Power tools, heavy machinery, and raw materials are all construction industry staples—and for a good reason, too.

They’re the heartbeat of every project, ensuring deadlines are met and quality standards upheld, regardless of the project’s nature, scope, or objectives.

However, many fail to realize that behind these amazing productivity-boosting machines, tools, and equipment lies the art of inventory control.

That’s why, in today’s article, we delve deeper into this crucial process, uncovering its secrets, discussing its benefits, and revealing strategies for more efficient implementation.

Let’s get started.

In this article...

What Is Construction Inventory Control

In its essence, inventory control—also referred to as stock control—involves managing and overseeing the levels, utilization, and conditions of the construction inventory at hand.

While in industries like retail, stock typically consists of goods to be sold to customers, in construction, inventory encompasses everything essential for bringing those blueprints to real life.

This includes three main categories of items: equipment and tools, materials, and consumables.

The primary objective of inventory control is, therefore, to ensure there are just enough of these items, and that they are in optimal condition so that the job can be finished on time and within budget.

As you can imagine, controlling that many different types of assets can be quite a feat.

It’s no surprise then, that inventory control is actually a very multifaceted process, involving various activities, such as:

- Receiving, storing, and transferring assets

- Strategically placing assets in designated locations

- Tracking asset locations

- Documenting product details and history

- Monitoring inventory conditions

- Processing purchase orders

- Implementing asset tracking technologies

- Generating reorder reports

But why is it that important to dedicate so much time and effort solely to this one aspect of project management?

Well, your equipment, materials, and tools are all inherently tied to the overall productivity and cost-efficiency of the project operations, so properly controlling them can, in fact, spell the difference between project success and failure.

Let’s delve deeper into this in the following section.

The Importance of Construction Inventory Control

Efficient inventory control gives you full visibility into your stock, telling you all you need to know about your materials, equipment, and tools.

Where are they located? How much is allocated to specific tasks? Are there items needing replenishment?

By providing answers to these questions and more, inventory control eliminates quite a bit of guesswork, in turn fostering better-informed decision-making.

This brings about two significant benefits: heightened productivity and increased cost-efficiency of the operations.

But how does stock control achieve this?

By tracking and managing inventory levels based on project requirements and usage patterns, stock control tackles two major inventory issues—stockouts and overstocking—both of which can detrimentally impact project budgets and timelines.

Stockouts are a more apparent issue and, consequently, receive greater attention.

This is understandable, as they can lead to severe consequences such as:

- Project delays

- Expedited shipping costs for urgently needed materials

- Increased risk of project interruptions or shutdowns

- Damage to contractor-client relationships due to missed deadlines or unmet expectations

Still, there is such a thing as “too much” in construction.

Overstocking can also cause considerable damage, resulting in:

- Increased storage, transportation, and handling costs

- Limited cash flow

- Increased risk of theft or damage

- Potential safety hazards on site

- Difficulty in managing and organizing assets

Inventory control takes care of both of these problems, ensuring there are just enough resources to get the job done, but without unnecessary overspending.

Now, adhering to budgets and deadlines is already a huge problem in the construction industry.

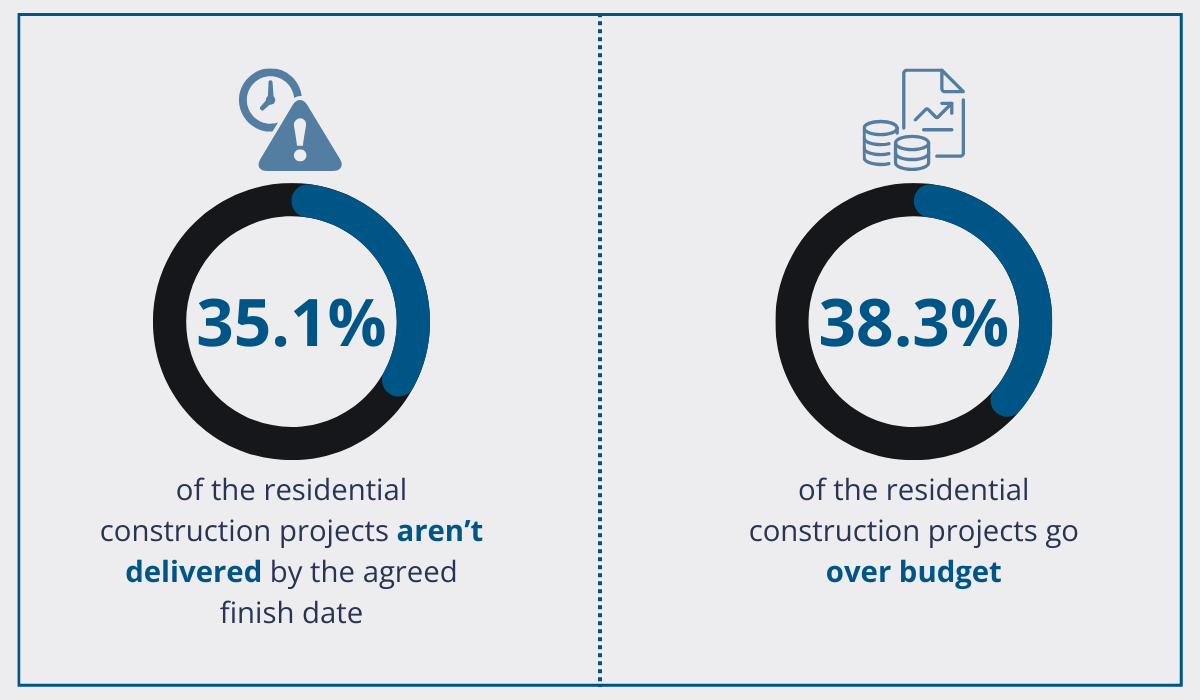

In fact, a survey conducted by the Association of Professional Builders reveals that over a third of residential construction projects fail to finish in time and within the allocated budget.

That’s why professionals in this sector must diligently explore all possible avenues to protect both the financial and operational aspects of their projects.

This is precisely where effective inventory control comes into play.

It ensures that all needed resources are available at the right place, at the right time, and in the right condition to facilitate seamless workflows, curtail unnecessary expenses, and ultimately, yield better project outcomes.

Construction Inventory Control vs Management: What’s the Difference?

You may have noticed that the terms “inventory control” and “inventory management” are often used interchangeably, but they are not exactly the same.

While they share similarities, they differ significantly in their scope, objectives, activities, areas of focus, and their impact on decision-making processes.

| INVENTORY CONTROL | INVENTORY MANAGEMENT | |

|---|---|---|

| SCOPE | Existing inventory in the warehouse | All the assets that will be used during the entire project lifecycle |

| GOAL | Ensuring there are enough items in stock, and that they are in good condition | Having the right machines, tools, and materials in the right place, at the right time throughout the entire project |

| ACTIVITIES | Receiving, storing, transporting inventory, and checking its quality | Predicting resource needs and ensuring those needs are fulfilled at all times through timely reordering and constant inventory tracking |

| APPROACH | Reactive | Proactive |

| TIME HORIZON | Short-term | Long-term |

Stock control, while a crucial component of inventory management, has a narrower focus.

It mostly deals with overseeing the current assets within warehouses or job sites, keeping tabs on their quantity, status, and condition, and taking care of day-to-day tasks such as inventory counting and warehouse organization.

On the other hand, inventory management encompasses a broader range of activities aimed at efficiently handling resources throughout the entire project lifecycle.

This includes:

- Strategic planning

- Forecasting resource needs

- Procurement of necessary goods

- Monitoring their usage

- Managing construction waste

Generally, stock control tends to be reactive, focusing on short-term adjustments to stock levels and immediate operational needs.

In contrast, inventory management takes a proactive approach, aiming for long-term optimization of asset acquisition and use to achieve project goals more effectively.

It actually uses data obtained through inventory control to analyze demand patterns, lead times, and reorder points more accurately, in turn enabling better decision-making for the future.

Therefore, while these two concepts are quite different, you can’t really have one without the other.

Inventory control keeps things running smoothly on a daily basis, while inventory management ensures you’re not just meeting today’s demands but setting yourself and your team up for success down the road.

In short, these two processes are the dynamic duo that keeps your projects on track, on time, and within budget.

Types of Construction Inventory Control Systems

There are two primary types of inventory control systems: periodic and perpetual.

Let’s examine their respective advantages and disadvantages, as well as the types of businesses each is best suited for.

Periodic

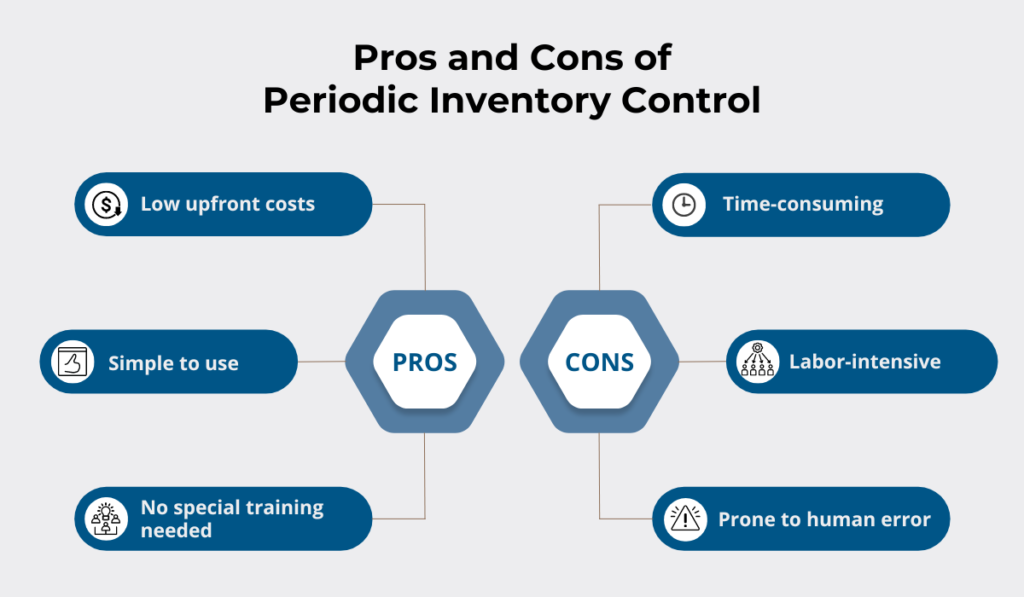

As implied by its name, a periodic inventory control system involves recurrent assessment of stock levels and conditions at predetermined intervals.

These intervals may vary from weekly to monthly or annually, depending on your specific business or project needs and activities.

The system typically entails manual counting and recording of asset data using traditional methods such as pen and paper or spreadsheets.

This, naturally, has its advantages and disadvantages.

On the positive side, periodic inventory control doesn’t require any specialized software, which directly translates to minimal training, ease of use, and lower implementation costs.

However, for businesses with a substantial volume of assets, this approach may be less efficient.

Manual stock control can be quite time-consuming and labor-intensive, often leading to costly data-entry mistakes.

A survey on Excel proficiency from Acuity Training further underscores this point.

It reveals that a significant portion of people are never properly trained in using Excel, and therefore make errors that can incur both time and financial losses.

Ultimately, the efficiency of periodic inventory control depends on the size of your asset portfolio.

For smaller construction companies, this system may be perfect for getting the job done without breaking the bank.

Still, larger companies with a greater number of assets spread across multiple locations may have to deal with human error that can disrupt project timelines and inflate expenses if they implement periodic inventory control.

Perpetual

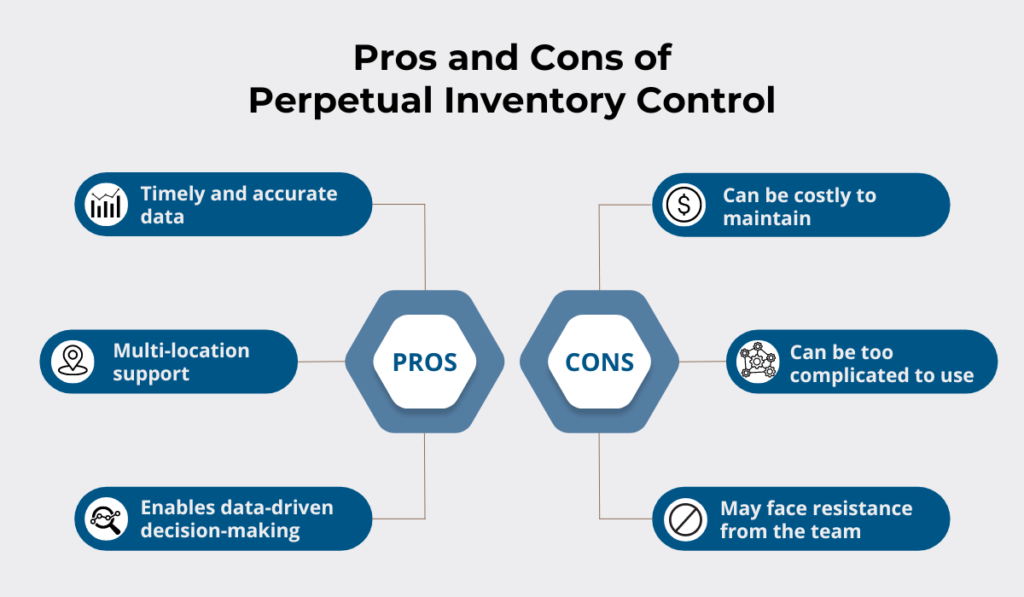

Perpetual inventory control continuously monitors inventories, offering either real-time or near real-time insights into the whereabouts and quantities of your machinery, tools, materials, and consumables.

To make this real-time monitoring possible, the system typically uses tracking technologies such as barcodes or RFID tags, coupled with dedicated software that serves as a centralized database.

Just like periodic systems, perpetual inventory control has both pros and cons.

For starters, due to the need for specialized software solutions, implementing and maintaining such a system can be costly, especially compared to manual methods.

Besides, if you opt for an inventory control system with a complex and feature-heavy interface, your workers may be hesitant to use it.

However, the benefits of perpetual stock control outweigh its drawbacks.

Unlike the periodic systems, perpetual stock control provides precise and timely asset data, even across multiple sites, facilitating informed, data-driven decision-making.

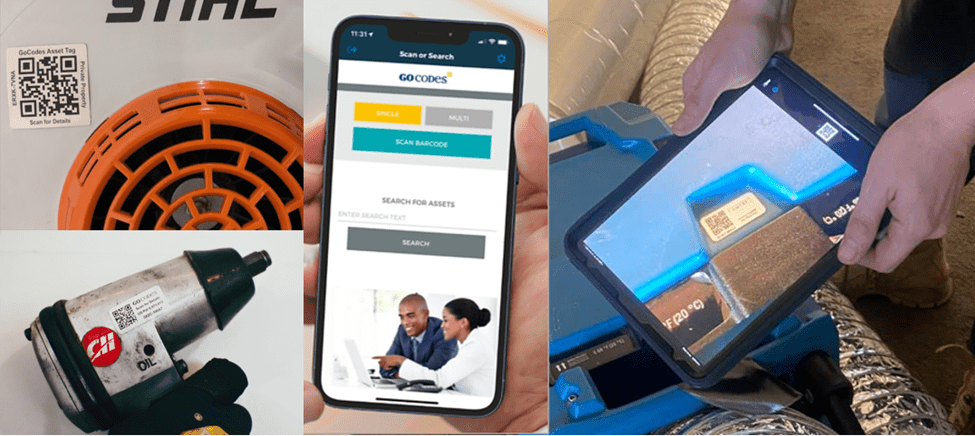

Take GoCodes Asset Tracking, our own inventory management solution.

It offers comprehensive insights into your assets, including their:

- Locations

- Quantities

- Current and past users

- Maintenance history

- Future service information and schedules

- Warranty details

Since the software records all the changes in your inventory automatically, you can be confident that your data is always fresh, accurate, detailed, and ready to be used to optimize your asset management game.

The best part?

GoCodes Asset Tracking is very user-friendly, even for less tech-savvy users.

Stock control using our system boils down to three simple steps.

First, attach our customized QR code labels to your assets.

Then, use our in-app scanner to scan the labels and update asset data.

Finally, access this information anytime, from any device with an internet connection, using our cloud-based software.

At the end of the day, there’s no denying that construction inventories can sometimes be too complex to stay on top of through manual methods.

Perpetual systems, on the other hand, handle this challenging task with ease.

They continuously provide information about your inventory conditions, levels, locations, and usage, allowing you to focus on more high-level tasks.

Conclusion

Overall, inventory control is an indispensable aspect of inventory management, and by extension, project management as a whole.

It helps ensure project teams have the right assets in optimal condition at their disposal so that they can deliver top-notch results every single time.

But remember: by consistently monitoring inventory levels, analyzing consumption patterns, and adjusting strategies as necessary, you not only ensure timely project completion but also outpace the competition and position yourself for long-term success.

In other words, each stride toward efficient inventory control contributes to the overarching success of your business.