Office equipment can range in price and size, making it more difficult to keep up with every single piece.

However, you can significantly benefit from an efficient tracking system as it helps you understand where your equipment is and provides different types of data, including maintenance stats.

This article will explain what you can gain from equipment tracking and why you should start doing it right away.

In this article...

Greater Inventory Control

When you invest in tracking your office equipment, you have more control over your office inventory.

Tracking equipment starts with understanding what pieces of equipment you own.

Before going down the monitoring road, you should make a note of key details concerning each asset you own, any warranties if applicable, scheduled maintenance dates, and current state, which will help you know which assets you have at your disposal.

This factor is helpful for smaller pieces of office equipment that can easily get lost around the office or storage rooms.

Even though they might be cheap to purchase, losing them repeatedly can rack up monetary losses for the team and cause inconvenience if you can’t locate them.

When you write down all the assets you own and have a clear overview of your inventory, you can store the equipment by grouping it in a way that suits your needs.

That way, your team will know the number of available assets and their location in the storage room, which lets them have more control over the equipment.

Understanding what exactly you have to work with also helps you determine the overall value of the office equipment you own.

Tracking your office assets will allow you to control them better.

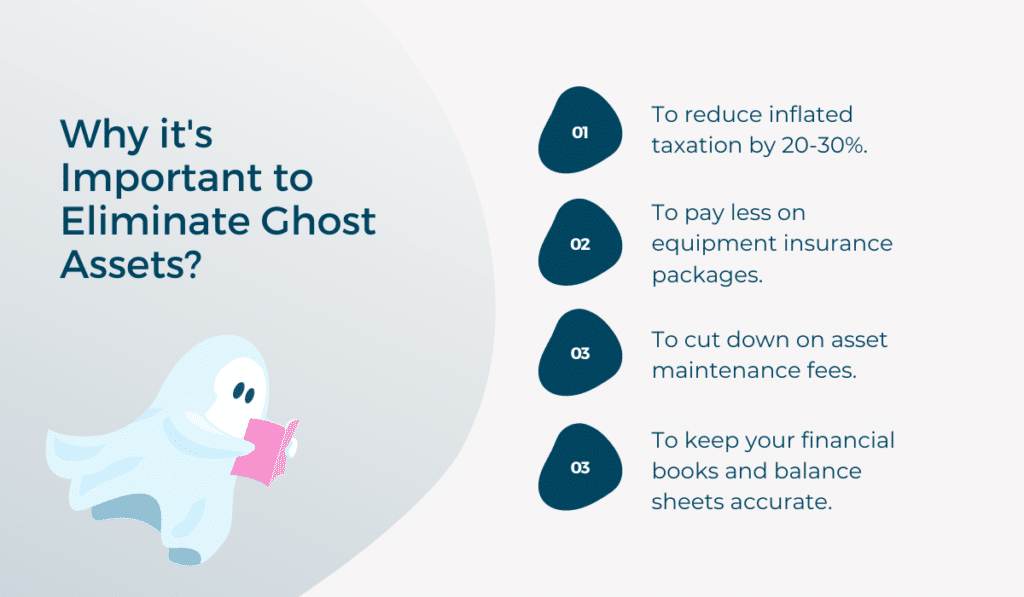

Ghost Asset Elimination

Tracking your assets helps you find any ghost assets you might have in your books.

Ghost assets are pieces of equipment that are present in your books but that you don’t physically have due to theft, loss, malfunction, or misplacement.

You’ve entered the assets into your books upon purchase. However, they were lost or damaged along the way, and no one noted it in your records.

They cause much bigger issues than simply confusion when an employee tries to find them but eventually fails.

Sadly, decision-makers often don’t understand how ghost assets affect their company.

When you’re unaware that certain assets are damaged beyond repair or misplaced, you count and rely on them for future use while they burden you with costs and decrease productivity.

The costs of ghost assets include paying taxes and insurance for equipment you don’t have, and investing in maintenance that cannot even happen.

Such charges are entirely avoidable and unnecessary, which is why equipment tracking can be beneficial for your company.

You will lose time and energy trying to find the items that are not there just because you see them in your books.

If this happens every time an employee looks for a ghost asset, it will slow them down, cause frustration, and make your inventory lists seem unreliable.

Office equipment tracking helps you eliminate ghost assets and the expenses related to them.

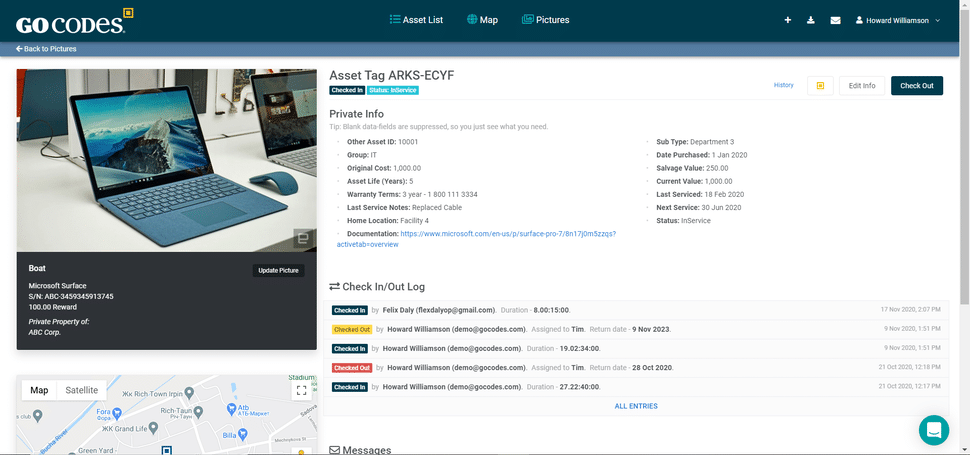

Knowing Where Your Office Equipment Is

Office asset tracking helps you know where your equipment is at all times.

When you track your equipment, you can quickly tell where the asset is and who is using it.

You can use pen and paper, spreadsheets, or software to keep track of your office equipment, but no matter the model you choose, you will be able to tell who is using the equipment or where it is.

The most important thing is setting up a system that lets the staff check the equipment out, allowing you to know where the assets are and if they are available.

Equipment tracking lets you know when the asset will be ready for future use.

If you opt for software, this information can be available to anyone who logs into the system and searches for the item, along with the last known GPS location and date of return.

Your employees will be able to plan future activities around available assets.

Use a tracking system that lets you understand where your equipment is, who is using it, and when they will return it, allowing everyone to plan around those dates.

Better Maintenance Management

Equipment tracking can help you manage your maintenance better, making it more efficient.

Tracking your assets also helps you be more cost-effective.

When you own assets that are either costly or very valuable to your team and business, you need to invest in scheduled maintenance.

If you wait for them to break down to fix them, you risk downtime and work disruptions, which can cost you more than scheduled upkeep does.

That’s why it’s a good idea to use a system that will let you track equipment and its maintenance logs, allowing you to never miss an upkeep date or maintenance-related information.

The maintenance data you get from asset tracking can help you discover any underlying issues.

When you notice that a piece of equipment often needs maintenance, you should look into the possible causes and weigh your options.

Either the quality is subpar, the maintenance team isn’t as effective as it should be, or the end-users do not know how to properly use the asset, which causes it to break down and need repair.

You can fix all three of these issues with better purchasing decisions or improved training for the staff to ensure they know how to perform maintenance tasks and use the assets correctly.

You can manage your maintenance better and save up if you track your assets.

Preventing Loss and Theft

Understanding where your equipment is and who is using it prevents loss and theft.

When you know who is using your equipment, you’re assigning accountability.

The person will understand that they are associated with the item on your check-out lists, whether on paper, spreadsheets, or software.

This will keep them aware they have to return the asset at the end of the day, week, or some other period.

It makes them responsible for any damage that happens to the equipment while it’s under their control. As a result, they will be more careful with it.

Suppose your system doesn’t allow you to connect a user with the asset.

In that case, all employees share the responsibility, which often results in thefts or misplacements since some individuals have a higher sense of accountability than others.

As a matter of fact, up to 95% of businesses experience employee theft, which is why you should invest in its prevention.

Software like GoCodes Asset Tracking allows you to scan the QR code on the item to see its last known location and usage data, ensuring that you know where someone last scanned your equipment and who is currently using it.

Knowing your equipment’s location helps protect it from theft and misplacement.

Better Regulatory Compliance

Using tools to track your office equipment facilitates adhering to regulations.

Tracking your equipment helps you comply with laws and regulations regarding maintenance and equipment testing.

You have to ensure you comply with rules and regulations set by the state, industry, or company management. Otherwise, you risk facing fines, penalties, or business closure.

Equipment tracking tools contain a lot of data you can use to ensure and prove compliance.

In certain cases, laws require that businesses test their equipment, perform maintenance to ensure their employees’ safety and health, or inspect the workplace to remove any threats.

To stay on top of all those tasks for each relevant piece of equipment, use equipment tracking solutions and the data they offer.

Such tools can remind you of the maintenance or inspection dates.

They allow the maintenance team or any employee to upload equipment data or images, giving an insight into the asset’s current state.

When damage occurs, anyone can update the information related to the asset, informing others of the need for repair, thus eliminating compliance risks.

Tracking tools can give you data needed to prove compliance and remind you of compliance-related obligations.

Easier Equipment Life Cycle Management

Tracking your equipment makes it easier for you to understand its life cycle.

When monitoring your assets closely, you create a database of information over time.

You should note each change, report damage, and make each maintenance progress and result readily available for everyone involved.

Every newly purchased item should be added to your inventory database, along with insurance, tax, and depreciation data.

You can then easily access all the equipment-related information, such as the purchase date, life expectancy, maintenance stats, and depreciation, which help you figure out which stage of its life cycle the item is in.

Understanding the stage of the lifecycle of your equipment lets you know whether to keep investing in an item or planning a new purchase.

When assets are close to the end of their life cycle, they might slow down or need more maintenance.

Still, if they slow down too much or need frequent, expensive upkeep, the data can help you understand whether it pays off more to invest in a new asset to avoid wasting resources on an item you won’t use for that much longer.

The data that you gather through asset tracking helps you understand where the equipment is in its life cycle and decide whether it’s time to replace it.

Knowing When to Repurchase Equipment

Good asset tracking provides extensive data on the quality of your equipment.

If you monitor your equipment from the purchase to the disposal stage, you will have detailed information on every aspect of its lifecycle.

This data includes the overall expenses, usage stats, maintenance frequency, and breakdowns, among others.

It also tells you how wise your investment was and whether it’s time to replace your item.

Frequent maintenance and breakdowns might point to an issue with the quality of the item. If you notice a pattern, you can determine which manufacturers to avoid and which to use again.

The gathered data also helps you realize if the time has come to replace existing equipment with new items.

Sometimes, even if the asset is not at the end of its life cycle, it might cause problems by breaking down frequently and incurring unexpected expenses.

Additionally, if you use software to track your assets, it can notify you when you run out of particular items.

You can order new equipment before you run out, thus reducing work interruptions.

Use the information in your asset tracking system to determine whether you need to replace your equipment.

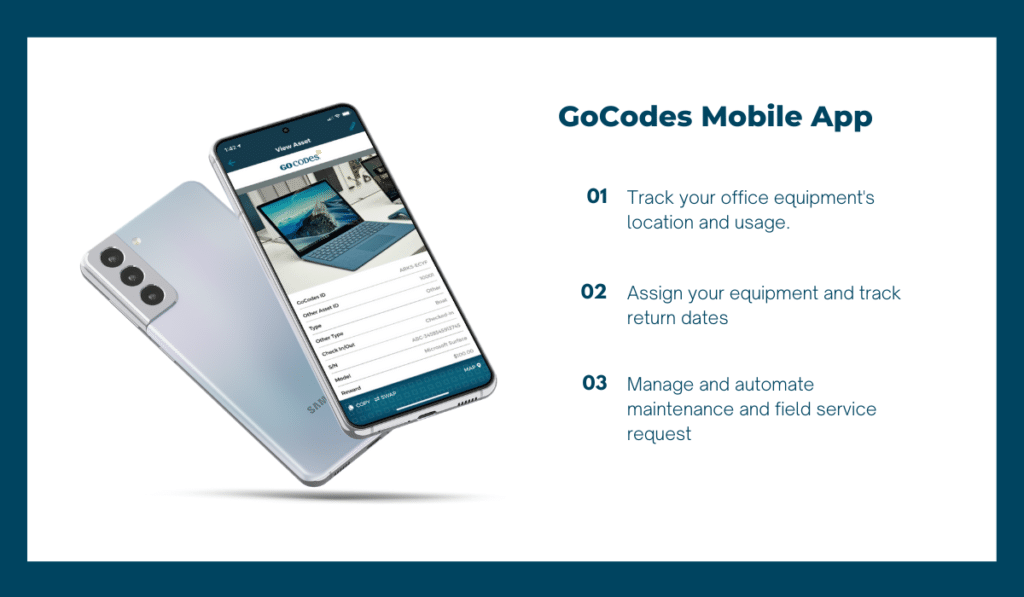

How Can You Track Office Equipment?

As mentioned before, you can track equipment using a simple pen and paper, spreadsheets, or different specialized software.

No matter which option you choose, it’s essential to be consistent and update your files whenever a change happens to rely on the data you have.

When choosing the right option for your team, think of whether you want everyone to have access to files and be able to update them.

Doing so would reduce the workload of the person in charge of equipment.

Also, consider the accessibility of the database—do you want your team to have access only from the office laptops, or do you want them to use the database when out in the field or working from home?

Software like GoCodes Asset Tracking can be used on smartphones.

This allows your team to use it on the go if they want to update an asset’s page or check equipment data.

Another thing to keep in mind is the reliability of the tool you decide to use.

Pen and paper are old-fashioned, easily lost or misplaced, and only one person at a time can use them. Spreadsheets have similar limitations, including the fact that they are single-user-oriented.

No matter which tracking option you choose, you have to ensure that your entire team can use it consistently and that it’s as easy and efficient as possible.

Conclusion

Managing your office equipment properly can help you in many ways, starting from giving you a complete overview and control of your inventory.

When you use an automated system, you can be confident that the data uploaded is correct and regularly updated.

Such data helps you eliminate ghost assets, know your equipment’s location and lifecycle stage, and decide whether to invest in a new item.

On top of that, monitoring your office equipment can help you determine whether you’re complying with laws and regulations.

Implementing tracking solutions is a cost-effective way to keep up with all your equipment and related data.