You’ve no doubt noticed those black-and-white square patterns that can be found on everything from cereal boxes to restaurant menus.

We know them as Quick Response (QR) codes.

While we often associate them with quick information access or creative advertising, their real potential comes to light somewhere a little less expected—in the construction industry.

Asset management, an extremely challenging part of running a construction project, can be made notably easier by incorporating these compact codes.

In this article, we’ll unpack the eight game-changing benefits of using QR codes in construction.

We’ll show you how this piece of technology, not much larger than a postage stamp, can promise significant strides in tracking inventory, trimming costs, and enhancing overall operational efficiency.

In this article...

Provides a Cost-Effective Solution

We’ll start with the benefit that holds the most importance in the construction field: cost-effectiveness.

At first, the idea of creating and printing QR codes may sound like it could well be an added expense. But the reality is entirely different.

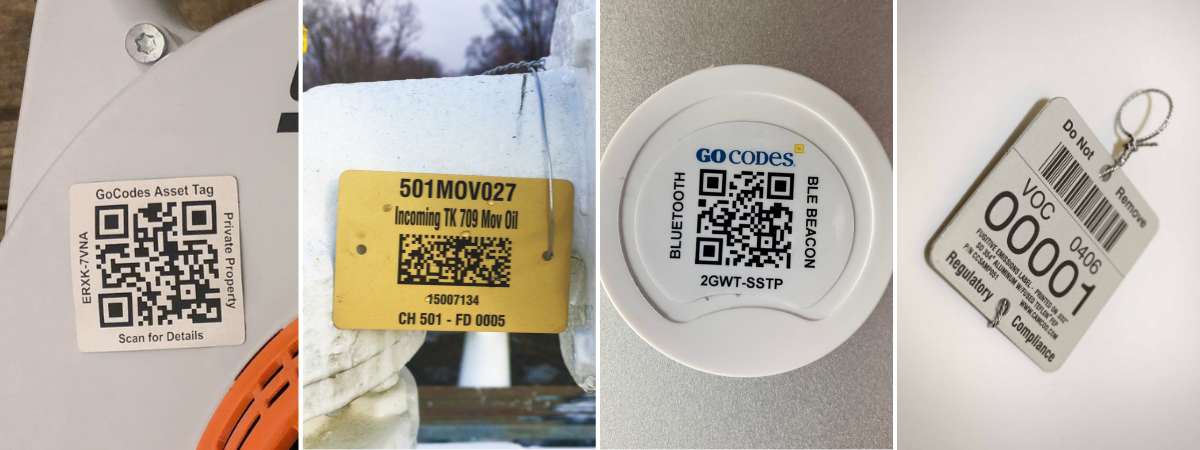

QR codes are incredibly easy to generate, and they can be conveniently printed on a wide variety of materials, be they paper, cardboard, plastic, or even metal.

The production cost for these is low, making them a budget-friendly option.

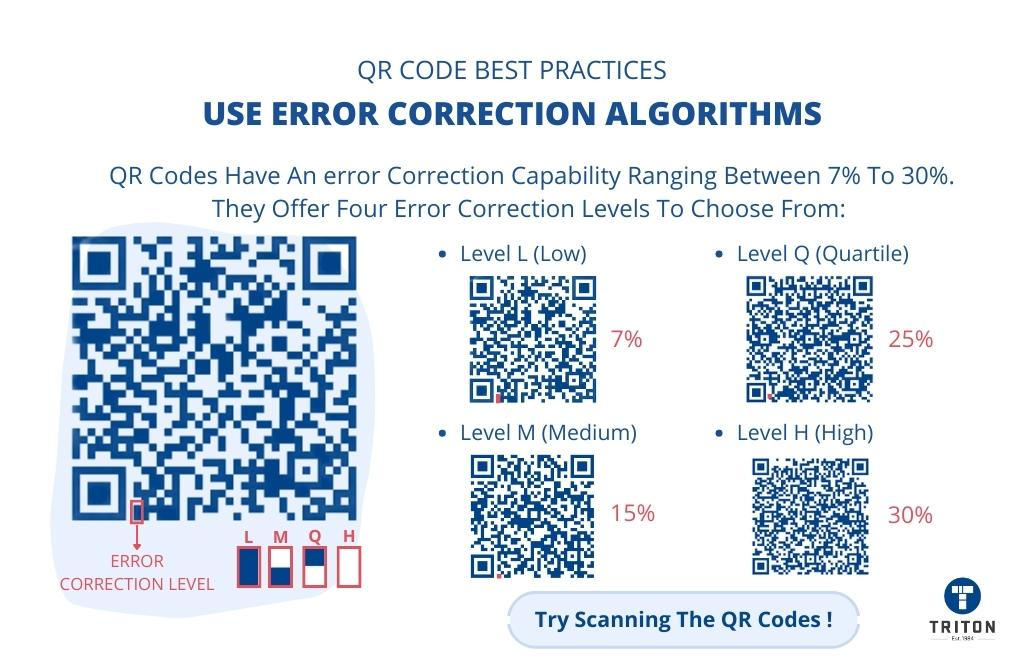

Also, they’re incredibly resilient. Whether the QR codes are damaged, dirty, or poorly printed—their efficacy remains largely unaffected.

In fact, they can endure damage levels anywhere between 7% to 30%, depending on their error correction level, and still manage to be scanned successfully, as you can see in the image below.

This essential quality makes them a reliable and low-cost option for the construction industry, where equipment often faces harsh conditions and rigorous wear and tear.

And if you bring advanced asset tracking software into the equation, the whole process can become even more economical.

That’s because this software not only has the ability to generate QR codes for you but its subscription plans often include high-quality labels that are resistant to chemicals and water and come with adhesive backings.

This means you won’t have to worry about the quality of the labels or whether they could weigh on your budget.

You just press print, stick them on your assets, and you’re ready to start tracking.

Either way, by embracing QR codes, you’ll opt for an affordable solution that minimizes expenses while maximizing the efficiency of asset tracking.

Enables the Use of Mobile Devices

Managing a construction project, especially when it’s spread across various locations, can present substantial logistical hurdles.

The vast array of tools and pieces of equipment required for such projects can make asset management a significant challenge.

However, when you attach QR codes to your assets and use your mobile device to scan them, the entire scenario changes.

Asset management becomes immediate and easily accessible.

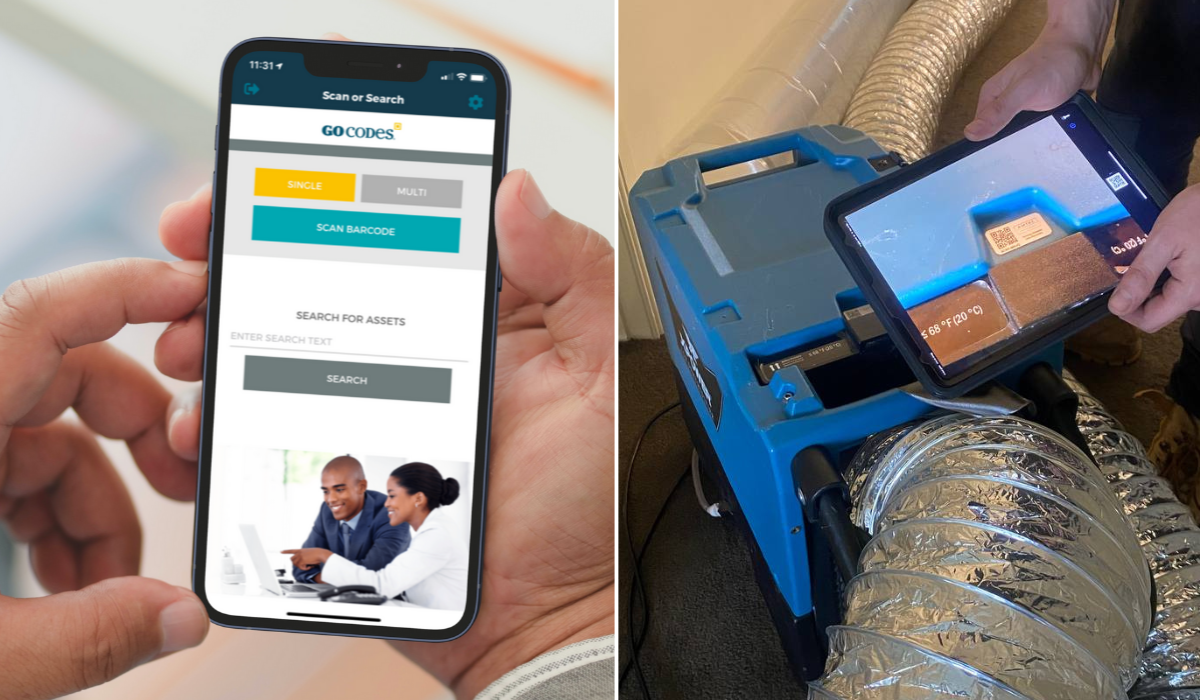

Let’s now take a closer look at our very own tool, GoCodes, to see exactly how mobile devices can fundamentally transform asset management.

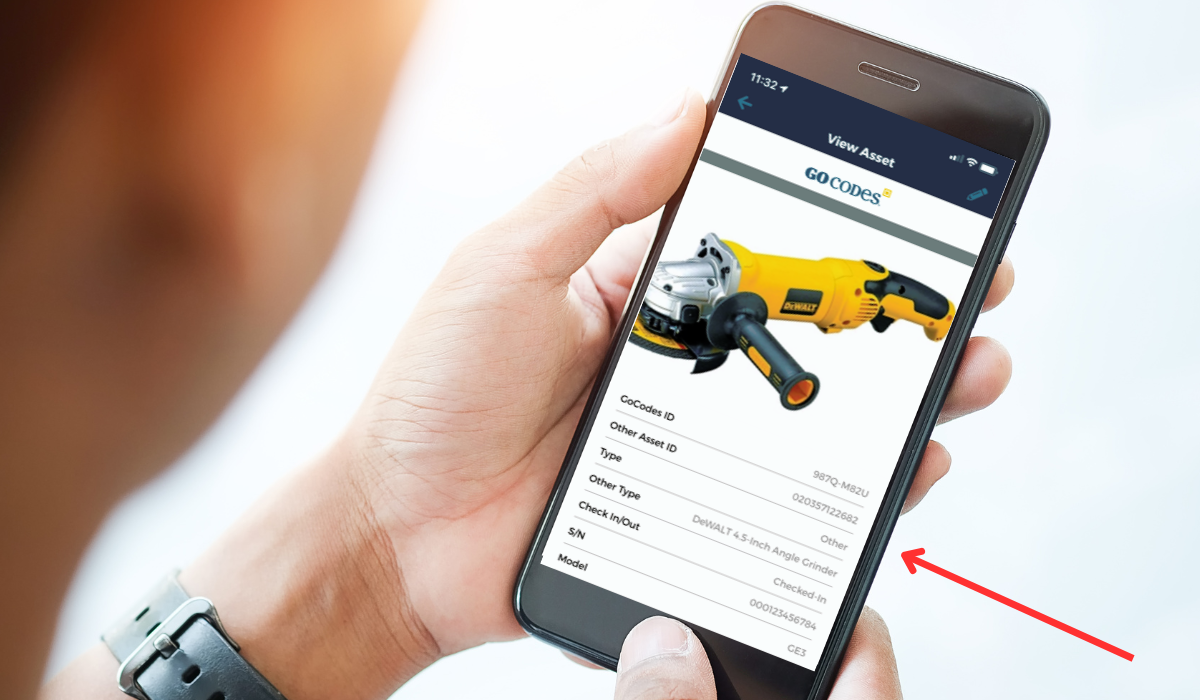

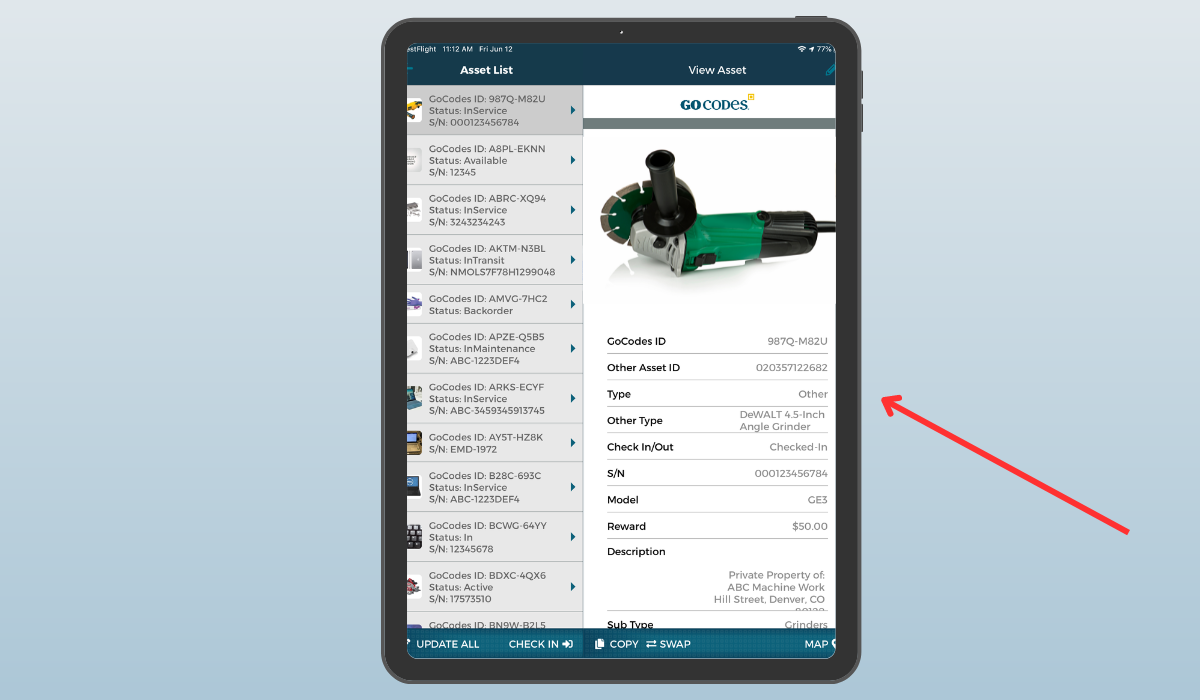

GoCodes comes with an app that can be installed on any smartphone or tablet.

With a single scan of an equipment’s QR code with this app, your on-site crew can access real-time information on any asset, right in the palm of their hands.

The best part of all this is that mobile devices are always within reach, and practically everyone knows how to use them.

The GoCodes app goes a step further in this user-friendliness with its intuitive interface, making it easy for anyone on the construction site to master its features, regardless of their level of education or tech-savviness.

This way, smartphones and tablets become a tool that grants team members instantaneous access to asset data, no matter where they are or when they need it.

No more going back to the office to manually update data or searching through folders of paperwork.

Now, it’s as easy as scan, read, and know, all from the convenience of the handheld device.

Ensures Complete Asset Visibility

In the construction industry, losing sight of assets, from small tools to heavy equipment, can lead to time delays, cost overruns, and substantial operational disorder.

This is where QR codes can streamline asset management by providing complete asset visibility.

How exactly do QR codes make this possible?

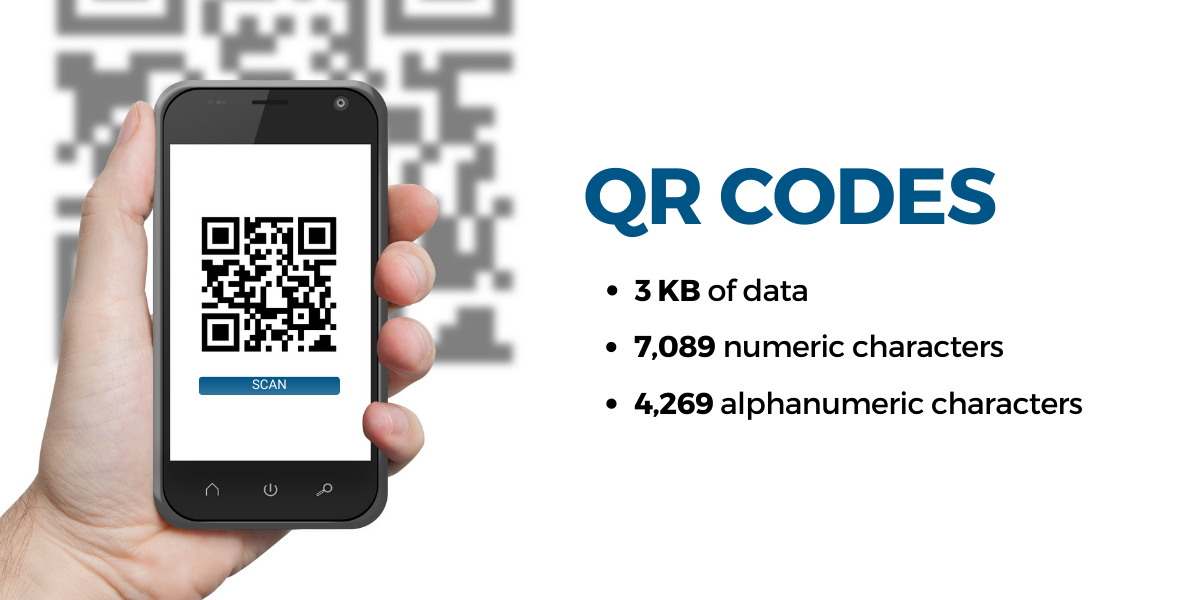

Unlike conventional barcode systems, QR codes can store a larger amount of data. About 3KB of data, 7,089 numeric and 4,269 alphanumeric characters, to be precise.

That’s why when team members scan an asset´s QR code, they can immediately access all its critical details: location, usage history, condition, maintenance schedule, and so forth.

This grants complete visibility of the inventory at any given moment—you know exactly what you have, where it is, and in what condition it is in.

For example, consider a construction project where various teams are operating across multiple job sites.

Having complete asset visibility means a project manager can, at any given moment, determine the exact location of a specific piece of equipment or monitor a particular tool’s usage.

This saves time and avoids unnecessary searching for lost or misplaced tools.

Moreover, these codes aren’t meant just for scanning–they’re also dynamic, which means they can be updated, too.

Unlike their static counterparts, where the encoded information is predetermined and unchangeable, dynamic QR codes allow for the information they hold to be updated at any time.

For instance, when an item moves from one job site to another or undergoes maintenance, scanning the QR code can instantly adjust its status across the system to reflect these changes.

And despite the changes to the asset page, the QR code pattern remains constant.

This means you don’t have to change or reprint the QR code each time the target information is modified.

As a result, all team members can access the most accurate information and maintain complete visibility of the entire inventory.

Simplifies Asset Identification

Managing a busy construction site involves juggling a myriad of tools and equipment every day.

Ensuring each of these assets is correctly identified, and thus efficiently managed, is paramount.

Even minor misidentifications can trigger bigger issues and lead to expensive errors, unnecessary time wastage, and overall reduced productivity.

However, simplifying asset identification isn’t as complex as it may appear—the answer lies in the strategic use of QR codes.

Think of a QR code as a unique ID card assigned to each of your assets.

By simply adhering a QR code to an item, you’re equipping it with a digital identification tag.

This means every tool and every piece of machinery in your inventory can be instantly recognized and properly monitored.

This eliminates the potential for confusion and mistakes, which often lead to misidentification.

A QR code isn’t just a tag, though.

Each QR code works as a mini database of all the information you would ever need about the associated asset, from serial numbers and model information to warranty details.

Just one scan and you can tell exactly what that asset is, as well as its entire history, right from its purchase date to the deadlines for recommended calibrations.

This simplicity in identification does wonders for streamlining operations.

That means no more second-guessing or sifting through piles of documents.

Just quick, confident identification based on accurate, real-time data.

Eliminates Human Error

A misplaced number in a spreadsheet, a small oversight on an inventory record, or an erroneous input in an asset database…

Small mistakes like that can slip in undetected and snowball into costly complications.

When it comes to asset management, where accuracy is crucial, human error can disrupt the delicate balance of operations.

Considering that 90% of spreadsheets contain at least one error, looking for a more error-free, QR-code-based solution for asset management can be a wise decision.

When you assign a QR code to each of your assets, you’re taking the critical data about that asset and locking it securely within that barcode.

Be it a piece of machinery, an expensive tool, or even an everyday office desk chair, a unique QR code allows you to keep accurate data about every item.

This leaves no room for ambiguity or typing errors–a simple scan offers you only precise information.

Updating assets is another potential loophole where errors often happen.

Many times, updating records can open up a Pandora’s box of potential inaccuracies–from logging the wrong information to updating the wrong asset.

But when your asset is paired with a QR code, the update process becomes more error-proof and as simple as scanning the code, and directly editing the real-time data.

Simply put, by including QR codes in the process, your asset’s data remains less unvarnished by human forgetfulness or inaccuracy, and asset management becomes more precise and reliable.

Increases Employee Accountability

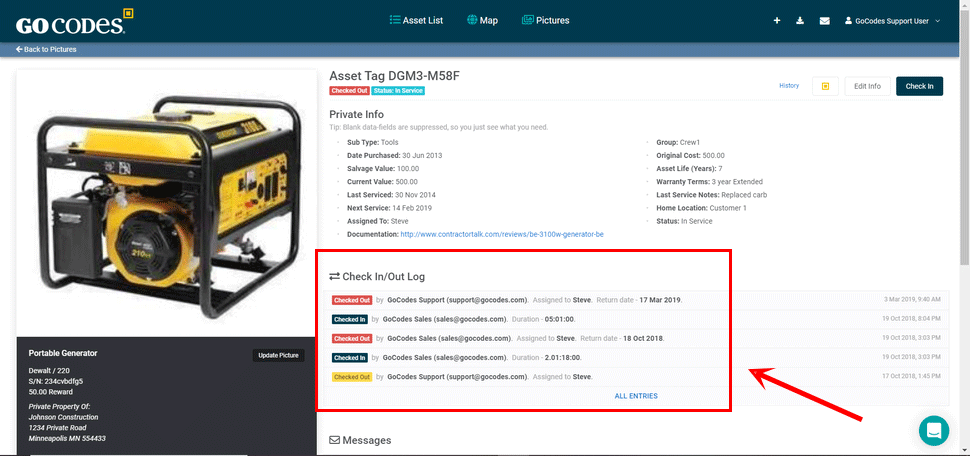

QR codes have one more distinctive feature.

They can contain information about the specific usage history of the asset—its check-in and check-out times, and the names of users.

Imagine employees borrowing a piece of equipment. Supervisors or asset managers would just need to scan the attached QR code and check out that equipment to those specific workers.

In a few seconds, their name is attached to the scanned asset, instantly recording that they’re responsible for it at that moment.

The same goes when they return the asset. Another scan of the QR code and the equipment is checked in.

Suddenly, you have a clearly visible trail of accountability—who used what, when they used it, and for how long.

This precision not only points a magnifying glass at your asset utilization but also keeps employees aware that their use of resources is monitored and recorded.

This way, QR codes encourage employees to think twice before casually leaving that expensive drill unattended or forgetting to return a borrowed wrench.

In other words, when accountability is integrated into asset management processes, the potential for lost, overlooked, or misplaced tools significantly decreases.

Improves Asset Maintenance

Ensuring every asset gets the right attention at the right time in terms of maintenance and repairs is crucial, but it can also quickly become an insurmountable challenge.

That’s mainly because of the sheer volume of tools and machinery that’s used in construction projects.

QR codes can be the difference-maker here, too, especially when paired with sophisticated asset-tracking software.

Again, we’ll use our own tool, GoCodes, to demonstrate this point.

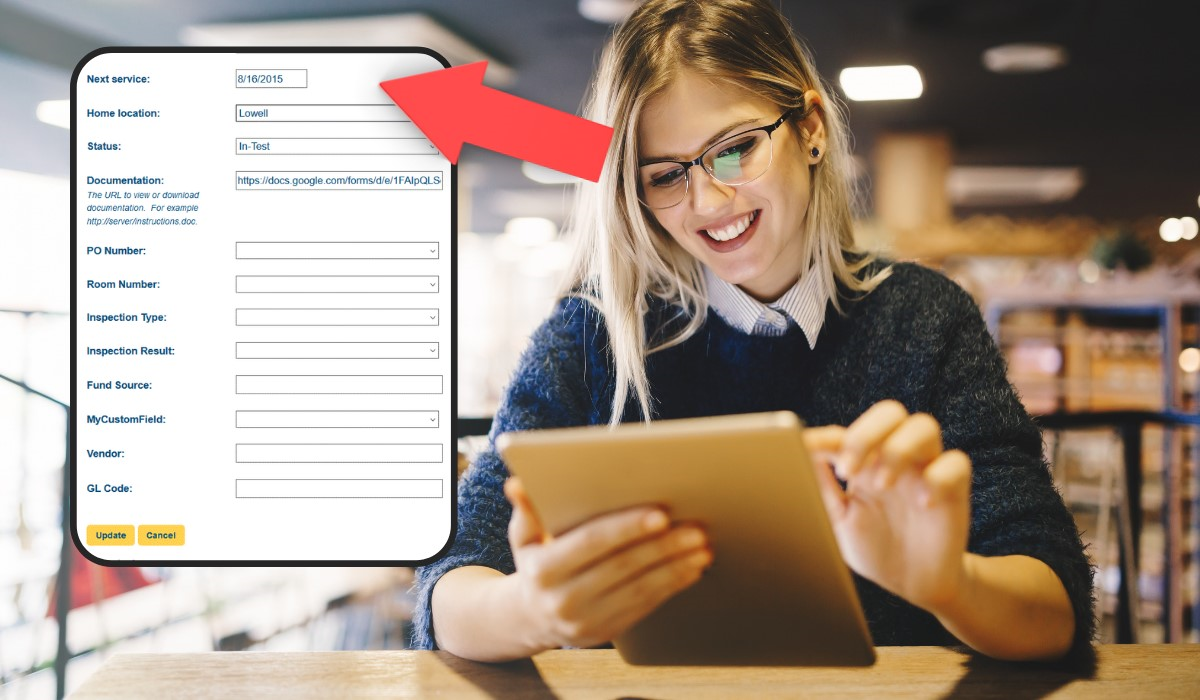

By scanning the QR codes with the GoCodes app, you can seamlessly open any given asset’s page and schedule future service tasks like maintenance work, calibrations, or repairs.

You can even set the exact date of the next service and ensure that you receive an automated email notification when the due date arrives.

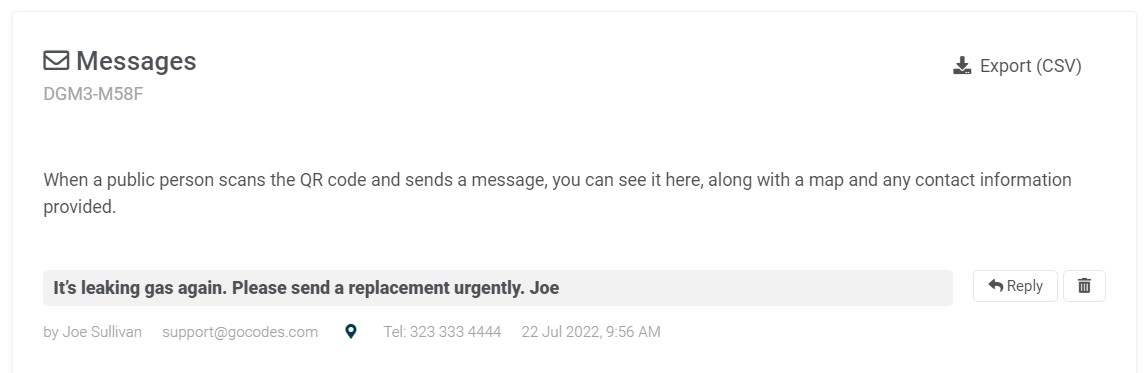

But, what happens when your team is out in the field and they encounter an asset that needs immediate repair?

Expecting your crew to call or email every time a piece of equipment needs service is not only inconvenient—it’s inefficient.

Here, too, your team can implement a service request simply by scanning the QR barcode.

Entering details such as the name and contact information along with a brief message, such as, “It’s leaking gas again,” they can set the repair process in motion.

Upon sending this message, supervisors or asset managers receive a direct email alert and text message, providing all the necessary information needed to schedule the repair.

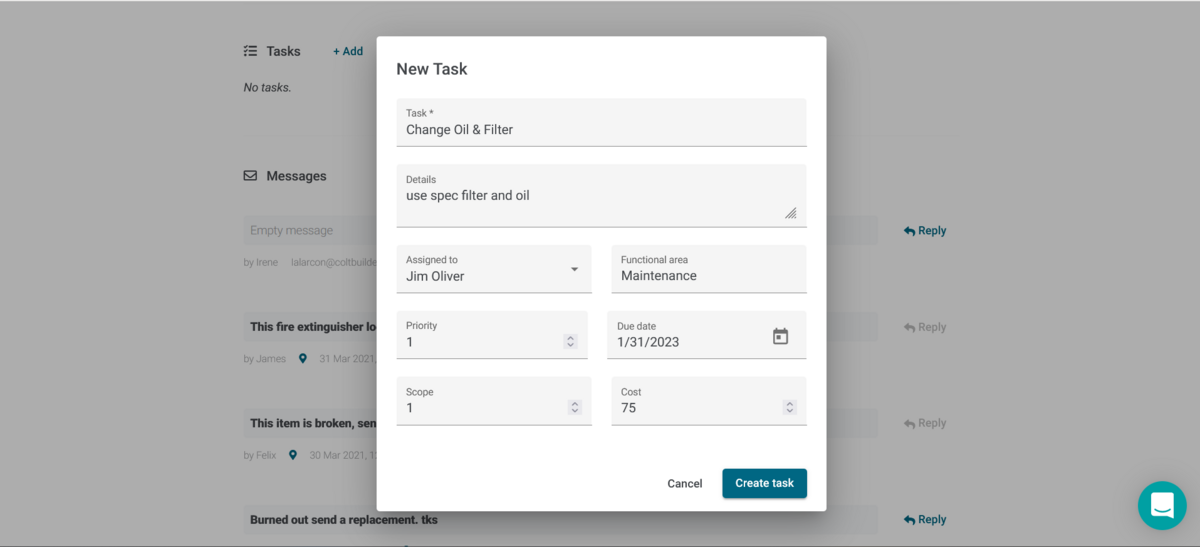

GoCodes can also help you with the assignments of maintenance work orders to specific employees.

Whether it’s a simple routine task like changing an air compressor filter or a complex repair job, you can allocate and manage work orders efficiently.

By creating a new task and assigning it to a team member, along with a corresponding deadline, you ensure that the right person gets the job done at the right time.

These examples illustrate just how straightforward maintenance tasks become when you use QR codes.

Since everything is automated, it becomes almost impossible to overlook maintenance.

Asset managers can expect timely notifications when it’s time for upkeep, and workers receive detailed work orders.

Equipment undergoing servicing gets tagged as unavailable during service hours, ensuring there’s no room for confusion in allocation.

Speeds up Asset Audits

Streamlining the asset audit process is a significant concern in the construction industry.

Audit allows you to review your assets, verify their physical presence, and cross-reference them against system records.

It can help expose disparities, missing pieces, unauthorized usage, or even theft.

However, asset audits traditionally involve manually checking and verifying every piece of equipment or tool in the inventory, one at a time.

This process can be laborious, error-prone, and long-winded, especially for large construction firms with vast inventory.

However, when you integrate QR codes into your asset management, the audit process becomes markedly efficient.

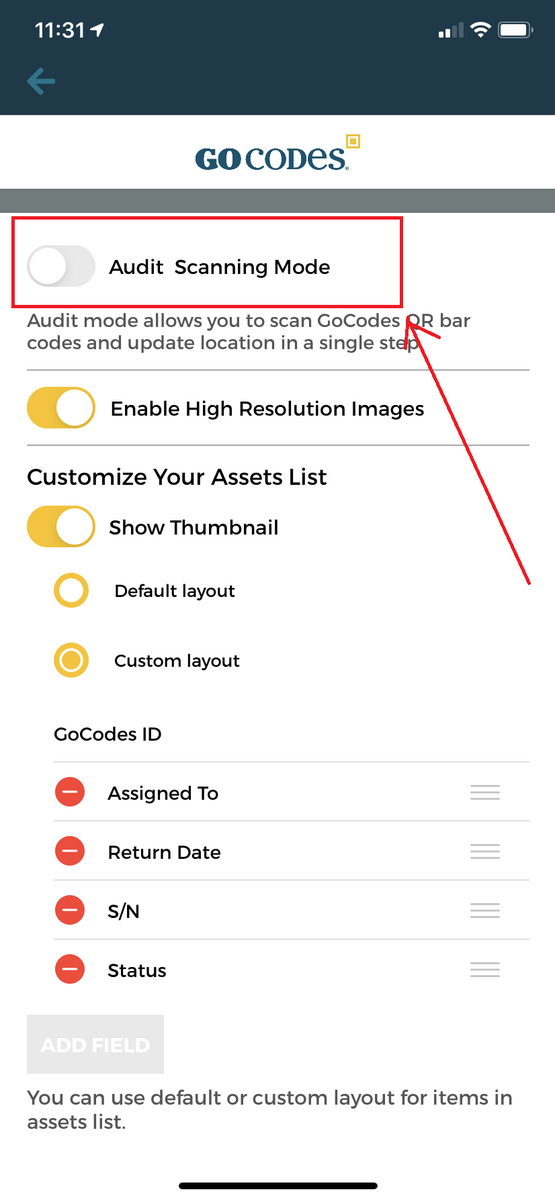

For this, you’ll have to enable an audit scanning mode in your app.

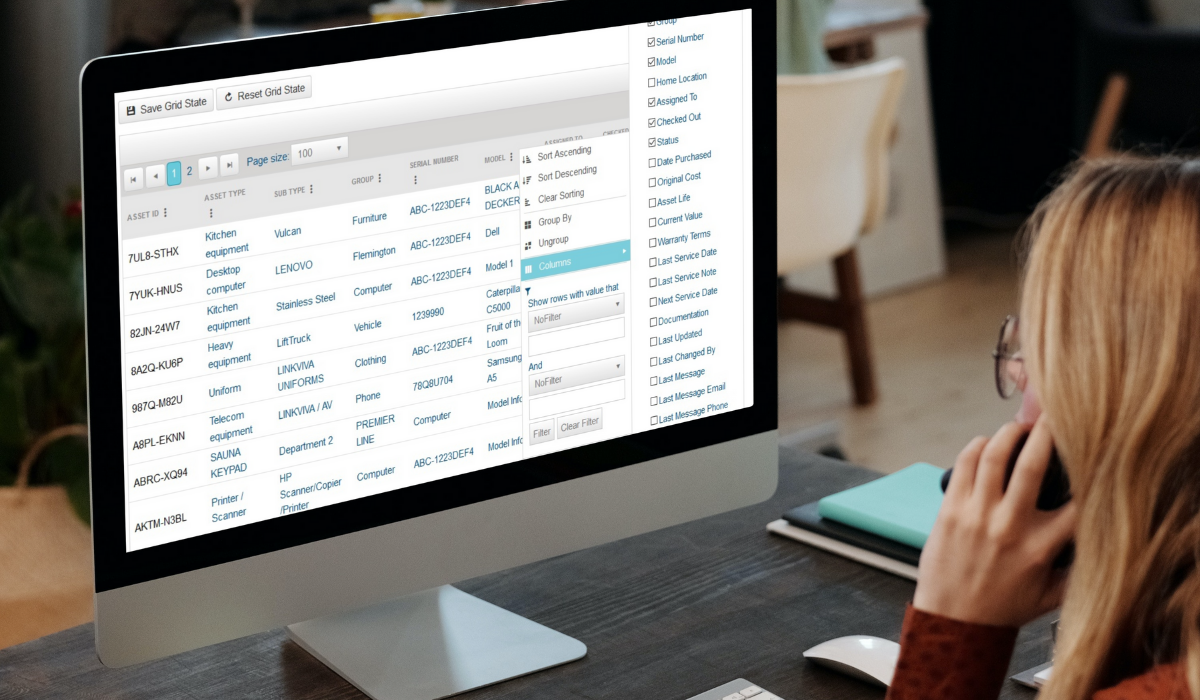

Once activated, you can scan QR codes, update asset location in a single step, and then customize your software dashboard to display the data you need.

For instance, if you wish to see the latest asset updates—which is crucial for effective audits—you can customize to view a list of your recent scans.

You can also gain information about equipment that has been acquired and disposed of since the last audit.

These features are especially convenient for handling asset audits in bulk, saving you precious time and improving accuracy.

Furthermore, you’ll also gain access to the audit trail and be able to inspect who entered the data or altered the asset records and when.

Auditors value this feature as it enables them to track changes and pinpoint where any discrepancies may have occurred.

Therefore, if you want to expedite your asset audits, and remove the manual process that you’ve been grappling with from the process, QR codes can serve as an excellent solution.

Conclusion

Now that we’ve explored QR codes and their remarkable applications in construction asset management, you’re likely viewing those inconspicuous black-and-white squares in a whole new light.

But what’s the use of all this information if it’s not applied? Your construction site won’t become more organized and efficient just by knowing the capabilities of QR codes.

So put this knowledge and insight into practice. Locate reputable asset management software that uses QR codes (GoCodes is one of them), employ codes on your inventory, and monitor the results.

Bit by bit, your asset management will improve, and become more efficient and much less burdensome.