All businesses rely on numbers and statistics to address their pain points and fuel growth, and there’s a simple reason for it.

Statistics give you clarity and certainty.

In this article, we’ve compiled a list of 8 productivity insights that can serve you as a roadmap to success.

When you understand the industry’s overall performance and challenges, you can benchmark your company against others and identify key opportunities for improvement.

After all: increasing productivity means unlocking your company’s full potential and building a competitive advantage.

So let’s begin!

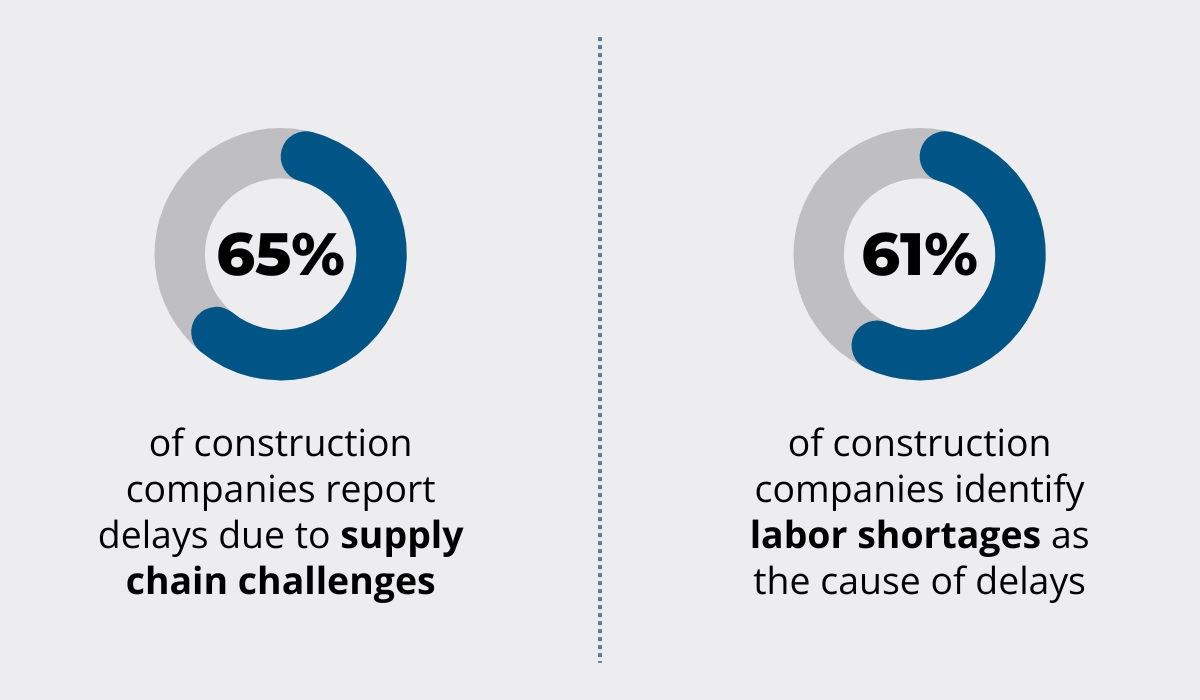

65% of Construction Companies Report Project Delays Due to Supply Chain Challenges

Mounting costs of delays lead to postponed, scaled-back, or even canceled projects, and nearly two-thirds of construction companies cite supply chain challenges.

The 2023 Workforce Survey Analysis, conducted by the leading US construction association, AGC, identified the shaky state of construction supply chains as a major contributing factor to delays, alongside labor shortages.

While it’s true that businesses can’t control materials shortages and skyrocketing prices, which are the legacy of the COVID-19 pandemic, and other looming uncertainties, some things remain manageable.

For one, improving outdated and inefficient supply chain management falls squarely under company control and responsibility.

Underlying productivity and efficiency issues will eat away at your profits until they’re addressed, which is why more and more companies seek automatization and optimization solutions.

Companies are also working on making veteran workers more productive, and many believe that AI and robotics hold the answers.

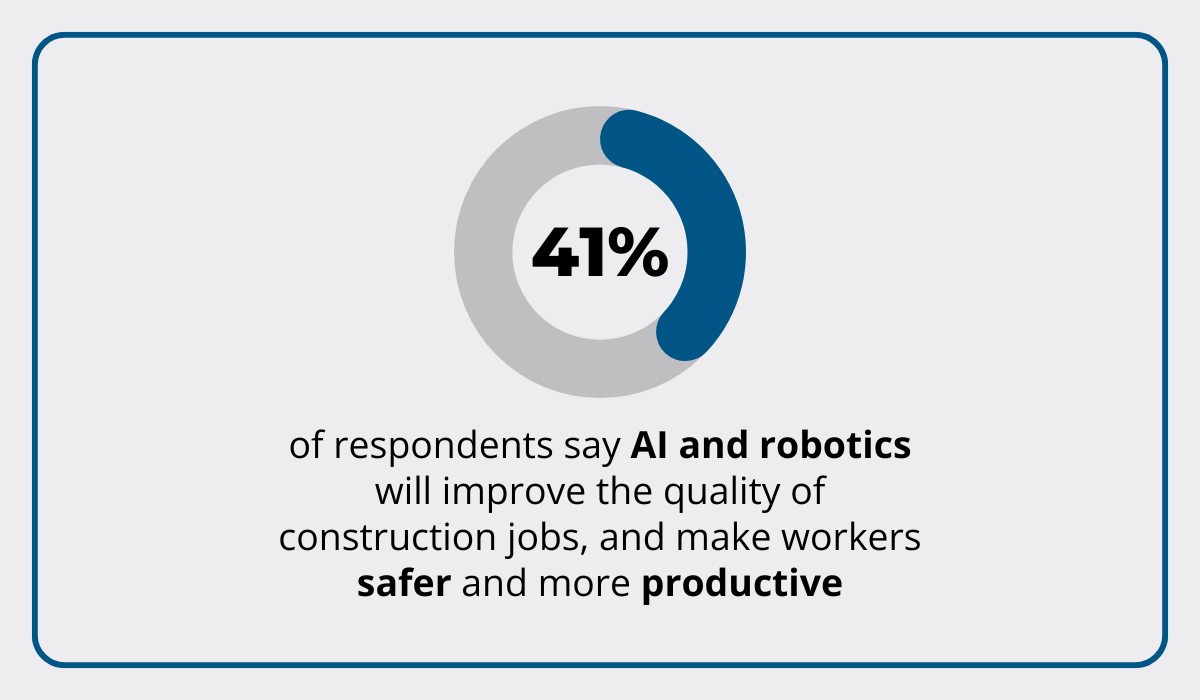

41% of Construction Companies Believe AI and Robotics Will Make Workers More Productive

Although it’s taking time, businesses small and large are firmly on board the digital transformation train due to its overall impact.

According to the AGC survey that we previously mentioned, construction companies see AI technology and different robotics solutions as productivity game-changers.

So, how does this technology create such an impact?

The key lies in the automation of tasks.

Some manual tasks are tedious and repetitive, while others leave room for human error, resulting in lesser job quality or serious injury.

It’s important to keep in mind this link between safety and productivity.

In the words of Eric Whitley, Director of Smart Manufacturing at L2L:

“Professionals thrive in environments where they feel valued and protected.”

Adopting tech that creates a safer environment instills trust, which means a happier, more productive workforce.

Whitley also highlights that this commitment to safety is the only way of sustaining productivity over longer periods.

However, keeping high productivity levels can be quite challenging, especially given how much time is spent on tasks that add little to no value.

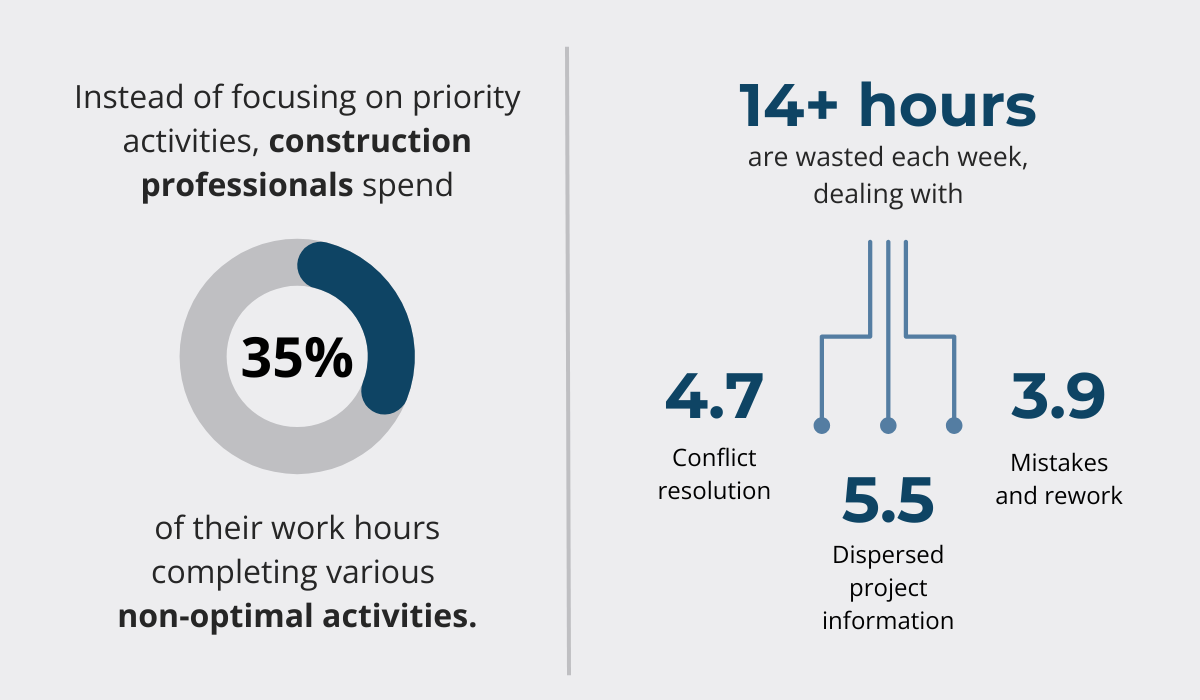

Construction Professionals Spend 35% of Their Work Hours on Non-Productive Activities

Construction professionals everywhere find themselves navigating different admin tasks, doing rework, or searching for a piece of information about the ongoing project.

While that is understandable and necessary to an extent, Autodesk and FMI research reveals alarming figures: 35% of work hours are invested in non-productive activities.

In a nutshell, that translates to one-third of workers’ time and energy invested in no-added-value tasks.

Not doing tangible, core work can create frustrations within the team, and jeopardize entire projects.

After all, neglecting vital operations, such as project execution and coordination, or stakeholder communication, invites delays and increases costs.

The main question is:

What can companies do to prevent this, ensuring optimal labor productivity and successful completion of projects?

Investing in the right technology to drive productivity has been the industry’s go-to strategy, which leads us to our next insight.

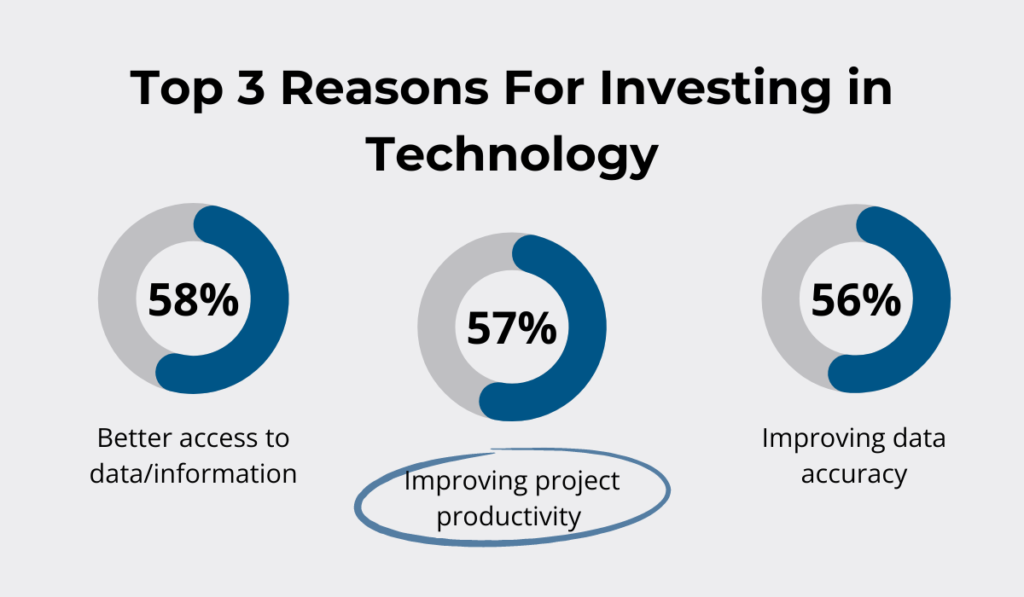

57% of Construction Professionals Are Investing in Technology to Improve Project Productivity

Relying on technology sets the stage for improved productivity and multiple benefits.

Digital solutions have transformed the construction industry landscape, and businesses that don’t want to be left behind are increasingly adopting different digital solutions.

The previously cited survey revealed the top reasons why companies invest in technology, with productivity concerns coming in second.

Whether the goal is better data management and accuracy, or increasing productivity, businesses are turning to technology based on their primary needs and pain points.

For example, our asset management solution, GoCodes Asset Tracking, stops you from losing or misplacing equipment, which is a common problem in construction companies.

The market offers a variety of solutions that increase productivity in different ways, from project management to design collaboration.

No matter which solution you choose and how you leverage it, it’s important to equip yourself to handle major “productivity killers” such as rework and address their root causes.

52% of All Construction Rework Is Caused by Poor Data and Miscommunication

There’s a good reason why data management and accuracy remain among the top reasons for adopting technology.

Having inaccurate data, or no easy means of accessing it, strains communication and contributes to mistakes.

The Autodesk & FMI industry report illustrates the connection between rework, data issues, and inadequate communication, revealing that 52% of global rework is caused precisely by poor data and miscommunications.

As explained by PENTA Building Group’s Cliff Cole, poor data and resulting reworks account for some major productivity losses.

Since fixing construction mistakes drains time, energy, and resources, it isn’t at all surprising that it ultimately decreases productivity.

What’s worse, however, is that these combined factors keep companies trapped in a situation where the costs keep stacking up, but there aren’t many options to move on to new projects.

To avoid getting stuck in this vicious circle, a good number of construction companies make it a point to regularly measure productivity.

29% of Construction Companies Measure Their Productivity Every Quarter

Collecting data to increase productivity and streamline operations doesn’t mean much unless companies make it a point to keep track of their productivity levels.

The hot issue, however, is how regularly you need to do this.

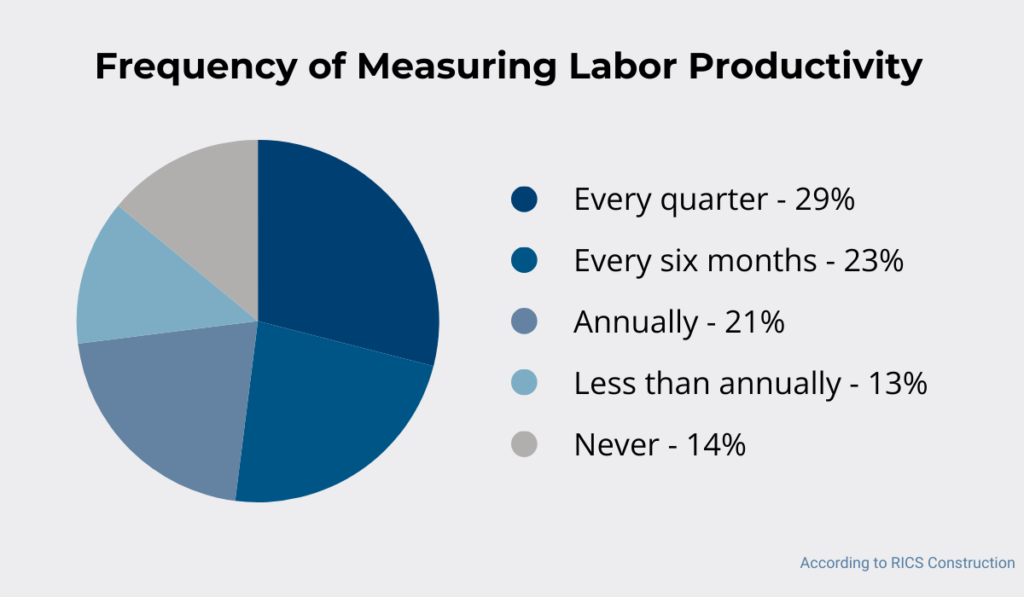

Well, the RICS Construction productivity report for 2023 gives a glimpse of how construction businesses across the globe approach this.

The findings suggest that only 29% of respondents frequently measure productivity, gaining new insights every quarter.

The biggest advantage of regular data tracking and measuring lies in collected insights.

Whether related to a single project or having a broader scope, productivity data helps businesses form comprehensive strategies and future predictions, while others suggest immediate tweaks.

In this way, companies have ample space to make adjustments that yield better output in the same year.

Nevertheless, the other figures deserve just as much attention.

According to the RICS data, nearly a third of the surveyed businesses don’t measure productivity regularly, with 14% admitting that they don’t keep track of productivity at all.

And our next statistic reveals why that’s a problem.

The Construction Industry Misses Out on $1.6 Trillion a Year Due to Low Productivity

Need a compelling reason to increase your productivity?

McKinsey’s analysis provides 1.6 trillion reasons to raise productivity levels starting yesterday.

That’s the amount of money that the industry is leaving on the table due to poor productivity levels.

The construction sector is worth mind-boggling amounts of money, taking one of the most prominent seats in the world economy.

It’s no secret, however, that it continues to trail behind other sectors in terms of productivity.

Although there are regional differences, tapping into productivity opportunities is equally important to APAC, European, and American companies.

On the other hand, lacking initiative means the added threats of low productivity, such as previously mentioned searching for project details and doing rework.

That comes with a hefty price tag of over $177 billion in labor costs, even if we take into account just one year.

Luckily, the construction industry has vast potential when it comes to productivity, which we’ll talk about next.

Productivity in the Construction Industry Has the Potential to Be 50 to 60% Higher

Discussing productivity opportunities in construction, the McKinsey report concluded that there is plenty of untapped potential in the industry, with the figures settling from 50 to 60%.

Moving beyond the macroscale of the world economy, the report showed that the construction companies are within reach of a substantial productivity boost.

But, there are certain conditions to be met.

McKinsey identified ten root causes of low productivity, ranging from factors that fall under external forces and industry dynamics, to company-level operations.

Based on the report, to successfully address these causes, companies need to take concrete action in different areas and pursue the following practices simultaneously:

In addition to the points we already touched upon, such as adopting technology or enhancing the supply chain, businesses should pay attention to onsite execution, regulations, and more.

It goes without saying, but companies shouldn’t limit themselves to just these practices.

Instead, the only guarantee of unlocking the incredible potential we highlighted here comes from keeping your eyes peeled and trying out different productivity tips and practices.

Conclusion

Every business has a unique growth path, but improving productivity is a surefire way to continue meeting your goals.

What makes this easier are insights from different companies, digested into convincing statistics.

We believe these insights will help you up your productivity game, so stick to the numbers and you’ll be ready to reach your desired outcomes!