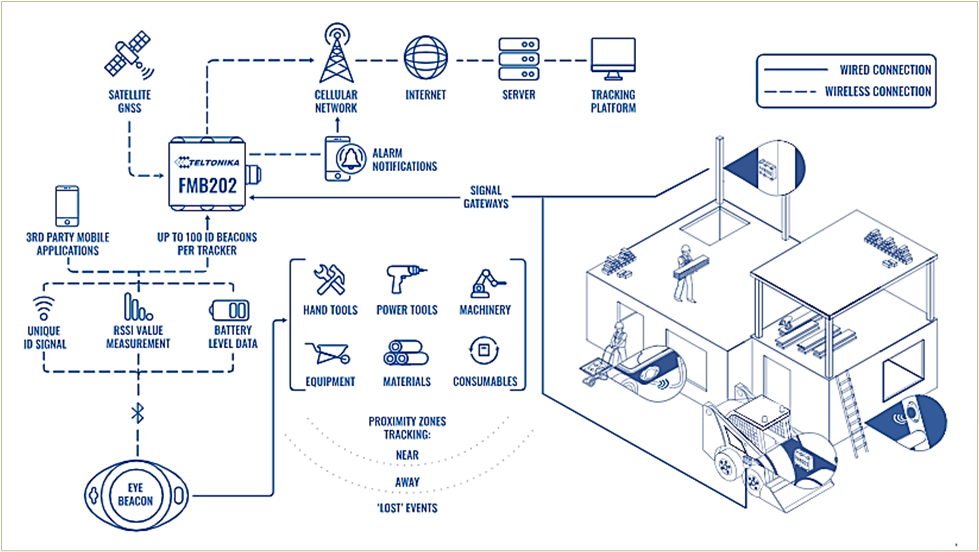

- Bluetooth beacons,

- GPS-enabled QR code labels.

The first two technologies rely on the proximity of tracked assets to a reader device (smartphone, laptop, standalone readers, etc.), allowing for real-time monitoring of asset movements within a limited range.

By strategically placing readers around a construction site or storage area, companies can create geofences and receive alerts when tagged assets move beyond these boundaries.

For example, you can attach Bluetooth beacons to valuable on-site equipment and turn your smartphone and other Bluetooth-enabled devices into moving or stationary beacon detectors.

As illustrated, the Bluetooth beacon-based tracking system and its geofence work much like GPS tracking, but on a limited scale.

In other words, if a beacon-wearing item is stolen from the site, you will be alerted when it leaves the reading devices’ range, but you won’t be able to track where it goes afterward.

Another simple and cost-effective method that can complement these geofence-enabled methods and further assist in protecting equipment and tools is GPS-enabled QR code tags.

As shown below, these robust asset labels, when scanned with a smartphone or tablet, will use the scanning device’s GPS function to automatically record the asset’s current location and show it on a map.

Although these QR code tags do not provide live GPS tracking, they can help you find misplaced items based on their last-scanned location and can serve as proof of ownership for lost or stolen and then discarded equipment and tools.

More importantly, such asset tags allow you to set up an automated asset check-in/check-out system, where workers scan assets when taking and returning them.

This increases transparency and worker accountability, preventing instances of internal theft or negligible handling of equipment.

Of course, all the above tracking devices and their software’s geofencing and location monitoring features can be applied to other valuable on-site assets, such as construction materials.

In essence, any construction item can be tracked and geofenced, ultimately creating a comprehensive real-time monitoring system.

Lastly, geofencing can also be used to monitor the movements of personnel, provided they give their consent to be tracked.

This can be done by tracking workers’ or company-owned smartphones (with the tracking app downloaded and location tracking enabled).

Alternatively, tracking devices can be integrated into workers’ personal protective equipment (PPE) or designed as wearables, like this GPS-trackable smart hard hat.

Regardless of what tracking method is used (phones or wearables), it enables managers to set restricted areas for certain personnel (and equipment) and receive alerts if they enter them without authorization.

This helps prevent internal theft and unauthorized access, enhancing overall site security.

To sum up, geofencing empowers you to protect your assets from theft and unauthorized use by creating invisible fences around designated locations and receiving real-time alerts in case of potential theft.

Improves Operational Efficiency

Now that we know the capabilities of different geofencing technologies, let’s look at how else geofencing can improve your construction workflows, namely operational efficiency.

By providing construction managers with valuable data on the movement of equipment, personnel, and materials within project areas, geofencing enables precise monitoring and management of resources.

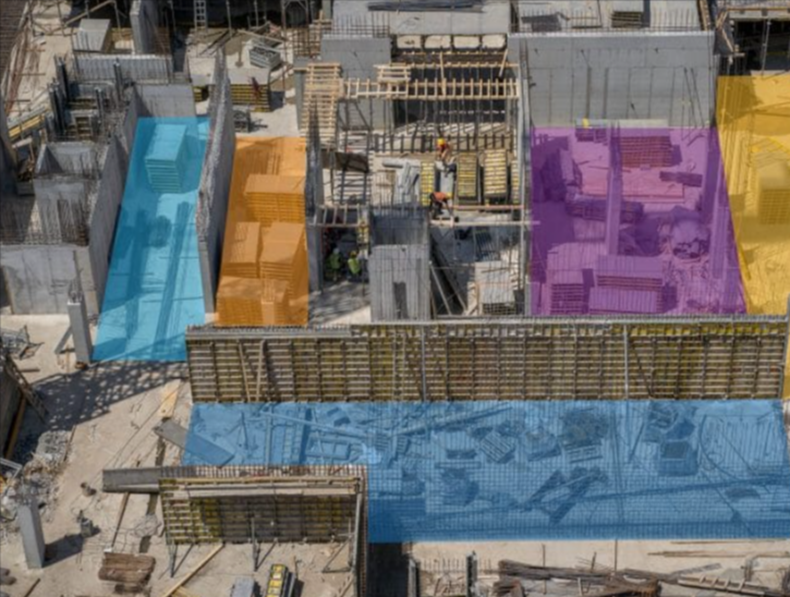

For instance, Gilbane Building Company leverages geofencing for real-time project progress monitoring.

They set different geofences around the jobsite and track when workers, equipment, and material shipments enter and exit these designated zones.

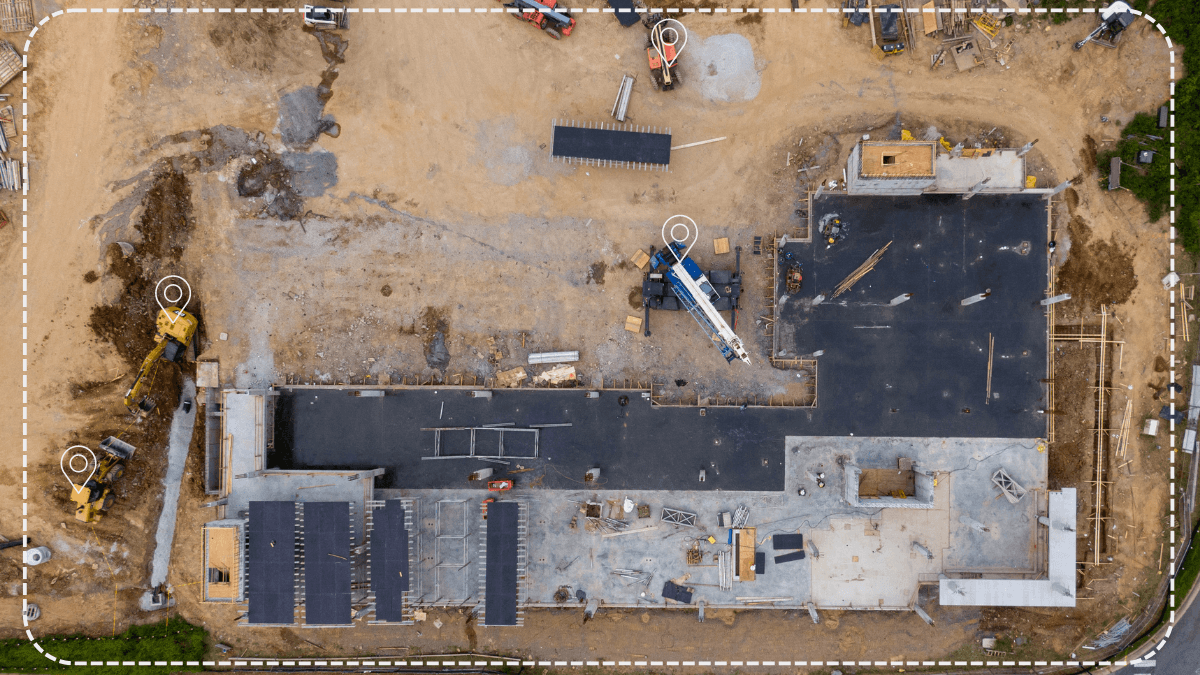

That looks something like what you can see in the image below:

By analyzing the data collected through geofencing technology, the company can measure progress and identify inefficiencies in equipment utilization patterns, material delivery routes, and jobsite staff movements.

Then, the company can use geofence-derived insights to optimize resource allocation, ensuring that materials and equipment are delivered to the right place at the right time, thereby minimizing downtime and avoiding costly delays.

Other uses of geofences to improve operational efficiency include:

- facilitating quick location and fast finding of on-site equipment, which saves time and minimizes disruptions to workflows,

- automating equipment check-ins and check-outs based on their geofenced location, which reduces manual record-keeping efforts and increases productivity,

- sending automated notifications to workers when they enter a specific zone (work updates, safety measures, etc.), which enhances communication and keeps workers informed in real time.

Overall, leveraging geofencing in construction operations has many efficiency-boosting applications that can help you streamline processes and enhance productivity, thus contributing to a more efficient and—as discussed next—safer work environment.

Increases Safety on the Construction Site

Geofencing can be used to enhance safety on construction sites by creating virtual safety zones and triggering alerts when workers enter hazardous areas or approach dangerous equipment or when drivers or operators are speeding on-site.

That way, construction managers can proactively manage safety risks and mitigate potential hazards, ultimately improving safety compliance and enhancing overall worker safety.

For example, the manager can draw virtual barriers around unsafe areas, such as zones with high-risk machinery or hazardous materials, like in the example below.

When workers approach these designated danger zones, they receive a geofencing alert (e.g., on their smartphone or some type of wearable device), allowing them to take necessary precautions and avoid potential accidents or injuries.

Similarly, geofencing can be utilized to create areas to control speed within construction sites, automatically triggering alerts when vehicles exceed predefined speed limits.

Whether only the manager and/or drivers/operators receive speeding alerts, this helps prevent accidents and injuries caused by excessive speeding and promotes safer vehicle operation on-site.

Therefore, by providing real-time monitoring and proactive risk management, geofencing allows construction companies to create safer work environments, reduce the risk of accidents, and protect the well-being of their workforce.

Reduces Fuel Consumption

Another benefit of GPS fleet tracking in general and geofencing in particular is that construction companies can optimize the routes and movements of vehicles and equipment within project areas.

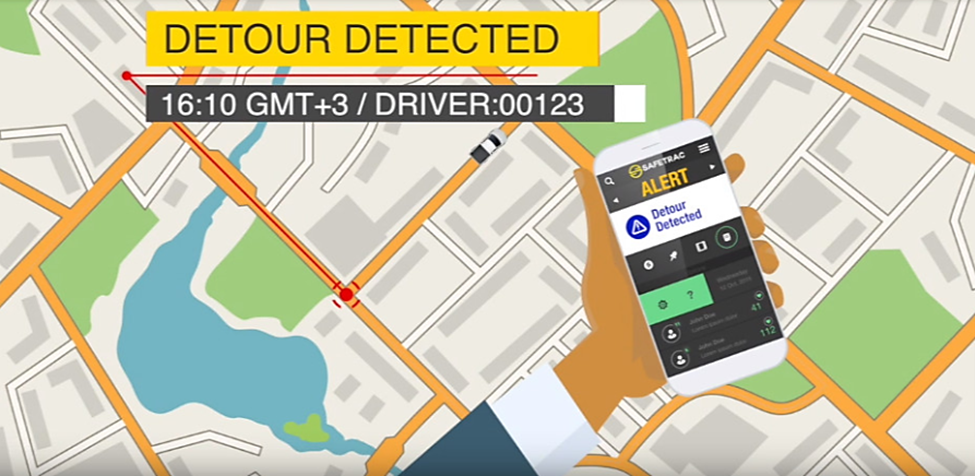

More precisely, managers can identify when drivers/operators are speeding, letting their machines idle needlessly, or taking unnecessary detours from their planned route.

Based on these insights, managers can take proactive measures to reduce fuel consumption and lower operational costs.

For instance, geofencing technology enables construction managers to create optimized routes for vehicles and equipment within defined areas.

This means managers can analyze historical data and real-time information to identify the most efficient routes to and within construction sites, thus minimizing unnecessary detours and saving fuel.

Furthermore, when your GPS trackers are connected to internal vehicle and equipment engine sensors, the fleet tracking system can monitor how much time each machine spends idling.

Although heavy equipment and vehicles should sometimes be idling for operational purposes, every time machinery is left powered on without reason, fuel is wasted—up to one gallon per hour.

Therefore, managers can monitor idling for each vehicle individually and receive alerts when idling exceeds a predefined time limit.

Likewise, they can set up geofences around designated minimum or no idling jobsite zones and get notified when idling limits are not adhered to.

This enables managers to encourage drivers to turn off engines when parked or waiting, thereby conserving fuel, and reducing emissions.

Given that sensor-enabled GPS trackers can also detect speeding, hard braking, and harsh accelerations, tracking and geofencing features of your fleet telematics system are excellent tools for monitoring fuel-wasting behaviors and taking appropriate actions.

Enables Accurate Time Tracking

Considering geofencing capabilities, this technology can play a crucial role in enabling accurate time tracking for both workers and equipment within designated project areas.

More specifically, virtual boundaries around construction sites or specific work zones allow construction managers to precisely monitor the arrival, departure, and duration of work of both employees and equipment within these areas.

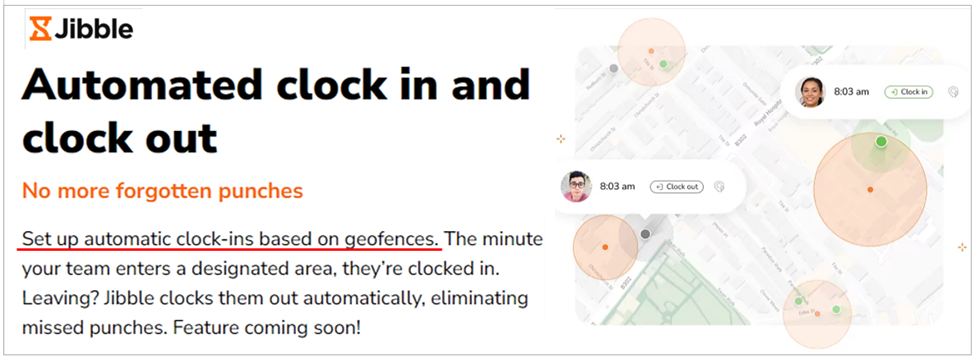

For instance, you can establish a geofence around your jobsite and let the tracking software automatically clock your workers in when they arrive to work and clock them out when they leave.

As illustrated above, each worker’s entry and exit from the construction site can be automatically recorded through geofencing technology, providing accurate, real-time data on their hours worked.

The employee time on-site is tracked via an app on their smartphones (consent required) or other tracking devices assigned to them.

The collected data can then be used to accurately calculate payroll, monitor productivity, and ensure compliance with labor regulations.

Similarly, geofencing can be applied to track the usage of equipment and vehicles on construction sites.

By setting up geofences around equipment storage areas or specific work zones, construction managers can monitor the time spent by equipment within these areas.

This enables accurate tracking of equipment usage, maintenance schedules, and billing for client projects, ensuring transparency and accountability in resource utilization.

To recap, leveraging geofencing for accurate time tracking of workers and equipment enhances accountability, transparency, and efficiency of your construction operations.

Conclusion

So, it’s clear that geofencing technology offers construction companies a multitude of benefits, from enhancing security and safety to improving operational efficiency and facilitating accurate time tracking.

Furthermore, managers can leverage geofencing to optimize resource utilization, streamline workflows, and ensure compliance with regulatory requirements.

Given all the above, consider integrating geofencing into your daily operations as an indispensable tool for achieving greater productivity, efficiency, and profitability.