In the extremely complex web of construction project management, one important aspect that often goes overlooked or underestimated is inventory management.

This, however, doesn’t undermine its importance.

From towering skyscrapers to residential buildings, every construction project requires an efficient handling of materials, tools, and equipment to ensure smooth operations and timely completion.

That’s why we decided to dedicate an entire article precisely to inventory management, diving into its components, benefits, as well as some practical tips.

After reading, you’ll realize exactly why this important process should never be overlooked.

Let’s begin.

In this article...

What Does Construction Inventory Management Entail

Inventory management entails strategically planning, organizing, tracking, storing, and utilizing resources needed for the successful completion of construction projects.

In construction, inventory is typically categorized into three main groups, which you can see illustrated below.

The primary goal of this process is to improve the overall efficiency of your operations by ensuring workers have access to all required supplies and machinery, while also maintaining efficient cost control, minimizing waste, and maximizing the quality of the finished structure to the fullest extent possible.

As you might expect, inventory management in construction is somewhat of a complex process, encompassing various components.

Let’s dissect each one to gain a deeper understanding of what it takes to fully master inventory control.

Planning and Procurement

Procurement and planning constitute a crucial part of inventory management.

Here, the focus lies on forecasting the project’s needs in accordance with its scope, timelines, and, of course, budget.

Additionally, this process involves the actual acquisition of materials, tools, and equipment, with the goal of ensuring they are obtained on time and meet prescribed quality standards.

Planning and procurement hold great significance within inventory management, particularly in terms of cost efficiency.

For example, this phase is the perfect opportunity for obtaining supplies at competitive prices, whether through negotiations, bulk purchasing, or strategic sourcing.

Naturally, this plays a major role when it comes to adhering to budgetary constraints, preventing cost overruns, and boosting the project’s overall profitability.

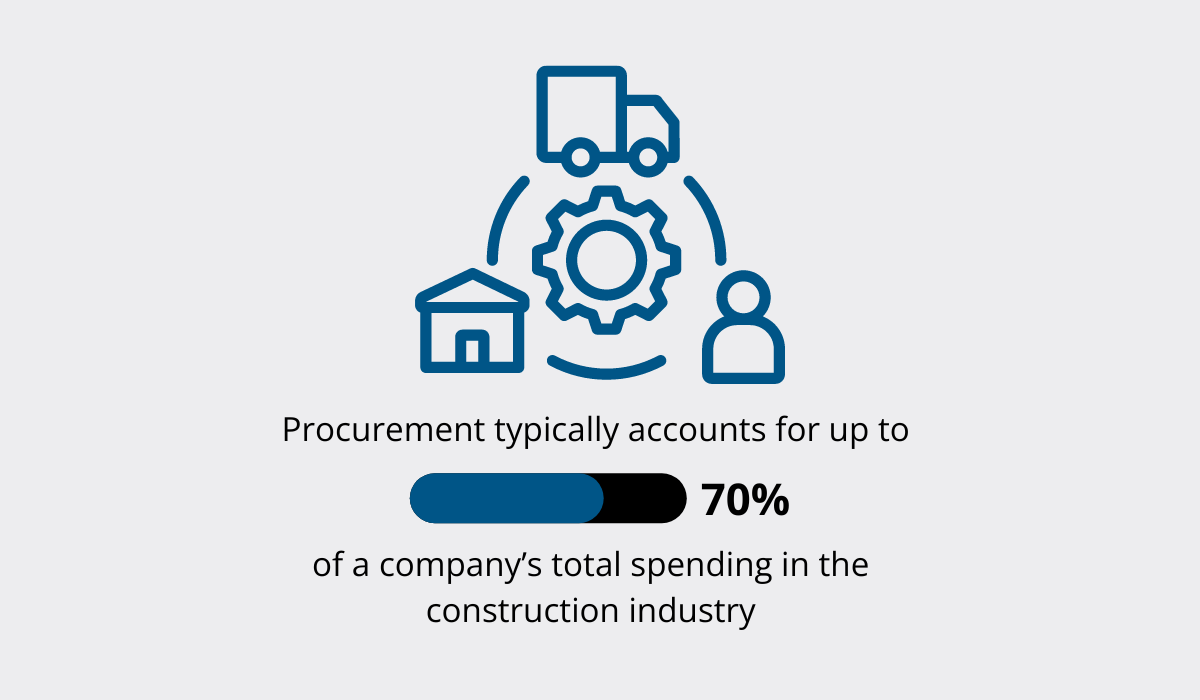

Construction inventory already is a substantial cost area in itself.

According to a study by McKinsey, procurement typically constitutes 40-70% of construction companies’ total spending.

That’s why it’s so important to plan strategically and prioritize smart procurement from the get-go.

It minimizes inventory expenses as much as possible, without compromising product quality or project schedule.

A true win-win-win scenario.

Storage Organization

Once the goods have been ordered and delivered, it’s vital to ensure they are properly stored.

Effective storage management, however, entails more than simply placing assets in a warehouse.

In fact, it involves a range of tasks, including:

- assessing storage needs based on factors such as quantity, size, weight, and frequency of material and equipment usage,

- installing shelving and racking systems,

- segmenting the storage area into zones according to item category and frequency of use,

- labeling assets for easier identification,

- establishing access policies and procedures, and

- implementing security measures like locks, surveillance cameras, and keycard access.

Being diligent about this process protects your equipment and materials against misplacement or damage, in turn extending machinery’s lifespan, minimizing material wastage or obsolescence, and ultimately enhancing operational efficiency.

Just imagine workers struggling to locate materials in a disorganized warehouse, or tools being constantly misplaced due to lack of adequate storage practices.

Such minor disruptions can quickly escalate into costly project delays.

Efficient storage organization, on the other hand, ensures that all supplies are adequately stored and easily accessible, thereby enabling uninterrupted workflow.

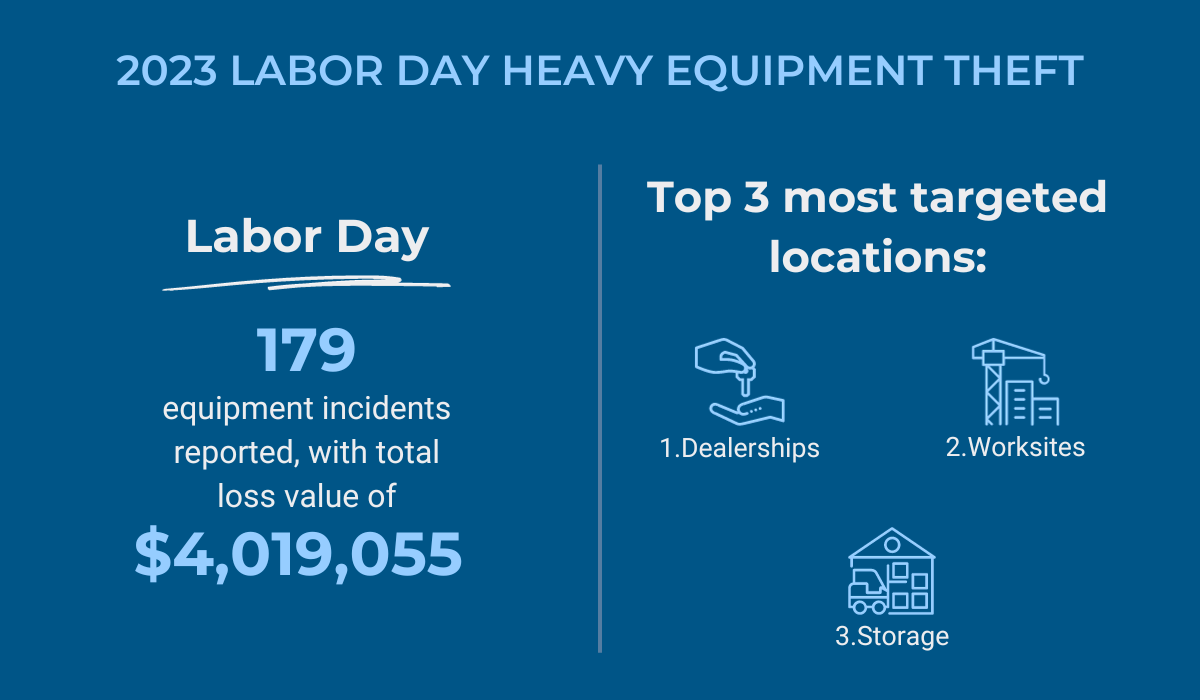

Most importantly, proper storage management serves as a deterrent against theft, a pervasive threat in the construction industry.

To understand the severity of this issue, look no further than the National Equipment Registry’s 2023 report on Labor Day heavy machinery theft.

On that single day, 179 theft incidents were recorded, resulting in a collective loss exceeding $4 million.

The most targeted locations? Dealerships, worksites, and storage facilities.

The bottom line is this: properly storing your valuable assets isn’t just a part of the job site routine.

It shields equipment from a myriad of threats, from adverse weather conditions to burglary and vandalism.

As a result, storage organization plays a key role in preventing substantial financial loss, boosting asset longevity, and ensuring smooth operations from a project’s start to finish.

Tracking

Even after acquiring and storing your supplies, your inventory management journey is far from over.

As a matter of fact, it’s just beginning.

Effective inventory control involves continuous monitoring of your equipment, materials, and tools throughout the entirety of the project.

Key activities in this process include:

- recording inventory levels,

- tracking asset location and movement,

- monitoring asset use and performance, and

- conducting audits to reconcile actual inventory with recorded inventory.

This process is crucial because it informs you whether you’re meeting your asset quantity and performance targets.

By catching potential issues early, you can address them promptly, preventing them from becoming larger problems that could impact both the schedule and the budget.

For instance, if you notice that a certain material is depleting faster than expected early on, you’ll have ample time to reorder without disrupting the workflow.

Similarly, if some of the rented machinery is underutilized, you can either reallocate it to another job site or return it to minimize costs.

The most reliable method for tracking inventory at the moment is undoubtedly through inventory management software.

Forget the spreadsheets and paper forms.

They are highly prone to human error and were never even designed for inventory control in the first place.

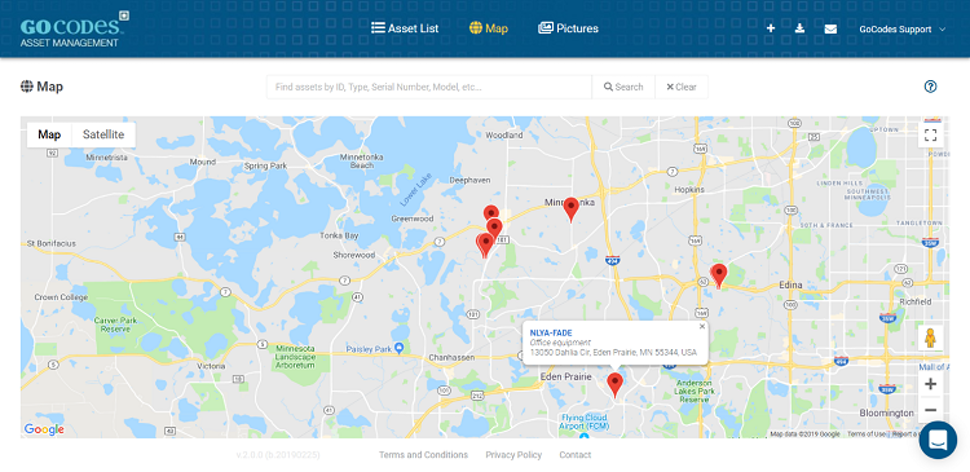

GoCodes, on the other hand, was developed with inventory management in mind.

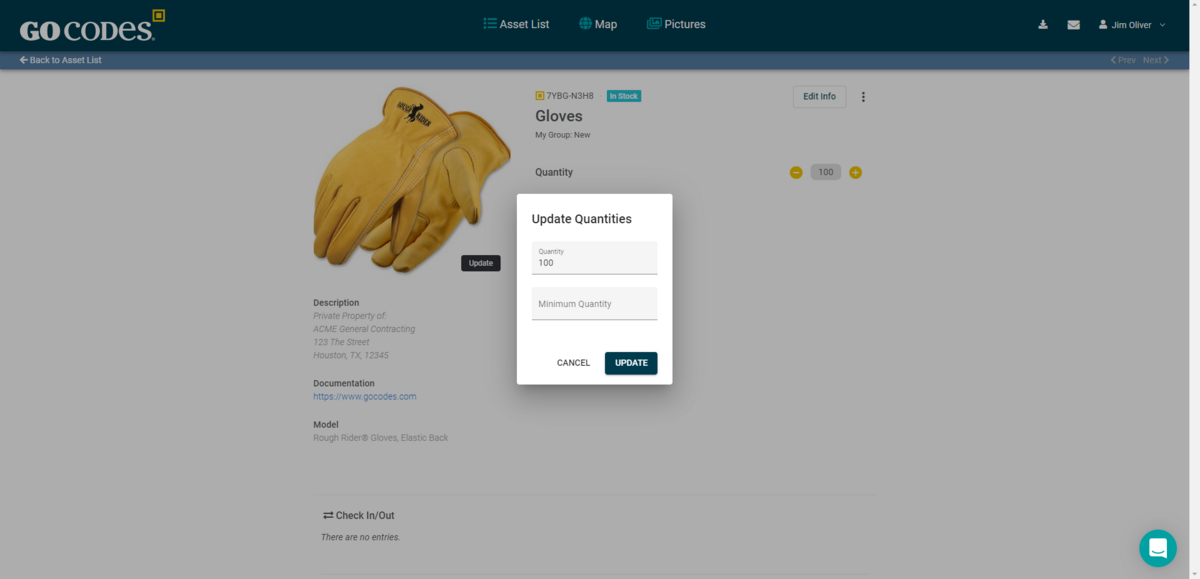

GoCodes is an automated inventory management system that allows you to update your asset records by simply scanning a QR code label affixed to a machine or tool using your smartphone.

This simple, yet efficient process ensures that your inventory records are always accurate and up-to-date.

The system automatically tracks equipment and material locations, users, statuses, and more, storing this data in a centralized log, thereby minimizing inaccuracies like typos or miscalculations.

With such reliable information and the history of each asset update readily available, those pesky audits suddenly become much less daunting.

At the end of the day, while forecasting resource needs during the planning phase is extremely important, we all know that actual construction work often brings unforeseen changes.

That’s why monitoring has such a huge role in inventory control.

It enables you to stay on track with your goals and targets, spot possible risks before they even occur, and therefore keep the project within the budget and on schedule.

Waste Management

Construction is notorious for producing a significant amount of waste, making effective waste management something to take very seriously.

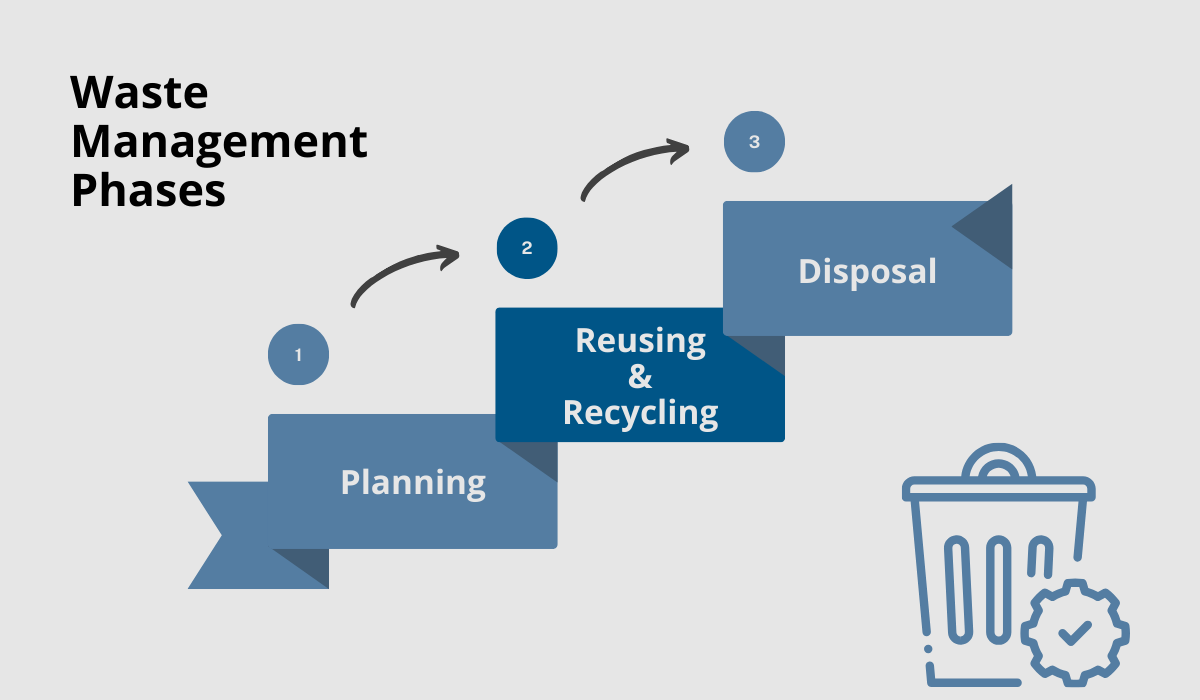

Proper waste control typically involves three key phases that you can see outlined below.

Planning plays a crucial role in preventing excessive waste from accumulating in the first place.

It focuses on assessing resource needs early on and optimizing their use or allocation to minimize discarded material throughout the project’s lifecycle.

The reuse and recycle phase aims to identify ways in which resources can be repurposed or recycled.

For instance, wood can be used as fuel or transformed into landscaping woodchips, and concrete can be crushed and reused as aggregate in new concrete mixes.

The final stage entails the appropriate disposal of waste, tailored to its specific type.

This is the least favorable option out of the three that, in a way, serves as a last resort if prior steps prove unsuccessful or inapplicable.

Strategic waste management extends beyond conserving valuable resources, though.

Namely, it also mitigates environmental impact and fosters a more sustainable built environment.

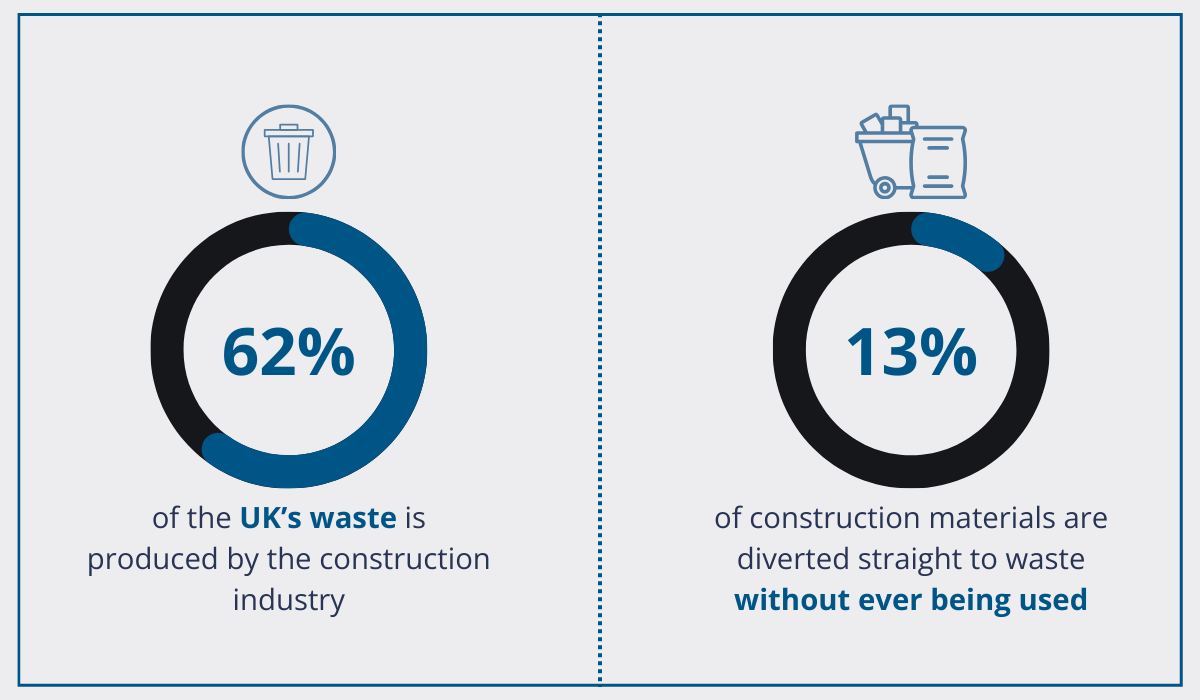

The significance of waste control in this context is further underscored by findings from Qflow‘s 2023 Annual Waste Report for the UK construction industry.

It reveals that construction waste constitutes 62% of the UK’s total waste, with a concerning 13% of it being discarded without ever being used.

These statistics highlight the critical role of construction in waste production and, consequently, the vital role of waste management in the mitigation of this large problem.

Ultimately, efficient waste control represents a sort of a double win.

On one hand, it maximizes resource utilization and enhances the company’s reputation as an environmentally responsible entity.

On the other hand, it contributes to environmental preservation by reducing pollution and emissions associated with extracting, processing, and transporting raw materials, as well as diminishing landfill usage.

The Importance of Construction Inventory Management

Construction inventory management offers significant benefits in two major ways: improved cost control and increased productivity.

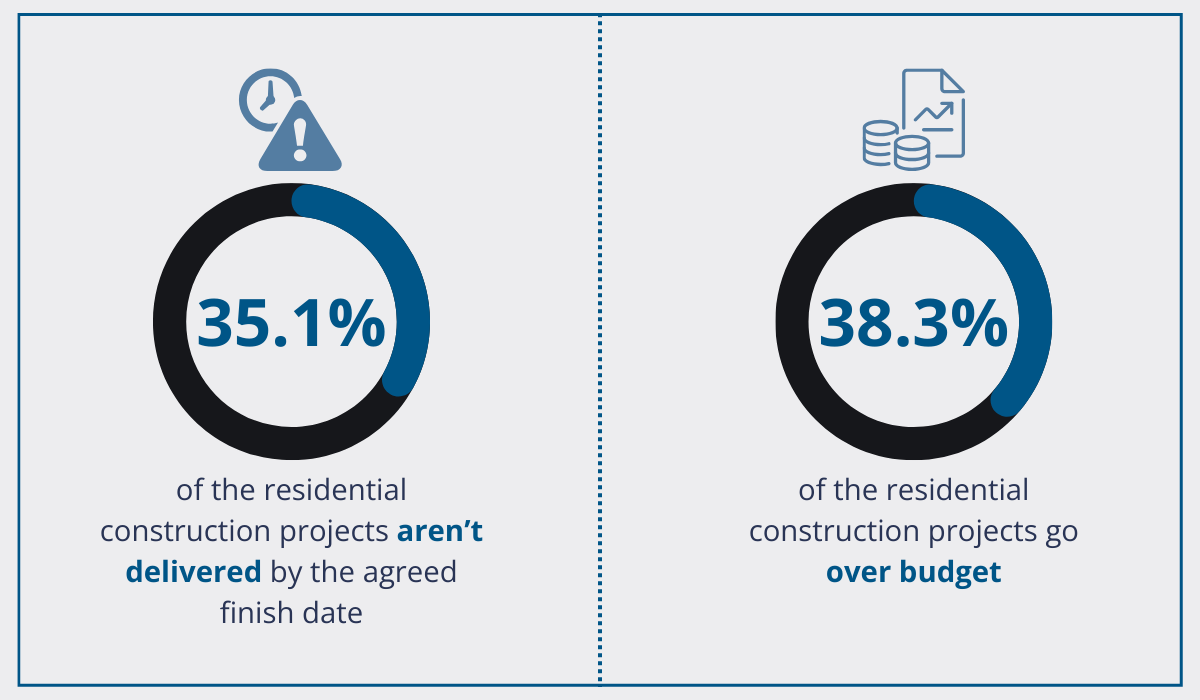

According to the Association of Professional Builders’ survey, these two areas are among the most challenging for residential construction professionals.

The survey reveals that over a third of projects suffer from delays and cost overruns, underscoring the pressing need within the industry for effective strategies to mitigate these issues.

Effective inventory management should be considered a vital component of such strategies.

As demonstrated in the previous sections, proactive inventory management addresses critical issues like material shortages, theft, excessive waste, and improper storage, all of which can disrupt operations and impede project completion.

In other words, this process plays a major role in preventing unplanned downtime and project delays.

Besides, by accurately forecasting resource requirements from the get-go, inventory management ensures the optimal allocation of tools, equipment, and materials throughout the project lifecycle.

This proves invaluable in mitigating unnecessary costs such as:

- Extra storage and handling costs

- Insurance

- Disposal costs for excess resources

- Costs associated with delays and rework

Overall, the significance of proper inventory management cannot be overstated.

In fact, it may be the key to ensuring projects get finished on time and within budget.

Therefore, it’s safe to say that investing effort into improving inventory management is more than worthwhile, as enhanced inventory practices directly correlate with improved project outcomes.

Now, this leads us to the question: How can you improve your inventory management?

How to Improve Construction Inventory Management

The answer to this question can be succinctly summarized in a single word: technology.

However, let us delve deeper into the topic.

In fact, allow us to illustrate how technology facilitates the optimization of inventory management through our own system, GoCodes.

First and foremost, GoCodes makes tracking and managing inventory much easier.

By affixing our QR code labels to your assets and using our smartphone scanner app, you can effortlessly access and update crucial information such as asset location, quantity, and status.

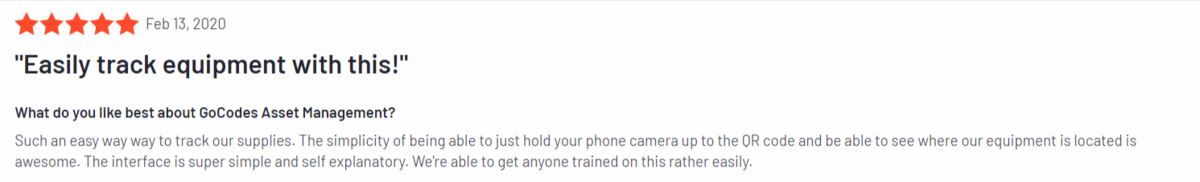

As you can see from our customer testimonial, the system is super efficient, with minimal training needed, catering to both novice and tech-savvy users alike.

Secondly, our system provides timely and precise data, enhancing your decision-making processes.

Since each change in the inventory quantities is automatically recorded, you are always in the know and able to optimize your strategies accordingly.

For example, if you’re running low on certain material, GoCodes will notify you immediately, empowering you to act promptly and ensuring that no important information escapes your attention.

Put simply, unlike manual inventory management methods like spreadsheets, GoCodes always empowers you to make data-driven, informed decisions.

Lastly, GoCodes protects your valuable assets from theft.

Thieves are quite unlikely to act once they see the asset label on an item because it signals to them that the tagged asset is being monitored.

Besides, each time a label is scanned for an asset data update, the GPS location of the update is automatically recorded, too.

This information can prove invaluable in recovering stolen assets if theft does occur.

All in all, improving your inventory management processes entails making them more simple, accurate, and efficient.

Without a system that meets these criteria, you are, essentially, missing a chance to make the most out of your resources and endangering the overall operational efficiency of the operation.

So give technology a try.

It might surprise you just how much it can improve your whole inventory management game.

Conclusion

Hopefully, now you realize just how important inventory management can be.

When executed correctly, it has the power to significantly reduce costs, ensure smooth operations, and enhance the overall quality of the structure you’re working on.

If this sounds like something that could benefit you, take a closer look at your current inventory management processes and identify areas for improvement.

Use this article as a starting point for enhancement, and start working on refining your inventory management strategies today.

Once you get there, you’ll realize it was entirely worth the effort.