Regular construction safety meetings are an essential part of ensuring the overall safety of any construction project.

They provide an opportunity for construction workers to discuss a wide range of topics related to safety, express their concerns, and learn about new safety protocols and procedures.

So, whether you’re a general contractor, project manager, safety manager, construction crew leader, or anybody else planning a construction safety meeting, what are some key topics that you should discuss?

Here are seven of them.

In this article...

Construction Site Safety Hazards

Of course, every construction site is dangerous, so the first overarching topic to be discussed in any type of safety meeting is construction site safety hazards, both those common to all jobsites and those specific to a particular one.

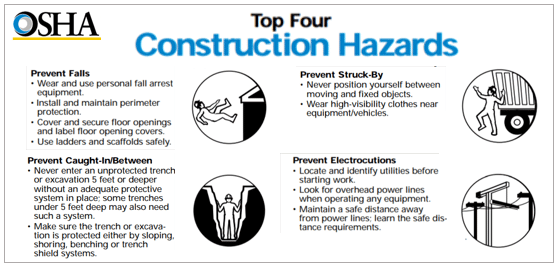

For instance, common safety hazards that are also the leading causes of fatal construction injuries are falls from a height, being struck by moving objects, getting caught in or between objects, and electrocution.

Here’s an overview of the top four construction hazards and steps to mitigate them, published by the Occupational Safety and Health Administration (OSHA):

In addition to these, some other general hazards to be discussed in construction safety meetings should include accidents and injuries caused by:

- not wearing proper PPE

- inadequate handling of heavy objects

- improper tool and equipment use

- ignoring lockout and tagout procedures.

We’ll discuss these hazards as separate topics later.

Besides common construction hazards, each site and project are unique in the sense of having a wide range of specific site hazards workers may be exposed to.

For example, workers may encounter asbestos when doing demolition or renovation or might be working with materials that contain hazardous chemicals.

Therefore, it’s important to identify and assess all physical, chemical, airborne, ergonomic, and biological hazards on a particular construction site and the risks they pose to construction workers and ensure that all workers are aware of them.

This will allow you to mitigate both common and specific construction site safety hazards, and one of the crucial steps in doing so is discussing them in construction safety meetings.

Personal Protective Equipment

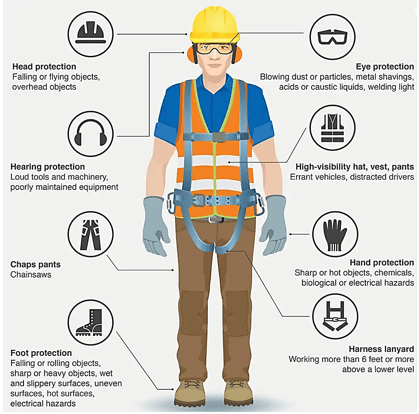

Another key topic to be discussed in construction safety meetings is personal protective equipment (PPE) that workers should use to protect themselves from jobsite safety hazards.

In other words, it’s not only crucial that workers are provided with appropriate and fitting PPE like hard hats, safety glasses and gloves, earplugs, and respirators, but that they’re also trained in how to properly use this equipment.

As a reminder, here’s an overview of some typical PPE used in construction.

Each of these and other PPE types, like respirators or wearable protection tech, should be covered during safety training and discussed in safety meetings, depending on the specific purpose, scope, and duration of a given meeting.

Naturally, some PPE should be covered as separate topics, such as how to correctly use safety harnesses when working at heights to prevent fatal or severe injuries.

Even simpler topics, such as why wearing a hard helmet on-site at all times is essential, can be turned into interesting and practical discussions with workers when supported by real-life examples and relevant statistics.

In summary, PPE is another essential topic that should be frequently discussed in construction safety meetings, ensuring that workers know when, why, and how to properly use different types of PPE to protect themselves from construction site safety hazards.

Handling Heavy Objects

Lifting, carrying, and handling heavy objects are commonly done on construction sites.

However, when not done correctly, these activities can be a source of many jobsite accidents and injuries.

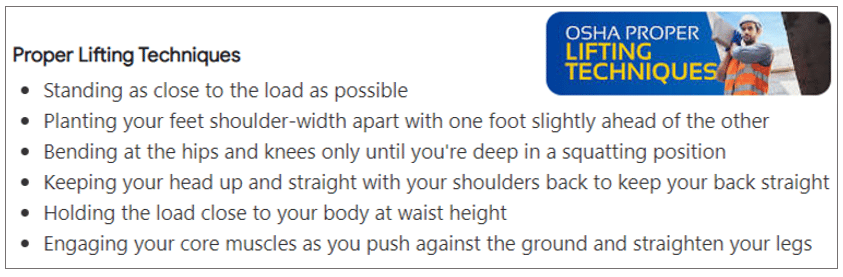

Therefore, safety meetings should be used to discuss how workers can use proper body mechanics and lifting techniques to lift or carry heavy objects, as well as when they should use appropriate lifting equipment.

This topic is important because back injuries are the most common injury in construction, accounting for almost one in five non-fatal jobsite injuries, and resulting in sick leave, compensation claims, and other costs for construction companies.

For instance, a safety meeting could be used to explain, show, or demonstrate OSHA’s proper lifting techniques, listed below, and discuss with workers their past experiences, examples, and practical tips on this topic.

Holding one or more safety meetings on this topic will remind workers of the risks associated with lifting heavy objects and good work practices to prevent injuries.

In this regard, the topic of providing additional PPE to all or at-risk workers, such as back braces, could also be worth discussing.

Of course, it’s also important to ensure that workers have access to and are trained to properly use lifting equipment, such as hoists and cranes, which may be covered in meetings jointly or separately with safe lifting techniques.

In summary, handling heavy objects in a way that will prevent injuries should be discussed in safety meetings, preferably often, in order to keep workers aware of the risks associated with lifting heavy objects and measures to minimize them.

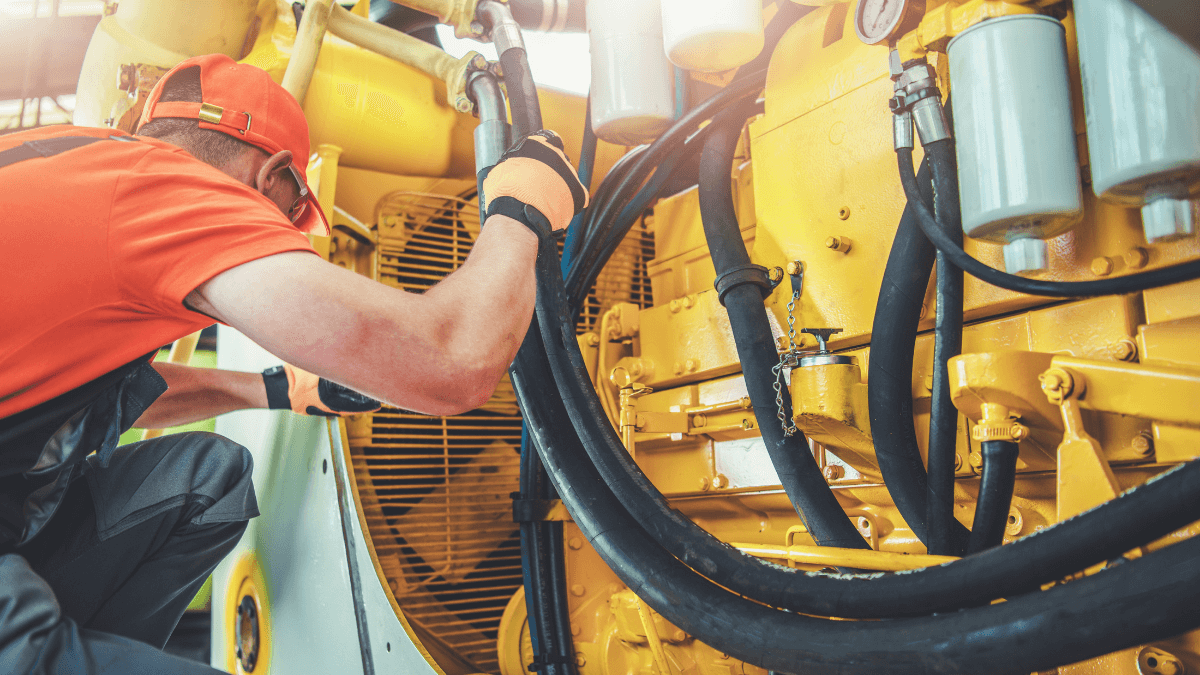

Proper Tool and Equipment Use

Discussing proper tool and equipment use in construction safety meetings will help prevent injuries resulting from mishandling tools and equipment due to workers’ lack of training, experience, or awareness.

Workers should be trained in proper tool and equipment use and regularly reminded about relevant safety protocols like inspecting tools and equipment for damage before use or wearing appropriate PPE.

So, contractors can use safety meetings to refresh workers’ memory on the correct use of tools and equipment they’re already familiar with, as well as to train them on how to use new technology.

Of course, as there are many types of heavy equipment and tools used for different purposes, this topic can be broken down into subtopics relevant to the tasks performed by the workers.

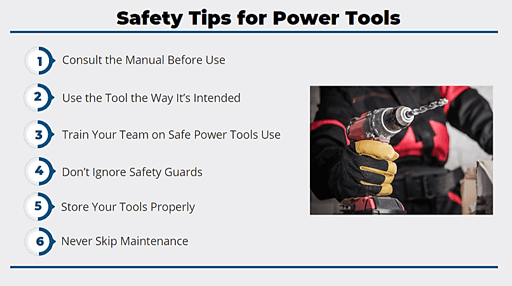

For example, just the safe use of power tools could be the subject of one or more safety meetings.

You can find more safety tips and potential topics for safety meetings in this article.

Although this is just a shortlist, regular maintenance is one of the more critical topics related to proper tool and equipment use.

In other words, discussing how workers can help prevent breakdowns, accidents, and injuries resulting from poorly maintained, damaged, or worn-out tools and equipment is an essential part of construction site safety.

In this regard, the topic of how workers can use tool and equipment tracking apps like GoCodes to track maintenance could also be worth discussing.

In any case, training and keeping workers updated on the proper use of tools and equipment, safety practices, and protocols provide a plethora of topics in construction safety meetings.

Lockout and Tagout Procedures

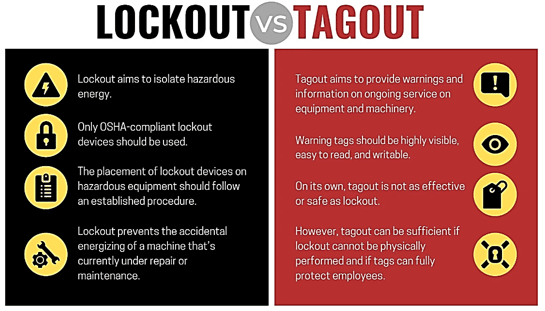

Discussing proper lockout and tagout (LOTO) procedures with workers in safety meetings is another important element in preventing fatal and severe injuries on your construction sites.

In essence, LOTO procedures ensure that, while construction equipment or machinery is being serviced, no one accidentally or unknowingly turns it on, thus endangering the persons servicing it.

According to OSHA, compliance with their lockout/tagout standard could prevent 120 deaths and 50,000 injuries every year.

The main differences between lockout and tagout procedures are shown below, courtesy of TradeSafe:

Put simply, lockout devices and warning tags should be used together unless it’s physically impossible to lock out a machine, i.e., ensure it’s disconnected from its power source.

In addition to serving as a warning not to energize a machine, tags also contain information on who is performing maintenance and other relevant details.

As OSHA noted, compliance with LOTO procedures will help prevent accidents and injuries resulting from the unintended activation of machinery under maintenance or repair, thus making your construction sites safer.

Therefore, it’s important to discuss the topic of lockout/tagout procedures with workers in construction safety meetings to ensure they are familiar with these procedures and understand how to follow them.

Emergency Procedures

Even when all the necessary preventive measures are being taken, accidents, injuries, and other emergencies can still happen.

Therefore, workers should be trained, and regularly reminded of what they should do in such situations, which only highlights the importance of discussing emergency procedures during construction safety meetings.

For instance, workers should know what to do in emergencies involving injuries, i.e., how to provide basic first aid while waiting for the site nurse or paramedics to arrive.

Additionally, workers should be informed of emergency escape routes and procedures in case of fire or other emergencies that require site evacuation.

Likewise, their familiarity with these protocols can be checked through another form of a “safety meeting”—emergency evacuation drills.

Of course, workers should also know what to do and how to report different emergencies like hazardous material incidents, cave-in accidents, or worker injuries.

In fact, all the above emergency procedures should, according to OSHA Standard 1926.35, be elaborated in an emergency action plan (EAP) that any contractor should make available to workers.

Or, to quote the standard:

The emergency action plan shall be in writing and shall cover those designated actions employers and employees must take to ensure employee safety from fire and other emergencies.

However, paragraph (e)3 of this standard prescribes that contractors with less than ten employees can communicate their action plan to workers orally but need not keep a written version.

Given all of the above, emergency procedures are a topic well worth discussing in construction safety meetings.

Topics That Workers Want to Discuss

Finally, construction workers participating in safety meetings should be encouraged to bring up topics they want to discuss.

After all, they are the ones who put their health and safety on the line, so they deserve to have their concerns addressed and their suggestions considered.

Moreover, an open dialogue with workers can help uncover previously undetected construction safety issues that could otherwise endanger someone’s life or health.

Therefore, construction companies should, whenever possible, treat safety meetings as open forums where workers can freely raise safety concerns and suggest potential improvements.

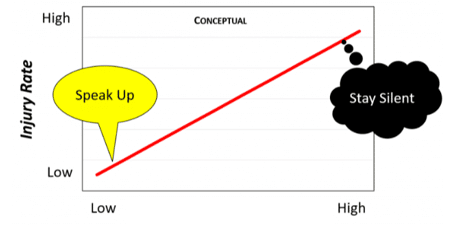

Of course, asking workers if they have any concerns during a safety meeting won’t be enough to get valuable insights if they are afraid to speak up because of the prevailing company culture.

And, as postulated in an article by Continuous Mile, it’s very likely that construction companies with a “stay silent” culture will have higher injury rates than those that encourage a “speak up” culture.

Therefore, to help create a culture of open and honest discussion about safety, construction companies should demonstrate that workers’ safety concerns will be addressed and their suggestions considered.

For instance, if several workers say their PPE does not fit their body frame, they should be provided appropriately sized PPE as soon as possible.

In this way, workers will see that the company cares about their safety and listens to their feedback, which will ultimately help all workers feel comfortable bringing up topics they want to discuss during construction safety meetings.

Conclusion

Having covered the key topics that can be discussed in construction safety meetings, it’s clear that there is no shortage of safety hazards, risks, and procedures that should be addressed to improve the overall safety of your construction sites.

Therefore, regular construction safety meetings are crucial because they provide opportunities for construction workers to discuss a wide range of topics related to safety, express their concerns, and provide suggestions, ultimately creating a strong safety culture.