For general contractors, subcontractors are an essential component of their success, both in terms of providing the expertise they might need, or additional workforce they might lack.

Consequently, having collaborative and productive relationships with subcontractors should be high on any general contractor’s priority list.

To achieve this, general contractors first need to ensure that subcontractors are capable of doing their job, and then they can proceed to build, maintain, and improve their relationship with them.

So, let’s see how they can do that.

In this article...

Prequalify Your Subcontractors

As hinted above, improving a relationship with a subcontractor might be difficult if you fail to make sure the subcontractor is the right fit for the job before hiring them.

In other words, you should prequalify your subcontractors to confirm they have the right skills, technical know-how, experience, and resources for the job.

Of course, you will also need to ensure that their quality, cooperation, and attitude are up to your standards, as well as that their price fits your (or your client’s) budget.

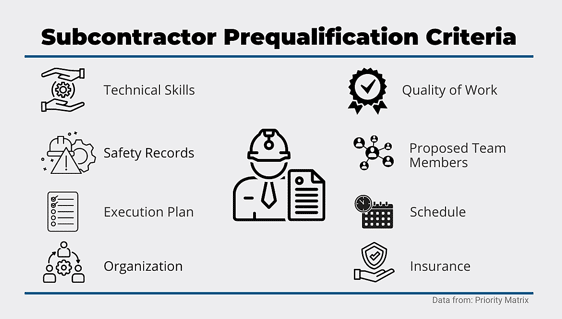

So, it’s clear that the process of hiring qualified subcontractors can include many different criteria, depending on the project at hand and the general contractor’s requirements.

For the sake of simplicity, however, here are the top eight prequalification criteria cited by construction project managers who were interviewed by Priority Matrix.

For instance, checking technical skills and the quality of work would involve verifying their qualifications, working license (when required), work history, and references.

It’s also a good idea to see how many team members they have and what their organization looks like, so you can assess them against the size of the project you’re working on.

An execution plan and schedule are also important, as they can tell you how well organized they are and whether they are free for the time period you need them.

As for their insurance and safety standards, you can ask them to provide/describe their insurance and safety policies, as well as a safety training program.

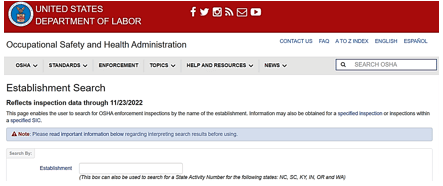

You can also check whether they got cited by the Occupational Safety and Hazard Administration (OSHA), which can be done by searching OSHA’s inspection list.

However, as noted on their website, you should be aware that OSHA citations can be corrected or modified and that different construction businesses may have similar names.

Nevertheless, it might be helpful when checking the subcontractor’s safety practices.

Most of the data necessary for prequalifying your subcontractors can be collected by sending potential subcontractors a prequalification questionnaire to fill out before meeting them face-to-face.

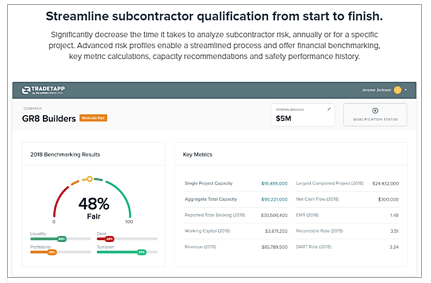

Of course, many background, credential, and reference checks can be done online, whether by googling, paying for specialized qualification services, or using online platforms like TradeTapp.

This app acts as a database where you can find relevant information about subcontractors and their performance metrics, which streamlines the entire prequalification process.

In summary, the first step in improving relationships with subcontractors involves screening them to make sure they meet your requirements for the job.

It’s a crucial step because the selected subcontractors will act on behalf of the general contractor, and everything they do reflects on them and their relationship with the client.

Have a Subcontractor Agreement in Place

After you have prequalified your subcontractors, it’s time to start the relationship by defining the roles and responsibilities of both parties in a subcontractor agreement.

A subcontractor agreement is the necessary first step for general contractors to build a positive relationship with their subcontractors—one based on transparency and trust.

Such an agreement should have clearly defined terms and conditions and it should set clear expectations, responsibilities, specifications, and timelines.

Remember, the subcontractor has no contract with the project owner, so having a subcontractor agreement is essential for ensuring they will do their portion of the work according to project requirements and your standards.

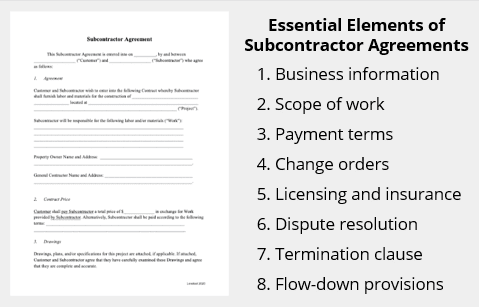

Although subcontractor agreements can get quite complex, there are essential elements each one should have.

For example, as each construction project almost always goes through some changes compared to the initial plan, the subcontractor agreement should define how change orders will be communicated and handled by the sub and how they can request a change order when needed.

That way, you’re avoiding confusion and preventing potentially costly mistakes, such as the subcontractor doing work that’s no longer required (but listed in their original scope of work) and then having to rework what they’ve done to comply with the new requirements.

The agreement should also define licensing and insurance requirements, i.e., make sure that the subcontractor has all the documents (license, insurance, bonds, etc.) needed for their work to be compliant with different standards and regulations.

Finally, as many provisions of your primary contract with the client can apply to your subs, they should be specified in flow-down clauses, and the subcontractors should receive a copy of the prime contract.

Overall, having a clear subcontractor agreement in place is the best way to define the roles and responsibilities of both parties and start your relationship based on transparency and trust.

Make Open Communication a Priority

Of course, no solid relationship with contractors can be established nor improved without open communication.

Hence, keeping subcontractors informed and updated and the lines of communication open at all times will not only prevent potential project delays and cost overruns caused by lack of communication, but will also allow subcontractors to share their expertise and experience to your benefit.

For instance, keeping a subcontractor in the loop about issues surrounding their specific project task or other problems you’ve encountered on the project can prompt them to offer solutions you might not have considered otherwise.

However, they can’t do that if they’re not informed about it.

Today, a great way to streamline communication is to use construction management software that enables all project stakeholders, including subcontractors, to communicate relevant changes or issues in one central place.

For example, PlanRadar ensures that everyone involved in the project can access the most current plans and documents, thus making sure the subcontractors don’t miss a change or new task.

This and other similar apps allow your subcontractors to be instantly updated about any changes relevant to their work and enable them to communicate, share photos and videos, and create daily reports.

Naturally, this makes subcontractors an integral part of your team, allowing you to avoid scheduling collisions, monitor their performance, and quickly make adjustments when needed.

Of course, there are many other ingredients required for truly open communication, such as being honest and transparent from the start of your relationship with a subcontractor.

To sum up, maintaining open and frequent communication with subcontractors is critical for maintaining positive relationships and getting valuable insights from them, which is nowadays best achieved by utilizing mobile software solutions.

Evaluate How Well You Coordinate Your Subcontractors

Poor coordination of subcontractors by their general contractor is a widespread issue that can lead to mistakes that can derail the project budget and schedule.

This issue is so common that in a 2020 study, 54% of general contractors pointed out the lack of subcontractor coordination as one of the leading causes of project delays.

Poor jobsite coordination affects subcontractors, their schedules, and your current and future relationship with them.

For this reason, general contractors should take an honest look at how well they coordinate their subcontractors and make any necessary improvements.

As said, whatever improvements might be required, construction management software that includes all your subcontractors can ensure that potential time and space conflicts between subcontractors are handled before any actual problems arise.

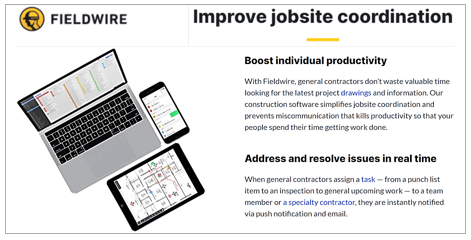

Naturally, the market offers a plethora of options, so it’s important to do your research and find a solution that can best improve jobsite coordination, such as Fieldwire.

In other words, when subcontractors are an integral part of your team communication, they can be informed about changes on-site or in their schedule, and they can report on issues that could cause delays, allowing you to streamline their coordination.

Of course, there are other tech solutions that can improve jobsite coordination, such as giving your subcontractors direct access to the tool tracking software you’re using.

For instance, contractors can use GoCodes Asset Tracking to track the location and usage of their tools and equipment at all times, thus preventing misplacement, theft, and poor maintenance.

When subcontractors are given access to this mobile app, they too can quickly locate the tools they need, see whether they’re available and who is using them.

In addition to facilitating coordination between on-site workers regarding the availability of tools and equipment, GoCodes Asset Tracking QR code tags will also prevent mix-ups concerning the ownership of similar or identical tools brought on-site by different subcontractors.

So, after evaluating how well you coordinate your subcontractors, consider which solutions could be used to address the identified weaknesses, such as centralized project management software or specialized tech solutions.

In that way, you will prevent delays and unplanned costs stemming from poor coordination, while also improving relationships with your subcontractors.

Give Your Subcontractors Positive Feedback

Just like with your employees, giving your subcontractors positive feedback can go a long way in improving your relationships with them.

In other words, if a subcontractor did their job within the time and cost agreed, and you’re satisfied with their quality of work and overall performance, make sure to tell them.

Firstly, such feedback will make it more likely they want to work with you again and sometimes even adjust their pricing to a more friendly rate.

And secondly, stressing what was great about their work also allows you to address any shortcomings you might’ve noticed, thus giving them a chance to further improve their performance on the next job.

Although some general contractors might find giving positive feedback difficult or unnecessary (“They’re just doing their job”), they should consider its many benefits, as discussed in the Forbes article referenced below.

In other words, subcontractors are tradespeople who, like anybody else, take pride in their work and want to do a good job.

So, when you confirm they did so (and pay them on time), it makes them feel valued and respected, which in turn builds their trust and loyalty.

Consequently, general contractors who want to build lasting and strong relationships with subcontractors should acknowledge their contributions and let them know their work is appreciated.

In summary, giving your subcontractors positive feedback is a great way to improve your relationship with them, especially when coupled with clear expectations defined in their contract, as well as open communication and coordination throughout the project.

Conclusion

So, what can general contractors take away from this article?

First, they should be aware of how critical it is for their business to build and maintain collaborative and productive relationships with their subcontractors.

Second, they can establish the foundations for a positive relationship by prequalifying their subcontractors and having a clear subcontractor agreement in place.

Finally, they can improve ongoing relationships with subcontractors by prioritizing open communication and close coordination and giving positive feedback.

Combined, these strategies can help you find and cooperate with the best subcontractors who also feel the same way about you, thus creating a win-win situation.