Today, GPS technology goes far beyond showing you the location of your car or smartphone and enabling you to get to the right destination.

In other words, technological advancements have greatly expanded the potential uses of GPS, particularly in the construction industry.

More precisely, construction companies use GPS for various purposes, such as tracking vehicles, heavy equipment, and tools, as well as monitoring worker safety and performance, and capturing project progress.

Ultimately, GPS technology allows construction companies to streamline their operations, increase productivity, and improve client satisfaction.

So, this guide will cover how construction GPS solutions work, their importance, and the features they should have.

In this article...

How Does Construction GPS Work

To better understand how useful GPS tracking can be in construction, let’s first explain what it is and how it works.

The Global Positioning System (GPS) is a network of satellites orbiting the Earth that transmit signals to GPS receivers, which then use the process called trilateration to determine their own position.

Although its name suggests otherwise, trilateration actually involves the use of at least four satellites, not just three, that a GPS receiver uses to calculate its position in three dimensions (latitude, longitude, and altitude) and also calculate the time.

Furthermore, when these GPS receivers are capable of storing or transmitting data in real time, they become GPS trackers.

GPS trackers come built into many devices (smartphones, car navigation) or they can be installed or attached to assets, such as construction vehicles, equipment, and tools, like standalone devices or asset tags.

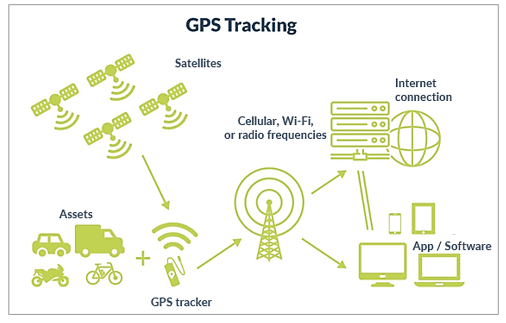

To better visualize how all this works, here’s a simplified view of GPS tracking, courtesy of PowUnity:

As you can see, it shows how the GPS receiver in the GPS tracker calculates and confirms the asset’s location with the help of satellites, which we discussed earlier.

Now, if the GPS tracker records data like the location and speed of a vehicle and stores it for later download and analysis, that’s called passive GPS tracking.

Mind you, a “passive” tracker is still actively collecting data, it just doesn’t immediately transmit it.

Instead, it stores the data it collected for later retrieval, such as passive GPS loggers on many long-haul trucks.

Conversely, when a GPS tracker can transmit data in real time, that’s called active GPS tracking.

In the image below, an active GPS tracker uses cellular, Wi-Fi, or radio frequencies to transmit the location data to a GPS tracking app/software, which then processes the information and presents it to the user in an understandable format (i.e., on a map).

The final result is that the user gets the GPS location of tracked assets on their device almost immediately, i.e., in real time.

We should note that there’s a third way to track the GPS location of assets known as GPS-enabled asset tracking.

This type of tracking involves affixing barcode or QR code tags to assets you want tracked.

These tags do not have a GPS receiver. Instead, the GPS location of a tagged asset is recorded every time the tag is scanned by a GPS-enabled device like a smartphone.

Needless to say, such asset tags are more affordable than traditional GPS trackers and can be used to track a large number of assets.

Finally, let’s just say that today’s GPS tracking technology provides a high level of precision of reliability, accurately locating a tracked asset within 16 feet or better.

However, the accuracy of a GPS tracking system will depend on signal strength, satellite position, weather conditions, and obstructions such as mountains and buildings, to name a few.

Overall, GPS is a satellite-based navigation system that enables construction companies to determine the precise location and track movements of construction assets such as vehicles, equipment, and tools.

Why Is GPS Important for Construction

The importance of GPS for construction stems from the complexity of construction projects, as it allows construction companies to improve their operational efficiency by streamlining their project management, reducing costs, and increasing productivity.

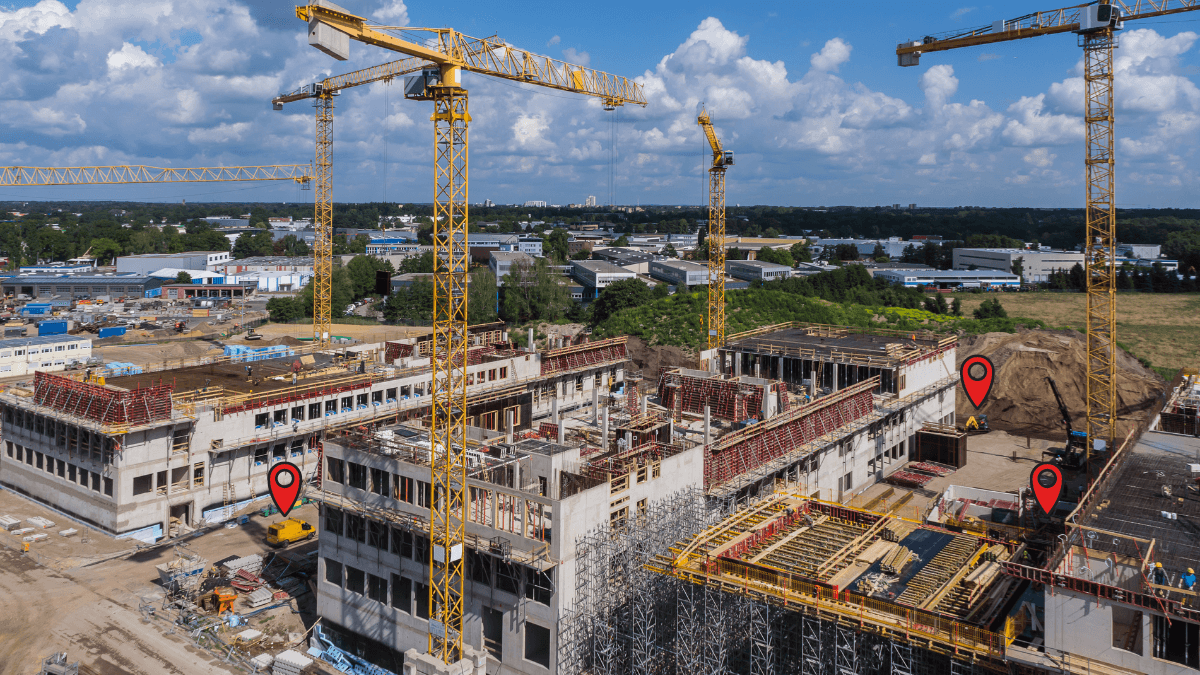

In other words, today’s GPS solutions enable companies to track almost anything on-site, such as heavy machinery, vehicles, mid-sized equipment, small tools, construction materials, and even workers (with their consent).

Moreover, when GPS tracking is combined with other technologies, such as built-in or external sensors, the Internet of Things (IoT), predictive analytics, and mobile apps, companies can collect and analyze all kinds of data on how their construction resources are used.

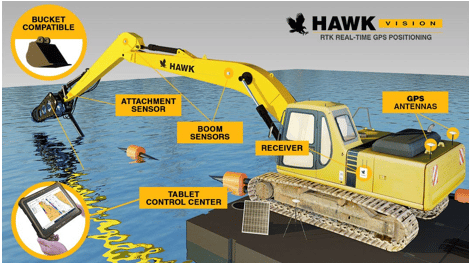

For example, the sensors on heavy equipment such as excavators and bulldozers can track operating conditions like fuel consumption, engine temperature, operating hours, the amount of material moved by the equipment, and other operating parameters.

Additionally, mobile apps can provide real time data and alerts about the location, usage, and maintenance of construction equipment, enabling companies to optimize the use of their resources, and improve their operational and financial performance.

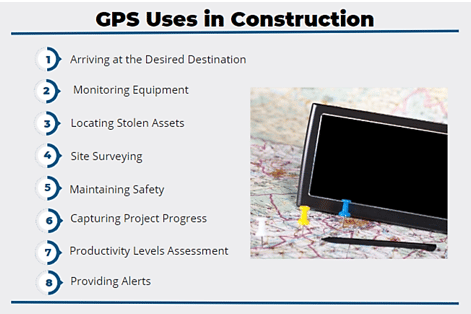

All these capabilities underline the importance of continuously expanding GPS uses in construction.

Here are just some areas where construction companies can use GPS to significantly increase their productivity and improve the bottom line:

For instance, GPS is extremely useful when it comes to construction fleet management.

Different route optimization software allows drivers/dispatchers to plan the most efficient driving routes in advance and adjust to changes that occur in real time, such as traffic jams, accidents, or weather conditions, to arrive at the desired destination on schedule.

Next, when GPS trackers are connected to internal engine sensors of construction vehicles and heavy equipment, fleet managers can monitor the idle time and fuel consumption, allowing them to reduce idling and other fuel-wasting driver/operator behaviors.

Of course, knowing the exact GPS location of their construction fleet and assets like tools, small equipment, and other items of value allows managers to prevent their theft or quickly locate them and alert the authorities in case they’re stolen.

For example, when Ben Kasper’s skid-street loader was stolen, he used the GPS tracker to find his property and bring the police to the scene, as reported by CBS News.

In the above article, Kasper describes how he located his loader:

They ripped out the phony GPS tracker I put in it, but the real GPS tracker was in it—and that got me notified of this location.

In addition to the prudent actions Kasper took, this sentence also underlines the importance of GPS tracking for quick recovery of stolen property, whereas GPS solutions can also be used to prevent unauthorized use and enhance worker accountability.

As for the other above-listed construction GPS uses and benefits for construction companies, you can read more about them in our article.

Overall, as technology progresses, so does the importance of construction GPS solutions that, combined with other technologies, enable companies to streamline almost any aspect of their construction operations, thus reducing costs and increasing productivity.

What Features Should Construction GPS Have

Considering all the different uses, the features that construction GPS solutions should have will depend on the specific needs of construction companies and the type of projects they’re working on.

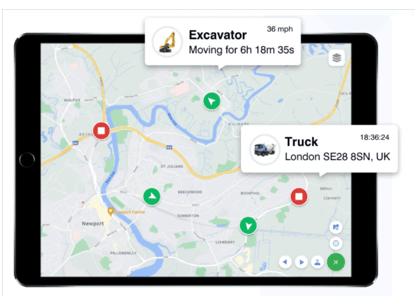

However, different GPS tracking software typically provides some common features, such as real-time asset tracking (active or passive), access to historical data, availability on mobile and other devices, geofencing, alerts and notifications, and reports and analytics.

For example, historical data allows for analysis of different construction processes and their improvement, while mobile access enables managers to monitor project progress and make informed decisions on the go.

So, let’s take a closer look at three important tracking software features: geofencing, maintenance alerts, and asset usage reports.

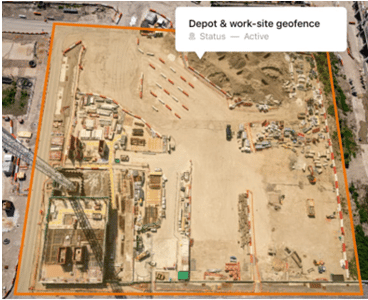

Geofencing

This software feature enables construction companies to set up an invisible virtual perimeter around the construction site—a geofence.

Simply put, geofencing allows project/site managers to use GPS trackers on vehicles and equipment to monitor their location, movement, and usage within a designated area in real time and receive alerts when they, for example, enter or exit the jobsite.

For example, Verizon’s GPS tracking solution allows construction managers to establish specific operating hours for heavy equipment and vehicles on the jobsite and be instantly alerted to any unauthorized movement outside those hours.

Keep in mind that workers’ smartphones or wearable protection tech can also be tracked within a geofence to enhance worker safety or monitor productivity, but companies need to obtain prior consent from workers.

In any case, geofencing can be used to increase jobsite safety and security, optimize the use of resources, enhance regulatory compliance, and boost productivity.

Maintenance Alerts

This construction GPS feature enables fleet/equipment managers to set up and receive maintenance alerts, which allows them to cut equipment downtime, avoid costly repairs, and enhance jobsite safety.

When GPS trackers are coupled with built-in or external sensors in vehicles and equipment, this feature allows managers to receive maintenance alerts when certain thresholds are reached, such as equipment’s operating hours or vehicle’s mileage.

Alternatively, tracking software enables managers to set a specific date when an alert will be sent to remind them of upcoming maintenance.

For example, our asset tracking software, GoCodes Asset Tracking, allows contractors to track the location, usage, and maintenance of their equipment and tools, schedule future maintenance tasks, and set reminders for themselves and/or responsible maintenance staff.

Overall, maintenance alerts are a great way to automate regular maintenance.

They help with reducing the risk of breakdowns and the resulting downtime or even project delays, as well as avoiding costly repairs caused by poor maintenance, and ensuring safety and regulatory compliance.

When coupled with data analysis and asset usage reports, maintenance alerts can be further optimized according to usage patterns and operating conditions of the equipment, leading to additional cost savings achieved through preventive and predictive maintenance practices.

Asset Usage Reports

Asset usage reports are another useful feature of construction GPS tracking solutions that enable fleet/equipment managers to analyze and optimize the usage of construction assets.

Simply put, when construction GPS tracking solutions track the location, movement, and usage of construction assets, they also collect different types of usage data, such as fuel consumption, operating hours, and maintenance records.

This data is then analyzed by the software, allowing managers to generate detailed asset usage reports showing how construction assets are being used, how much time they spend on different tasks, and how long they sit unused.

Based on this information, construction companies can improve their equipment management and overall productivity, cut costs, and make better-informed decisions.

In essence, asset usage reports generated by construction GPS solutions are a crown jewel of asset tracking technology, allowing construction companies to tap a goldmine of valuable insights they can use to streamline their operations.

When the information from such reports is properly utilized, construction companies can make data-driven decisions, optimize the usage of construction assets, reduce costs, and enhance productivity.

Conclusion

Having covered how construction GPS solutions work, their importance for construction, and the standard features they should offer, it’s clear that GPS can assist construction companies in better managing almost every aspect of their construction operations.

When a company selects the right combination of GPS tracking options, it can optimize the use of construction resources, reduce costs, increase productivity, and boost client satisfaction and profits.