If you’ve landed here, you’re probably interested in how your company can reduce asset theft, improve maintenance, and increase productivity by using QR codes for asset tracking.

Many industries experience the benefits listed above when relying on QR codes.

However, we’ll focus on construction company owners and managers and look at how they can take full advantage of QR code-based asset tracking to achieve the above outcomes and more.

So, if you fit this description, let’s explore eight reasons why you should use QR codes for asset tracking.

In this article...

Provides You With a Cost-Effective Tracking Solution

Where asset tracking is concerned, QR codes are so cost-effective and easy to use that they’re often used together with other tracking technologies like GPS trackers, Bluetooth beacons, or even RFID or NFC tags.

In other words, quick response (QR) codes—in tandem with asset-tracking software—are the most affordable tracking solution on the market by a long shot.

To explain why, it’s best to describe the core components of a QR code asset-tracking system and how they work.

In essence, such a system consists of:

- QR code labels or tags (affixed to your equipment, tools, and other assets)

- a scanner app (to scan QR codes with mobile devices like smartphones and tablets)

- asset-tracking software (to process the data, serve as the central database, and provide user-friendly features)

When these components are in place, users can scan the asset’s QR code and instantly access its info page.

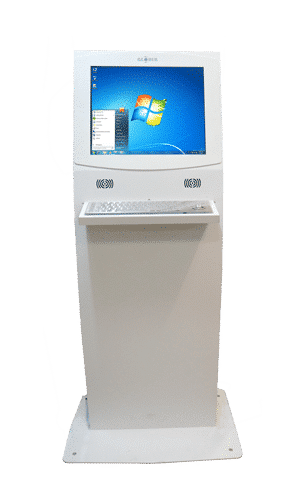

These images show all the above system components.

As we’ll see, the QR code tracking system’s simplicity (scan the tag for quick access) and ease of use are also integral parts of its affordability.

More specifically, the only “hardware” you’ll need to purchase to start tracking your assets are QR code labels, while an in-app scanner and cloud-based software are downloaded to internet-connected devices your company and your workers are already using.

Therefore, the cost of implementing a QR code tracking system includes either a monthly or an annual subscription to your tracking software and—if not included in the package—the price of QR code labels or tags.

That makes it the most affordable tracking solution on the market.

Makes It Possible to Use Mobile Devices as Scanners

As mentioned above, QR codes make using mobile devices as scanners possible.

In other words, traditional barcode tracking in warehouses and stores typically uses special, handheld scanners connected to the central tracking system.

However, QR code tracking doesn’t need separate devices but uses the scanning function of smartphones and tablets to turn them into mobile, handheld scanners.

This practical and cost-saving function is enabled by an in-app scanner powered by tracking software, which allows workers and managers to quickly scan the QR code with their mobile device and access the individual asset’s info page in the system’s central database.

Our asset-tracking solution, GoCodes Asset Tracking, is a great example of an integrated package that includes an easy-to-use smartphone app, a built-in QR code scanner, and customizable QR code labels.

Unlike some other tracking solutions, GoCodes Asset Tracking relies on a powerful scanner app instead of requiring companies to purchase additional, specialized scanners.

In addition, its patented QR codes and reliable asset-tracking software with an in-app scanner come in one integrated package with all the features required to reap the benefits discussed in this article.

In summary, another reason to use a QR code-based asset tracking system is that it enables you to use mobile devices (you already have) as scanners.

Gives You Complete Visibility Over Your Assets

In essence, QR code-based tracking allows you to tag, track, and manage a vast number of your assets, like heavy machinery, equipment, power tools, and other items used in construction operations.

This alone results in greater asset visibility.

Why?

Because other tracking methods are generally too expensive or impractical to be applied to every asset, from a mini screwdriver to a mega-crane.

On the other hand, the low price and simple application of QR code labels enables companies to track as many assets as they want, thus increasing the number of tagged assets covered by the tracking system.

In practice, this digital visibility allows managers and workers to access, search, and filter the software’s central inventory of tracked assets, as well as each asset’s info.

In this example, the asset list is on the left, and individual asset data is on the right.

Moreover, for tagged and tracked assets, your tracking system will record who scanned an asset.

It will allow them to update relevant asset data (e.g., current location and usage, performed inspections, and maintenance tasks).

Simply put, this takes asset visibility to another level. It allows workers to review important asset info and immediately record their actions, enabling managers to monitor the location, usage, and condition of tracked assets.

Even better, some tracking solutions will automatically record the asset’s GPS position when its tag is scanned with a GPS-enabled device (smartphone, tablet).

As explained later, these automatic location updates (every time a QR code tag is scanned) help construction companies minimize asset theft, facilitate recovery, and hold employees accountable for assets.

Last but not least, since all relevant asset data is recorded, safely stored, and readily available, this gives users access to the asset’s complete history.

This includes previous users and locations, maintenance records, etc.

The visibility of historical data in one easily searchable database can be very useful when, for example, planning asset procurement and allocation, scheduling maintenance, passing compliance audits, or negotiating insurance premiums.

To recap, a QR code-based tracking system gives you complete visibility over your assets.

It digitizes, records, and tracks all asset-related info (past, present, and future) on any number of tracked items.

Streamlines Asset Identification and Data Updates

Since QR codes enable users to simply scan the asset tag to identify a specific asset and view and update the asset info, this results in streamlined asset identification and data updates.

In other words, when asset-specific records were kept on paper and/or spreadsheets, tracking and capturing asset management actions involved a lot of time-consuming, manual data entry and often frustrating searches for relevant information.

Conversely, when assets can be identified in a few seconds with a simple scan and their data quickly updated, this saves your workers a lot of time.

For example, if a piece of equipment fails on-site, a service technician can pull up asset info in seconds to see when it was last serviced and what the issue was.

Quick access to information helps them do their job more efficiently.

Naturally, all these scans and data updates are recorded by software and made available to managers in real time on any internet-connected device.

This gives them access to continuously updated info on who is using assets, where, and what’s their maintenance status, allowing them to track, manage, and improve asset management practices and increase efficiency across your construction company.

Ensures Data Accuracy by Eliminating Human Error

Just as much as it saves time, a QR code-based asset tracking system will ensure your asset data is accurate by eliminating human error.

For example, to start tracking assets with QR codes, you’ll need to:

- affix QR code labels/tags to tools, equipment, and other assets

- link each QR code (unique identifier) to a specific asset

- populate the software’s database with initial data for each asset

Below, you can see the central database, QR codes, and scanning functions needed for the initial asset inventory.

Since this process involves finding physical items to be labeled with QR tags, it can help you identify assets on your inventory list that can’t be found because they have been lost or stolen without anyone noticing (ghost assets).

Likewise, this process might reveal assets your company has, but they somehow slipped out from official asset management and accounting records (zombie assets).

In any case, the initial asset inventory performed to populate the tracking system’s database will help you by removing past mistakes, inaccuracies, documentation gaps, and oversights.

At the same time, future human errors associated with manual data input will be greatly reduced.

Instead, the system will automatically update many data points (user, date and time, location) and allow users to easily update others.

Overall, a QR code-based tracking system will help you remove past mistakes and ensure future asset data accuracy by automating and streamlining data input, thus minimizing errors.

Allows You to Hold Employees Accountable for Assets

Again, QR codes and a smartphone app with a built-in scanner are all you need to hold your employees accountable for assets.

In other words, QR codes allow you to establish an easy-to-use and effective asset check-in/check-out system, where workers scan the asset when taking it (check-out) and then again when returning it (check-in).

Just the fact that employees are aware that the tracking system keeps track of who’s using tools and equipment can significantly reduce instances of theft, negligent behavior, or poor maintenance.

Additionally, when managers are scheduling and allocating assets, your tracking software should allow them to assign or reserve those assets in advance and set automatic reminders to be sent if the asset is not returned on time.

In short, this powerful check-in/check-out feature helps you hold employees responsible for assets.

This approach minimizes misplacement, careless handling, and substandard maintenance (since the system also tracks who performed service tasks).

Lastly, workers can use the check-out feature to exchange tools and equipment on-site, thus creating a transparent, digitally recorded chain of accountability.

Reduces the Risk of Theft and Helps Recover Assets

In addition to enabling you to hold employees accountable for assets and thus their loss, or damage caused by misuse or neglect, a QR code-based tracking system further reduces the risk of theft and helps recover assets in several ways.

We’ve already mentioned GPS tracking, where the tracking app automatically records the last-scanned GPS location of an asset.

Although this passive, scan-based GPS tracking will not show you where a stolen asset is currently located, knowing the asset’s last-known location can be helpful in finding it.

Another feature of QR code asset labels is that they can be made from tamper-proof materials or affixed in ways that make their removal from a stolen asset difficult, if not impossible.

In other words, QR code tags can make reselling stolen assets harder and serve as proof of ownership when assets are found and need to be identified, thus helping in asset recovery.

All things considered, when asset users and locations are automatically recorded by the software and QR code labels are hard to remove, this reduces the risk of theft and helps recover assets.

Simplifies and Speeds up Your Asset Audit Process

Whatever type of asset audit you’re running, QR code asset tracking will streamline and accelerate the process.

For example, if you wanted to run a quick audit to check what assets are present at a specific jobsite (or warehouse), your employees could activate the tracking software’s audit mode that enables them to scan multiple assets at once.

Since the location of audited assets is automatically updated, this significantly simplifies and speeds up the audit process.

The same is true for any type of audit, such as safety compliance, performance, and other equipment audits.

Likewise, the ability to access up-to-date asset data in one place, analyze it, and generate different reports will save a lot of time and effort asset managers and accountants typically spend on asset auditing processes.

Wrapping up, a QR code tracking system helps your employees perform field audits more quickly and easily by allowing them to scan multiple assets.

At the same time, it provides office-based managers and audit teams with relevant data analysis and reporting features needed for easier and faster auditing.

Conclusion

Instead of recapping the eight reasons why QR code asset tracking is the simplest, easiest, and most affordable way to track your assets, we’ll limit ourselves to just a couple of final thoughts.

One, a carefully selected QR code-based tracking software with the right features will enable you to minimize asset loss and theft, increase worker accountability, improve maintenance, and maximize overall productivity.

Two, you’ll be able to take advantage of digitized and automated workflows and data-driven insights to generate cost and time savings and enhance your company’s profitability.

As you can see, those are great reasons to use QR codes for asset tracking.