If one of your field workers informed you that the machine they were using on a project broke down mid-service, how long would it take to get them a replacement?

Take into account that you would first have to check how many of these machines you currently own, whether any are available, or when one would be.

You should be able to get this information in an instant. If you can’t, you’re not tracking your equipment correctly, which is a big mistake.

Knowing where your equipment is and who is using it can propel your productivity and efficiency, among other things.

If you’re still on the fence about asset tracking, let’s look into some of the essential benefits it brings your business.

In this article...

Improved Physical Asset Visibility

Tagging your assets gives you the opportunity to monitor them, allowing for better visibility.

In other words, creating and placing identifying tags on all your assets lets you understand where they are, who is using them, and when they will be available.

This helps you manage your resources better, which is a pain point for many companies. In fact, more than two-thirds of them think poor schedule management is a crucial contributor to lower productivity.

Of course, the less productive your company is, the more money you lose. Moreover, you become less reliable, which puts off potential customers.

To prevent that, you need to track your assets and always know where they are. That way, you’ll have a clear overview and be able to schedule the equipment, knowing precisely what to count on and when.

For example, if you find out you need a bulldozer in two weeks at the construction site, you can check where your bulldozers are and whether any will be free to use when you need them.

If so, you should have a system that lets you schedule the asset, thus allowing you to plan and guarantee that the required machines will be ready when necessary.

More Efficient Maintenance Tracking

If you want to track a piece of equipment efficiently, don’t forget its maintenance!

With asset tracking, you should have an insight into previous and future preventive maintenance.

This is made possible by maintenance logs, i.e., reports explaining what problems were found and fixed during servicing.

The team should keep accurate logs of all sessions to ensure nothing goes unnoticed. However, if they do this on paper or in spreadsheets, the information won’t be readily available to others who use the equipment.

Using asset tracking software is a great way to keep your data in a centralized, easily accessible location. This type of software allows your team to simply upload the latest maintenance information to the asset’s page.

Anyone who has new data to add, whether it’s an updated operational manual, maintenance log, or a new future servicing date, can do it without having the asset close by.

In other words, your maintenance staff can make all these changes in the software without interrupting operators using the machinery.

Moreover, when you use software to schedule servicing, you can set up notifications to let you know when a certain machine is due for maintenance.

This way, you will not only never miss a service date but also avoid booking an asset that needs maintenance.

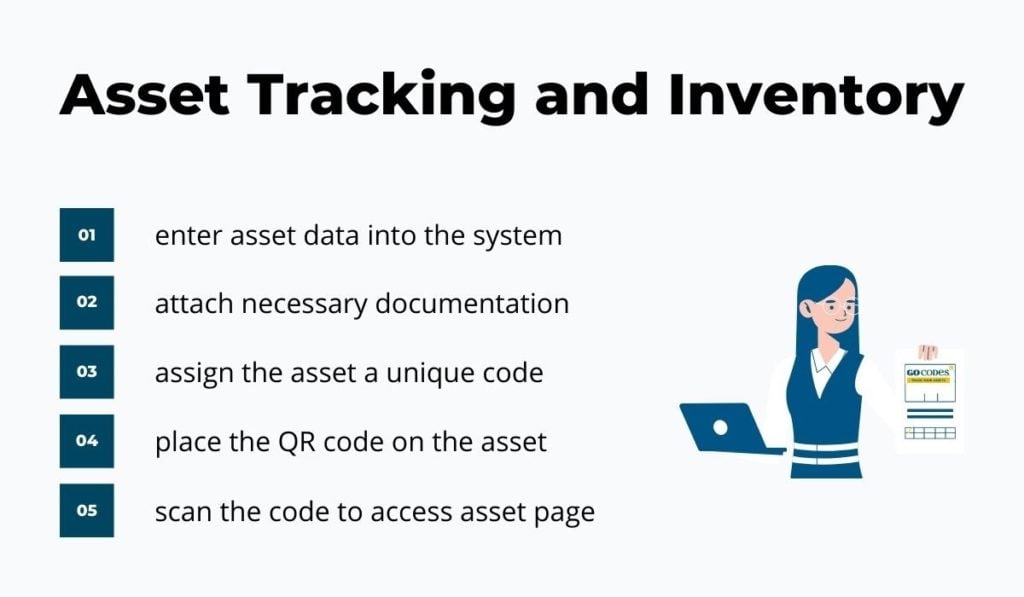

Simplified Inventorying Process

Tracking your equipment can completely transform your inventory process.

When you’re up-to-date on your assets, you know exactly what you have, how much you have spent, and what you have to reorder. In other words, you won’t, for instance, waste money on ghost assets, items you are paying for but no longer own.

Of course, if you manage inventory manually, you will waste time and energy, which is why many companies do so rarely or with insufficient accuracy.

However, with a simple investment in asset tracking software, you only have to do it once.

When you do it the first time, you need to be thorough and make a note of every piece of equipment you own, list its specifications, maintenance information, and attach related documentation, like manuals and service logs.

You should then assign the asset a unique identifying code and tag it with a corresponding QR code that leads to the main page where you’ve listed all this data.

So, when your maintenance team decides a machine can no longer be used, they can simply scan the code and change the status accordingly, automating your inventory process.

When you purchase new assets, you should add all their information into the system and assign it a QR code to ensure the inventory is always spot on.

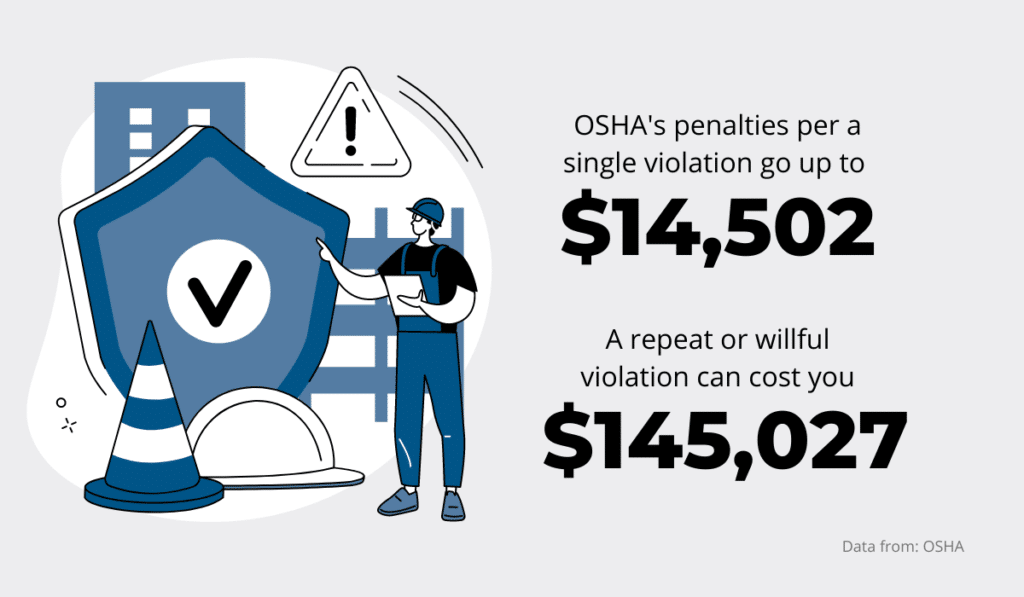

Easier Asset Audits

Using software to track equipment information simplifies your audits.

When you tag your assets, you always know what you have, what condition it is in, how often it is maintained, and where it is.

On top of that, you can always add the necessary information for future inspection or audits, like equipment testing, calibration, and all the maintenance-related data.

With this information at hand, you can easily create audit reports and prove your compliance with the rules and regulations of the construction industry.

For example, if a safety incident with equipment happens at the workplace, whoever is assigned to inspect the construction site will require information on the asset in question.

You’ll have to quickly present evidence of your continuous investment into the equipment. Without proof, institutions like OSHA can fine you up to $14,502 per serious violation and a hefty $145,027 for a willful or repeated one.

Clearly, producing reports and documents that prove compliance is a must for anyone who doesn’t want to risk such monetary losses.

If you use software for asset tracking, auditing will become child’s play, as a software solution enables you to generate real-time reports in a couple of clicks. This option guarantees that you can get quick and accurate data almost immediately.

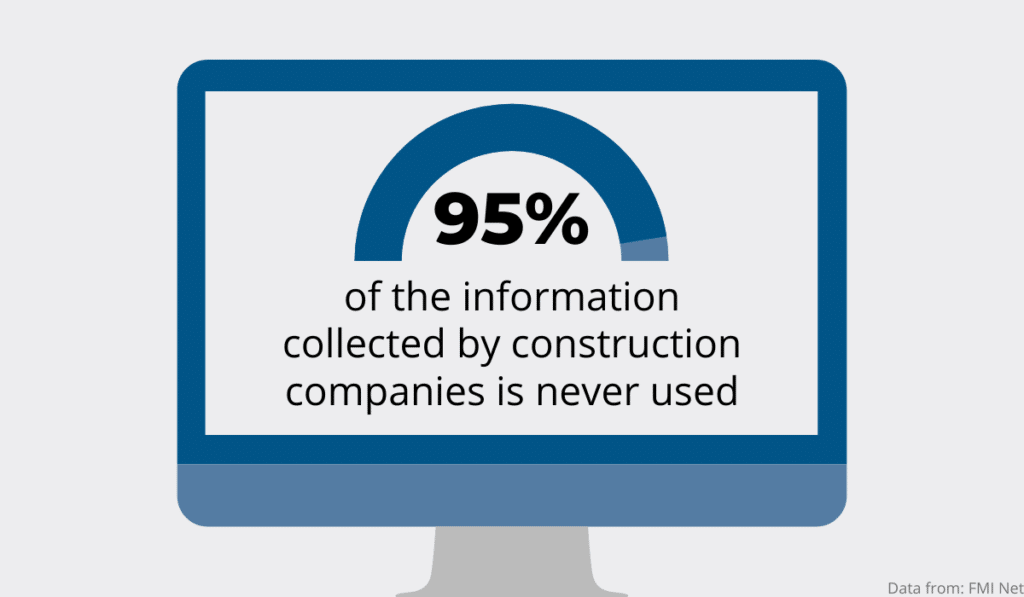

Enhanced Cost Control

If you’re trying to stay on top of your spending, turn to asset tags.

According to McKinsey, construction is one of the least digitized industries in the US, which means it doesn’t use digital tools to its advantage.

Even worse, the data construction companies do capture goes unused.

More precisely, a whopping 95% of such information is only collected but never analyzed or used to improve processes.

If you’re already gathering data, you should find a way to use it to your advantage.

When you use a digital tool—software or an app—to track your equipment, it will gather various data, such as frequency of use, maintenance stats, or last known user.

With this information, you can ultimately improve your cost control. For example, asset tracking reports will show you which equipment is constantly or never in use, helping you improve asset management.

Since you pay just to own and maintain an asset, it’s better to sell the items you don’t use. That way, you’ll get some money in return and save on all the depreciation and servicing costs.

On the other hand, if your equipment is always in use, consider buying more to speed up your projects and get the job done quicker. At the same time, you will reduce the utilization of the asset, which helps lower your ownership costs.

Tracking your machinery’s maintenance will also point to machines that cost more to repair and service than you get out of them. This is often the case with defective machinery or older, overused assets.

Once again, the data you get from asset tracking will help you manage your funds better and save money.

Reduced Risk of Asset Loss

Tagging your equipment significantly decreases the risk of theft.

Knowing where your assets are and who is using them significantly reduces the risk of theft.

Firstly, it makes employees more responsible since they must return the equipment at the end of the day. The asset will stay assigned to them until they do.

Then, asset tracking also makes it more difficult for an employee to steal an asset since their name is on the list of asset users.

It’s easy to understand why thieves would be put off from stealing tagged and tracked equipment. Tags imply that the owner can trace the last known location of the asset, for starters.

Additionally, the tags serve as proof of the thieves not being the rightful owners. Metal tags or QR codes aren’t easy to pull off or scratch away, so thieves will have difficulty removing them without damaging the equipment.

If they leave these tags on, the seller might notice the tags don’t correspond to the person selling them.

For example, with software like GoCodes Asset Tracking, you get unique QR codes. Anyone with a smartphone can scan the code and access a page that tells them more about the owner.

In other words, the thieves won’t be able to manipulate this data because they’re not registered users. The person scanning the code will be able to leave you a comment, and you’ll get notified of your asset’s last known location.

Improved Customer Service

Tracking your equipment through tags ultimately helps your customer satisfaction.

Once you know what equipment is available and when, it’s a lot easier to avoid double-bookings. For example, if you know you will need a crane in three weeks, tracking software lets you book it in advance.

Therefore, you’ll ensure the asset is there exactly when needed and planned, which will increase customer satisfaction.

Keeping your customers happy is an excellent way of promoting your business in the long run. After all, the overwhelming majority of people believe word of mouth more than they do advertising.

In other words, if a customer tells their friends in the industry about how many issues your delays caused them, these friends will probably not do business with you. So, the best way to deal with this is to find ways to improve your customer satisfaction.

Another way tagging helps you stay on track with your project is that it allows you to locate tools and check them in and out seamlessly.

This option will be very useful in construction, as one of the most common customer complaints is delays, which always cost extra and cause rescheduling and dissatisfaction.

Your construction team can use the app to verify which tool or equipment is available right now and check it out with a simple QR code scan.

That way, you’re eliminating long waits and workers taking each other’s tools, which can cause delays and problems with tasks.

Conclusion

Tagging your assets can completely transform your business in the sense that it finally allows you to have a better overview of everything you own, its condition, and care.

Your inventory becomes seamless once you add all the equipment data into a tracking system.

With this information, your audits become effortless, and it’s much easier for you to perform cost management.

Moreover, tagging your equipment lowers the risk of theft, which can cost you a lot, especially during a project.

Finally, all of these points will affect the quality of your customer service, leading to increased customer satisfaction and better reviews.