Like most things in life, changes are inevitable in construction.

Clients often make adjustments to the original plans, thunderstorms delay construction work, or the terrain on which you build requires unforeseen additional interventions.

All of these changes lead to alterations to the original contract, which need to be managed. That’s where change orders come in.

Essentially, change orders account for all additional work and costs and help you keep the project on track.

That way, you keep your client’s expectations (and budget) in check, and, most importantly, change orders can help you prevent costly disputes and legal action due to modifications to the original contract.

But let’s take a closer look at what change orders are, their main types, and the essential elements of a change order form.

In this article...

What Is a Change Order?

A change order is an official, client-requested modification to the construction project.

It is a document that addresses any change that can ultimately impact the project’s budget and timeline.

After the original plan and contract are created, the client may decide that they don’t reflect their vision.

In those cases, they can submit a formal request (i.e., the change order) to suggest alternatives, additions, or deductions.

Also, clients are not the only ones that can make changes to a construction project. Change orders can be necessary for a slew of other reasons:

- Drawing errors, inaccurate specifications, and omissions

- Inaccurate estimates (material cost, labor hours, project schedule)

- Hidden conditions at the site

- Unplanned events (vandalism, natural disasters, etc.)

- Failed inspections

Obviously, no plan is set in stone, and construction projects are highly subject to change. But any change to the original estimates can severely delay project completion and increase costs.

Since change orders are expected to happen, contractors often try to minimize the number of change orders for construction projects.

For example, this contractor sees the value in charging extra for change orders during construction that his colleague implements in his business practice.

That way, the client will be less inclined to make numerous changes on a whim, and the project can progress according to the original plan.

In general, there are two types of change orders in construction: additive and deductive.

When it comes to additive change orders, it usually means expanding and adding new elements to the project scope.

For example, creating a new wall in a previously open-plan space.

On the other hand, deductive change orders deal with eliminating elements from the original contract.

Depending on the type of construction project, this can sometimes help save resources.

Yet, no matter the type of change order, when you’re dealing with modifications to the original design, it’s necessary that contractors and the clients agree on the proposed changes and sign the change order document for legal purposes.

Because if you happen to fall into a dispute, you will have a written and signed agreement from the client for any changes in project scope and its effects on final project outcome, costs, and schedule delays.

In short, change orders are legal documents routinely used in construction. They amend the existing scope of work and capture any modifications made to the original contract.

What Is a Change Order Log?

Since change orders have such a significant impact on construction projects, you’d think that most construction companies have an efficient way of handling them.

Well, the reality is much more worrying.

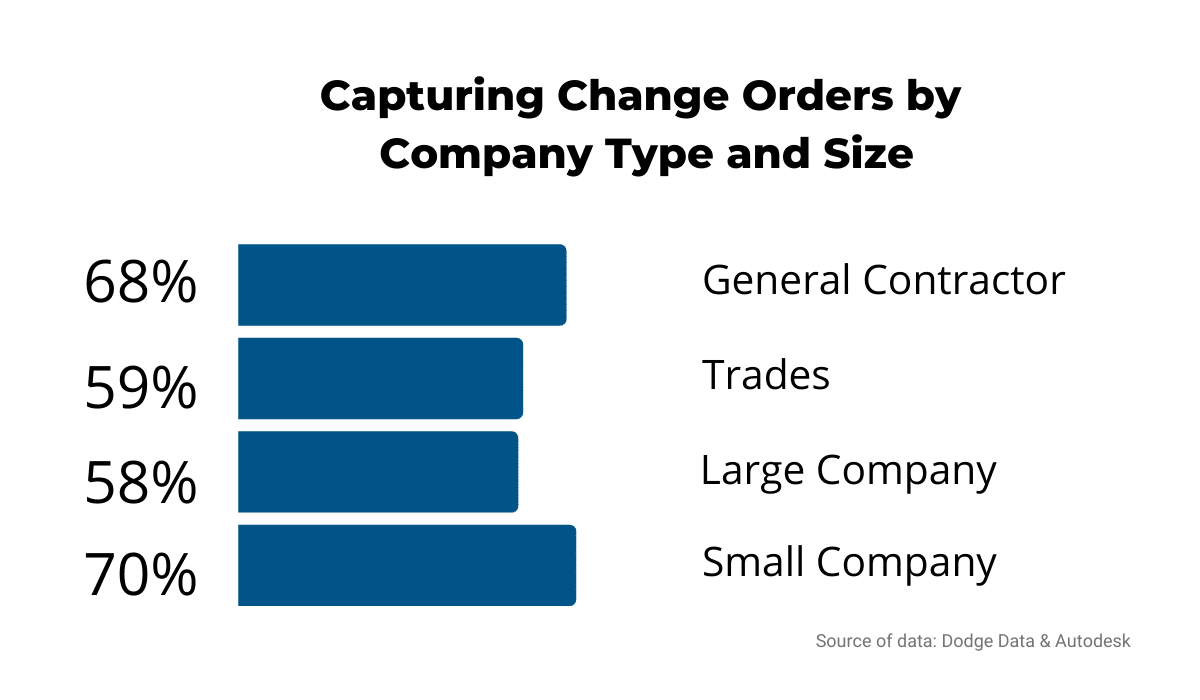

According to a recent survey conducted by Dodge Data and Autodesk, only 64% of contractors regularly document change orders for half of their projects.

And that number seems to diminish the bigger the company is. Or in other words, smaller construction companies are more diligent in managing change orders than larger ones.

This is troubling since change orders impact large projects more than smaller ones. In some cases, we’re talking about millions of dollars in disputes.

For example, in a dispute between Dynamic Systems Inc. and Skanska USA, the HVAC contractor (Dynamic) argued that numerous change orders for their project in Valhalla, New York, increased the total price from $17.8 million to $22.5 million.

Fortunately for Dynamic, they proved that the primary contractor approved all of their change orders, and they were paid for the additional costs and interest.

This is why it’s important to have change order logs.

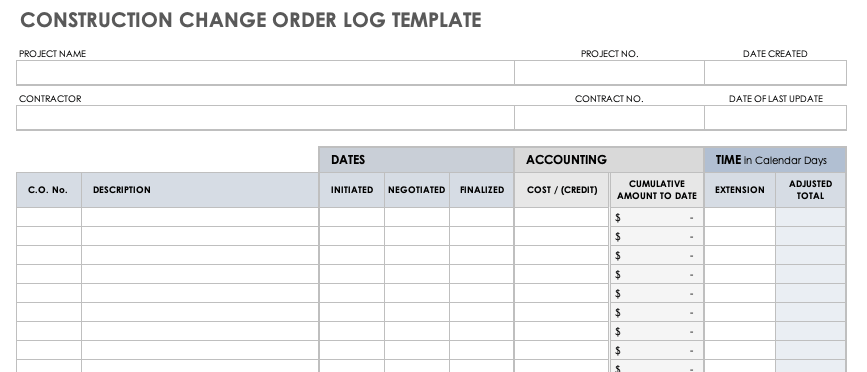

A change order log is a list of all change order requests which capture details such as date, creator, status, and needed actions.

General contractors collect change orders and save them in any convenient place (Excel or project management software).

Basically, every time a change order is made, it needs a change order log.

Furthermore, careful change order logs help keep the entire project on track. Since change orders collect necessary information, there’s more transparency in costs.

So both parties are on the same page financially.

Also, when these documents are up-to-date, there is minimal risk of necessary changes not being recognized and implemented on time.

Finally, because change orders are official documents, you’ll need to hold them for several years.

This depends on the state regulations in which you’re operating, but construction companies generally should archive documents for at least three years.

All in all, having your change orders collected and stored in change order logs is essential to handle potential disputes and comply with governmental regulations.

Types of Change Orders

We’ve already mentioned that change orders, in general, come in two types.

Yet, there are also several different ways change orders are used to document changes in project scope and their effects on project costs. Let’s go over them briefly.

Lump Sum

A lump sum change order is used when a firm price can be created based on a quantified change in scope.

Most often, this happens when the required changes are extensive due to external conditions.

Additionally, lump sum change orders also define the changes in cost, which include direct costs, markup, and profit (determined by the contractor).

They can increase the contract cost or add credit to the contract value.

Zero Cost

This type of change order does not affect the final contract value, but it’s used to document project changes.

Similarly to lump sum, the scope of work can be quantified beforehand, but the costs do not change.

Changes in the scope of work should be tracked, regardless of their effects on the project costs.

If anything, zero cost change orders can help contractors and clients communicate better about their visions for the final project outcome.

For example, if a client wants to change countertops in their kitchen from granite to quartz (but the price remains the same), the official and documented request for change helps contractors fulfill their wishes and increase the client’s satisfaction with the project.

Time and Material

A time and material (T&M) change orders occur when the cost of the changes can’t be determined.

Usually, changes in work scope happen due to hidden or unforeseen circumstances, so the true costs can only be calculated after the work is completed.

In this case, contractors will track time and material spent on these change orders and add costs for labor.

On the other hand, the client can request a breakdown of these charges to justify the cost of change orders.

Therefore, the contractor and the client must negotiate factors for a T&M change order as part of the original contract.

That way, all expectations are met, and clients are not faced with a bill they weren’t aware of, meaning they have no reason to refuse to pay.

Unitary Cost

A contractor will use the unitary costs change order before any change-related work begins.

This type of change order is negotiated for additions in scopes of work that are out of the project owner’s control.

The unitary cost change order is commonly used for scopes of work that contractors do consistently. Basically, completed work is based on and defined by specific measurement units.

For example, concrete finishers will have a unitary cost change order for pouring cubic yards of concrete.

But while clients can’t control the quantity of work being added, they can negotiate the cost of this additional work, including the contractors’ profit and markup, before the work is completed.

Elements of a Change Order

A truly efficient change order has all the relevant information regarding modifications to the original contract. So you have to ensure that your change orders have the following elements:

Project basics | This usually includes the contract number, the owner’s name and contact information, project name and address, and the change order number, among other things. |

Revised scope of work | Proposed changes should be described in detail, with the assumption that the person reading the document isn’t as familiar with the project as the person writing it. This should also include the reasons for the change and, if needed, a photo, or drawing attachments to clarify why the change order is necessary. |

Justification | This is a separate field in the change order form where you can explain in more detail why you want to make changes to the original contract. |

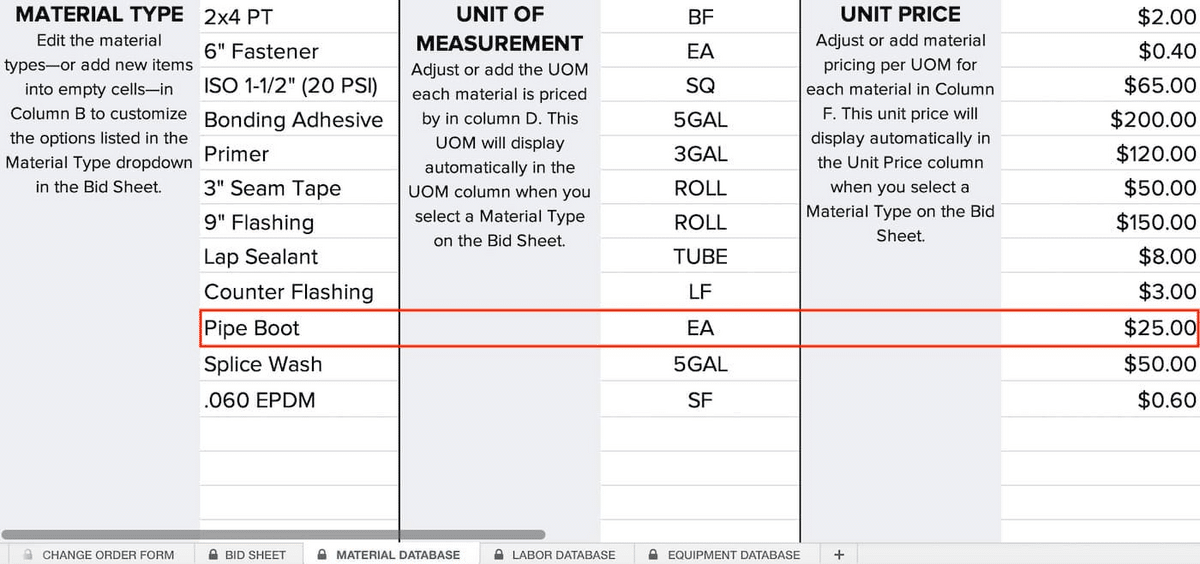

New pricing | Calculate all additional material and labor costs and include the final cost in the change order form. |

Adjustment to project milestones | Time is also a big factor since additional work often means recreating and adjusting the project schedule. If the change order alters the completion date in any way, it should be listed in the change order form. |

Signatures | Clients and contractors have to sign the change order form to confirm their agreement to the proposed changes. Not to mention, this legally binds both parties and makes the changes official. |

Creating a change order boils down to having as much detail as possible. That way, the client and the contractor can make an informed decision and agree to the proposed changes.

So, having these elements in your change order form will ensure you clearly outline all the necessary information.

Change Order Template Example

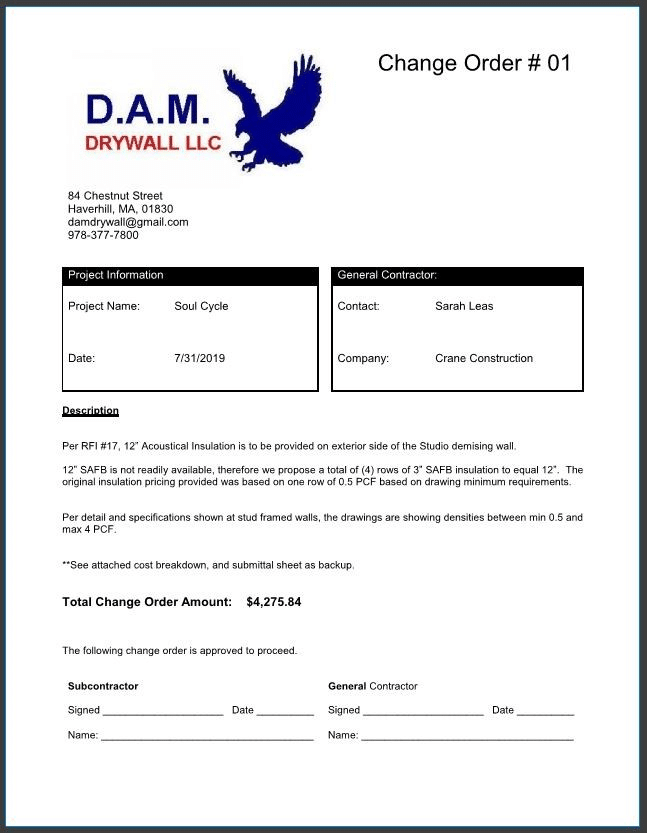

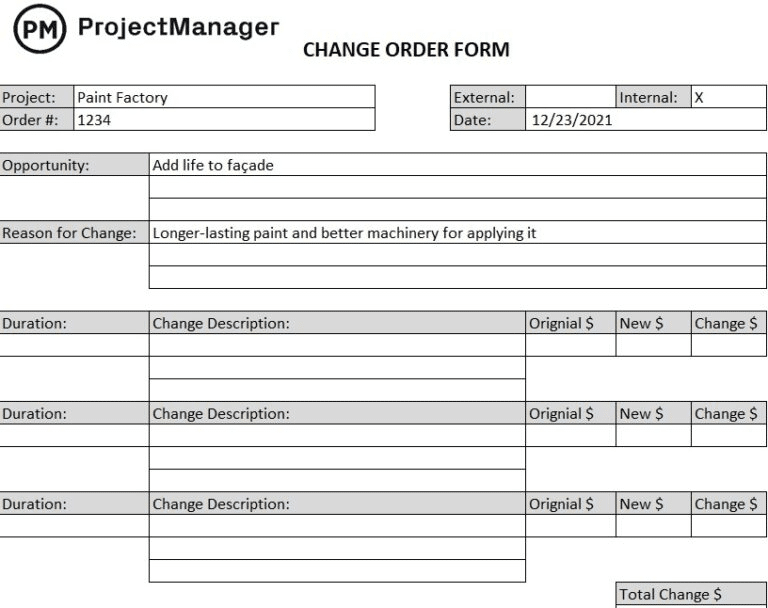

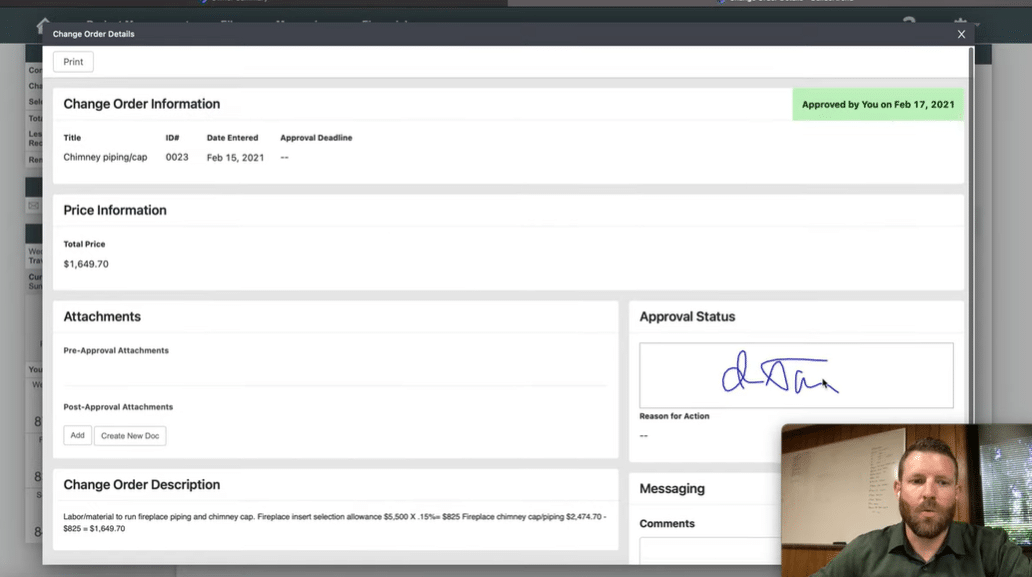

Now that you’re aware of the basic elements of a change order, here is how it looks in practice.

At the top, there are fields that include the project basics (change order number, date, name of the project).

Also, in this form, you can see where the request came from (internally or externally). In case of an external change order request, it might mean an aspect of the project failed an inspection.

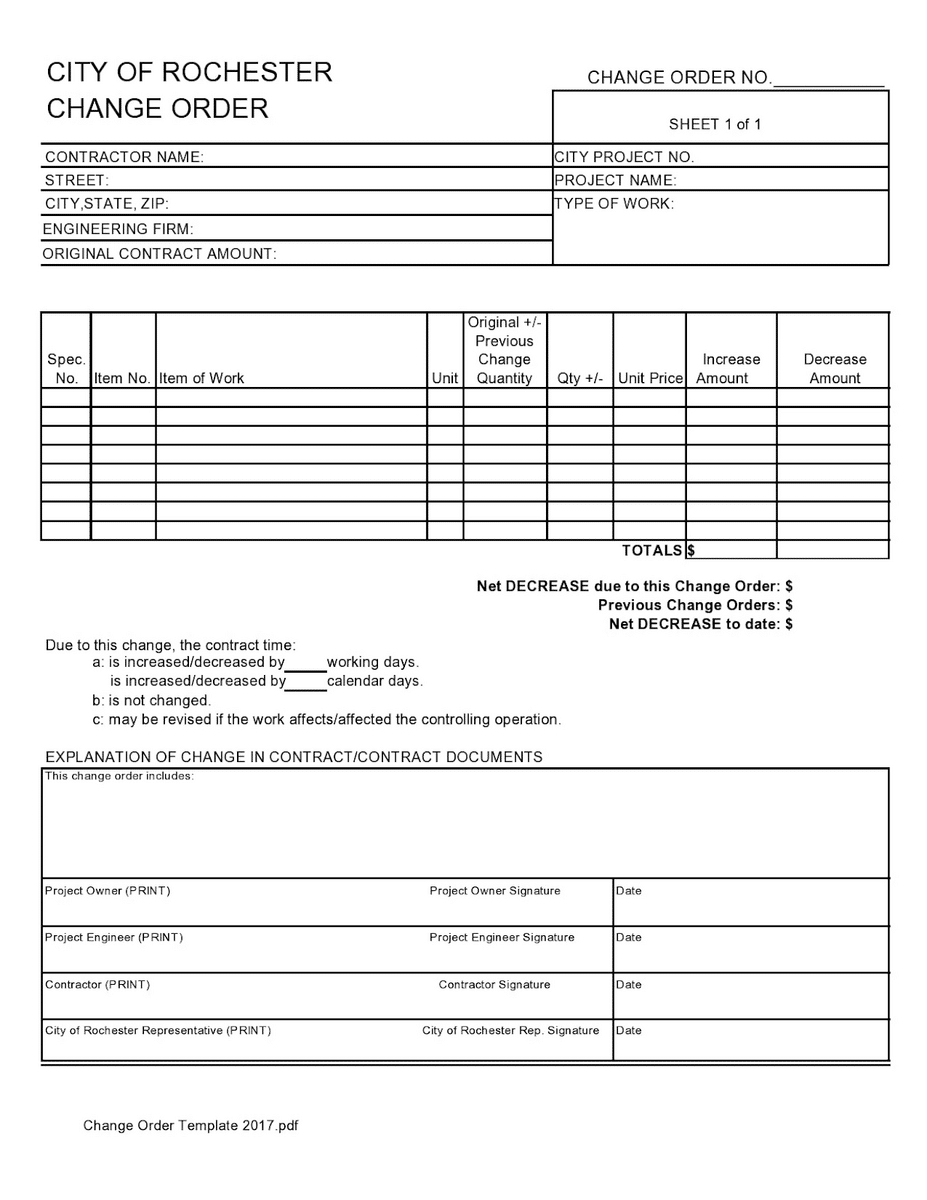

The opportunity field in this change order form is actually a brief description of a proposed change. The main purpose of this section is to summarize the main point of the change order.

Then, the form has a separate field for justification.

Here the requester should clearly explain why the project needs a change order and how it will benefit both parties and the final project outcome.

In this case, a longer-lasting paint will mean less maintenance after the project is finished, and using better painting equipment will ensure the paint is applied with the required quality in mind.

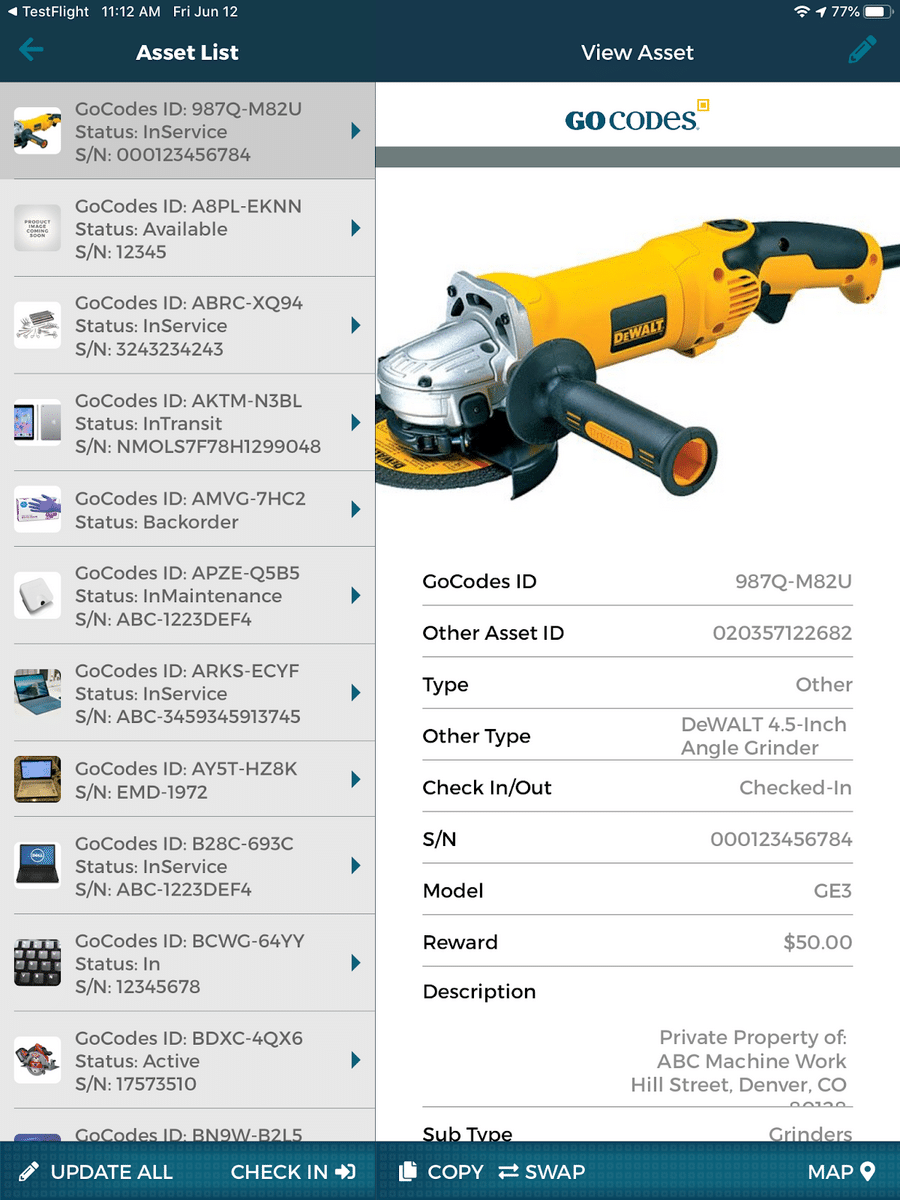

But if you also have the right asset tracking software like GoCodes that will find the equipment in your inventory in seconds, deciding on approving the change order or not will be much easier.

Knowing you have the right equipment at your disposal to fulfill a change order can further accelerate the change order process and keep the project on track.

Finally, there are several fields where the requester can calculate additional material and labor expenses that deviate from the original contract.

Also, they can fill in how long the additional work will last and add to the existing project timeline.

Here you can give more details, so remember that the more information you give, the faster your change order will be approved.

Also, at the bottom of the change order form, there should be a separate field for signatures to make the change order official.

Now, we’ve briefly gone over a paper version of a change order, but more and more construction companies are switching to cloud-based software to manage their change orders.

The forms should still have the same information, but sharing them with key stakeholders is more efficient.

After all, they only need a good internet connection and access to a construction project account.

The most important thing to remember is that no matter the format of your change order form (paper or digital), it should include the necessary information to finish the project to satisfy everyone involved.

Conclusion

The simple truth is that construction projects are prone to changes, mistakes, and unforeseen circumstances. So, change orders will be essential for almost any project you undertake.

Hopefully, this simple guide to change orders helped you understand what change orders are and their importance for handling construction projects with minimal repercussions.

Now, you can take up any project with the assurance that you’ll be able to manage any changes in the best way possible.