Key Takeaways:

- Geofencing helps prevent theft on the construction site and the costs associated with it.

- Creating virtual boundaries makes it possible for construction companies to prevent time theft.

- Inventory levels can be tracked with the help of geofencing technology, preventing costs that come with overstocking.

The cost-cutting potential of technology is one of the main reasons why businesses decide to invest in the best possible software solutions.

Over the past years, geofencing has emerged as the construction industry’s game changer in many departments, including cost management.

So, if you’re curious to learn more about using geofencing to stay on top of construction costs, you’ve come to the right place.

Let’s dive right in.

In this article...

Prevents Loss of Equipment

Loss of equipment and machinery hurts construction businesses worldwide, and the thieves are showing no signs of stopping anytime soon.

Although many companies turn to installing state-of-the-art surveillance systems or hiring a whole army of security personnel, different reports indicate staggering costs of theft.

Research done by UK-based construction tool supplier, Herts Tools, revealed different factors that led to £17.5 million in stolen tools in just one year.

You’re probably thinking that tools are pretty easy to steal, and that it’s different with machinery.

Well, Bauwatch’s findings will make you think again.

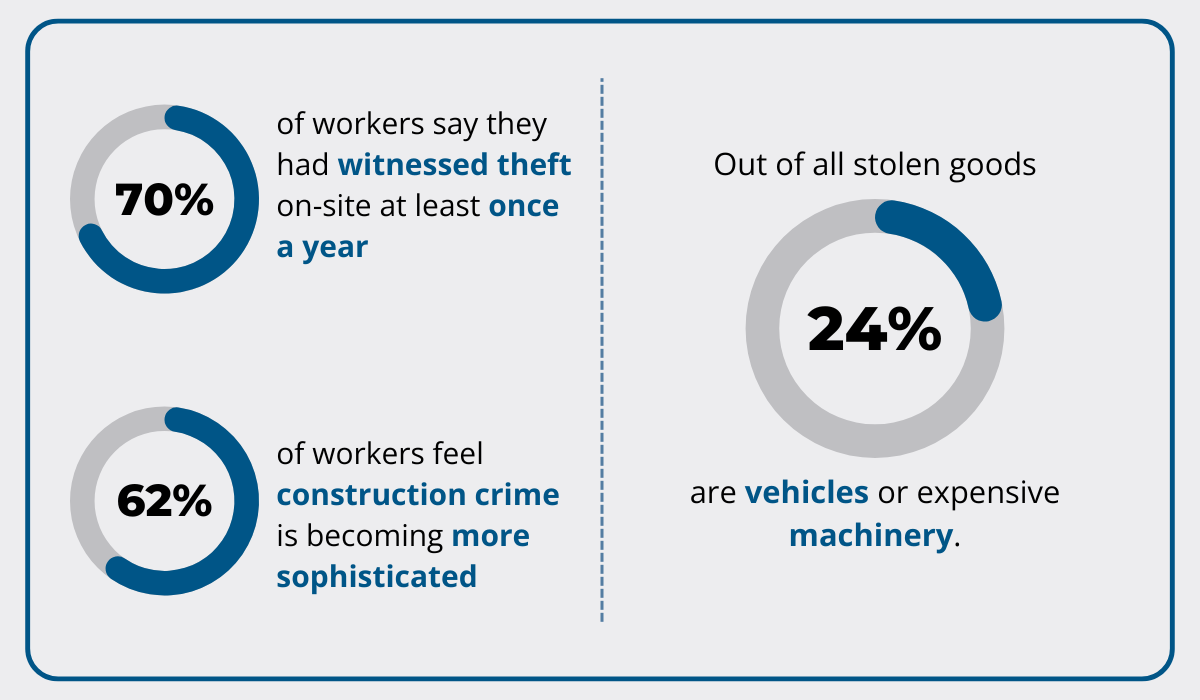

The construction industry loses £800 million to theft each year, and according to Bauwatch’s security specialists, valuable equipment and machinery account for nearly one-quarter of all stolen goods.

These numbers are not surprising, given that six in ten people (62%) feel that thieves rely on increasingly elaborate methods.

So, how can you protect yourself from losing both time and money to construction theft?

Geofencing is a pretty dependable solution.

Virtual boundaries act as a mighty deterrent against theft, and their real-time alerts enable a timely reaction in cases of emergency.

To put it simply, being able to draw invisible fences all around the job site and track your key assets makes life difficult for any would-be thief.

Thanks to geofencing software, there’s no way for anyone to move vehicles and equipment outside of the established perimeter without you knowing.

Whether it’s a case of unauthorized access or a security breach, managers are immediately alerted to sudden movement and can asses the situation before taking necessary action.

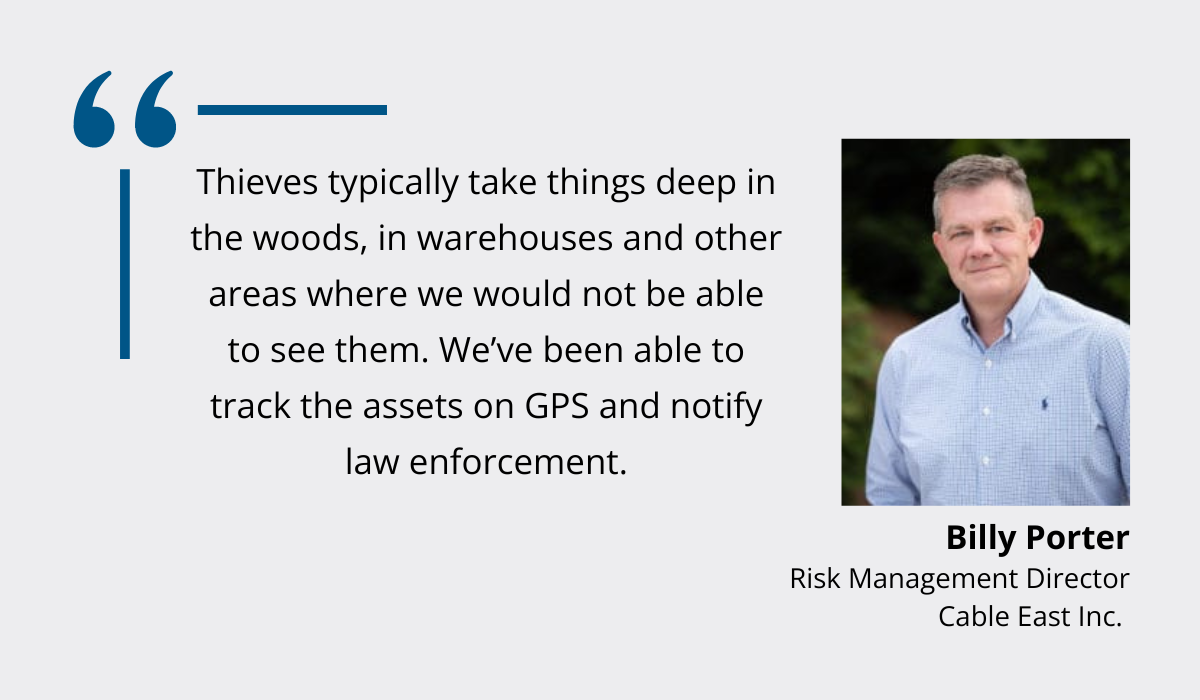

The reason why companies increasingly rely on asset tracking and geofencing solutions is experiences such as the one shared by Cable East Inc.’s Risk Management Director, Billy Porter.

This telecommunications construction company from Georgia nearly suffered a loss of $2.5 million worth of equipment and machinery.

Luckily, as Cable East Inc. had previous experiences with theft, they decided to implement a fleet management solution and avoid the devastating ripple effect of theft.

So, if you’re also looking to sleep soundly even with your expensive equipment left unattended overnight, you’d be wise to consider different geofencing solutions.

Such a system works by combining geofencing software and pre-installed trackers, beacons, or QR code labels that let you keep a close eye on all your equipment.

Our asset tracking solution GoCodes Asset Tracking deftly combines several different elements, but the crucial cost-saving feature is the loss alerts, which enable you to handle security breaches quickly and with the best possible outcome.

This is what that looks like in a nutshell:

- You receive an instant alert as soon as your equipment crosses the predefined geofence.

- You’re immediately prompted to notify the law enforcement.

- The missing equipment is tracked in real time and you can easily share location updates.

Keep in mind, though, that real-time geofencing notifications can be leveraged in multiple ways, and not just theft prevention.

One of these ways focuses on enhancing your workforce management, which we will explore next.

Optimizes Workforce Management

Employees are the backbone of every successful business, driving results and making a difference.

Sometimes, however, the results are less than they could be, and the difference is anything but positive.

Whether it’s the lack of clarity about the tasks, stress, low morale, or general attitude, every company has employees who cut corners one way or another.

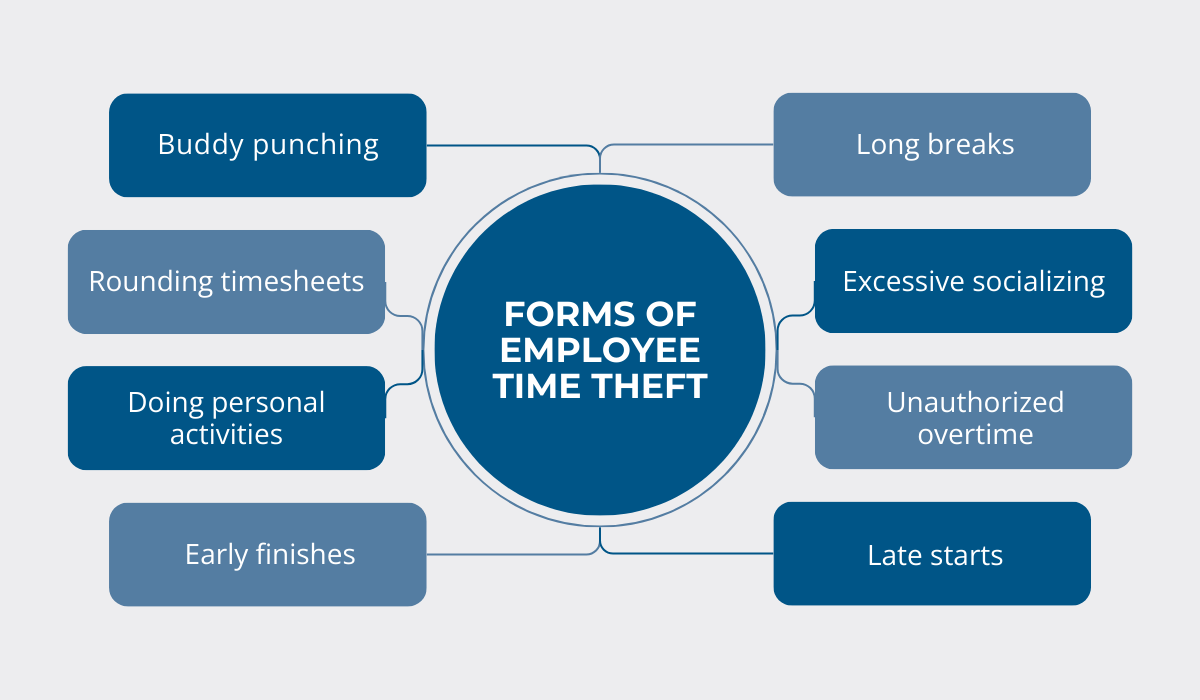

Very often, this happens in the form of conscious or unconscious time theft.

In practice, time theft can be many things, from rounding out the timesheets by adding 15 extra minutes and clocking out early every few days, to doing unauthorized overtime.

The one thing all these practices have in common is that they erode trust and are quite costly for employers in the long run.

Luckily, there are ways to put a stop to time-thieving, and geofencing is one of them.

No matter which geofencing solution you choose, the core idea remains the same: you can define virtual borders around areas of interest and record every notable action there.

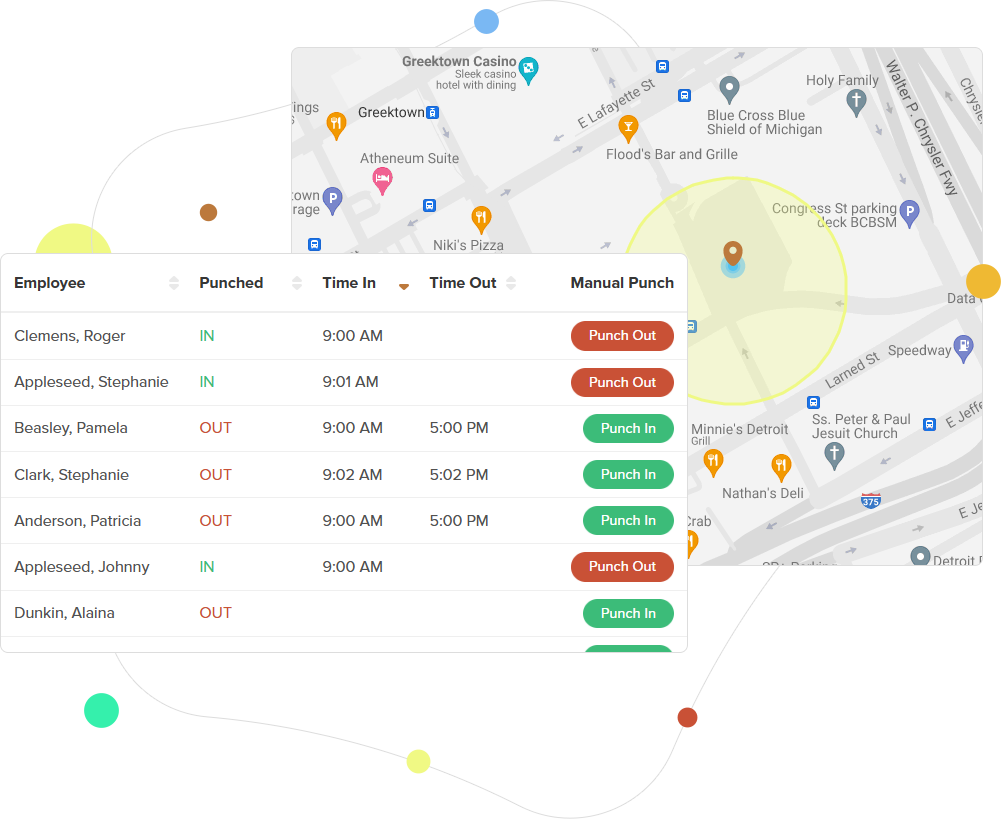

In the context of workforce optimization, this would mean automatically logging workers’ entry and exit times and having a better clue of their overall activities.

You can collect key information presented through a simple layout, like in the example below.

As soon as the worker approaches the designated geofence, they receive a prompt to clock in, which promotes efficiency and eliminates (un)intentionally inaccurate reporting.

Geofenced time-tracking feature often ties in with shift scheduling and automated payroll processing, which optimizes workforce management and reduces costs even more.

And if you’re not sure if time theft is such a big problem, take a look at some numbers related to the 2018 time theft case at California State University.

An investigation found that the two employees took extended breaks and frequently left their posts entirely, concealing time and attendance abuse for several years.

Just two people ended up costing the State over $100,000.

Businesses that implement geofencing eliminate the risk of suffering such losses while promoting a stronger and healthier team culture based on integrity and honesty.

Additionally, geofencing’s ability to restrict access to construction sites outside of work hours makes unauthorized overtime work impossible.

This, again, helps you avoid some unseen labor costs and potential legal conundrums.

Finally, such location-based restrictions also help lessen some of the operational wear and tear, which brings us to our next section.

Reduces Equipment Wear and Tear

All construction equipment, from non-powered tools to heavy machinery, comes with an expiration date.

There are some lifespan differences, but general estimates state that construction equipment can last anywhere between 10 to 15 years, with 10,000 hours being the manufacturers’ usual benchmark for heavy-duty assets.

Of course, longevity is possible only with proper care and maintenance, and that’s where geofencing technology can lend you a helping hand.

For instance, geofencing allows you to designate specific no-entry areas for machinery that shouldn’t be operated on certain types of terrain or under harsh weather conditions.

With alert triggers up, even if workers wander into these zones by accident, they can immediately right their course and avoid unnecessary wear and tear.

In fact, different types of geofencing alert triggers are uniquely suited to combat key factors that impact equipment’s lifespan.

By setting up virtual boundaries, you are collecting a wealth of data that warns you of changes in outside conditions, general equipment health, and driver behavior.

Ultimately, these forewarnings reduce costs by minimizing the need for extensive repairs and reactive maintenance.

And truly, the consequences of equipment breakdown go well beyond immediate repairs, making geofencing an even more valuable cost-control tool that helps you avoid:

- Downtime

- Excessive maintenance

- Lost production

- Equipment repair and replacement costs

- Sacrificing quality

- Safety risks

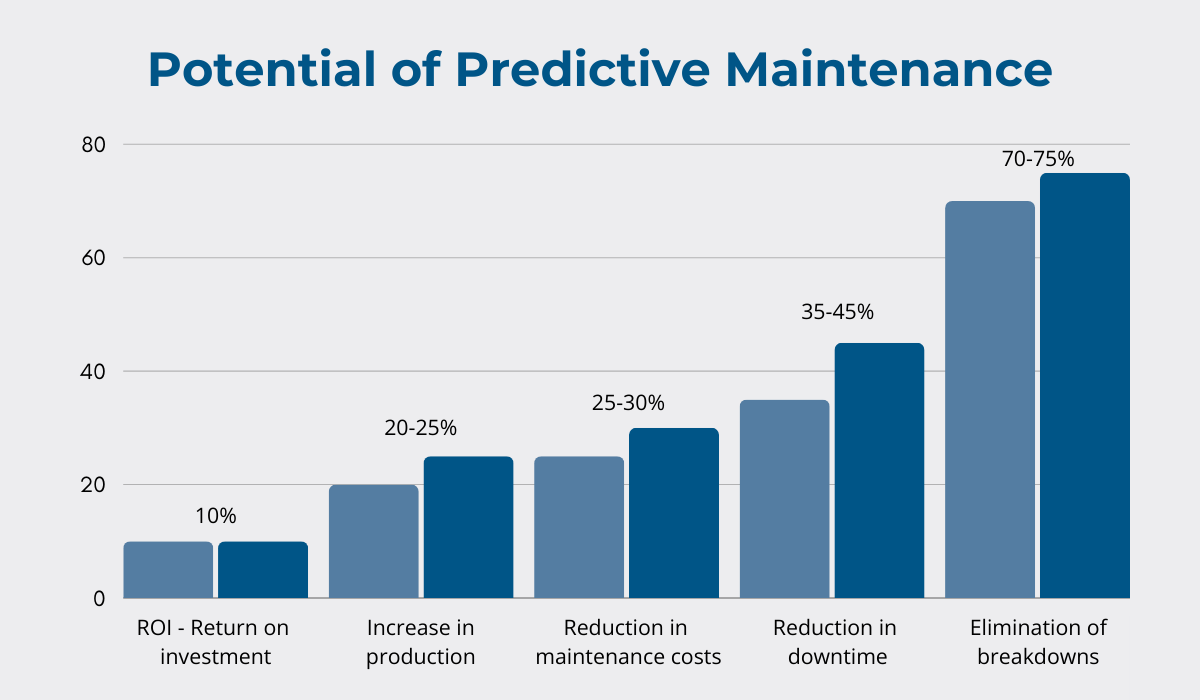

The potential of predictive maintenance, bolstered by geofencing and asset management solutions is made particularly clear in the US Department of Energy’s recent report.

Adopting a predictive approach promises an increase in ROI and production, while significantly reducing maintenance costs, downtime periods, and chances of total machinery breakdowns.

The most forward-looking strategy leverages geofencing technology to monitor the detrimental changes in equipment and schedule maintenance when needed, preventing bigger problems in the future.

User-friendly asset tracking solutions like our GoCodes Asset Tracking ensure that timely maintenance is easy to schedule through automatic alerts, while keeping a few more equipment management tricks up their sleeve.

For example, companies using GoCodes Asset Tracking have several options for calculating equipment depreciation and getting a sense of their equipment’s current market value.

Ultimately, geofencing features function as a part of a wider cost-efficient system that ensures you’re doing everything to extend your equipment’s lifespan and eliminate unnecessary costs.

Improves Inventory Management

Keeping all the equipment accounted for and in peak condition makes a world of difference in construction, but a well-organized inventory is no less important.

Inventory management means keeping track of optimal levels of goods and materials—the lifeblood of construction sites—and having a firm grasp of future demands.

Having extra geofencing visibility and real-time data on the inventory and entire supply chain paves the way for better decision-making, giving businesses more incentive to invest in this technology.

What it means in practice is strategically placing your geofences to give you all the necessary insight into inventory movement.

For optimal inventory management, this would mean placing virtual fences around different storage areas and warehouses.

However, the impact of geofencing doesn’t stop after the initial shipment comes in.

Even more importantly, managers can keep using geofences to monitor the movement and use of materials across the construction site and note when certain goods have been checked out and if they need reordering.

If someone asked you about the most disruptive, yet preventable on-site situations, what comes to mind?

Chances are that material procurement and allocation-related issues are among those.

Incorrect and outdated inventory information creates several obstacles down the road, making both shortages and overstocking much more likely to occur.

Thankfully, geofencing and smart inventory management solutions help address these and similar challenges that can otherwise seriously hinder your operations.

The results of accurate tracking translate to consistently optimal inventory levels, which consequently reduces the costs of storage and handling.

However, geofencing can also enhance workflows and operations.

The positioning software allows you to configure different trigger events, effortlessly automating various tasks.

For example, when a shipment crosses the geofence, this can automatically trigger unloading procedures and notify relevant personnel.

In any case, the value of geofence data is what makes the biggest difference in boosting supply chain efficiency, as pointed out by developer and technical consultant, Myra Sharma.

Sharma explains that the geofencing solution helped said business manage stock replenishment more proactively, but that the resulting data also led to streamlined warehouse processes and reduced costs.

But remember: inventory management is just one dimension of geofencing.

There are plenty more opportunities for you to create success while keeping the costs in check!

Conclusion

Geofencing unlocks plenty of real-time insights that allow construction businesses to track and reduce various expenses.

However, this technology’s impact is most felt when it functions alongside different systems, minimizing asset wear and tear, revamping inventory or payroll procedures, and enhancing overall security.

So, if you want to turn costs into gains, be proactive and take advantage of everything that geofencing has to offer!