Key Takeaways:

- We’re seeing increased integration of 5G technology and AI into the telematics systems.

- The Internet of Things is streamlining fleet management and tracking through IoT devices like QR codes and Bluetooth beacons.

- Cloud-based solutions continue to revolutionize fleet management, allowing remote access to fleet data and real-time monitoring.

- These technologies are also improving safety and driving sustainability outcomes

Fleet telematics, i.e., solutions that combine GPS tracking, sensory, and telecommunications technologies with fleet management software, are quickly transforming the fleet operations of many construction companies.

That’s not surprising since the benefits of fleet telematics systems for construction companies can be immense, leading to increased operational efficiency, improved fleet security and driver safety, and reduced fuel and maintenance costs.

In this article, we’ll explore six already established or still emerging technological trends in fleet telematics that are reshaping the way construction companies manage their vehicles and equipment.

In this article...

Remote Fleet Management

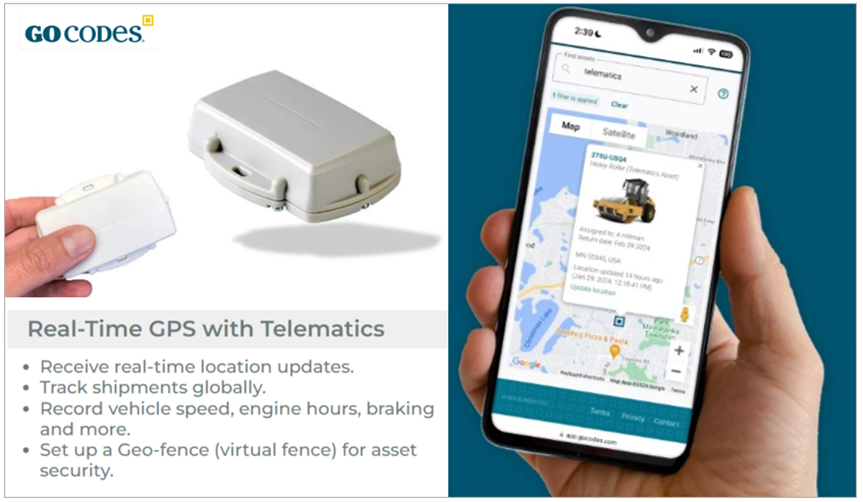

When it comes to remotely monitoring the real-time location of construction trucks, vehicles, and heavy equipment, GPS fleet tracking systems have been around for a while.

Such systems use satellite signals and cellular/radio communications to, ultimately, provide minute-by-minute location updates for all your fleet vehicles equipped with a GPS tracker.

Although their components are meant for remote tracking, these systems did not enable fleet managers to manage them remotely from anywhere, i.e., their control panel was typically available in a single location on one or a few computers.

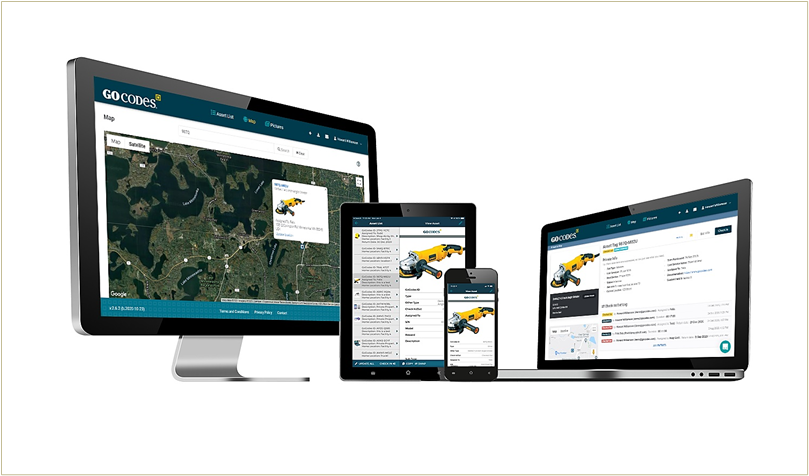

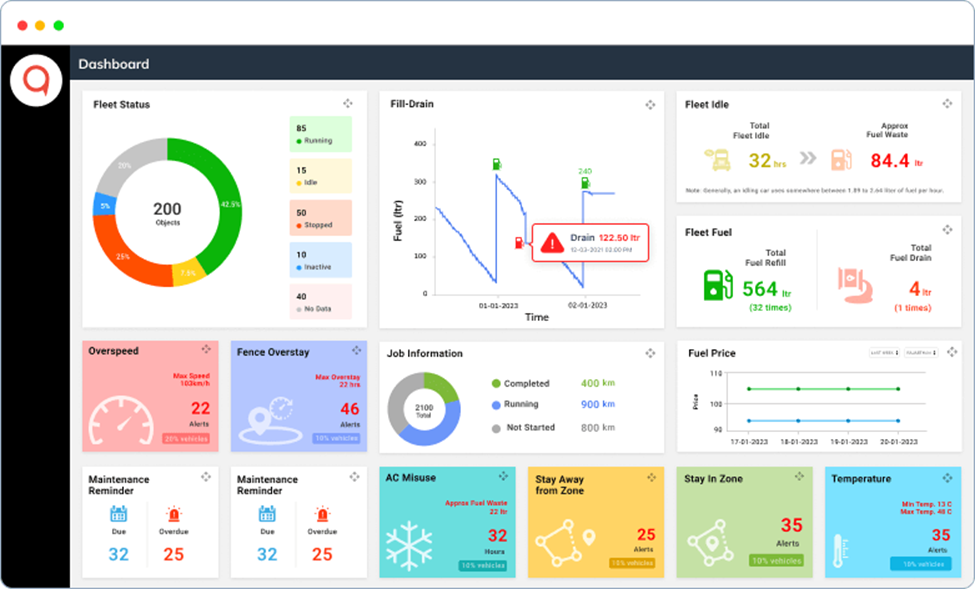

Then came cloud-based software solutions that transformed this landscape, enabling fleet managers (alongside drivers/operators and other users) to access fleet data from any internet-connected device, such as their smartphone, tablet, or laptop.

This cloud-based mobility enables managers to monitor vehicle locations and routes, identify potential issues, and optimize resource allocation to maximize efficiency in real time, whether they are in the office or on the go.

With the current location and status of the fleet in their pocket, managers can make informed decisions on the spot.

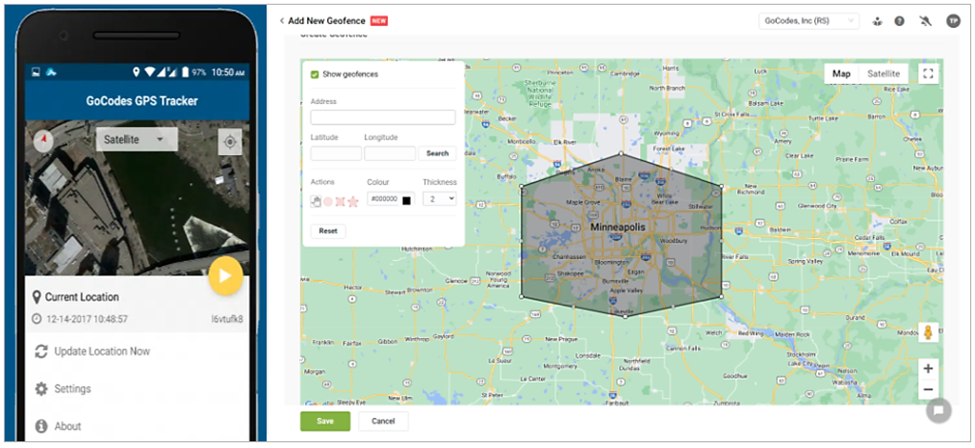

For instance, if a tracked vehicle leaves the predesignated virtual zone (geofence) set around a specific job site or storage yard, the fleet manager will receive an immediate alert, allowing them to take swift action to investigate (human error, unauthorized use, theft).

Other examples of remote fleet management in real-time include:

- rerouting the nearest vehicle to pick up an early delivery,

- alerting drivers/operators of road/weather conditions and rerouting if necessary,

- monitoring vehicle parameters (speed, engine hours, braking, etc.) and alerting drivers/operators of unsafe behaviors,

- tracking vehicle/engine diagnostics and scheduling proactive maintenance.

Of course, some of these functions wouldn’t be possible without another rapidly evolving aspect of remote fleet management: sensory technology.

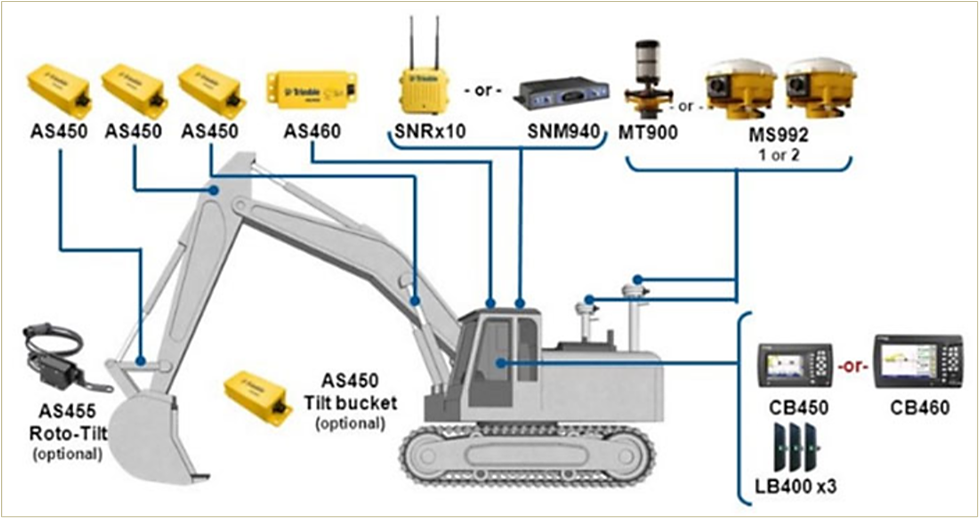

In other words, there is a range of sensors that can be located inside a GPS tracker, come built-in with the vehicle/equipment, or be installed later.

In essence, these sensors determine what vehicle/engine/environmental data GPS trackers will be able to collect and transmit to the fleet management software’s database for processing, interpretation, and analysis.

This, in turn, determines what fleet managers and other users will be able to do remotely.

In summary, remote fleet management enabled by GPS tracking and mobile apps is nowadays considered a standard component of fleet telematics systems.

Together with advancements in built-in or external sensory technology, including cameras, these systems keep expanding the scope of what fleet managers and other users can do via an app on their smartphone, tablet, or any other device.

Integration of 5G Technology

As data transfer and communication technology continues to advance, the integration of 5G technology into fleet telematics systems marks a significant leap forward in speed, connectivity, and efficiency.

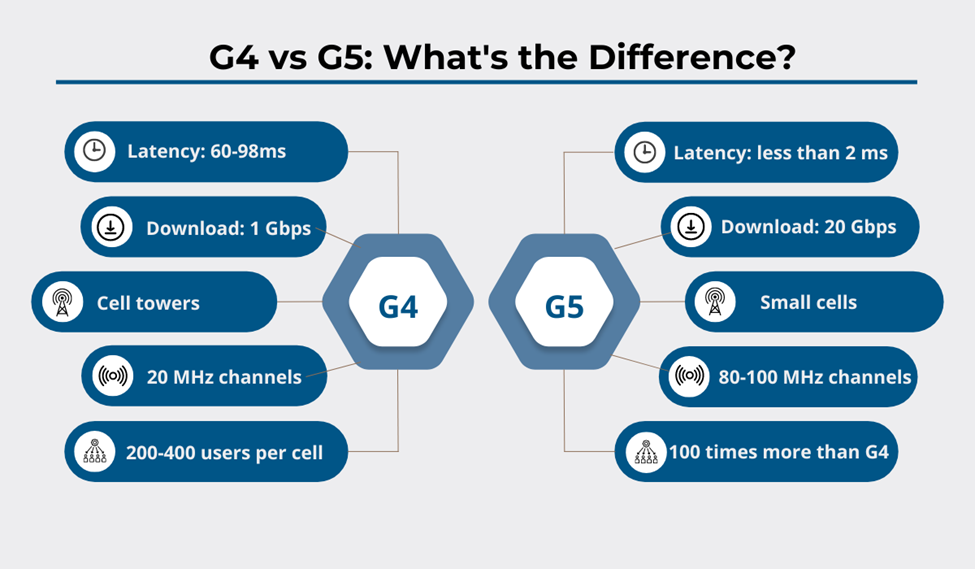

As illustrated below, 4G, or fourth-generation cellular technology, has been the standard for mobile data transmission, offering download speeds of up to 1 Gbps with 20 MHz channels and latency (time delay) of 60-98 milliseconds.

In comparison, the next generation of this technology, 5G, provides download speeds potentially reaching up to 20 Gbps and utilizing 80 to 100 MHz channels, leading to significantly reduced latency of less than 2 milliseconds.

With these advantages on its side, 5G will enable data transmission speeds as close to real-time as possible, which is particularly relevant for on-road vehicle safety and accident avoidance.

For instance, a road collision alert (apply the brakes) would, due to 4G latency, take 4.6 feet in a vehicle’s distance before the driver gets the alert while a 5G vehicle would need only one inch.

Likewise, other real-time benefits of 5G for fleet management/driver assistance can include blind spot detection, forward-collision warnings, and pedestrians-on-road alerts.

Moreover, 5G’s speed and improved connectivity will significantly enhance the capabilities of dashcam video feed, augmented reality (AR), and artificial intelligence (AI) tools.

To recap, the integration of 5G technology into fleet telematics is already bringing tangible benefits to fleet managers and drivers, and this trend will only accelerate in the future.

Internet of Things (IoT)

Another trend in fleet telematics was created with the rise of the Internet of Things (IoT).

As the name suggests, various IoT devices (e.g., QR codes, RFID tags, Bluetooth beacons, some external sensors) enable you to collect and exchange data about your construction assets over the internet.

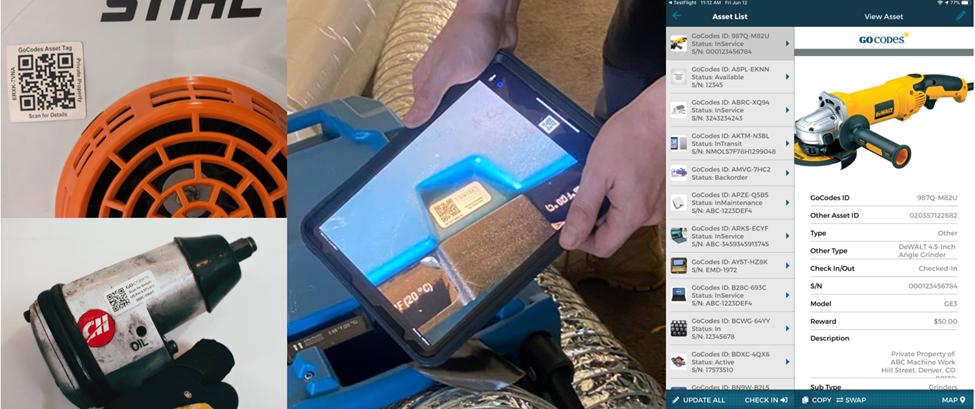

For instance, if a QR code tag is affixed to all your assets (vehicles, equipment, tools, PPE, spare parts, inventory items), this allows users to easily scan the asset’s QR code with their smartphone or tablet.

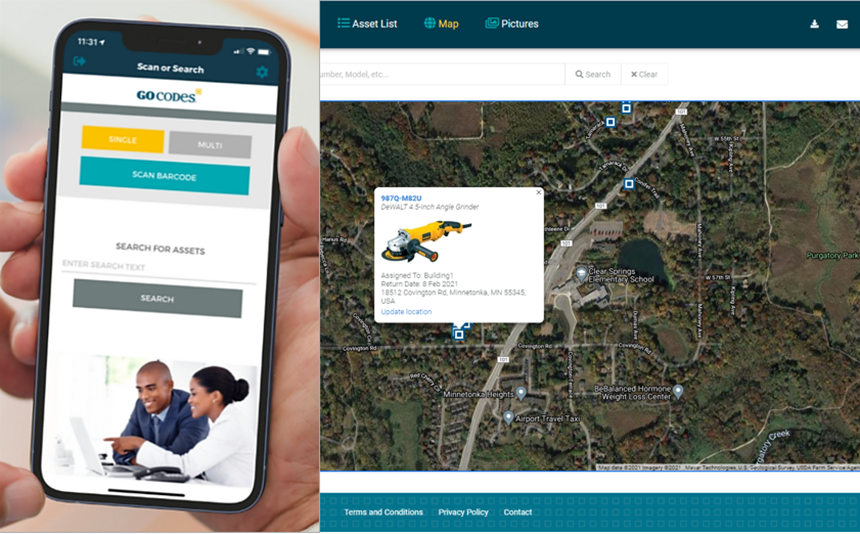

When they do so, the asset-tracking app on their mobile devices, like our GoCodes Asset Tracking, uses the internet to give them instant access to that asset’s info page and the software’s central database of all tracked assets.

This IoT functionality of QR codes enables you to connect construction assets and items that would otherwise not be tracked and whose data would be collected manually with the central cloud database.

Moreover, each time a QR code tag is scanned, the tracking app will use the scanning device’s GPS locator to record the scanned asset’s current GPS position and show it on a map.

When these two IoT-enabled functions (scan-based data access and GPS location updates) are combined, this results in many features that streamline fleet management, such as:

- maintenance tracking, planning, and scheduling, including automated alerts for upcoming maintenance sent to assigned service technicians,

- easy check-in/check-out of equipment and tools by scanning QR codes when taking and returning assets, including automated alerts for overdue returns,

- inventory tracking and management, including automated low inventory alerts.

The simplicity, affordability, and ease of installation make QR codes one of the most used IoT-enabled devices you will find even on GPS trackers and other often-used IoT devices, such as Bluetooth beacons.

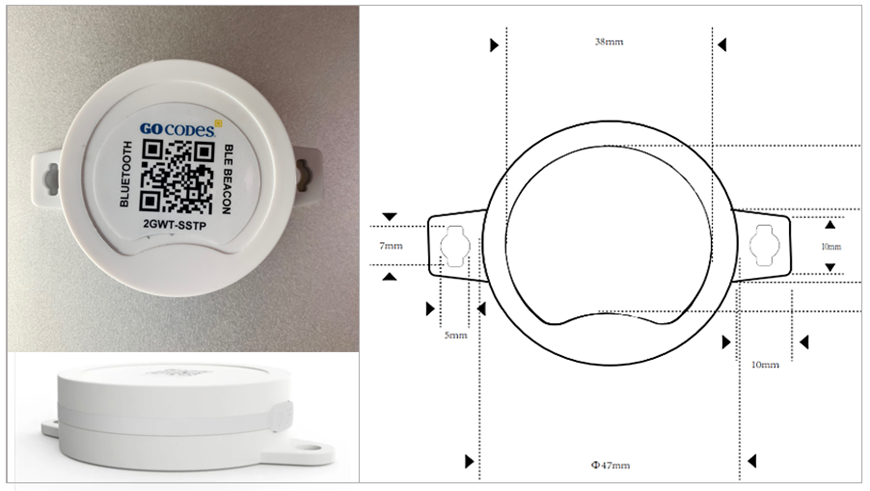

Bluetooth beacons (trackers) are small, battery-powered devices that use Bluetooth technology (short-range radio waves) to continuously send out data detected by Bluetooth-enabled devices (smartphones, tablets, laptops).

Each beacon will typically be detected by the receiving device within a range of 300 feet (100 meters).

Upon detection, the Bluetooth signal-receiving device will relay the beacon’s location (and other data like temperature and pressure when sensors are involved) to the central asset management system.

For instance, this enables workers to easily, in real-time, find any equipment they’re looking for on a jobsite.

Additionally, just like with GPS trackers, beacons can be used for geofencing, where managers receive an alert if a beacon-wearing asset leaves the detection range of their Bluetooth-enabled device.

This enables them to react quickly in case of theft or unauthorized use.

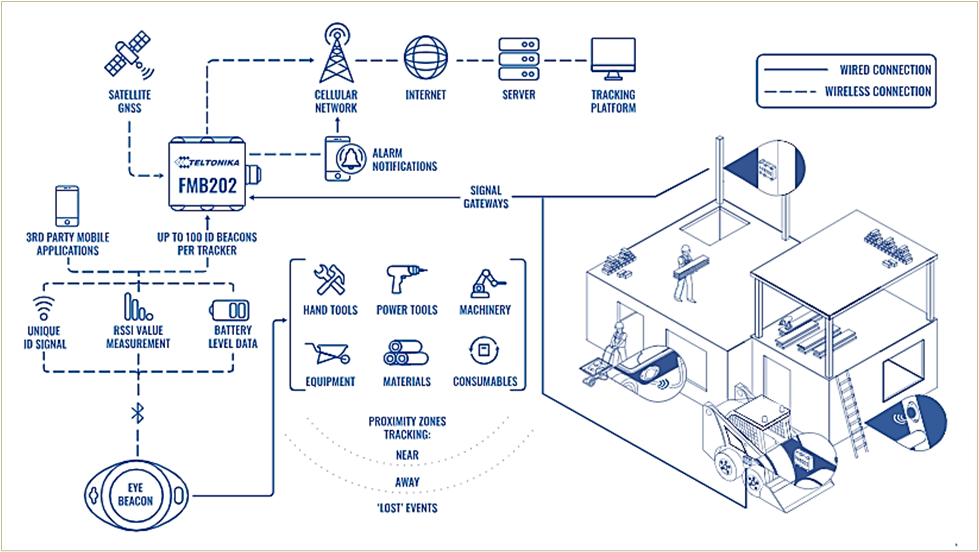

Furthermore, some fleet telematics systems use their GPS trackers installed on fleet vehicles and/or specific jobsite locations as receivers of Bluetooth signals emitted by asset beacons.

As illustrated, this can enable real-time monitoring of not only vehicles and heavy equipment, but all other assets present on-site, such as hand and power tools, materials, and consumables.

A potential downside of this full-blown IoT system can be the price of all stationary/mobile GPS trackers and beacons, as well as the often-impractical size of beacons when fitted onto small tools and equipment.

That’s why such systems are perfectly complemented by and made considerably more affordable with GPS-enabled QR codes.

All in all, when IoT devices are combined with GPS tracking, sensors, and software, the possibilities for streamlined fleet/asset/inventory management are practically endless (and still evolving).

Increased Focus on Safety

In all construction activities, including fleet operations, safety is of paramount concern.

This primarily refers to the safety of drivers/operators, and fleet telematics technologies allow construction companies to implement major enhancements.

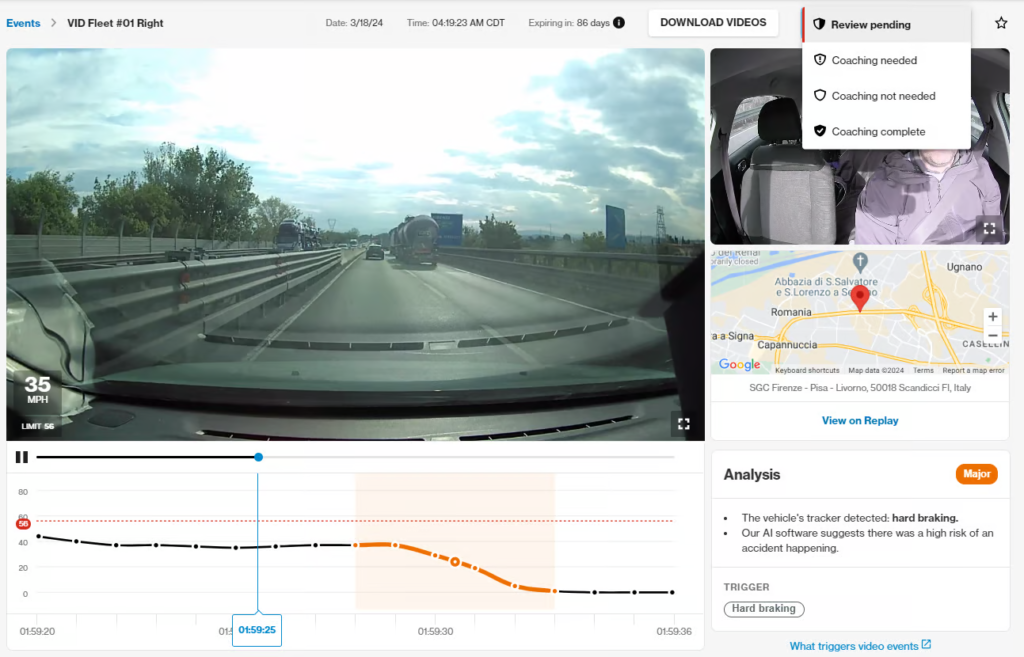

For example, most GPS trackers come with an internal accelerometer (speed sensor), and this basic functionality already increases focus on driver/operator safety.

More precisely, fleet managers can now monitor vehicle/equipment speed, harsh braking, and hard acceleration to identify driver/operator unsafe (and fuel-wasting) behaviors and address them through coaching.

Likewise, they can track engine hours to monitor the working hours of drivers and operators for compliance with fatigue prevention regulations.

Such telematics-enabled GPS tracking software solutions also enhance the safety and security of fleet vehicles through geofencing, maintenance tracking, and related automated alerts.

Some telematics systems will also provide real-time alerts for drivers/operators when they engage in unsafe behaviors like speeding, hard braking, or tailgating.

Of course, these safety-related telematics capabilities are further enhanced when built-in or external vehicle/equipment sensors are part of your fleet telematics system.

Sensors can detect critical vehicle parameters such as engine diagnostics, tire pressure, and fuel levels, alerting operators/managers to potential maintenance issues that could compromise safety on the road/jobsite.

Another safety-enhancing aspect of fleet telematics involves road- and driver-facing dash cams.

As described, dashcams provide invaluable real-time footage of road conditions and driver behavior, serving as a deterrent against reckless driving and providing evidence for accident investigations.

Full-blown, AI-driven dash cam solutions can monitor external road parameters (e.g., upcoming speed restriction zones and stop signs, pedestrians on the road) and internal driver/operator parameters (distracted or fatigued driving) and provide real-time alerts.

Overall, GPS tracking data, sensors, and dashcams each contribute to creating a comprehensive safety net for your construction fleet, promoting a culture of safety, and ensuring the well-being of drivers/operators and the protection of valuable assets.

Supported Sustainability

Given their capabilities, it’s clear that fleet telematics solutions can support sustainability initiatives, primarily by enabling construction companies to manage their fleets in an environmentally friendly and economically viable manner.

For instance, GPS tracking enables fleet managers to optimize route planning and vehicle/equipment utilization, leading to reduced fuel consumption and lower carbon emissions.

At the same time, real-time monitoring of vehicle/equipment parameters allows managers to identify issues or inefficiencies and implement proactive maintenance strategies, further minimizing environmental impact.

Additionally, they can utilize fleet management software to analyze various fleet data, including how driver/operator habits affect fuel consumption.

Armed with this knowledge, fleet managers can implement eco-driving initiatives, promoting fuel-efficient driving behaviors among drivers and operators.

Likewise, since telematics keeps track of when specific drivers are engaging in speeding, harsh braking, and unnecessary idling behaviors, fleet managers can give feedback or even incentivize eco-friendly driving practices through driver scoreboards.

Similarly, the wealth of fleet performance data allows companies to evaluate the efficiency of specific vehicle/equipment models, track maintenance expenses, and analyze the total cost of ownership.

This enables construction companies to make informed decisions about transitioning to alternative fuel vehicles or electric vehicles, contributing to long-term sustainability goals.

In summary, telematics plays a crucial role in supporting sustainability efforts within construction fleets, offering opportunities for reducing environmental impact, optimizing resource utilization, and driving economic efficiency.

More Use of Artificial Intelligence

Although AI-based, machine learning algorithms are already part of many data analysis functions of fleet telematics software (now advertised as AI-powered), the recent rise of AI solutions will further enhance the capabilities of telematics systems.

We already mentioned AI dashcams capable of detecting road conditions or distracted driving behavior and alerting the driver/operator in real time.

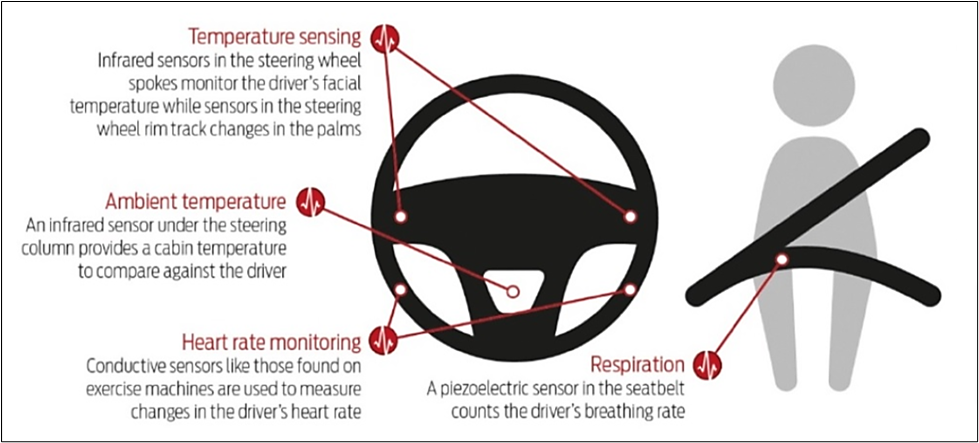

Such solutions can be expanded with various sensors that, assisted by AI, monitor driver health, i.e., vital signs such as heart rate, body temperature, and blood pressure.

Such sensors enable an AI-driven system to alert the driver/operator if it detects that, for example, their heart rate (or any other critical health parameters) is outside of normal range.

This enables the driver to stop and address the problem, potentially preventing accidents or health emergencies.

Another major role of AI algorithms and programs in fleet management is related to their ability to process and analyze vast amounts of data—collected by various telematics devices—to identify patterns and trends.

This empowers fleet managers to make better-informed, data-driven decisions and optimize fleet operations for efficiency and cost savings.

All in all, the rise of AI brings new opportunities for improved integration of fleet telematics hardware and enhanced data analysis, functionality, and ease of use of fleet management software.

Conclusion

In closing, it’s clear that the described trends, when combined, already provide construction companies with a diverse array of tools and solutions to enhance fleet operations.

In the future, all the described technologies will continue to advance spurred by developments in the fleet telematics landscape and other industries.

Ultimately, the technologies involved, from GPS tracking and mobile apps to 5G, IoT, and AI, will continue to revolutionize how construction companies optimize their fleet management to improve productivity and reduce costs.

Embracing these trends—prudently and gradually—will not only improve your fleet’s efficiency and safety but also position your company for long-term success in a dynamic industry.