The Internet of Things (IoT) has been entering different industries and spheres of life.

The term stands for a network of devices or tools connected to the internet or each other, thus allowing a data flow while automating processes.

IoT does things like monitor the user’s health through phones and watches, predict maintenance for vehicles, and automate checkouts at a supermarket.

In other words, it’s become so commonplace that you’re already reaping the benefits of this technology.

It has even made its way into industries that aren’t known for their easy acceptance of new technologies, such as construction. Therefore, the fact that there were 11.3 billion active IoT devices in the world in 2020 doesn’t come as a surprise.

However, you may be wondering how you can use IoT in construction and what exactly you’ll get out of it. If that’s the case, you’ve stumbled upon the right article.

Let’s take a deep dive into the world of construction IoT!

In this article...

Purpose of IoT in Construction

IoT’s main objective is to save you time, money, and energy by connecting your devices.

On the Internet of Things, devices, tools, and equipment you own are connected over a network, allowing them to exchange data and you to collect it. This technology also lets you control a lot of your assets whenever you’re online and get essential data from them.

In simpler terms, IoT helps your devices gather and send the necessary information to you or other relevant tools and machines.

The point of IoT is to connect everything in an accessible way, helping you to do your job with minimal risks and costs, yet with maximum efficiency and productivity.

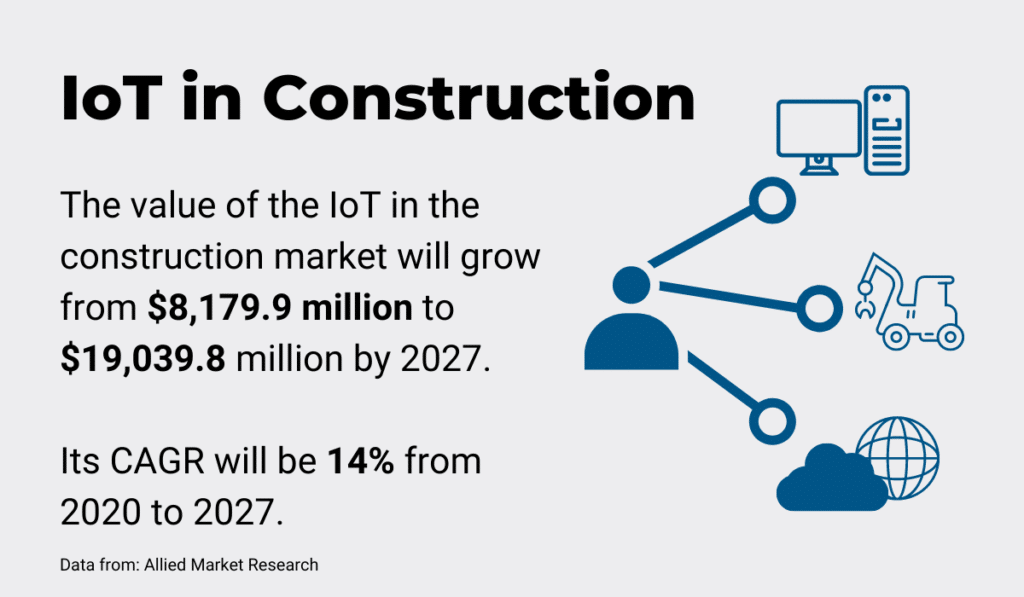

According to Allied Market Research, the construction industry is starting to see the appeal of introducing IoT in everyday business. Their report found that the value of IoT in construction in 2019 was $8,179.9 million.

The report also notes that the IoT value will increase to $19,039.8 million by 2027, projecting growth of over $10 million. In other words, the market will grow at a compound annual growth rate (CAGR) of 14%.

These numbers aren’t surprising if you consider that this technology serves the construction sector in more ways than one, including:

- Reducing operational cost

- Maximizing productivity

- Improving project management

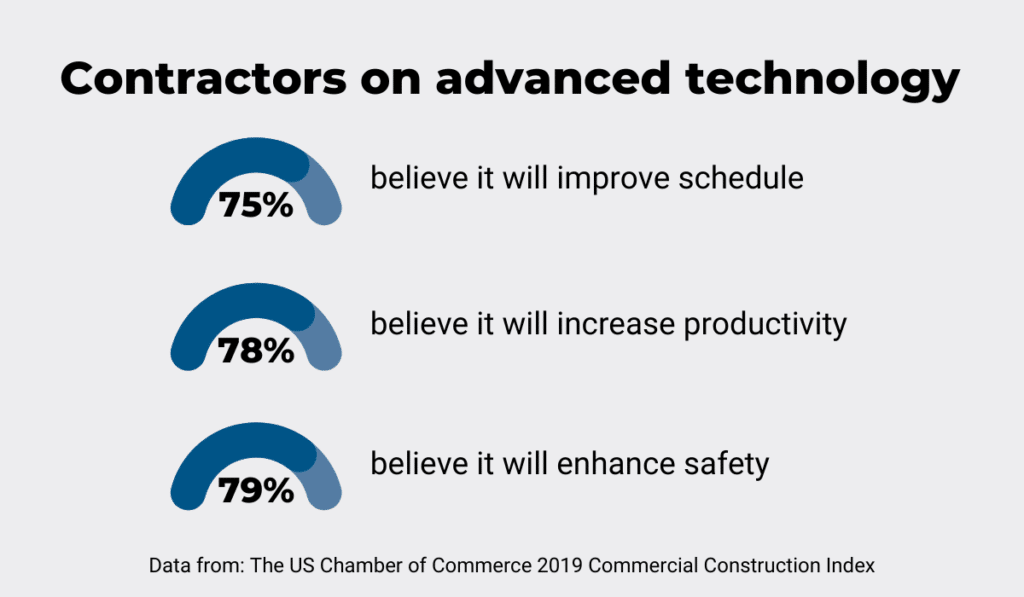

The US Chamber of Commerce 2019 Commercial Construction Index reports the US contractors’ attitudes regarding advanced technology.

Over 70% believe that this type of tech can improve their scheduling, boost productivity, and make their construction sites safer.

Clearly, the construction industry is starting to adopt new technologies and has certain expectations from them.

Let’s see what you can look forward to from implementing IoT and how you can use it in your everyday operations.

What Are Some Applications of IoT Construction Solutions?

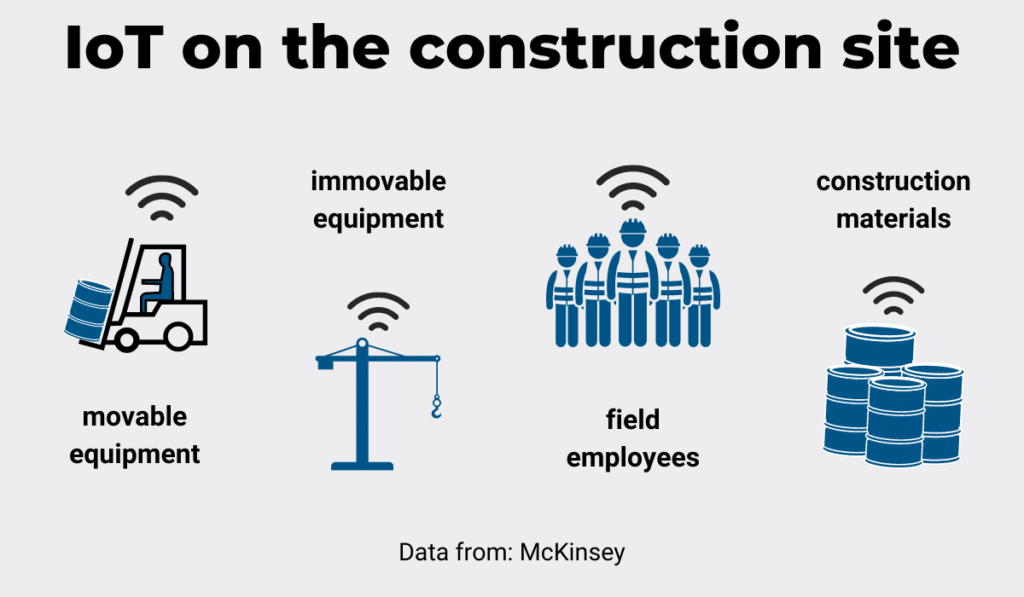

IoT helps you track your employees, movable and immovable equipment, and current worksite conditions, thus increasing your overall productivity and efficiency.

There are different ways you can implement IoT at your worksite, starting from the wearable technology for your workers, and sensors placed around the site or the machinery, to remotely controlling the equipment at the worksite.

Wearables

Wearable devices for your employees, or wearables, have been rising in popularity ever since companies realized their usefulness.

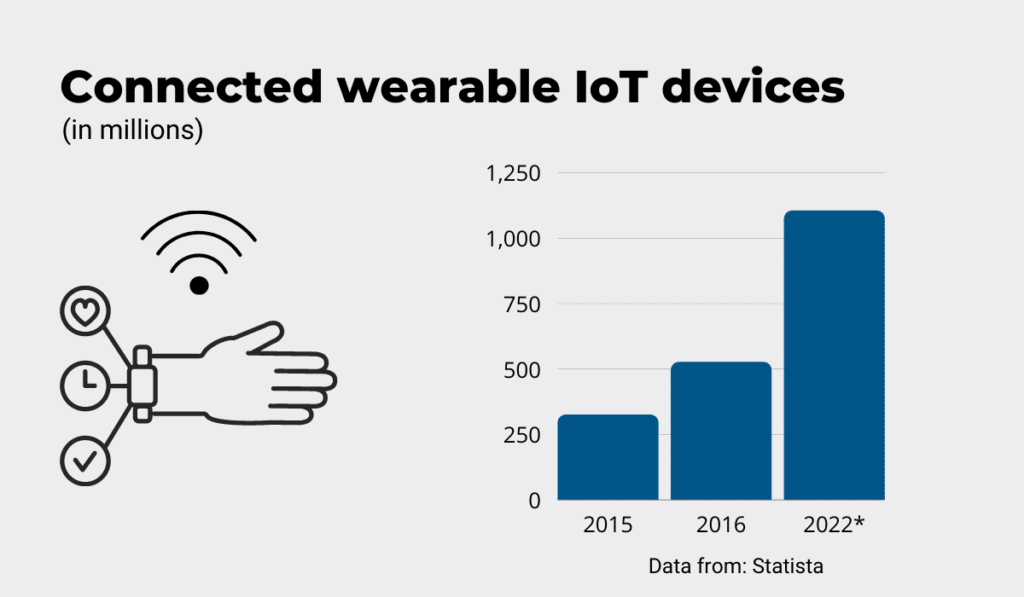

Back in 2016, the number of connected wearable devices was 325 million. The number grew by an astonishing 201 million the following year, attesting to their popularity.

It’s no wonder that the number is supposed to reach 1 billion in 2022. After all, wearable technology is simple to use and collects a lot of data about the person wearing it and their surroundings.

This is how wearables work: your employees wear, for instance, a smartwatch, goggles, smart shoes, or a safety helmet.

The device in question is connected to the network, allowing you to track available data, such as movement. That way, you can monitor safety and productivity, for example.

McKinsey explained some possible IoT applications in a 2015 study, The Internet of Things: Mapping the value beyond the hype, which remains relevant even today.

The report mentioned augmented-reality goggles that display instructions in the field of vision, allowing workers to read instructions for the task without accessing a computer or a phone.

In some cases, you can also have an expert guiding the worker remotely through AR goggles.

Sensors

You can implement IoT on your worksite using sensors attached to movable or immovable equipment. These sensors will let you track motion, noise, vibration, and similar aspects of the worksite.

According to McKinsey’s Internet of Things report, sensors give companies data in large quantities even though such companies only use a small percentage of said data. In the case of an oil rig with 30,000 sensors, the portion of used data was only 1%.

Mark Hung, the vice president of Gartner Research, called IoT “a solution looking for a problem.” This is because IoT provides so much data that companies simply don’t know what to do with all of it.

Nevertheless, the data those companies do end up using is immensely helpful.

For instance, in the case of work with hazardous substances, embedded sensors can track exposure levels. If they become dangerous, sensors alert your workers, thus limiting their exposure.

Sensors can also alert your workers of a vehicle approaching, which is extremely important on construction sites where there is a lot of noise, so the workers often have to wear noise-canceling headphones.

On top of that, sensors can monitor your energy consumption, which helps you make necessary changes. In fact, McKinsey’s study also predicts that IoT can help companies reduce their energy use by 20%.

Maintenance Systems

If you’re focused on optimizing your servicing process, think about incorporating IoT into your maintenance.

The McKinsey report also predicts that the value of IoT improvements to equipment maintenance could reach more than $360 billion a year. In other words, the construction industry could save that amount yearly if it relied on IoT for servicing.

Investing in sensors for your equipment, whether movable or immovable, will help you track the machinery’s condition. The machine itself will let you know when it’s time to fill up the fluids, when the tire pressure is too low, or when the engine is overheating.

All of these are signs your equipment needs maintenance.

Instead of letting the machine run to the point of failure and then investing in expensive, often last-minute repairs, or even purchasing new equipment, IoT will let you prevent and repair problems on time.

Therefore, it will help you make the most out of the machinery you own.

Real-Time Site Map

Understanding where your workers, equipment, and materials are at any given time through IoT enables you to create a real-time map of the worksite.

That way, you have an overview of who is where and who is doing what, allowing for easier planning and work distribution.

IoT can help you keep an eye on employees, all kinds of equipment and devices, and the materials needed to finish the project. In other words, you can monitor each part of your construction project using this technology.

For example, if heavy machinery is working on one side of the construction site and the workers aren’t allowed to go near it, you can send them to parts to do another task, thus boosting productivity while keeping your team safe.

Without IoT, it would be challenging to have this level of insight from your office. You’d only have this much information if you went to the worksite yourself, and that’s not always feasible.

Remote Management System

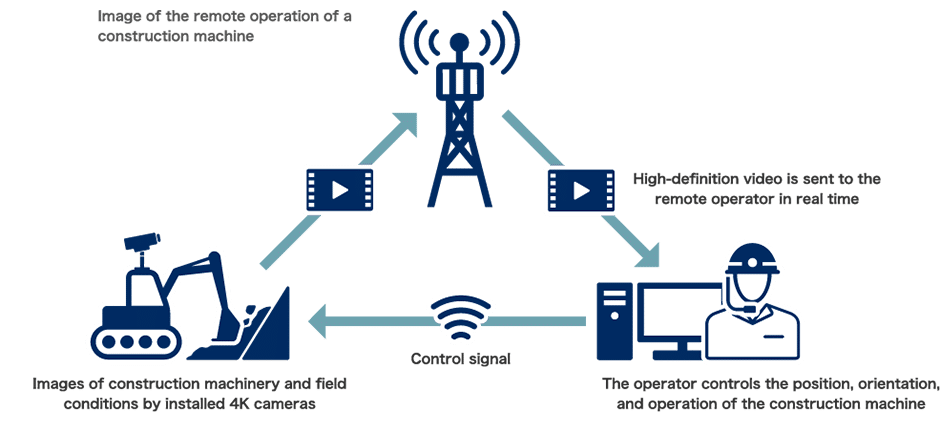

One of the most useful applications for IoT is remote management.

Since all the devices are connected, and the data is easily accessible, you can manage your team and equipment remotely from anywhere with an internet connection.

For instance, you can instruct one of your workers to wear goggles with a built-in camera, which allows you or an expert to look at the worksite and the task at hand without actually being there.

The cameras can also be set up throughout the construction site or on the equipment itself, giving you a better overview.

In some cases, if the environment or conditions at the worksite are too dangerous, you can use entirely remote-controlled equipment, thus minimizing risks for your employees while they remain productive and get the job done.

Benefits of Using IoT in Construction

Now that we’ve explained some of the most common potential applications of IoT in construction, let’s explore a couple of the benefits this kind of technology offers.

Once you fully understand what you could get out of it, you can decide if IoT would be a good fit for your company.

Theft Prevention

Implementing IoT on your worksites could help you save tons of money.

The National Equipment Register’s report on stolen equipment states that $300 million to $1 billion worth of equipment is stolen yearly from US construction sites. Most estimates land in the $400 million range, but that is still a lot of money to lose.

The worst part about machinery theft is that it causes monetary losses not only in the form of the price of the asset itself but also through unexpected downtime, project delays, costly last-minute equipment rentals, and other similar complications.

So, the total cost of the theft amounts to more than the equipment’s worth alone.

When you use IoT to track your equipment, you’ll always know where it is. Asset tracking apps like GoCodes help you tag your equipment with a barcode that anyone with a smartphone can read.

Whenever the code is read, you get alerted of its GPS location.

Besides, the check-in/check-out system the app offers will help you determine who is responsible for the equipment during a specific period, thus promoting accountability for company property.

Efficiency

Using this type of technology at your construction site can boost your efficiency.

According to a McKinsey study, 98% of large construction projects experience cost overruns and delays, with the average delay estimated at a whopping 20 months.

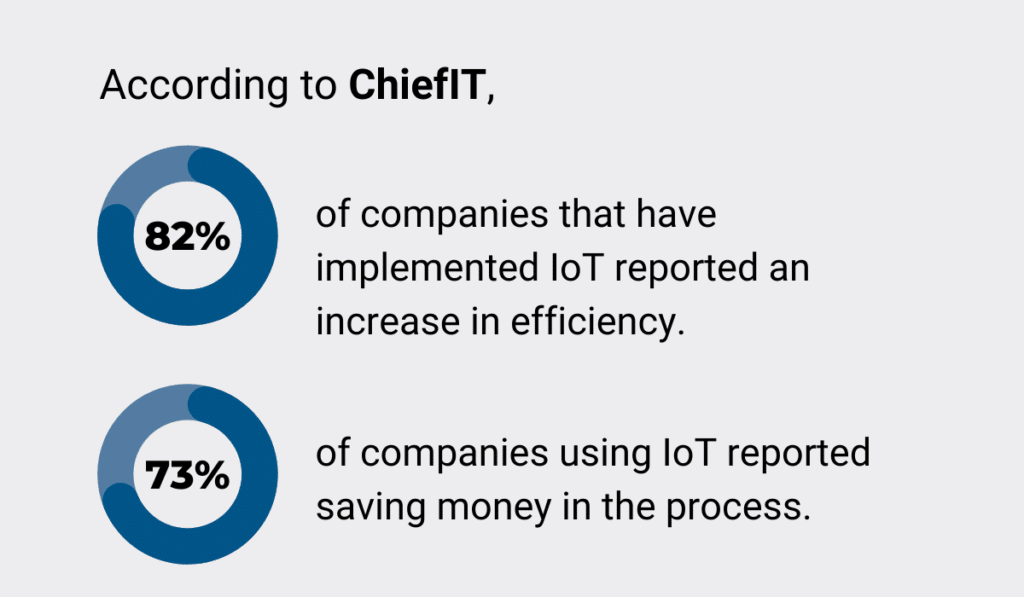

However, some businesses understood their productivity was lacking, so they implemented IoT solutions—and the strategy worked. 82% of such organizations reported improved efficiency, while 73% saved money.

If you understand the possible applications of IoT, you can easily conclude why that was the case.

Firstly, IoT gives you a detailed overview of everything going on at your worksite.

You can easily spot if your workers aren’t productive enough or if their skills would be better used on a different task or site altogether.

The same thing applies to your equipment if you use equipment tagging.

Tracking every detail of your project allows you to spot any inconsistencies or possible causes of delay, which means you can react promptly and prevent delays from happening.

Health and Safety

Safety is one of the biggest concerns in the construction industry because around 20% of all worker fatalities happen at the construction site.

On top of that, construction workers get injured at a rate that is 71% higher than in other industries, meaning they are always at a risk of fatal and non-fatal injuries.

Because construction companies are aware of this fact, they are trying to implement as many preventive measures and solutions as possible to protect the workers.

Interestingly, 60% of construction professionals believe wearable technology will help increase their safety. Since IoT provides complete job site visibility, it’s easy for companies to spot dangerous situations and react in time.

For example, a company received alerts about three-foot falls taking place in the same location daily.

When the company inspected the site, they realized that a worker wasn’t using a ladder to go into an excavation pit. Instead, he jumped.

Because of the alerts, the company could react promptly and warn the employee about the possible dangers of neglecting to use the proper equipment.

Challenges Facing Construction IoT

IoT faces challenges just like every other type of network technology.

Even though it’s been around for a while, we still haven’t completely mastered IoT and its possibilities. Because of this, it’s susceptible to cyber attacks.

On top of that, IoT can feel restrictive and controlling to some workers, which might cause unease at the workplace.

Data security is a big deal nowadays since companies that fail to protect personal data risk enormous fines.

Just ask Halifax, a company that had to pay at least $575 million for their 2017 failure to secure data. Of course, they’re not the only ones who have faced the consequences of neglecting to protect their customers’ personal information.

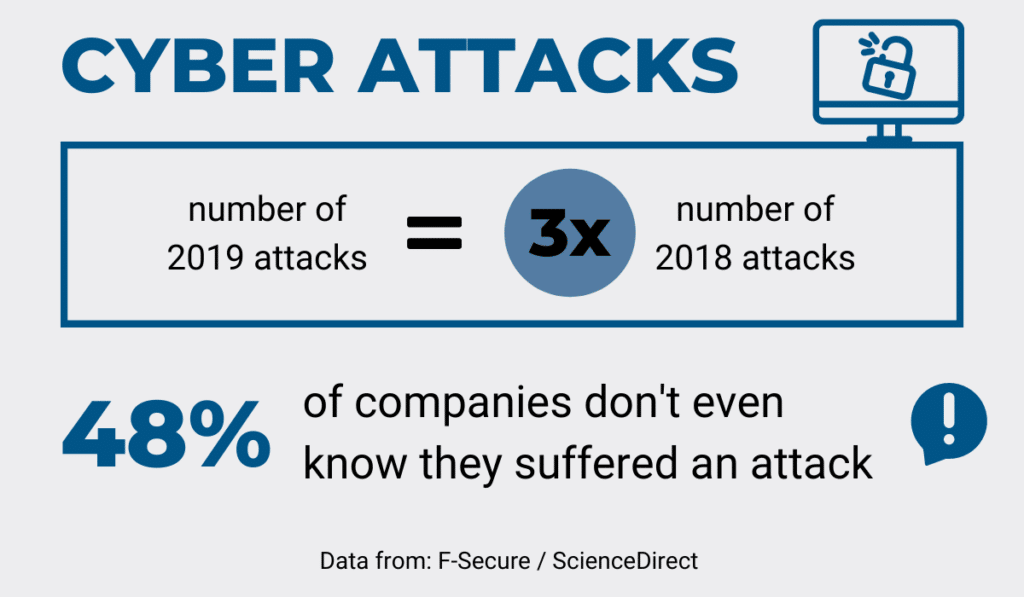

To top it all off, the number of 2019 cyber IoT attacks was 3x the number of 2018 attacks.

This dangerous trend of cyberattack growth has continued up to 2021—the first half of the year saw a doubling in the attacks compared to the second half of 2020.

The worst part about all these attacks? Almost half of the companies are unaware there even was an attack.

So, it’s no wonder that 32% of IT leaders cite security as a top barrier to IoT success.

It’s hard to secure data when it constantly changes and when you only use such a small percentage of it.

Still, you can minimize the risk by hiring professionals and investing in sound security systems.

The other significant challenge to introducing IoT into your business is the fact that your workers might feel like you’re violating their rights.

After all, you’re able to track their every move, monitor their every movement, heartbeat rate and the number of steps they take. This can make many feel uncomfortable and even alienate them.

Some Amazon workers quit their jobs because they were restlessly tracked while on the clock, with IoT monitoring even their bathroom breaks. Ilya Geller, a former employee, described his experience by saying:

You’re keenly aware there is an algorithm keeping track of you, making sure you keep going as fast as you can, because if there is too much time lapsed between items, the computer will know this, will write you up, and you will get fired.

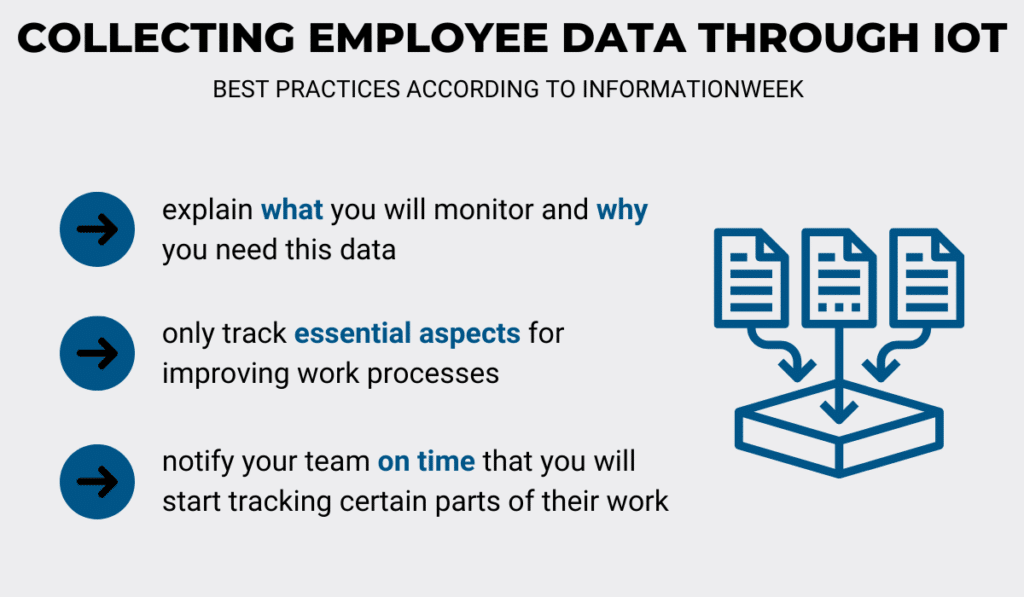

If you don’t want your workers to feel that way, ensure that you track only the aspects crucial for your business. Also, find ways to get the data you need without violating their privacy.

Also, your employees might react better to IoT monitoring if you notify them on time and explain precisely what data you will collect and why. They will know what to expect and what information they will be giving to you.

That way, you can avoid possible issues with your employees over the use of IoT.

Conclusion

The Internet of Things helps you connect and gather data from all the devices at your worksite, whether they’re wearables, sensors, or the equipment itself.

You can use the collected information to prevent theft, boost productivity, or improve the health and safety of your worksite, among other things. Of course, IoT gathers an abundance of details your team can use for different purposes, so there’s no limit to its possibilities.

The downsides to this type of technology are its susceptibility to cyber-attacks and possible pushback from your team if you decide to make wearables obligatory in the field.

Get on the trend and start benefiting from new technology!