With the growing complexity of construction projects, soaring prices, and a shortage of skilled labor, it might be the right time to consider whether co-location could help you deal with some of these issues on your next construction project.

If you, as the company owner or project manager, are wondering about the advantages of co-locating design and construction teams, you can learn more about them in this article.

We’ll cover the top five benefits of well-managed co-location that can propel your project to the next level of productivity, teamwork, innovation, and overall success.

In this article...

Increased Efficiency

The ultimate benefit of co-locating design and construction teams is increased overall project efficiency.

It is facilitated by physical proximity, direct communication, and improved collaboration between team members and different team leaders.

This results in fewer errors, miscommunications, and requests for information (RFIs) and improved accountability.

Before diving into how co-location leads to increased efficiency, a little background.

So, what exactly is co-location?

Although they’re not entirely synonymous, co-location is often equated with the “Big Room” concept.

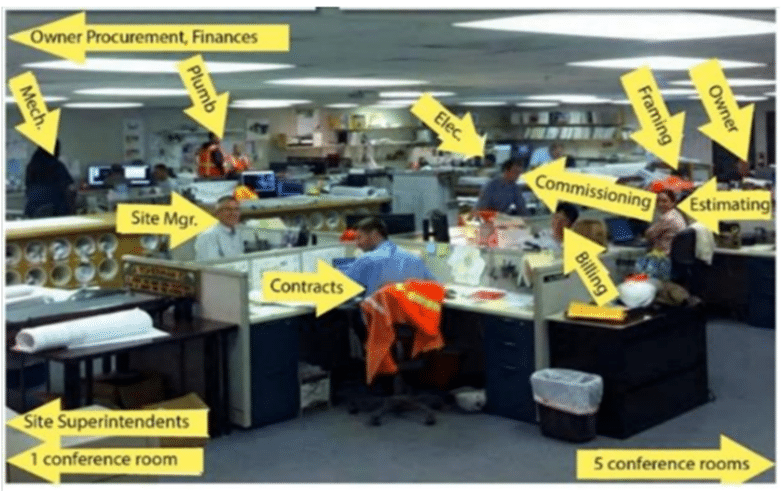

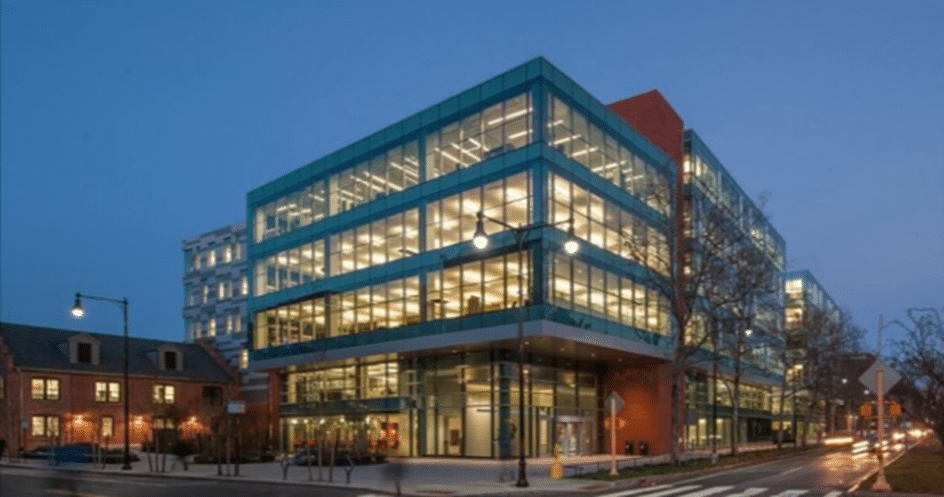

This is where the entire construction project team (client, architect, engineers, contractors, consultants, etc.) is located in a single space to enhance coordination and increase productivity, as illustrated below.

As such, co-location is often associated with lean construction and integrated project delivery (IPD).

It increasingly implies the use of building information modeling (BIM) and collaboration software tools.

This is because both Big Room and BIM are focused on streamlining the construction process by minimizing errors, miscommunication, and mix-ups between project stakeholders by providing tools.

That allows for a direct and transparent flow of information from the design stage throughout the project lifecycle, including post-construction maintenance.

Co-location provides a space where all project stakeholders can work together and align their respective tasks with the overall project goal.

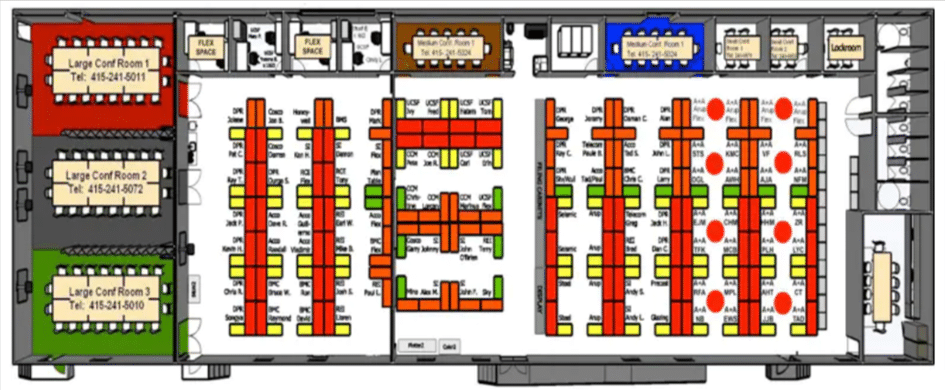

Here’s how that space was organized when DPR Construction used the Big Room on one of their projects.

As you can see, the Big Room in question had easily changeable workstations surrounded by three large and several smaller conference rooms, along with break rooms and hang-out spaces.

Members of design and construction teams were able to easily meet and discuss different aspects of their work, both formally and informally.

This concept aims to prevent many issues, potential conflicts, and blame-shifting that a project with dislocated teams might encounter.

Sharing the same space with all others working on a project builds trust and strengthens collaboration.

It does so in two key ways—first by having the client’s representatives present to directly answer questions and address issues as they appear and, second, by allowing team members to directly communicate with each other, and with different team leaders.

This minimizes miscommunication, reduces the number of RFIs through more direct information-sharing, and, ultimately, drives the buy-in and accountability of all project stakeholders, thus raising the overall project efficiency.

Stronger Collaboration

Simply by being in one room together, design and construction teams are compelled to join forces, creating a single project team characterized by stronger collaboration.

Ultimately, this leads to more efficient project delivery.

So, why would project stakeholders, in these times of unparalleled virtual interconnectedness, need to physically be in the same space to strengthen their collaboration?

A short answer would be because face-to-face interactions drive familiarity, build trust, improve relationships, and strengthen collaboration.

In other words, people basically work together better when they can, instead of using emails, phone or video calls, and other indirect communication, turn to their team members in person and get a direct response.

Furthermore, as projects are growing increasingly complex and work environments more remote, the need for in-person, hands-on collaboration between different teams is becoming more critical, especially on large construction projects.

Finally, when people collaborate face-to-face on solving issues, they stop identifying only with their role (e.g., designer, engineer, contractor). Instead, they start seeing everyone as a member of one team with a single common goal—completing the project on (or ahead of) schedule, within (or under) budget, and with the required (or better) quality.

For example, on one of their projects, Burns & McDonnell used seven client representatives (leads) responsible for different project aspects such as design, engineering, construction, environmental, etc.

In direct interaction with those leads, they reduced the time spent on getting answers and ultimately established a collaborative approach.

Once the project got going, you couldn’t tell the difference between the client, design, and construction teams.

Of course, collaborative tools like mobile ClickShare screens were also essential to allow other participants not present in the Big Room to get updates, share ideas and work together.

Overall, although it’s not a magic wand, co-location allows teams to collaborate in person, thus fostering professional and personal relationships between different team members.

This strengthens collaboration and focuses teams on the project instead of their specific (and sometimes opposing) interests.

Access to Information

When all team members are in one room when needed, that drives everyone’s access to information and can result in innovative solutions that save both time and money.

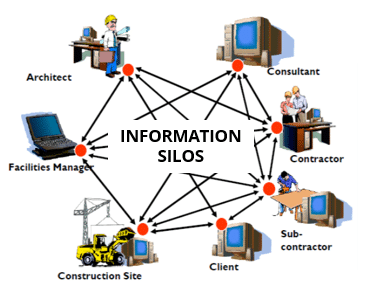

In the design-bid-build projects that still dominate the market, the design phase of a project is often done in an information silo separate from the construction team.

Moreover, once the project is underway, this often creates an adversary relationship between them, creating room for (un)intentional restriction of information flow and people feeling like they’re working alone instead of one cohesive unit.

When this happens, a lot of information can be lost, omitted, or misunderstood. At the very least, access to it can be restricted.

One way of breaking those silos and enhancing access to information is to co-locate design and construction teams.

As co-location is usually combined with BIM or the use of other construction management software that provides a single source of information for all project stakeholders, having design and construction team members in one room enables unparalleled access to both formal and informal information for both teams.

As such, teams are able to resolve many issues even before they appear.

For instance, Consigli Construction Company co-located both teams at the project site during the project’s pre-construction stage.

Long story short, this successful collaboration managed to cut the previously estimated budget by $2 million and the schedule by almost five months, resulting in the award-winning building you see below.

Jeff Navin, Project Executive, highlighted the four top benefits of co-location on this project:

- Reduced inefficiencies related to waiting for information in non-co-located settings

- Easier access to all team members in one room

- Reduced coordination time

- Reduced number of RFIs

It can be said that all the above benefits stem from improved access to information, which is often instant, less formal, and more effective.

For example, getting relevant information was often as easy as walking across the room and asking a team member instead of writing emails, requests for information, messaging, or calling.

The latter all take more time and provide less opportunity to really understand the conveyed information.

Overall, when the full team is in one room, that breaks down information silos, quiets down egos, and enhances collaboration, which in turn drives access to information of all team members, and can result in innovative solutions and cost and time savings.

Faster Problem-Solving

By now, it’s clear that, if done correctly, co-location leads to faster problem-solving, as it fosters a collaborative approach, stronger trust, clear rules and guidelines, and better decision-making.

First, for co-location to work in favor of the project owner, enable more effective communication, and thus better problem-solving, the management of design and construction teams needs to agree on the rules the combined team will use.

Better yet, as quality problem-solving is predicated on open communication and cohesive teamwork of all involved, it’s often best to hold facilitated pre-Big Room workshops to allow for shared process development and initial team-building between different teams.

For instance, that’s what Banner Health did in preparing the on-site Big Room for the project of building their new hospital addition in Tucson, Arizona.

In these mandatory 1-day exercises, all team members were encouraged to share their suggestions and engage in initial collective problem-solving.

They were determining the guiding principles, policies, and rules to be used by the new entity—the unified project team located in the Big Room.

Needless to say, this had countless positive effects when the co-location started, such as increased commitment and accountability, stronger relationships, and improved collaboration, all of which are prerequisites for faster and better problem-solving.

Another example is Burns & McDonnell, whom we’ve already mentioned.

They structured their team as seven self-directed functional units, each with one client lead as the primary contact for their working group, like construction, engineering, real estate, etc.

The team members were grouped by their function, not their company.

This created a sense of camaraderie and collaboration, built trust, and resulted in a faster problem-solving process from start to finish.

Back in Tucson, the project team embraced the idea that trying and tweaking processes for improvement early on was essential for the project’s success.

As the project progressed, monthly surveys and evaluations were carried out to identify any process issues, find solutions, and make adjustments, thus further minimizing obstacles to practical problem-solving.

Overall, if it’s properly planned, organized, and managed, co-location leads to better decision-making and faster problem-solving through effective collaboration of the unified team working in the Big Room.

Reduced Coordination Time

The last overarching co-location benefit is reduced coordination time throughout the project life cycle, which stems from the co-located team members working in close physical proximity and having more direct and higher-quality interactions.

Coordination time can be further reduced when it’s supported by updated information on different ongoing project processes provided by various technological and software solutions increasingly used in construction.

First, let’s just acknowledge how complicated it is to coordinate so many stakeholders coming from diverse backgrounds and different companies, especially on complex construction projects.

So, co-locating design and construction teams in the Big Room seems like a simple solution to this coordination issue.

However, as said, this process itself requires some careful consideration and coordination, planning, and organization.

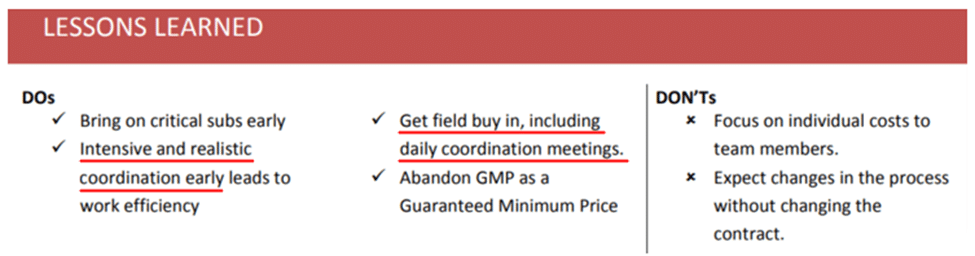

On that note, look at the lessons learned by Tarlton Construction on one of their Big Room projects:

As you can see, the importance of early and daily coordination is clearly highlighted and having all team members in one room reduces coordination time by default.

In other words, when coordinating with someone means sitting at the same table with them instead of losing time on countless email threads and messages, it automatically cuts the required coordination time.

Simultaneously, higher-quality interactions between team members lead to better decision-making.

Naturally, coordination can be further accelerated by using different construction technologies like BIM, drones, and AI, and digital solutions like collaboration tools and equipment tracking software.

For example, coordination is enhanced when the Big Room team knows where all the tools, equipment, and machinery used on-site are at any time, which is achieved by tracking their location in real-time.

If that sounds interesting, you can try GoCodes.

Thus, everyone working together in the same space leads to higher-quality interactions, both formal and informal, which in turn speed up project coordination.

Coordination time can be further reduced by tracking different project processes and providing the co-located team with updated information that enables quality decision-making and facilitates coordination.

Conclusion

To sum up, in addition to all the above co-location benefits like increased overall efficiency, stronger collaboration, and faster problem-solving, the most significant benefit of co-locating design and construction teams is the unleashed potential and innovation of the new entity that emerges—one team with one goal.

If it’s managed well, co-location can help you deal with many issues construction projects face and increase the likelihood of outstanding project performance.