Asset tracking introduces countless benefits to construction businesses.

Perhaps most importantly for construction companies seeking peak efficiency, using asset tracking software makes it easier to save money while performing everyday operations.

Moreover, asset tracking software can help eliminate ghost assets, which introduces a host of advantages all on its own.

Construction companies that use asset tracking also save money by maximizing asset utilization and reducing maintenance costs.

This practice also promotes easy monitoring of asset life cycles, as well as preventing theft. Finally, asset tracking can result in lower insurance premiums.

So, let’s go over some ways in which using a software solution for asset tracking can save money for your construction company.

In this article...

Eliminates Ghost Assets

The equipment that a construction company has listed in its asset register, despite the fact that it is no longer in good repair or even available for use, is referred to as ghost assets.

Ghost assets cost your construction company money because you may still be paying insurance and taxes for them, even though they are no longer serviceable.

Accidentally relying on items being available for use or sale when they are not can also lead to plan delays, as well as customer service problems and supply chain issues.

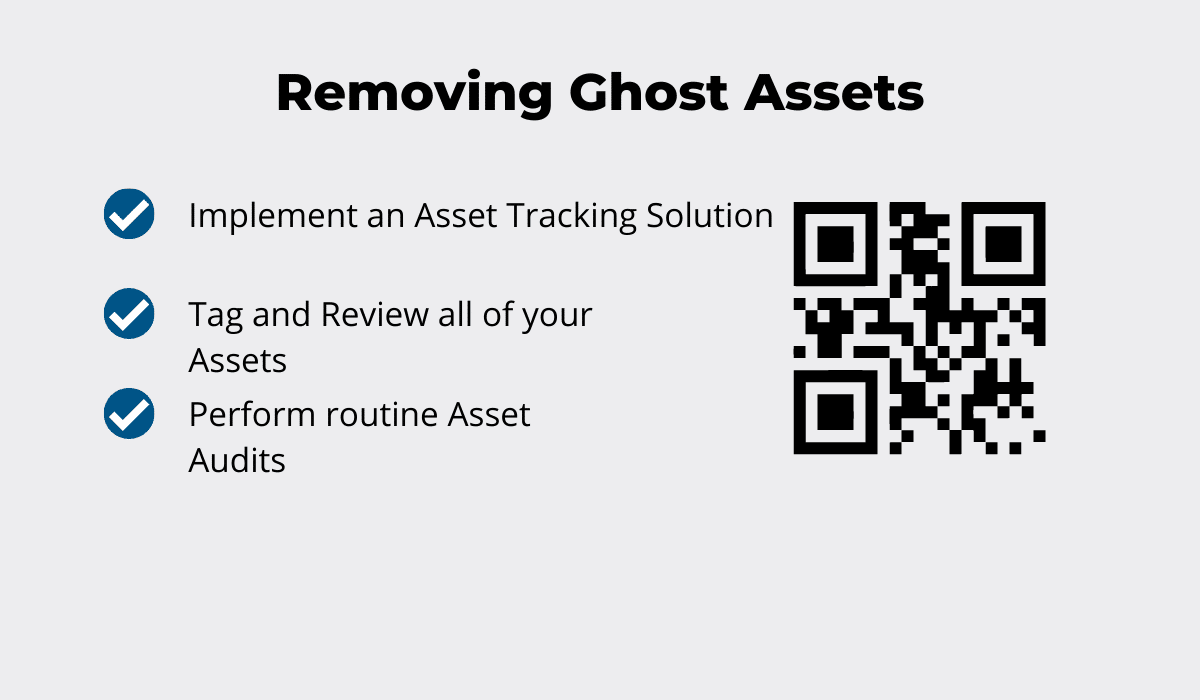

As you can see, it’s important to eliminate ghost assets through asset tracking. Here is what the process of removing ghost assets involves:

The last line of this visual mentions asset audits. Asset audits are regular reviews of inventory levels. They are much easier to accomplish with a robust asset tracking system.

But which asset tracking solution is best for your company? That will depend on your own specific needs. However, there are certain features that you should look for.

Our own solution, GoCodes Asset Tracking, offers unique QR codes for condition-friendly tags that can be attached to assets.

These tags are easily scannable, using the technology your employees probably already use on a daily basis, such as smartphones and tablets.

This scanning, if performed as necessary, helps build and maintain an up-to-date asset register with no ghost assets.

Thanks to this process, you will have an accurate idea of what your construction company has in hand.

That makes it easier to plan and build budgets, as well as take depreciation deductions when the time comes to prepare tax documents.

Maximizes Asset Utilization

Asset utilization is often a major problem for construction companies.

Often, the nature of a construction company’s work involves duplicate assets that are spread out over many work sites.

That makes it difficult to keep track of each item, let alone manage them effectively.

Idle assets are a waste of money, but with asset tracking software, your construction company can monitor when and how each asset is used.

This allows your organization to maximize asset utilization by scheduling their use more efficiently.

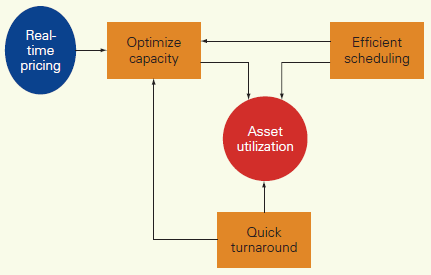

Asset utilization has many aspects that contribute to optimal implementation. Here is one representation of how it works:

Achieving this requires planning. It doesn’t happen automatically. In fact, according to Gartner, Inc, 30% of companies don’t know the following about their assets:

- which items they own

- which employee is using them

- where the assets are located

- where they are scheduled for use next

However, when assets are properly utilized, companies and their employees have more time for productive work.

Even if this adds up to just a few minutes a day, it can yield positive results for each member of your team.

In addition, an asset utilization plan can be implemented even in organizations where it’s important to create different levels of authorization for different types of users.

For example, if certain employees, such as work crew managers, require access to your tracking system, but operators do not, it’s easy to apply appropriate authorization for each user.

Since users aren’t tied to office assets such as computers, it’s easier to receive data updates and update information on the go.

That means data-driven decisions are made more easily and more quickly.

When you know where your assets are, it’s far easier to address downtime or unexpected staff shortages.

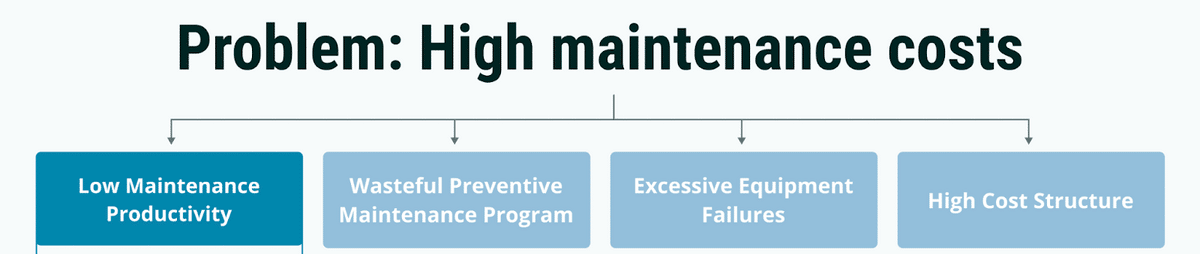

Reduces Maintenance Costs

It’s a well-known fact that preventive maintenance costs less than reactive maintenance and keeps your assets in good condition for longer.

Your company can keep costs down by using asset tracking software to schedule preventive maintenance, which lowers the risk of assets suddenly malfunctioning or unexpectedly breaking down.

Maintenance costs are an unavoidable part of every business, but construction companies are especially vulnerable to them because of the many mechanical assets they tend to deploy.

However, asset tracking software can help to lower maintenance bills.

This chart lists some of the many other contributors to high maintenance costs. Such costs can negatively affect your bottom line in more ways than one.

According to Mintek, companies can save anywhere between 12 and 18 percent on maintenance costs simply by focusing on preventive maintenance rather than reactive maintenance.

And preventive maintenance is much easier with asset tracking. Every time one of your team members scans an asset tag, more data becomes available for assessment.

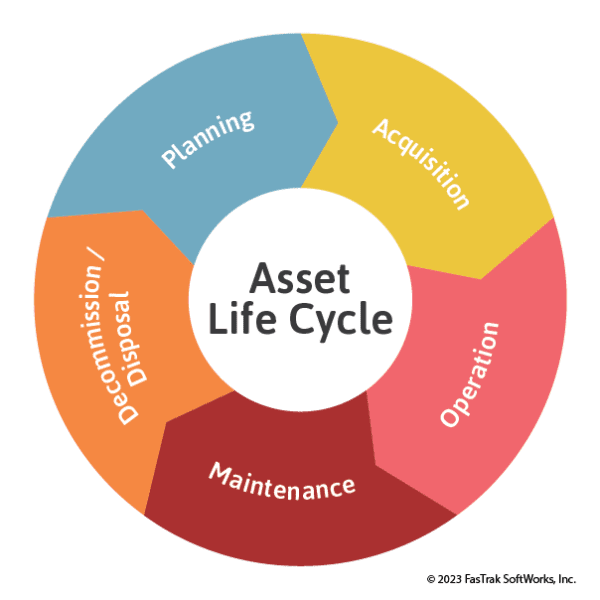

Monitors the Life cycle of Assets

Monitoring the life cycle of assets is a must for construction companies.

By an asset’s life cycle, we mean the ways in which your equipment produces and ages while in your company’s care:

Knowing where your major and minor assets are in this cycle is important in a number of ways, as it allows your construction company to save resources, and make effective decisions.

When you use a solution like GoCodes Asset Tracking, it is easy to manage fixed assets.

The entry for each asset is seamlessly integrated with a wealth of information about it, such as its origin, date of purchase, warranty information, manufacturer, and dates of major maintenance actions.

Access to this information contributes to easy preventive maintenance scheduling, while also allowing your company to establish performance baselines and accurately monitor depreciation.

Failing to track an asset’s life cycle can deliver many negative consequences.

For example, your company will have little idea of how your asset has declined, or how quickly.

This can lead to unexpected breakdowns and a lack of knowledge concerning how well your asset is performing.

Maintaining awareness of asset performance, then, can help to avoid spending on emergency repairs, panic buying, and adding extra employees to a job in order to meet deadlines.

Prevents Asset Theft

You’re probably aware that asset theft is a major problem in the construction industry. Stolen construction equipment adds up to nearly a billion dollars every year.

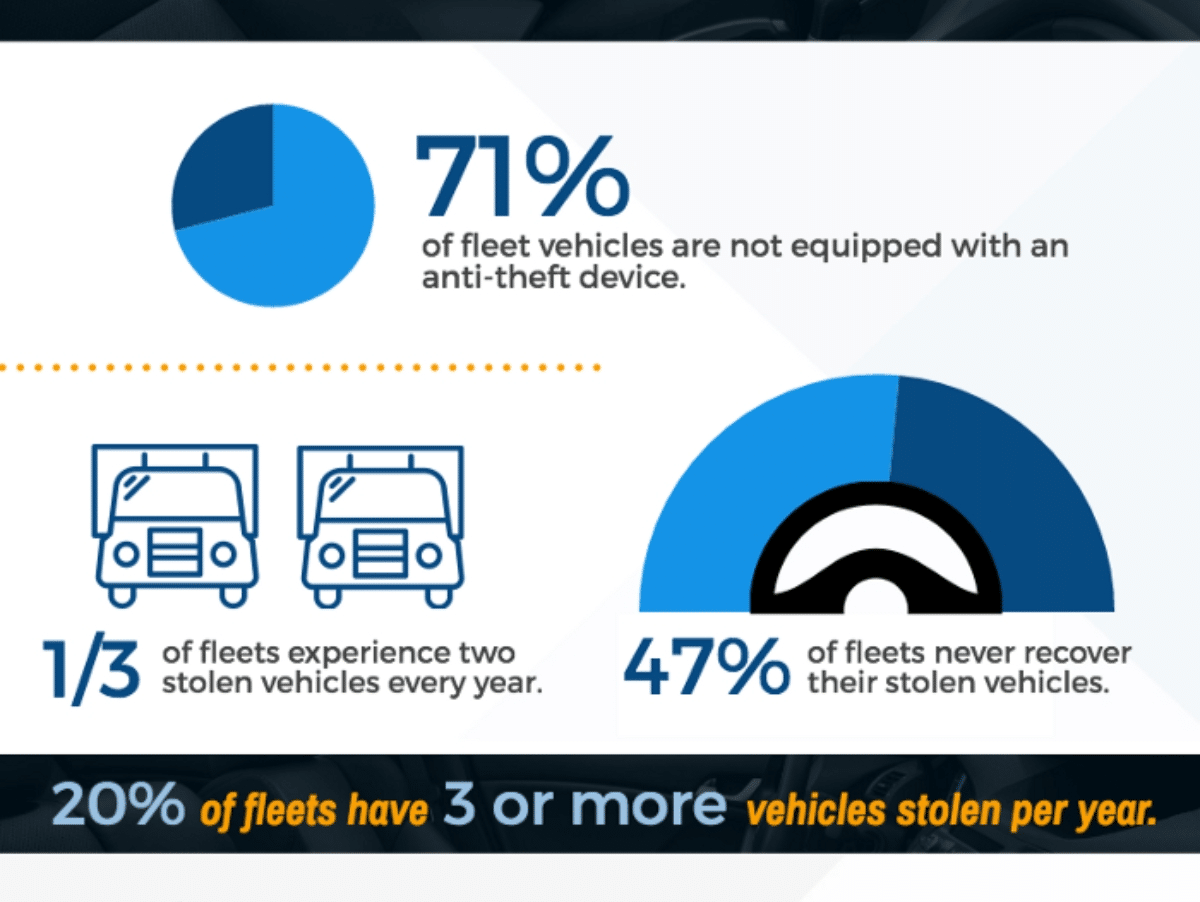

Here are more statistics concerning the severity of construction equipment theft:

However, with asset tracking software, your construction company can protect itself against equipment theft.

Your company will maintain better control over your assets with tracking, which means that you and your employees will not have to worry about spending a lot of money to replace missing or stolen assets.

Because dedicated software solutions such as GoCodes Asset Tracking offer GPS tracking, missing or stolen assets are more easily located and recovered.

GPS tracking assists in helping to reduce construction equipment theft because it can maintain a virtual fence around parked vehicles or tool cages.

With the use of special Bluetooth beacons, the tracking system, such as the one implemented by GoCodes Asset Tracking, can send an alert to security personnel or law enforcement when items are moved without authorization.

Even if an item leaves company property or construction sites without permission, a GPS asset tag can aid greatly in recovering your property.

Lowers Insurance Premiums

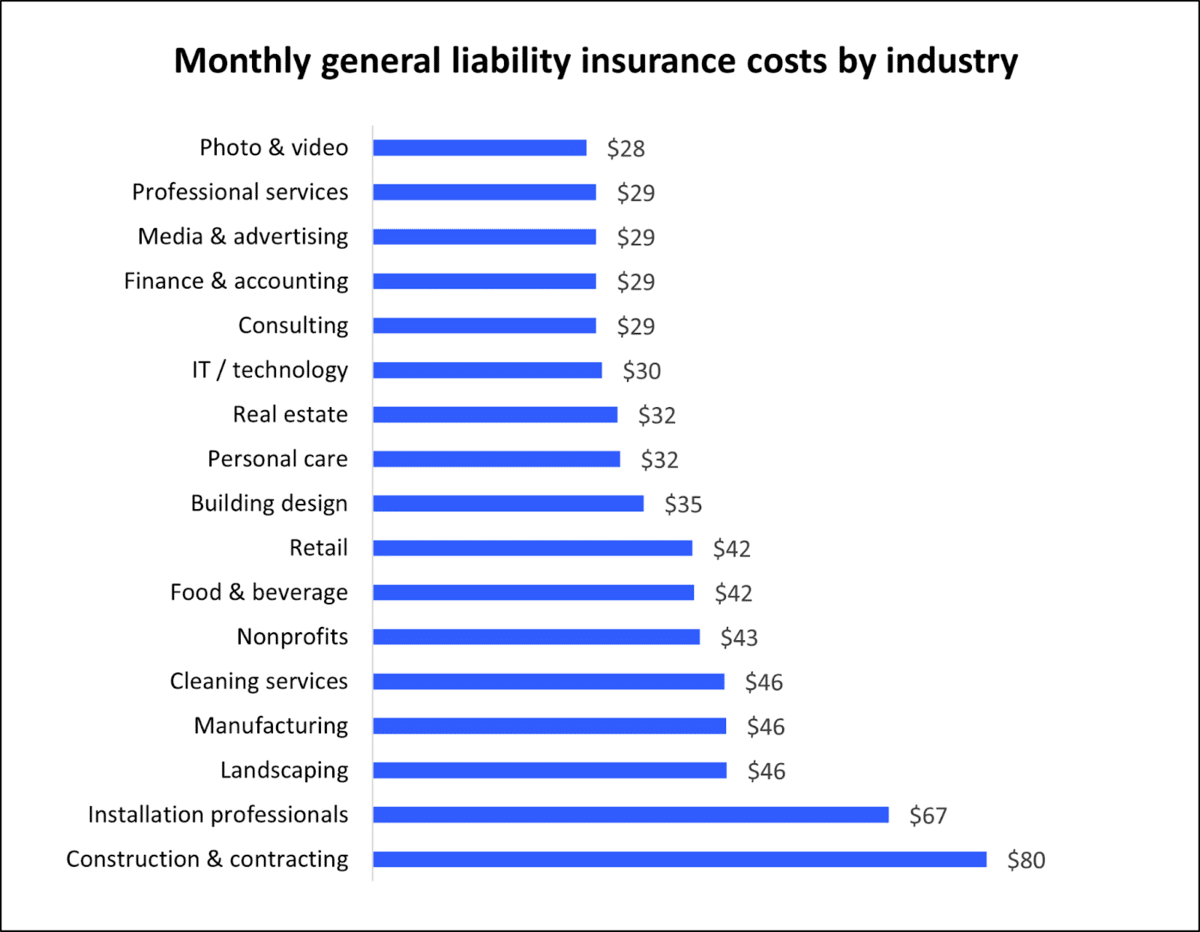

When the general public thinks about the costs associated with running a construction company, they might name labor salaries, maintenance expenses, or the cost of equipment.

However, there is another hidden major cost inherent to basic operation in construction that those outside the industry usually fail to consider—insurance premiums.

In fact, as this chart shows, construction and contracting have the highest monthly general liability insurance costs of most major industries:

Therefore, it is in a construction company’s best interest to keep these costs as low as possible.

Asset tracking is one of the key ways to achieve this, because using a GPS-powered asset tracking software solution demonstrates that your organization has taken steps to protect your valuable equipment.

Fleet managers who use GPS-based anti-theft measures might also see improved driver behavior, fuel savings, and easier regulatory compliance.

All of this signals to the insurance company that your company presents a lower risk than others, which may result in discounts or more affordable premiums.

Conclusion

Asset tracking software can help save money for your construction business. It is likely to contribute to eliminating ghost assets, leading to improved resource management.

Investing in asset tracking software helps to maximize asset utilization, as well as reduce maintenance costs.

Since this technology is also useful in preventing asset theft, your company might enjoy lower insurance premiums.

Finally, since asset tracking software is extremely useful in following an asset’s life cycle, scheduling regular service actions can help to prevent unexpected breakdowns.