Key Takeaways:

- Telematics integrates telecommunications with information technology to enable remote monitoring and management of vehicles, machinery, and equipment in real time.

- Fleet management collects and interprets fleet data to ensure proper allocation, maintenance, and functioning of vehicles and equipment.

- The synergy between telematics and fleet management software helps fleet managers optimize fleet operations, improve efficiency, and reduce costs.

If you’re a construction company owner or manager looking for solutions to manage your fleet of vehicles, trucks, and machinery, you’ve certainly run into terms “telematics” and “fleet management”.

Although they might’ve been presented as one and the same thing, they’re not.

In this article, we’ll clarify what each term actually means, highlight the differences between them, and explore how they complement each other in streamlining your construction fleet operations.

In this article...

What Is Telematics

Let’s start by explaining the newer of two technologies we’re discussing, namely the inner workings of telematics.

In a nutshell, telematics can utilize a combination of:

- GPS (Global Positioning System) tracking technology

- vehicle’s onboard diagnostics (OBD) unit (i.e., its built-in sensors)

- a range of additional external sensors (installed inside a GPS tracker or the vehicle)

Therefore, telematics integrates telecommunications with information technology to enable remote monitoring and management of vehicles, machinery, and equipment in real time.

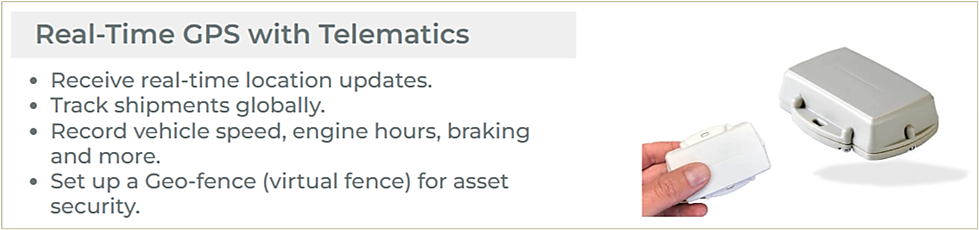

Mind you, the only absolutely necessary component from those above is a GPS tracker installed in each of your fleet’s vehicles.

In other words, you can get battery-powered GPS trackers that can be easily attached to your vehicles and that’s it, you’re done—at least in terms of hardware installation requirements.

However, such trackers will typically only track a vehicle’s location, speed, and traveling direction, while other vehicle data will remain untapped.

More advanced GPS trackers can have a range of their own sensors—like accelerometer, temperature, and humidity—which allow them to extend the range of data they collect while not being connected to the vehicle’s internal systems.

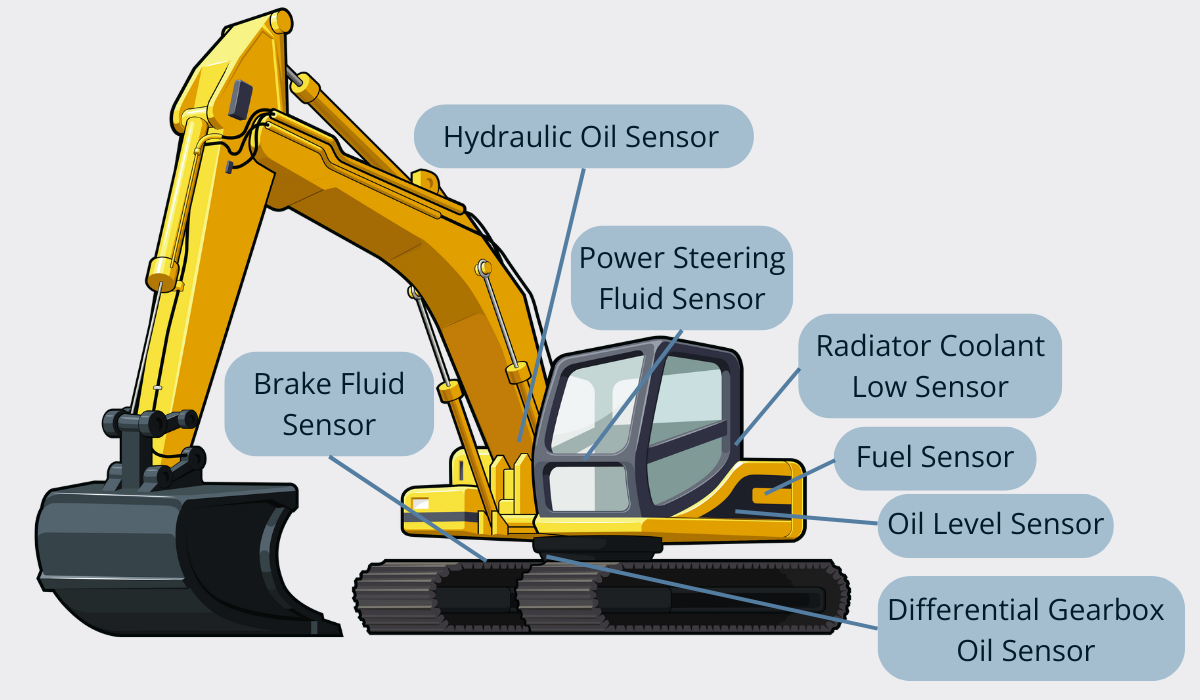

Next, when a tracker is linked to your vehicle’s OBD system (a network of internal vehicle sensors), its abilities grow exponentially, allowing it to monitor various aspects of the vehicle’s operation.

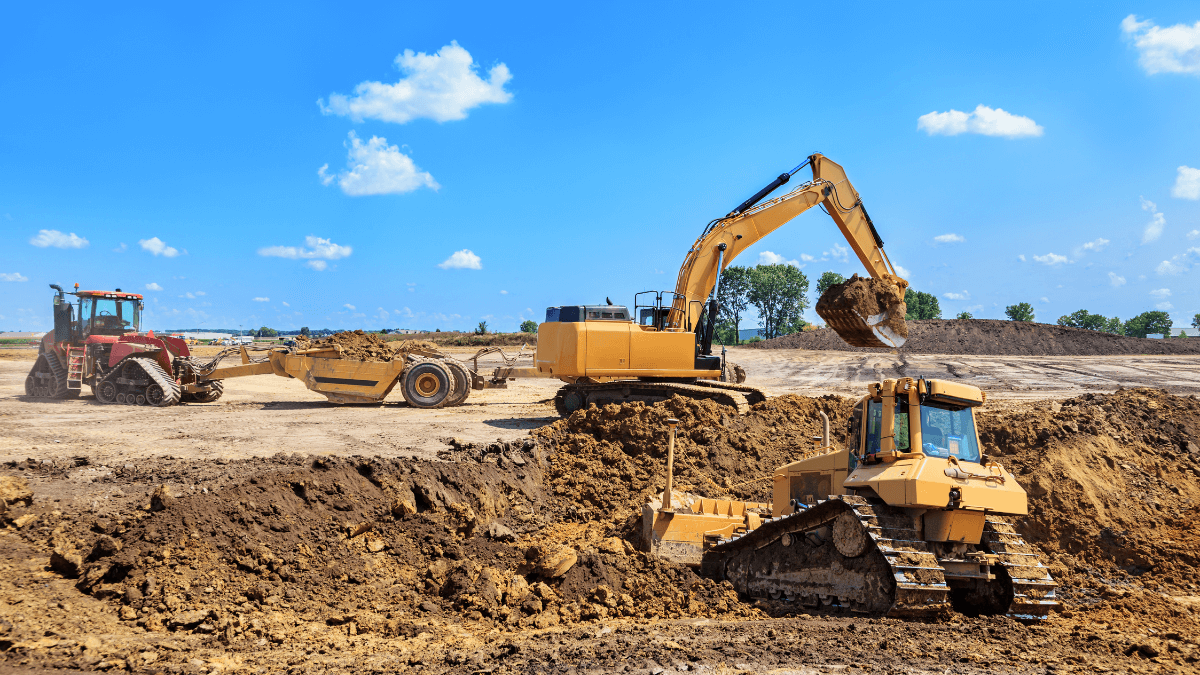

Finally, your construction vehicles and heavy equipment can have multiple additional built-in or subsequently installed sensors connected to the GPS tracker, meaning they can track and detect an even wider range of parameters.

Regardless of what internal or external sensors your construction equipment has, these sensors will work together to provide the GPS tracker with data on various aspects of its operation, allowing for efficient performance monitoring and diagnostics.

Having covered the vast possibilities of a telematics system depending on its sophistication level, let’s see how all that data is collected for later retrieval (passive GPS) or real-time updates (active GPS).

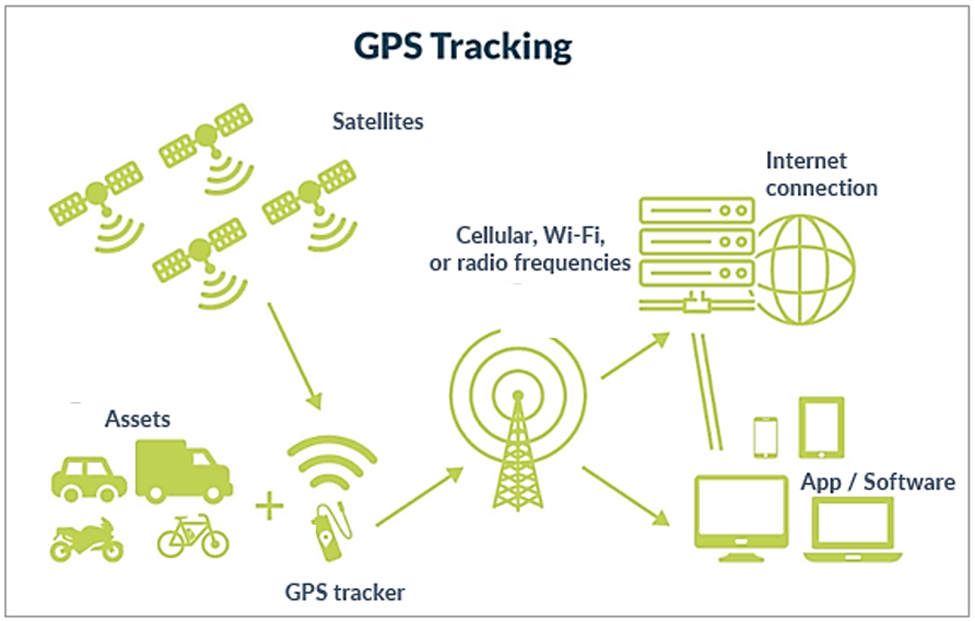

Basically, each GPS tracker uses satellite signals to triangulate its position, i.e., determine where the vehicle is located anywhere in the world.

You can see how this works in the image below.

As illustrated, any data collected by the tracker’s or vehicle’s sensors is encrypted and, using cellular, Wi-Fi, or radio frequencies, sent to the central database (server), which relays it to their final destination—fleet management software.

Other increasingly used telematics devices that use the same data transmission principle are road-facing and driver-facing dashcams.

As their name suggests, these cameras record what’s happening on the road and in a vehicle’s cabin, respectively.

For instance, road-facing cameras can detect and alert drivers in real time about a range of potential risks, such as upcoming stop signs or driving too close to another vehicle.

Similarly, driver-facing cameras can notify drivers if they’re engaging in distracted driving behaviors, like using their phones while driving.

To sum up, telematics is a broad field that encompasses the use of GPS tracking in conjunction with various sensors to monitor vehicles remotely and collect a multitude of parameters crucial for more efficient fleet management.

What Is Fleet Management

Compared to telematics, fleet management has been around much longer, dating back to the 19th century and a fleet of horse-drawn carriages used for mail delivery.

As you can imagine, ensuring these stagecoaches are well-maintained, horses well-fed and rested, and drivers properly scheduled required some organizational and administrative efforts, hence giving rise to early fleet management.

Fast forward closer to our timeline, paper forms and lists used to monitor the status of vehicles in a fleet were first replaced by digital documents and spreadsheets and, soon thereafter, by far more practical fleet management software.

At present, such cloud-based software solutions—available on any internet-connected device at any time—are still widely used for fleet and inventory management in conjunction with telematics technology.

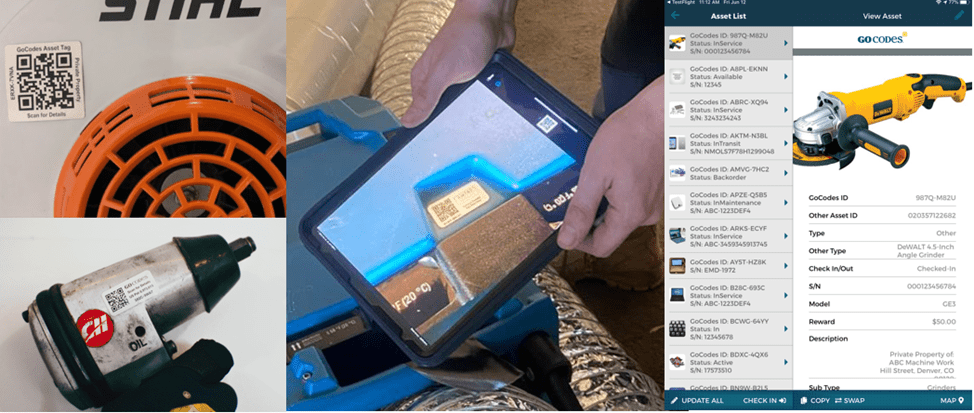

For example, barcodes or QR codes attached to all your assets allow you to digitize, organize, and streamline most administrative fleet, asset, and inventory management tasks.

As illustrated, a worker can scan the QR code or use the software app on their phone to access the central cloud database and update it, allowing all other users (i.e., fleet managers) to see the changes in real time.

This ability has many practical fleet management applications, such as:

- scheduling and tracking the allocation of fleet vehicles and equipment, related maintenance tasks, inspections, and repairs,

- implementing efficient check-in/check-out procedures for vehicles and equipment, where users can scan QR codes to record usage and status changes,

- digitizing and storing important documentation (warranty, manuals, maintenance records, etc.), and

- keeping accurate records of inventory levels for spare parts, tools, and supplies.

Since these are only a few fleet, asset, and inventory management features, it’s clear that cloud software with a built-in digital scanner in conjunction with rugged QR codes represents a simple and cost-efficient method for administrative fleet management.

For instance, you can utilize our QR code-based solution, GoCodes Asset Tracking, to also monitor fleet compliance with regulations and safety standards by recording inspection results, certifications, and compliance documentation.

Furthermore, you can leverage its reporting and analytics features to generate reports and review data on fleet performance, equipment utilization, maintenance costs, fleet audits, and depreciation.

All these features strike at the core of fleet management, which aims to optimize the utilization, maintenance, and administration of construction vehicles and equipment to ensure smooth operations.

Moreover, such systems can already have some telematics properties like, for example, the GPS location of your QR-coded asset being automatically captured every time somebody scans the QR tag.

This passive, scan-based telematics feature allows you to track the location and users of a range of less expensive, smaller equipment and tools, thereby increasing worker accountability and reducing asset theft and loss.

Naturally, this system can be enhanced through integration with our other telematics devices, such as active GPS trackers and Bluetooth beacons, as we’ll discuss later.

To sum up, fleet management came before telematics, and is concerned with collecting and interpreting fleet data to ensure proper allocation, maintenance, and functioning of vehicles and equipment.

The adoption of software solutions enhanced many aspects of fleet management, and telematics technology came as a natural extension by providing real-time insights into vehicle performance, driver/operator behavior, and operational efficiency.

Telematics vs Fleet Management: Key Differences

Given what was said about telematics and fleet management, the key difference between them is that the former would not be of much use without the latter.

In other words, telematics focuses on data collection and transmission (the body), while fleet management software focuses on data analysis and interpretation (the head).

Even more precisely:

- telematics provides the raw data necessary for monitoring vehicle/equipment performance and location in real time, and

- fleet management software transforms this data into actionable insights to improve operational efficiency and reduce costs.

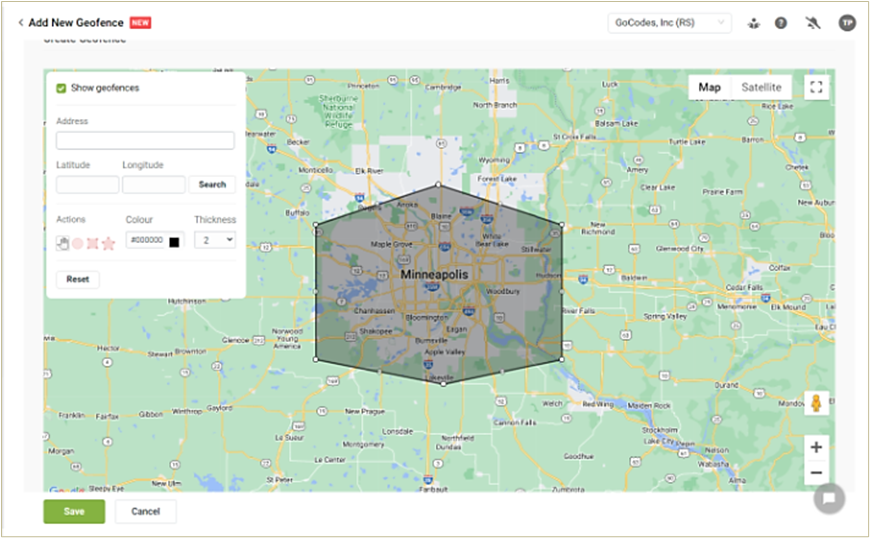

To illustrate, let’s take one of the telematics-enabled fleet management software features, geofencing, as an example.

These invisible, virtual fences are used for enhanced fleet safety and security.

For geofencing to work, you first need telematics, i.e., real-time GPS trackers.

As illustrated, such trackers will monitor the real-time location and status (speed, engine hours. harsh braking, etc.) of your fleet vehicles and equipment.

However, without fleet management software that will overlay the incoming location data on a digital geographic map, geofencing wouldn’t work.

More specifically, it is the software that correlates all the data on the map and allows you to set up geofences around specific areas or routes, ensuring you’ll be alerted if a vehicle exits the geofenced area or departs from its set route.

This distinction between telematics devices and software holds true for all other data collected by GPS trackers and its or vehicles’ sensors.

As said, these devices gather real-time information on vehicle location, speed, fuel consumption, engine diagnostics, and more.

On the other hand, fleet management software takes that data and integrates it with data from various other sources to provide actionable insights and optimize fleet operations.

A typical example is route optimization, where software can analyze historical driving routes of vehicles and correlate them with current traffic and weather data to suggest the best route at this moment.

To recap, telematics relates to all the devices that make fleet management more efficient, while fleet management solutions could, albeit less effectively, operate without telematics devices, as shown in our QR-code tracking example.

How Telematics and Fleet Management Work Together

So, it should be clear by now that telematics perfectly complements fleet management, allowing managers to gain a comprehensive view of their fleet operations in real time.

Moreover, a range of various telematics devices enables construction companies to pick and choose, i.e., set up a telematics-based fleet management system that fits their specific needs and budget.

For example, GPS trackers with internal speed sensors can inform the fleet management system whether some drivers are prone to speeding or harsh braking, allowing managers to train or incentivize them to change their behavior for increased safety and fuel economy.

Therefore, one level of telematics and fleet management software collaboration focuses on improving future driver actions by collecting historical driving data.

Another level is when driver behavior is immediately corrected by providing real-time alerts directly to the driver.

Similarly, telematics data provides insights into engine performance, fuel usage, idling time, and maintenance needs, while fleet management software analyzes this data to optimize routes, plan maintenance, and promote fuel-efficient driving habits.

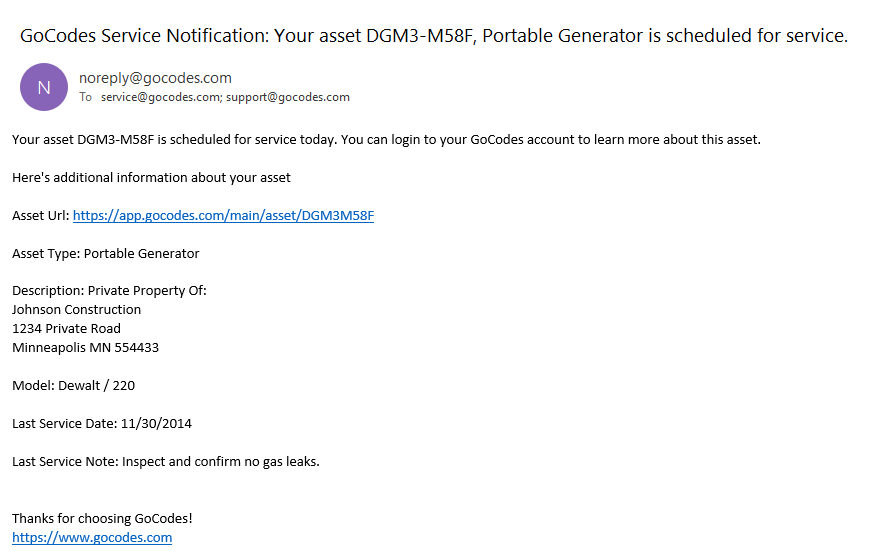

Moreover, fleet managers can receive alerts and notifications about potential issues detected by telematics devices (oil level and pressure, engine temperature, etc.), allowing them to schedule maintenance before problems escalate.

At the same time, they can leverage software to set maintenance work orders in advance and ensure that service technicians will be alerted when maintenance is due.

When we add all possible machine sensors, AI-driven systems, and dashcams to this already powerful mixture of telematics and software, it becomes clear that such advanced solutions can revolutionize all aspects of fleet management.

In summary, the synergy between telematics and fleet management software empowers fleet managers with actionable insights, enabling them to optimize fleet operations, improve efficiency, and reduce costs.

Conclusion

So, what can we conclude from all that was said about differences and similarities, i.e. complementary nature of telematics and fleet management?

Two things.

First, it should be clear that the analytical power of fleet management software combined with the data collected by telematics devices brings unprecedented opportunities for construction companies to manage their fleets more efficiently and cost-effectively.

Second, as these technologies continue to evolve, embracing a telematics-driven fleet management system will be crucial for companies aiming to stay competitive, i.e., optimize productivity while retaining profitability.