Are you interested in using Bluetooth (BLE) beacons for real-time tracking of construction assets like heavy machinery, equipment, and tools on a jobsite to prevent theft and streamline your construction operations?

Likewise, do you want to learn how to easily locate assets, navigate complex jobsites or warehouses, establish efficient access control, and increase jobsite safety and security?

If so, this guide will explore the inner workings of BLE-based asset tracking systems from a perspective of a construction company owner or manager.

In other words, we’ll provide all the details necessary to decide whether, when, and how to use Bluetooth beacons.

In this article...

What Is Bluetooth Low Energy (BLE)

Bluetooth Low Energy (BLE) is a wireless technology that uses radio signals for short-range data transmission (up to about 300 feet or 100 meters).

These signals are detected by Bluetooth-enabled devices like smartphones, tablets, and laptops.

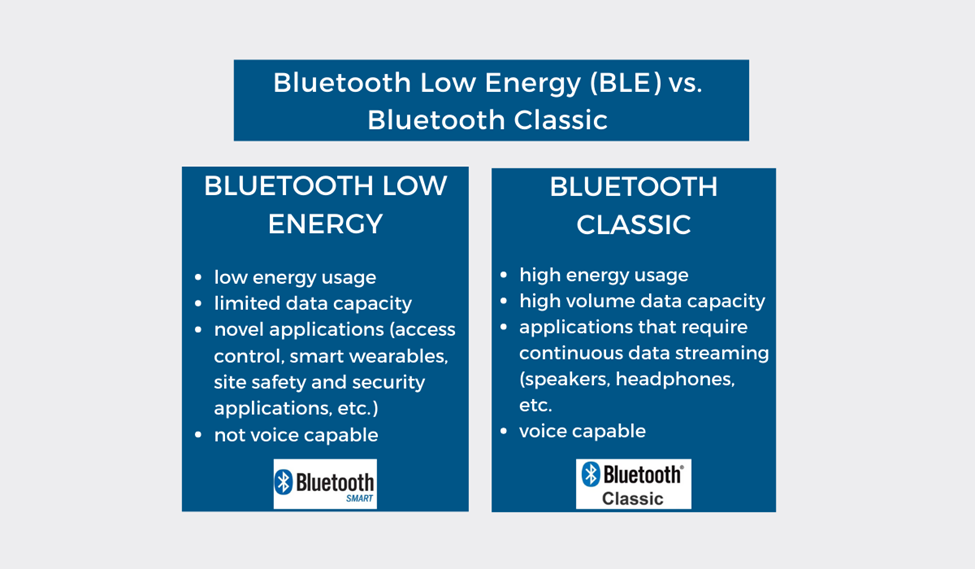

Despite what some might think, Bluetooth Low Energy and Bluetooth Classic are two distinct technologies used for different purposes.

While Bluetooth Classic is used for continuous data streaming that requires more battery power, Bluetooth Low Energy was designed with infrequent, smaller data transfers and low energy consumption in mind.

Here are the main differences.

These characteristics of BLE technology—coupled with simplified data exchange protocols, faster connection, and lower latency compared to Bluetooth Classic—make it ideal for asset tracking and other construction applications.

For now, it’s enough to remember that beacons use Bluetooth Low Energy (BLE) technology designed for small data transfers with low energy usage.

Why Are Bluetooth Beacons Used for Asset Tracking

Low energy consumption is just one of many reasons Bluetooth beacons are used for asset tracking, particularly in the construction industry.

Other reasons include their size, high reusability, and the fact that a beacon-based tracking system requires no additional hardware other than Bluetooth-enabled devices you and your workers already use.

We’ve rounded up these and other advantages into four main reasons why Bluetooth beacons should be used for tracking construction assets.

Easy Implementation

Compared to some other asset-tracking technologies (GPS, RFID, NFC) and system setups, a BLE-based tracking system can be implemented quickly and easily.

Naturally, the complexity and hardware requirements will depend on your needs and budget.

For example, you can get asset-tracking software with pre-programmed beacons in one package, attach them to your high-value equipment, and start tracking them in real-time using a single smartphone (with the tracking app installed and Bluetooth turned on).

Here’s how this practical setup works.

When beacons are the only hardware you need, implementing such a system on the jobsite or warehouse can be very simple.

All you need to do is attach beacons to the assets you want tracked, and you’re ready to go.

Depending on the size and layout of the site or facility, you might need other system components to establish efficient real-time tracking, namely stationary Bluetooth signal receivers strategically positioned across the tracked area.

These BLE receiver units (hubs/anchors) can be installed in specific places to improve the tracking coverage and positioning accuracy of a BLE tracking system.

Naturally, this raises the cost and complexity of implementing the system.

However, that doesn’t change the fact that a beacon-based tracking system is still the easiest way to track your construction assets in real-time as they move on a jobsite or warehouse.

Real-Time Location Visibility

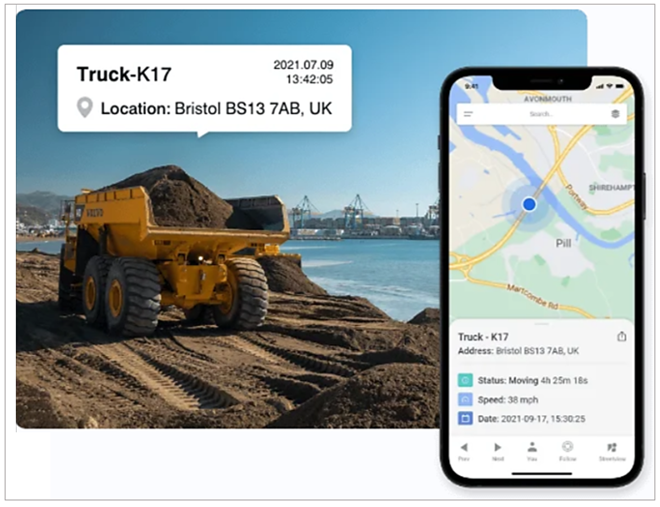

Other than Bluetooth beacons, the only asset-tracking method that provides real-time location updates are GPS trackers, which can track assets globally but don’t work well indoors.

Moreover, active GPS trackers can be expensive (including cellular data costs), and that’s why companies typically use them to track construction vehicles and heavy equipment, but not every asset on-site.

Conversely, a beacon-based system will provide real-time location visibility within a limited area using publicly available, free radio frequencies and will do so well indoors and outdoors.

In other words, Bluetooth beacons are simpler, less expensive versions of GPS trackers that provide actual real-time visibility of where your assets are (within the tracking system’s range).

Cost-Effectiveness

A beacon-based tracking system generally involves lower upfront costs than active GPS trackers, making it the most affordable method for real-time asset tracking.

For instance, the cost of tracking assets with BLE beacons includes the price of beacons and potential stationary BLE receivers, installation costs, and monthly/annual subscription to your cloud-based tracking software.

Conversely, GPS tracking can include all the above costs for similar or even the same components, plus a cellular data plan for real-time communication between GPS trackers and your tracking app.

However, there are even more affordable asset-tracking systems that can be used when attaching beacons to assets is impractical (due to size limitations) or too expensive (due to the number of beacons).

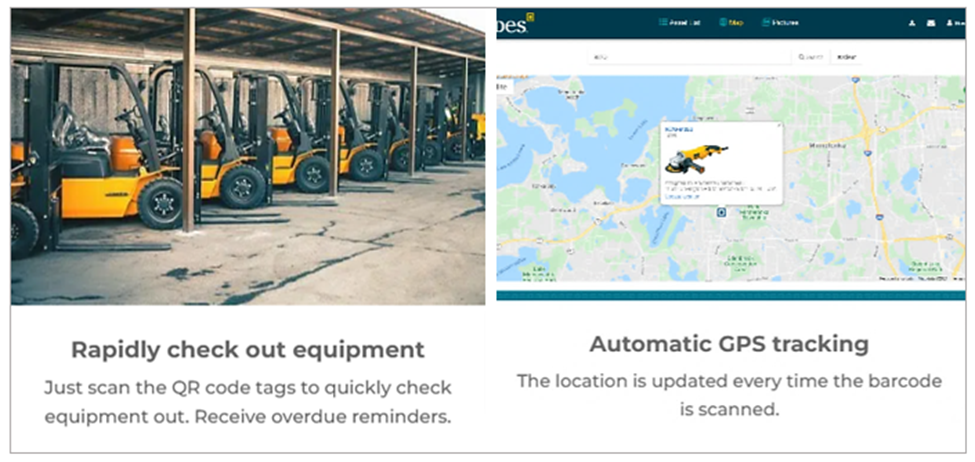

One such method involves attaching rugged QR code labels/tags to your tools and equipment for location and usage tracking purposes.

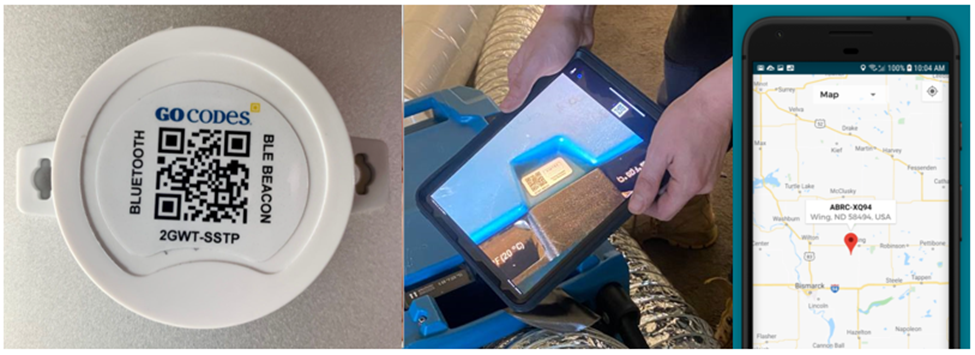

In fact, affixing barcodes to your assets is so simple and cost-effective that your Bluetooth beacons will probably also have one (to facilitate asset and beacon identification), like in this example.

As you can see, QR codes are used to scan the asset/beacon and instantly access the tracking app, which will record the scanned item’s GPS location and show it on a map.

Since this occurs independently from Bluetooth beacons’ tracking function, QR codes, and BLE beacons essentially complement each other, enabling construction companies to set up a comprehensive asset-tracking system that goes beyond the range of Bluetooth beacons.

As for BLE-based tracking systems, another significant advantage is the high reusability of Bluetooth beacons and the extreme portability and flexibility of the entire system.

In other words, you can simply move beacons from one asset to another and continue tracking with little or no beacon setting adjustments.

Moreover, you can easily relocate the entire tracking system (beaconed assets, mobile devices) from site to site, particularly if no fixed BLE receivers are involved.

In summary, although not the most affordable tracking method (QR codes), Bluetooth beacons are the most cost-effective and energy-efficient way to achieve remote, real-time tracking of your assets.

Versatility of Applications

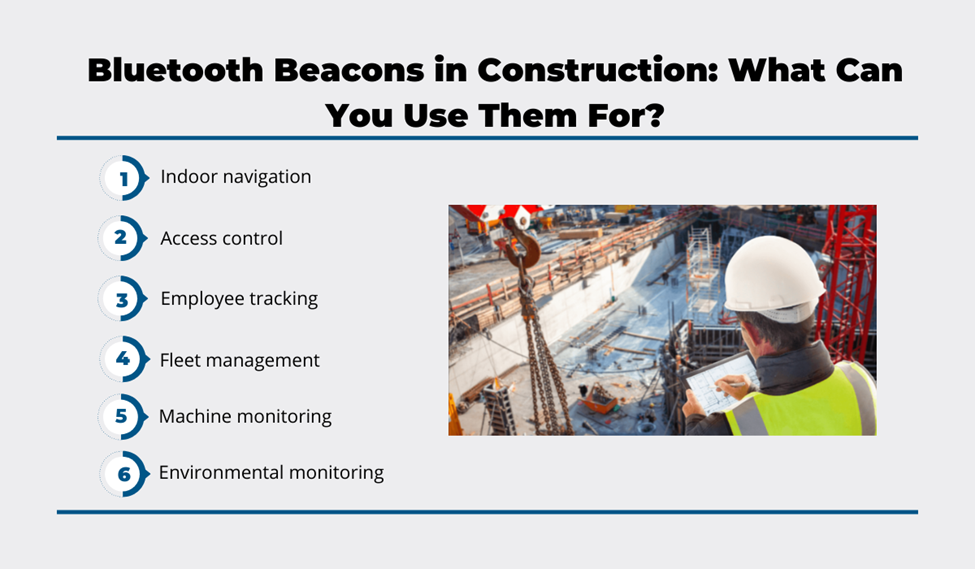

Due to their low cost and easy implementation, Bluetooth beacons are used in various construction applications beyond asset tracking.

For instance, beacons are great for locating out-of-sight assets and navigating workers through large worksites or warehouses to find them quickly.

As said, Bluetooth technology works well outdoors and indoors, allowing for real-time tracking in buildings and underground areas with no GPS signal.

These two examples would constitute “indoor navigation” in the below image, while the other five show the remaining main applications of BLE beacons in construction:

You can explore each of these ways to use beacons in more detail in our article on the topic.

Here, it’s enough to say that the BLE beacons can have sensors that enable them to monitor internal machine status (e.g., temperature, pressure) or outside environmental conditions (e.g., extreme temperatures).

In other words, when beacons are sensor-enabled, that considerably widens their range of asset-tracking applications and can help improve maintenance practices and prevent machine breakdowns (fleet management).

However, even without sensors, Bluetooth beacons have many important roles, such as controlling access to jobsites, tracking on-site workers for safety and efficiency-monitoring purposes, and preventing asset loss and theft.

What Types of Assets Can Bluetooth Beacons Track

A short answer would be any physical item that can be fitted with a beacon, from a mega-crane to a mini generator.

However, although relatively small, BLE beacons are still too big to be attached to some small tools and equipment.

For such assets, scannable QR codes can be used to track their location and usage, as we explained.

Otherwise, the sky’s the limit, meaning Bluetooth beacons can be attached to all or just high-value construction tools, heavy equipment, vehicles, IT assets, and other items present on a jobsite.

For example, new appliances that just arrived on-site for installation can be equipped with a beacon.

If they’re stolen from the site (i.e., taken out of range of the BLE tracking system), the tracking app will instantly alert the site manager.

Long story short, beacons can be used to track all types of construction assets, the only limitation being beacon-to-asset size.

How Does Bluetooth Beacon Asset Tracking Work

Although you probably gathered how Bluetooth asset tracking works up to this point, it’s still worthwhile laying it all down in simple terms.

So, as we learned under “Easy Implementation,” the core components of a beacon-based tracking system are:

- Bluetooth beacons (or tags, as explained in the next section)

- asset-tracking software installed on Bluetooth-enabled devices

- optionally, stationary Bluetooth signal receivers

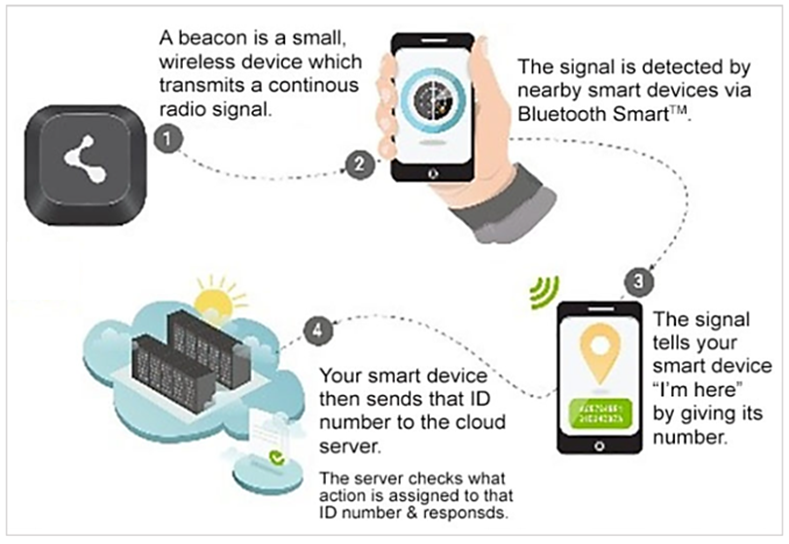

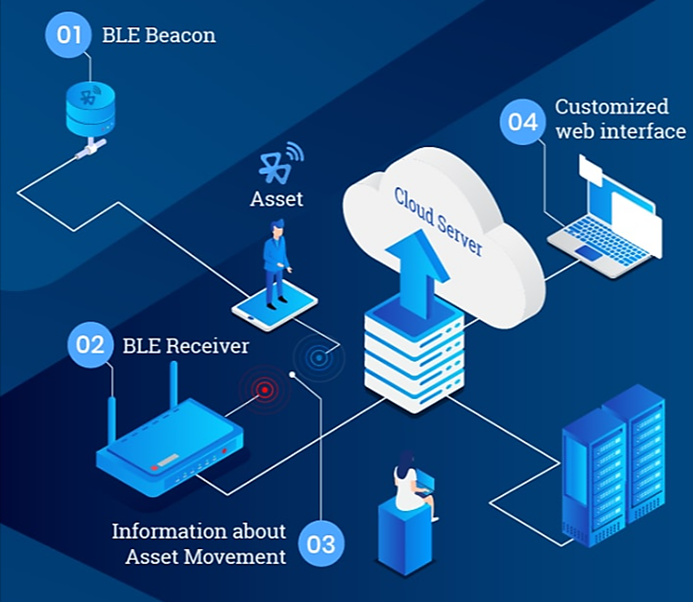

When attached to assets, beacons act as radio signal emitters, while mobile and stationary Bluetooth devices act as radio signal receivers.

When detected, asset-specific BLE signals are routed to the central cloud server, where the tracking software will process the data, calculate the asset’s position, and show relevant info through a user-friendly user interface.

Courtesy of Comparesoft, you can see this process here.

This means that your tracking software will collect asset location data from multiple points (like workers’ smartphones) and use it to provide real-time location updates for all assets within the system’s range.

Naturally, workers can use the tracking app to easily find assets by entering the software’s database and following location-specific instructions, while managers can protect assets from theft and monitor jobsite workflows.

Overall, a Bluetooth asset-tracking system is based on lightweight, robust beacons attached to assets that emit signals detected by various mobile and/or stationary devices and interpreted by tracking software.

Should You Use Bluetooth Beacons or Bluetooth Tags

Depending on your asset-tracking needs and preferred BLE terminology, you might use both beacons and tags, or they mean the same thing.

Confusing, right? Let’s explain.

First, whether someone says “BLE beacons” or “BLE tags,” they’re most likely thinking of the same small, battery-powered devices we just described.

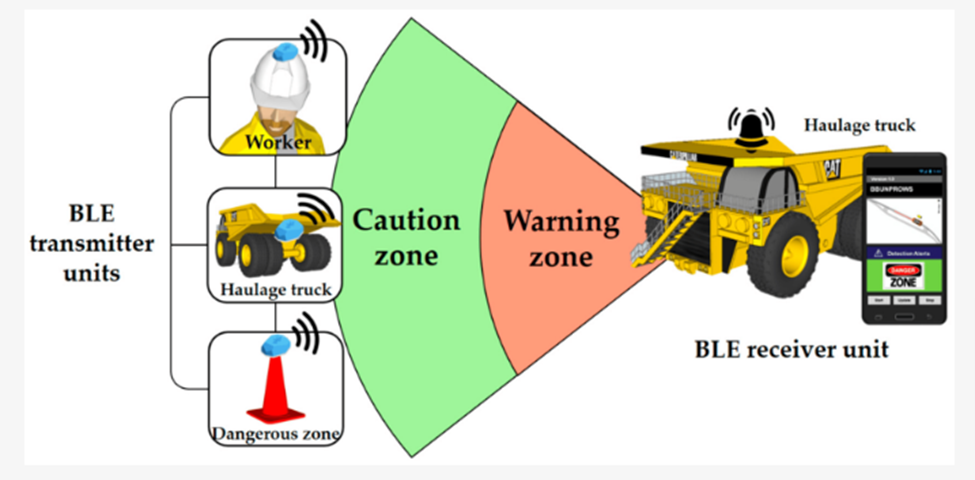

However, in some minds, beacons refer to stationary devices that emit signals that trigger an action when detected by the tracking app, such as sending proximity alerts to a worker or truck when they get too near a dangerous zone.

In the above image, workers and haulage trucks would have mobile “BLE tags,” and the geofenced area (dangerous zone) would be secured with stationary “BLE beacons.”

Regardless of this potential distinction, both beacons and tags are BLE transmitter units, as opposed to BLE receiver units (mobile and stationary BLE receivers).

To add to overlapping terms, some people will also use “beacons” to describe fixed BLE signal receivers (hubs, anchors), which can be used to enhance the accuracy and coverage of asset tracking.

Therefore, the question is not whether to use beacons or tags but how many of them (plus how many mobile and/or stationary receiver devices) you need to establish and implement an effective BLE tracking system.

How to Implement a BLE-Based Asset Tracking Solution

If you want to implement a BLE-based asset-tracking solution that will fit your needs and budget, there are a few crucial parameters to consider.

On the technical side, you should ensure that BLE beacons you’re getting are high-quality, with long battery life, strong signal strength, and—preferably—already configured for optimal tracking in construction environments.

On the operational side, your specific requirements (i.e., what you want to achieve with BLE-based tracking) and your budget (i.e., how many assets you want to track) are the key decision-making factors.

To illustrate, imagine your primary goal is to protect high-value equipment from being stolen from the site in broad daylight.

In this case, you could use one or more phones positioned strategically around the site to keep watch over the beacon-wearing assets in their range.

If one of these assets goes missing, the tracking app will immediately alert you.

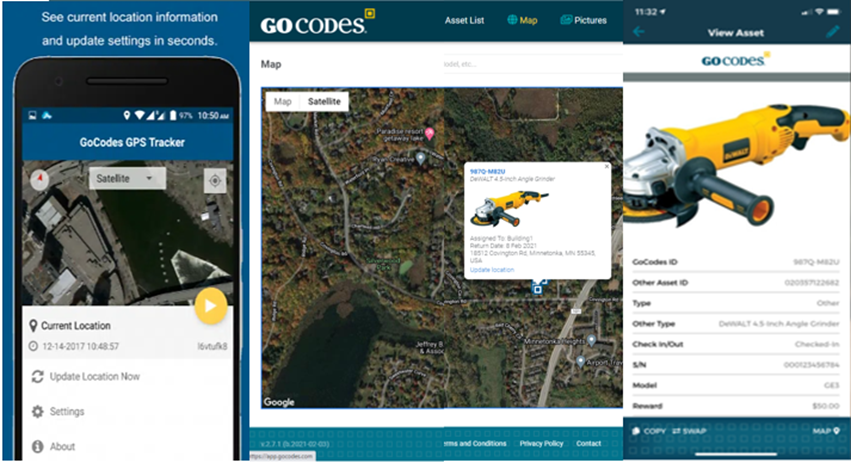

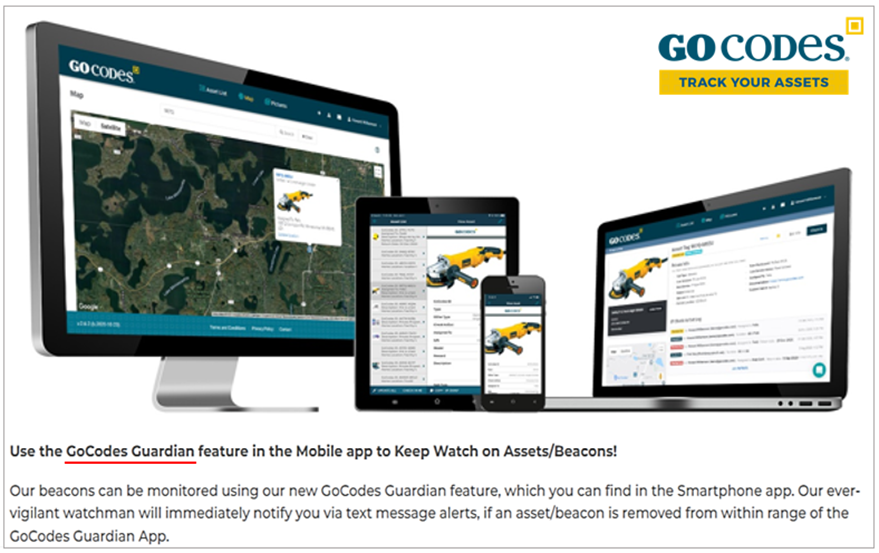

For instance, that’s precisely what Bluetooth beacons enable our asset-tracking solution, GoCodes, to do.

As you can see, each phone with the Guardian feature and Bluetooth turned on will act as an invisible 300-feet security perimeter, alerting you if any assets leave the system’s range.

GoCodes will also deliver customized QR code tags we already mentioned to be attached to all your assets, including those with beacons.

This will enable workers to simply scan the QR code and access the asset’s info page and the software’s central database.

Those QR codes also serve a double purpose shown below.

These two powerful features—automatically tracking asset users and locations—alone can significantly reduce theft, negligent behavior, and poor maintenance of your assets.

When combined with the remote, real-time tracking advantages of Bluetooth beacons, such an integrated solution enables construction companies to implement a multi-layered tracking system that minimizes theft and maximizes jobsite productivity.

Overall, BLE-based asset tracking should not be hard to implement when you’ve considered technical and operational needs and your budget and found an asset-tracking solution that fits both.

Conclusion

We’ll close this guide by reiterating that Bluetooth beacon-based asset tracking is a versatile, flexible, easily implementable, and cost-effective way to streamline asset management, enhance jobsite safety and security, and increase your company’s overall productivity.

Whether you decide to combine beacons with other complementary tracking methods or not, look for an all-in-one tracking software with quality beacons and an easy-to-use app that has the tracking features you need.