It is the beginning of the work day at your construction site. Workers have punched in. Tasks have been given out.

Everyone has geared up and assumed their work posts. But before the work starts, you are informed that disaster has struck.

Two bulldozers are missing from the site.

Now, if you have been in a similar situation before, you know the amount of headache that comes with it.

Solving this issue will eat up your whole day—and that’s just the best case scenario.

You’ll have to talk with the police, file a claim with the insurance company and determine the best way to replace the missing equipment.

However, no matter how well you handle the immediate aftermath, unfortunately, you might find that the robbery has already irreparably damaged your project.

In this article, we will explore the full extent of the impact equipment theft can have on your construction project or company.

In this article...

Costly Project Delays

Construction companies often undertake projects on a tight schedule. A day of production is expensive and resources are limited.

Therefore, before starting a project, companies must meticulously plan out every detail so they can fit the tasks in as few days as possible.

As a result, each day, workers have specific assignments to complete and a clear timeframe to stay within.

Extending that timeframe would automatically delay all subsequent tasks, ultimately causing a prolonged production time and increased costs.

That is precisely what can happen if someone steals your equipment.

Of course, if you only have a couple of missing tools, you can easily replace them without significantly impacting the workflow.

However, because of their value, construction machinery and vehicles are seen as more attractive targets for theft.

Considering they are indispensable for most of the heavy lifting, losing one of them also has a more pronounced impact on production.

Let us say you lose a bulldozer used for removing topsoil for roadwork. Workers cannot simply match its massive workload by chipping away at the rest of the topsoil with shovels.

Instead, you have to buy or rent a replacement and get it on the site as quickly as possible. Until you do, the production will be suspended, at least on the affected part of the site.

The problem is that you’ve already paid the salaries, equipment rental and materials in advance.

Even if you let the workers stay home as the operations grind to a halt, you will still suffer monetary losses, since the project will be prolonged and your company will have to pay for each day beyond the deadline.

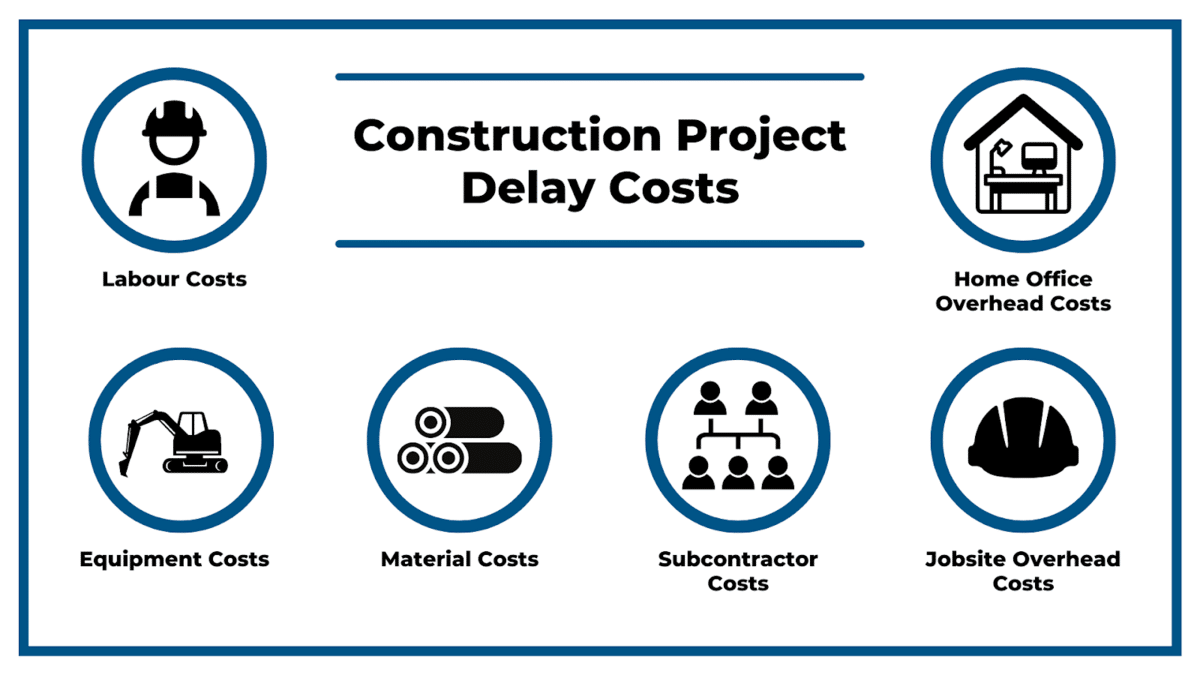

Naturally, this can add up to a lot of money. In their research on project delay pricing, James G. Zack Jr. and Peter V. Badala group delay costs into six different categories.

Source: Academia.edu / Illustration: GoCodes

You will have to pay all these expenses each day you overextend the project. Therefore, you should try shortening the delays as much as possible.

To conclude, equipment theft can cause production stoppages, which escalate into project delays and generate high costs down the line.

Restricted Cash Flow

Production delays due to stolen equipment can also have a detrimental effect on the company’s cash flow. In construction, managing the allocation of income to cover expenses can be a sensitive task.

Why is that?

Well, companies usually take on multiple projects at once. Each has regular expenses for materials, salaries, equipment and other daily operations.

These are essential to cover if you want the site to remain operational.

As for income, construction companies rarely receive a lump sum of money for the whole project.

Instead, they are paid in installments in regular intervals (e. g. weekly or monthly) or by the percentage of completion.

Therefore when you receive a progress payment for one project, the money is split among others according to need.

So, how does stolen equipment disrupt this balance? It is simple.

Any delay in operations puts you behind in reaching the project’s payment milestones. And until you reach them, you will not get paid.

Consequently, you will be unable to pay your expenses on other projects, creating a ripple effect across the entire company.

You can cut the delay by immediately buying replacement equipment with the company’s money, knowing the insurance company will pay out. And it will.

In time.

You see, insurance claims can take a lot to process—up to several months.

Therefore, even if you have a surefire case, you will still be down for the replacement price until they reimburse the money.

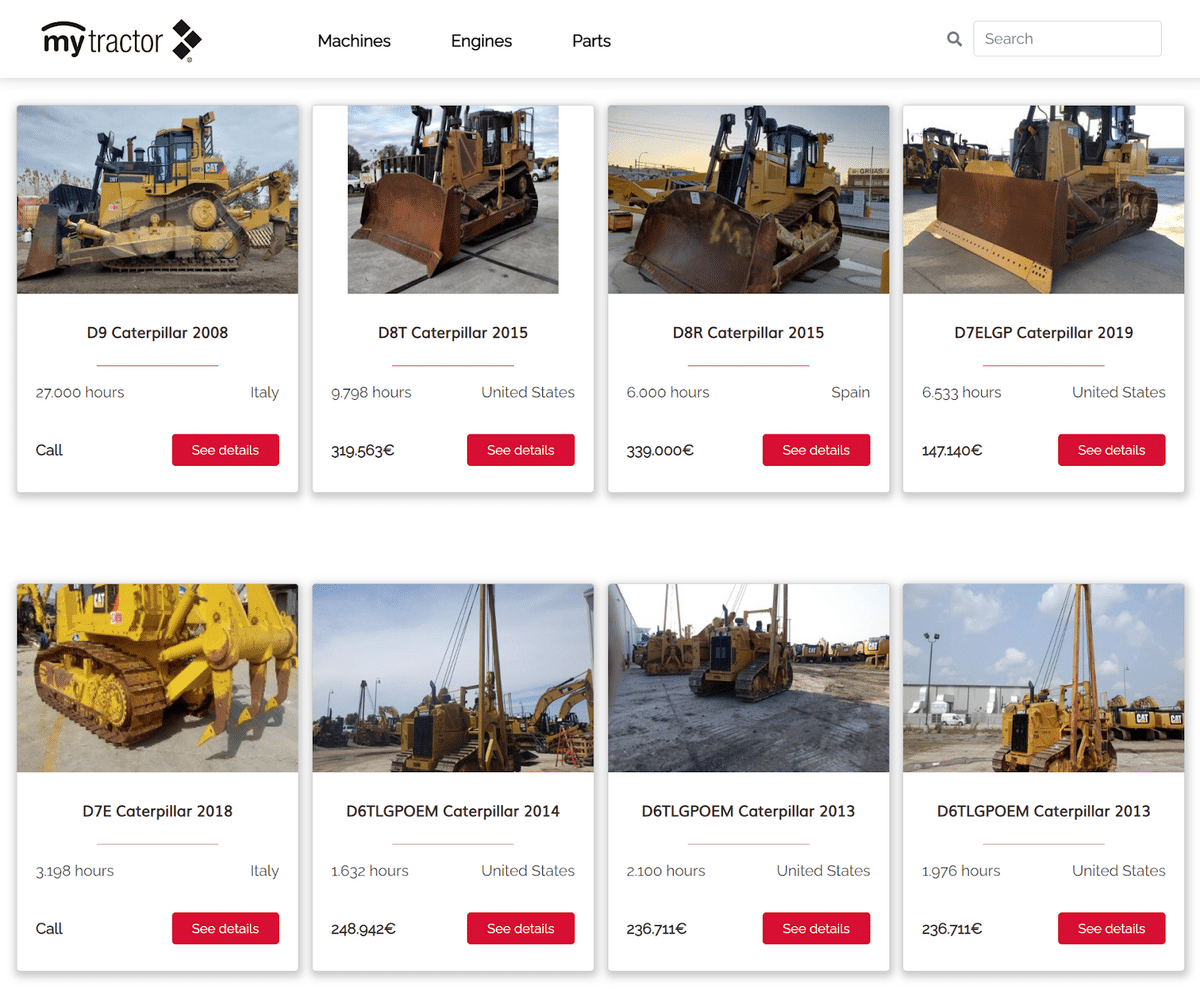

And as you can see, new machines are not cheap:

If you do not have an extra $300 thousand not already tied up in projects, your company could struggle to cover its expenses, even without the delays.

Ultimately, a missing piece of equipment could have an adverse effect on your income, creating negative repercussions for the entire business.

High Replacement Costs

In a way, you can avoid restricted cash flow by renting a replacement for the stolen equipment. After all, it quickly puts you back in business, and it takes much less money to rent than to buy.

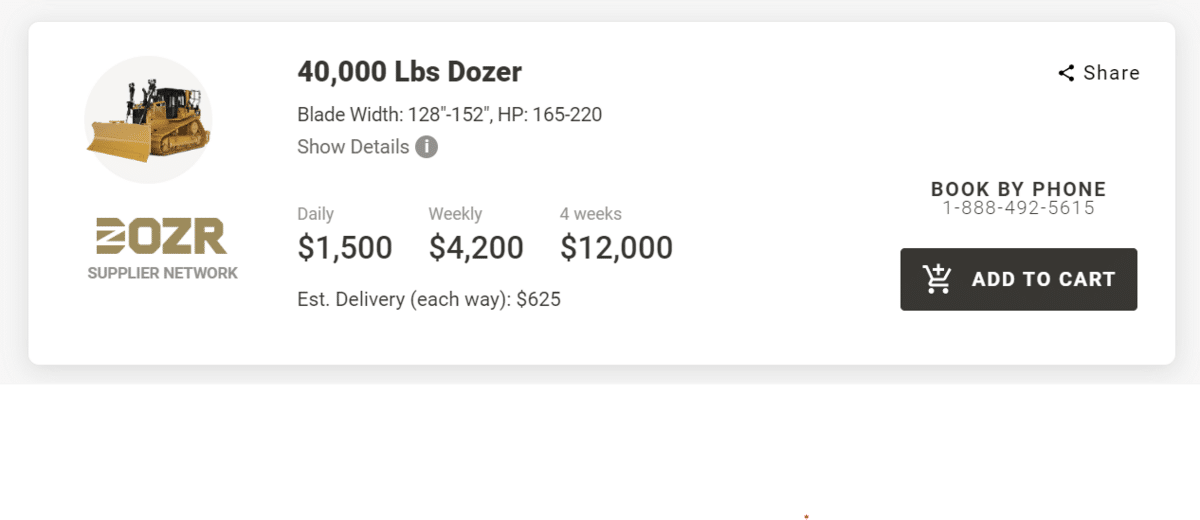

As shown below, an estimated rental price for a 175HP bulldozer is $4200 a week.

On the other hand, buying one will take anywhere from x10 or x100 of that amount. Still, whichever option you choose, you will have to deal with some replacement costs.

Here is a quick breakdown.

Renting may help shorten the delay and reach your payment milestones, but it is expensive in its own right. Sure, when you get the insurance money, you can use it to cover those expenses.

But in that case, you will still need to buy a new bulldozer. This solution works if you need the machine only for a short time.

If you decide to buy a replacement immediately, it will prolong the delay as the buying procedure takes longer to complete.

As mentioned, this may lead to problems meeting the company’s financial obligations.

However, once you receive funds from the insurance, you can cover the extra expenses and still own a bulldozer.

I would suggest this move if the company has a surplus of money in the bank.

In summary, whichever route you take to solve the missing equipment issue, it will be hard to avoid replacement costs, so choose the best approach for your situation.

Increased Insurance Premiums

So your equipment has been stolen.

For a moment, let us presume the best-case scenario. You already have a replacement machine in your warehouse, ready to go.

All you have to do is file a report with the police and insurance, get the other asset on the construction site, and you’ve essentially avoided all of the costs mentioned above. Right?

Sort of, but not really.

Here is the deal. The insurance company will pay for the lost equipment, but they will also raise your premiums.

This monthly expense might seem minor, but it slowly adds up over time. Therefore, you could end up paying hundreds or thousands of dollars without realizing it.

All in all, it is hard to avoid the potential impact of equipment theft on construction companies. Therefore, the best bet is to try to reduce their number.

The first step that can help you do that is investing in an equipment tracking system like GoCodes.

Granted, GoCodes is an asset tracking solution. Therefore, it cannot directly help you stop a robbery, but it can be of great use in various other ways.

For instance, when potential thieves notice that the equipment has GPS trackers, they will be much less likely to risk stealing it from you instead of looking for a more effortless opportunity.

Since highly specialized equipment is not widely available to the public, selling it on the down-low is almost more complicated than the act of stealing itself.

And when the equipment is protected by technology, doing so becomes even more difficult.

In summary, even a perfect response to equipment theft can cause financial damages, so consider investing in proactive measures, such as tracking software.

Conclusion

From a young age, parents and teachers have always taught us that stealing has consequences.

That may be true for the perpetrator, depending on whether or not they get caught. However, it is absolutely true for the victim.

Although there are systems in place to protect your company from the full impact of equipment theft, they are primarily reactionary and cannot offer a complete recovery.

Therefore, the best way to protect your assets is to invest in security and theft prevention measures to avoid the consequences altogether.