Asset tracking plays a larger role in business operations than people often realize.

Its benefits reach far beyond simply knowing how many of each tool you have.

In fact, do it correctly, and you’ll see your maintenance costs and unplanned downtime rates reduced and your operational efficiency increased.

These are only a few of the advantages of proper asset tracking.

Therefore, if you’re interested in propelling your business forward, keep reading to find out the ins and outs of effective asset tracking.

In this article...

The Dos

First, let’s get into some of the best practices that help take your asset tracking to the next level.

Follow these, and you’ll see the improvement in no time.

Identifying Everything That Needs to Be Tracked

The first step in implementing proper asset tracking is determining what assets your company owns and identifying the most important ones.

Essentially, you must first figure out what exactly needs to be tracked.

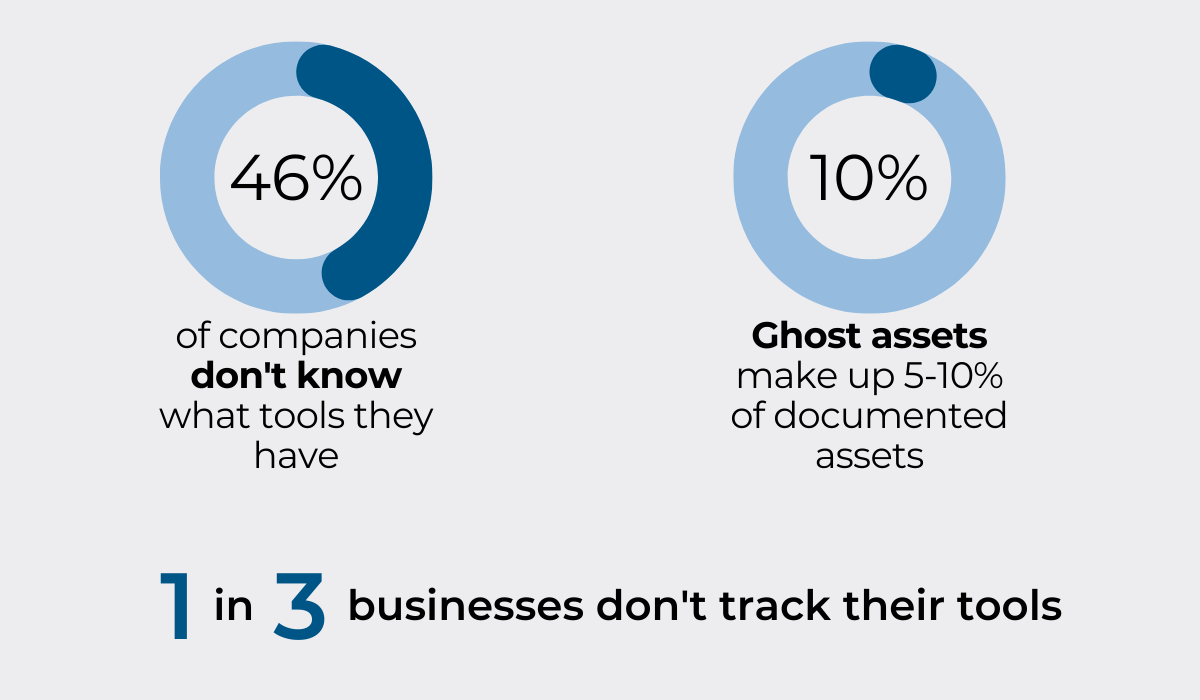

Although this sounds obvious enough, it seems that many companies still don’t appreciate the actual value of asset tracking.

All of the numbers point to a lack of awareness of asset tracking’s importance, which is surprising since asset tracking is known to be quite beneficial when it comes to productivity optimization, cost reduction, and many other aspects of business operations.

Asset tracking is not only about identifying the quantity of each asset, however.

Many different metrics need to be observed to ensure proper asset tracking, such as, for example:

- Check-in/check-out times

- Runtime vs. downtime

- Planned vs. unplanned downtime

- Asset location

Therefore, to get started with asset tracking, you must first collect all the data required to determine your asset baseline and perform a thorough audit.

The audit will inform you in detail about what assets you have, how many of each asset you have, and what metrics should be further tracked for each asset.

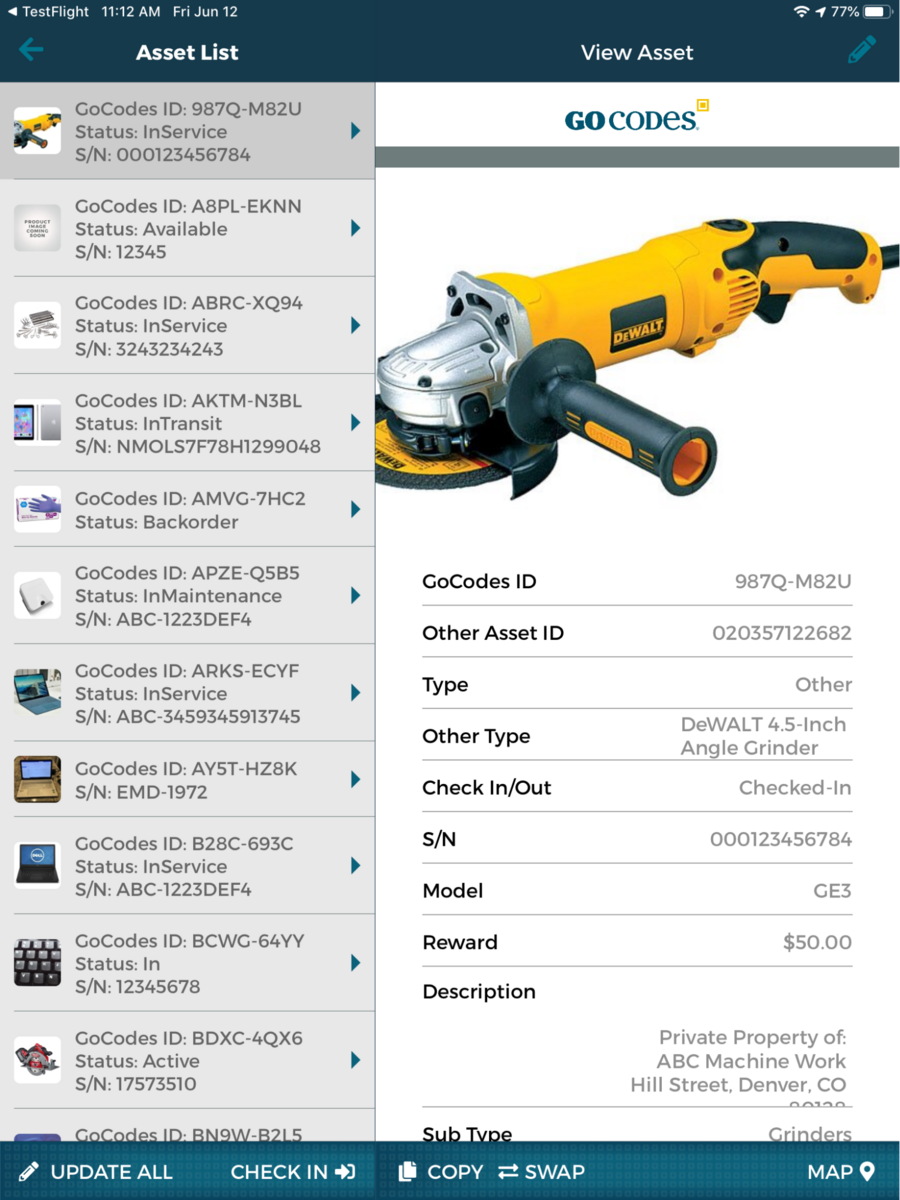

Choosing Easy-To-Use Asset Tracking Software

Now that you’ve determined what needs to be tracked, it’s time to actually start tracking and monitoring your assets.

And what better way to do that than by relying on software specifically designed for that purpose?

Bear in mind, however, that not every asset tracking software is right for you or your team.

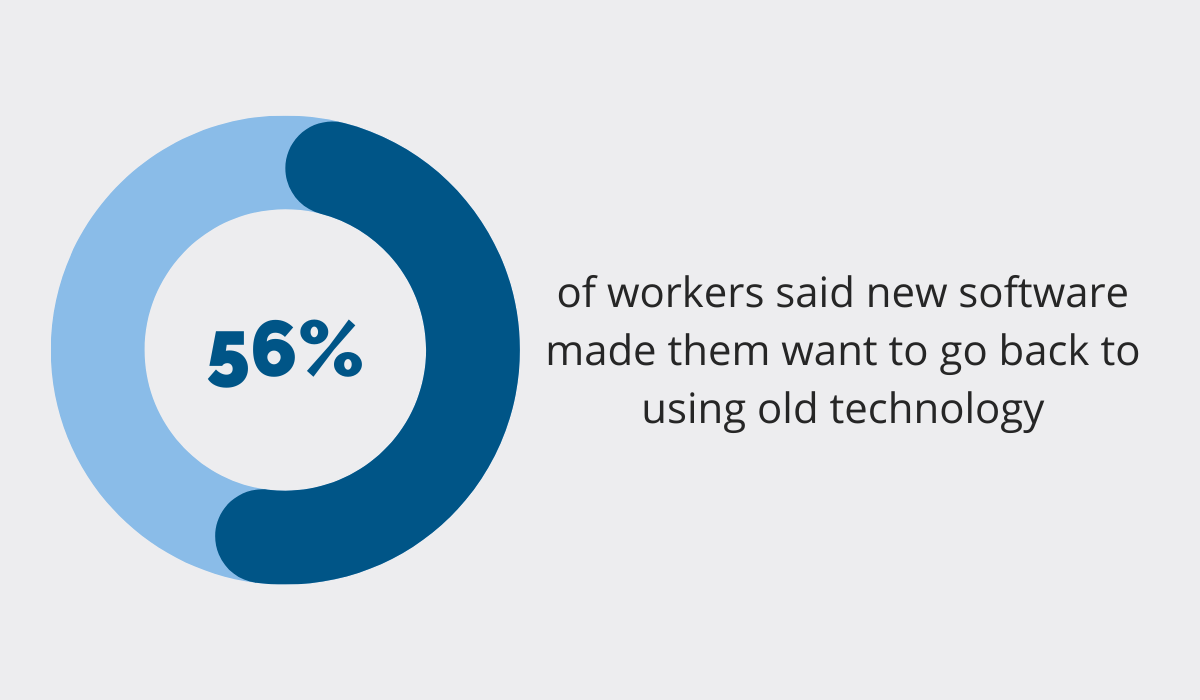

According to the survey by Gartner, Inc., 56% of respondents claimed they would prefer to go back to the old technology instead of implementing new software.

Unfortunately, you’re also likely to encounter this kind of reluctance to new system implementation.

Therefore, you need to be strategic about the new software acquisition and make sure everyone will use it, otherwise, there’s no point in buying it.

Looking for user-friendly solutions is the key to getting your team on board. They need to know that new technology will make their job easier and not create more problems.

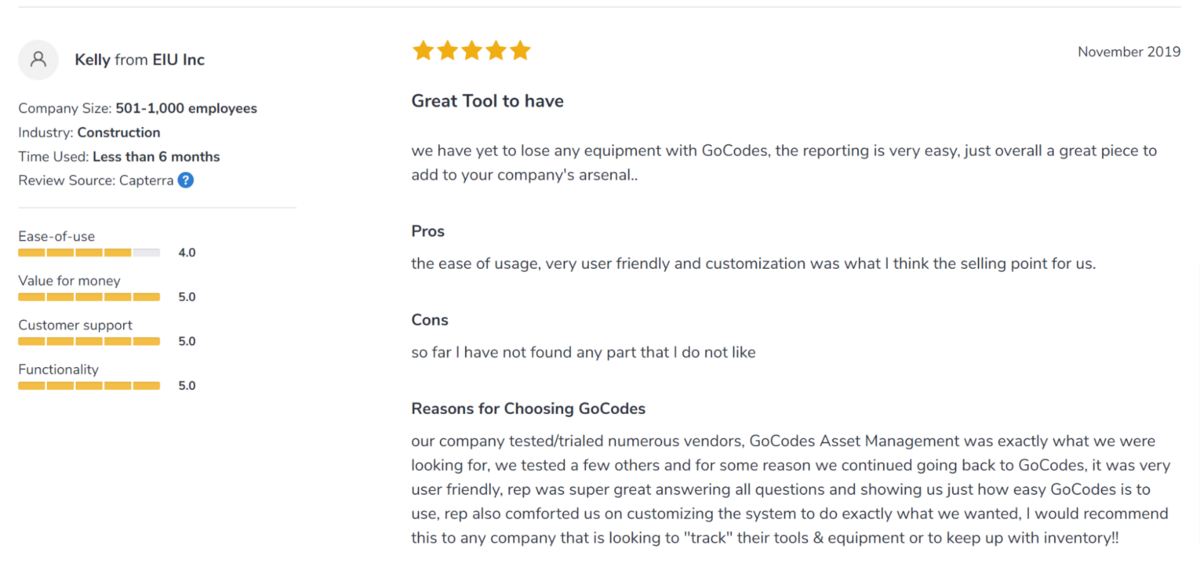

At GoCodes, we pride ourselves on creating a solution that is easy to use, even for less tech-savvy employees.

Simply tag your assets with our customized asset labels and scan the label with our scanner app to update the information about a particular item on the go. It’s really that simple!

Still, if you’re not entirely convinced and want to try the software out for yourself, don’t hesitate to request a free trial. This is the best way to determine if the software truly suits your needs.

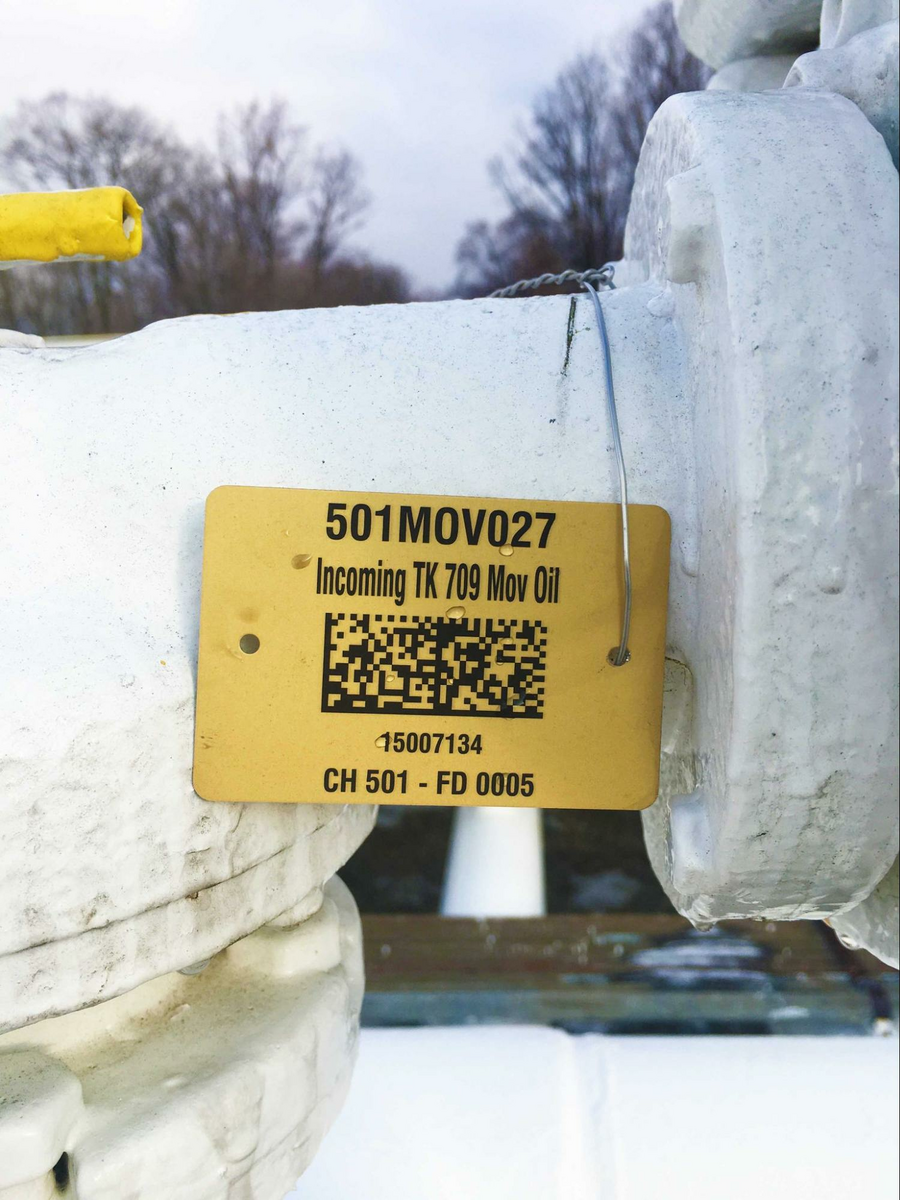

Selecting Asset Tags Based on the Environment

Tagging your assets is an essential part of asset tracking. However, not every tag is suitable for every environment.

To elaborate, asset tags are made of different materials that vary in their durability, and therefore each of them can withstand different conditions.

In other words, specific environments can cause damage to less durable labels, making them unscannable and, therefore, unusable.

So consider the type of asset you want to tag and the conditions in which the item in question will be used. This will tell you what kind of label you need for it.

Will the asset be used inside, in an office environment, or will it be exposed to constant motion, extreme temperatures, or abrasive chemicals?

For instance, when it comes to indoor use, tags printed on polyester, polypropylene, or vinyl will do a good enough job because they are capable of resisting exposure to water, oil, and general-use cleaners.

And if the environment requires greater durability, asset tags can be made of more sturdy materials, such as anodized aluminum or stainless steel.

To find out more about what kind of tag your assets require, read our detailed guide.

Assigning Unique Tracking Numbers to Each Asset

Construction companies would hardly be able to operate without a large number of assets.

And, while they certainly are what ensures project completion and business success, it can become quite difficult to track all that machinery, tools, and construction materials.

Especially when you have many of the same or similar pieces.

Therefore, to avoid confusion and ensure efficient asset tracking, a unique tracking number should be assigned to each asset.

Having serial numbers double as tracking number seems like a logical solution, but it frequently results in mix-ups, so it’s advisable to come up with a unique number to ensure one asset can be distinguished from the others within your asset tracking software.

Here are some other reasons to consider generating unique identifiers for your assets.

The real problem here is that serial numbers are not really unique.

They might differ among specific asset types from one particular manufacturer, but nothing guarantees they’ll be unique among assets of all other types from all other manufacturers.

Therefore, generating a unique tracking number is the way to go.

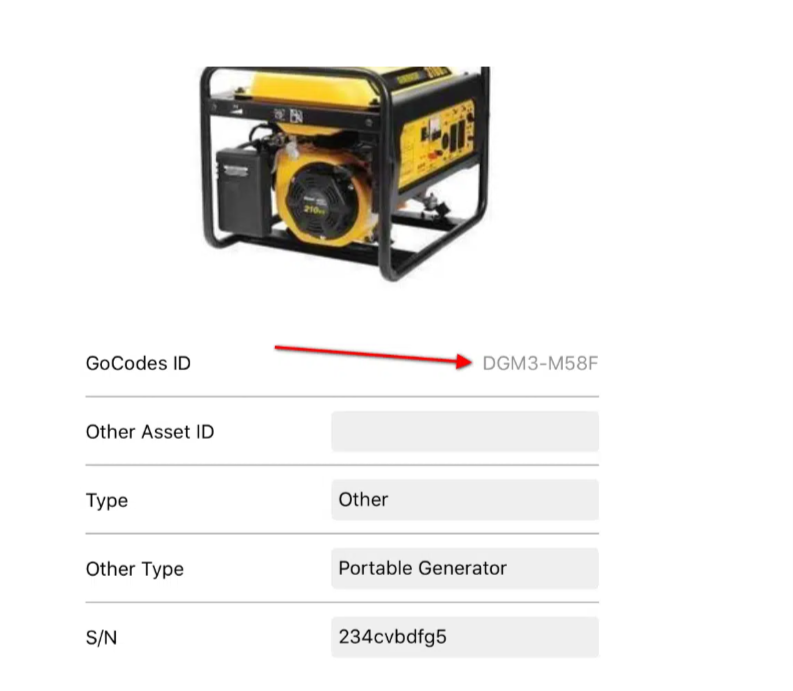

What is more, you don’t even have to do that on your own because some asset tracking software solutions provide unique IDs for clients and their assets.

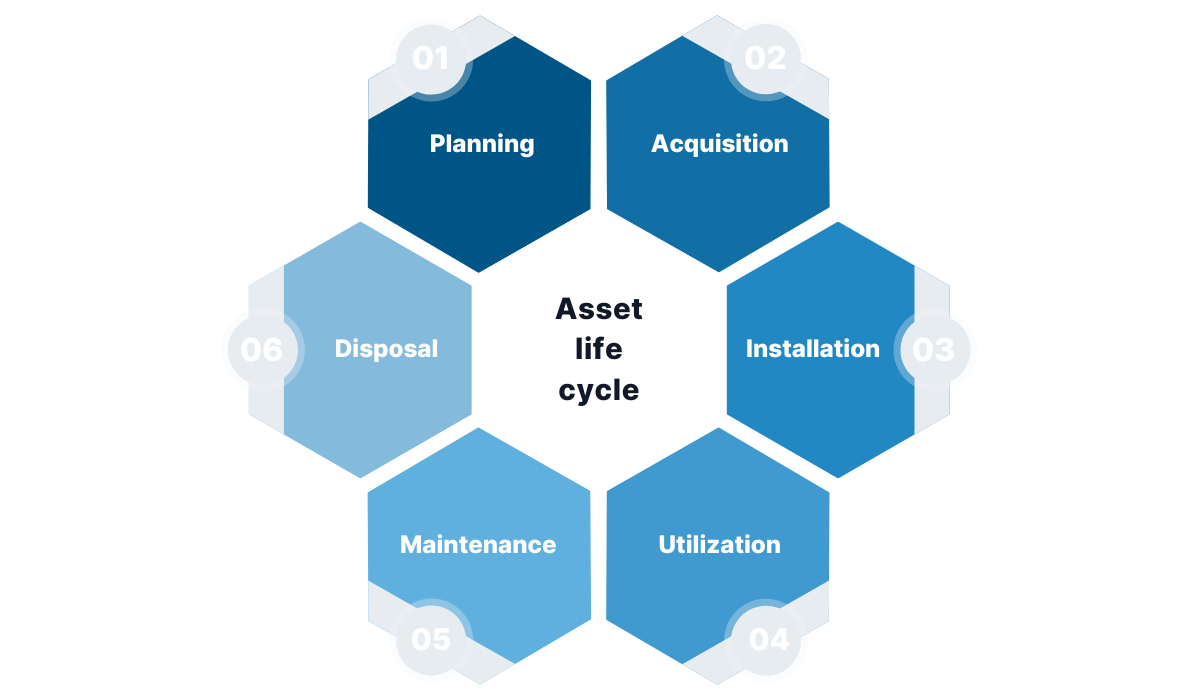

Tracking New Assets as Soon as They Arrive

Asset tracking doesn’t end with tagging and monitoring all your current assets. It requires constant work and an influx of data for you to get accurate insight into your asset utilization.

That’s why it’s essential to tag new assets as soon as they arrive and integrate them into the system so you can immediately start tracking them.

Sure, it might be tempting to start using that shiny new piece of equipment immediately but to get genuinely accurate and meaningful data, you have to track your assets through their whole lifecycle.

In other words, assets need to be monitored from the acquisition phase through utilization to their disposal so you get detailed knowledge about how much exactly a particular asset costs your company versus how much it contributes to its profitability.

That sort of information helps with future asset acquisition planning.

The Don’ts

Now that we’ve covered what to do to ensure efficient asset tracking, let’s get into some of the mistakes businesses make when tracking their assets.

Here are the five that are most likely to affect your asset tracking in a negative way.

Failing to Record All of the Important Asset Data

We’ve already briefly touched upon the fact that asset tracking entails monitoring not only asset quantity but all the different information pertaining to your assets.

Failing to do so means dealing with inaccurate or incomplete data, which comes with many problems, such as unplanned downtime, reduced profits, increased maintenance costs, reduced productivity, and job site efficiency.

Therefore, make sure you enter all the relevant data into your asset tracking software.

Some of the examples of data to record include:

- Asset name

- Asset model

- Unique tracking number

- Insurance information

- Date of purchase

- Price of purchase

- Maintenance schedule

- Compliance information

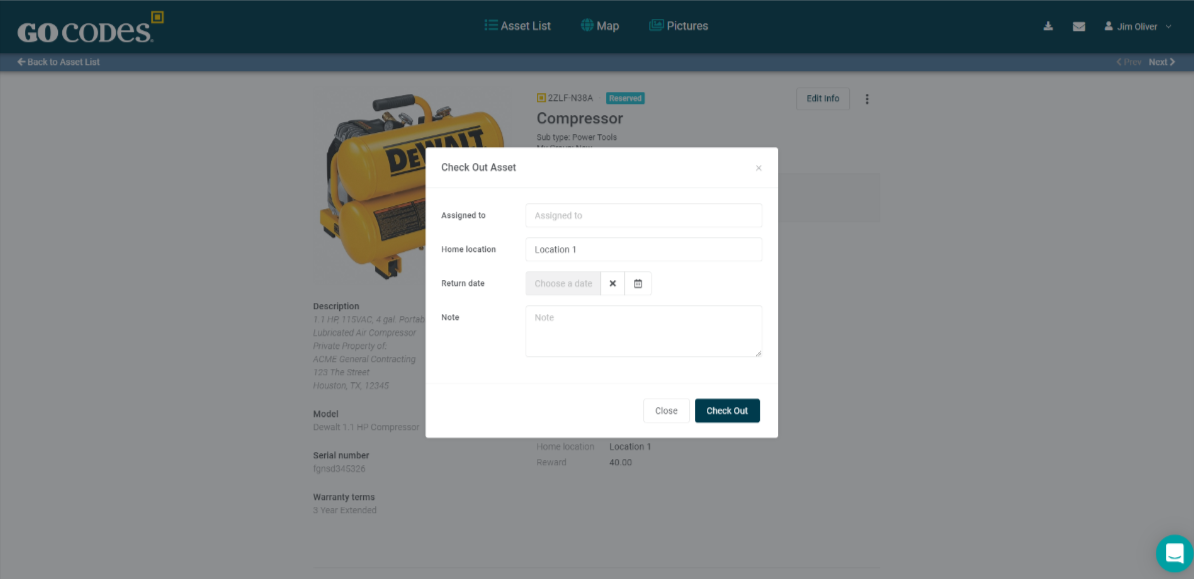

You can see a typical entry below.

Having all that information at your disposal at all times is a massive lifesaver in situations where you’re required to retrieve a particular asset’s data quickly.

In other words, long gone are the days of looking through different paper and digital files and spreadsheets to find those insurance details or data on previous asset maintenance.

With asset tracking software, it’s all in one place.

Ignoring the Need for Accurate Location Tracking

Location tracking is probably the first thing that comes to many people’s minds when discussing asset tracking.

Having said that, construction workers still waste considerable amounts of time looking for misplaced tools.

There are also the inordinate theft rates that are plaguing the construction industry.

Many such problems at construction sites stem, at least partially, from inaccurate location tracking.

Working toward improving location tracking can provide your business with many benefits.

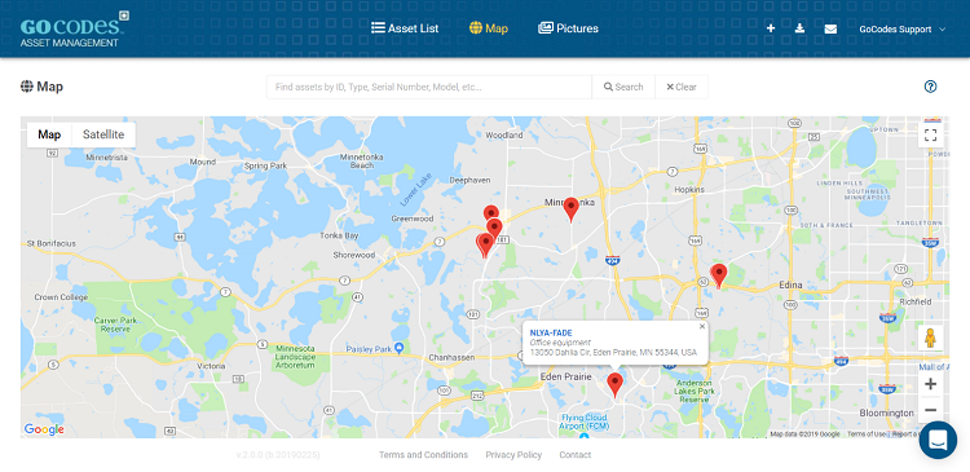

GPS location tracking is the best way to go when it comes to accurate location data. Asset tracking software often relies on QR codes to track the GPS location of assets.

Asset location can be easily updated on the go each time an asset’s QR code label is scanned by a GPS-enabled QR code reader, such as a smartphone.

Basically, the location of the smartphone serves as an asset’s location.

That way, geospatial information of both fixed and mobile assets can be accurately tracked because each time anybody checks in or checks out an asset, its location is automatically updated.

Not Being Clear About the Employees’ Responsibilities

Asset tracking, just like almost any aspect of the construction business, is a team effort.

Yes, it might be up to you to find asset tracking software that your employees will be on board with, but the team needs to do their part and make sure the software is properly utilized.

They need to be aware that they’re the ones that are responsible for assets while they’re using them, and that includes knowing how to properly use the software to track these assets and handle incoming work orders issued through the asset tracking software.

With an asset tracking system, employees are held accountable because the software provides visibility to their actions.

In other words, each time an asset is checked in or checked out, it is immediately shown to everyone on the team, along with information on who was the last one to use the tool.

Moreover, the software lets you assign different tasks to individual workers so everyone knows what they’re responsible for each day.

For example, if a bulldozer needs an oil change, the software lets you set that task up, assign it to a team member, and even set the deadline for the task completion.

Neglecting to Properly Track Asset Utilization

Knowing where your assets are and who’s using them is not enough. You also need to know whether those assets you invested so much money in are being properly utilized.

Therefore, do pay attention to asset check-out and check-in, GPS location, but also to ignition on and off times, miles, fuel use, utilization of equipment parts, etc.

Ignoring that extra information means missing out on valuable knowledge—knowledge that could help you more strategically allocate your assets and, in turn, increase the company’s productivity.

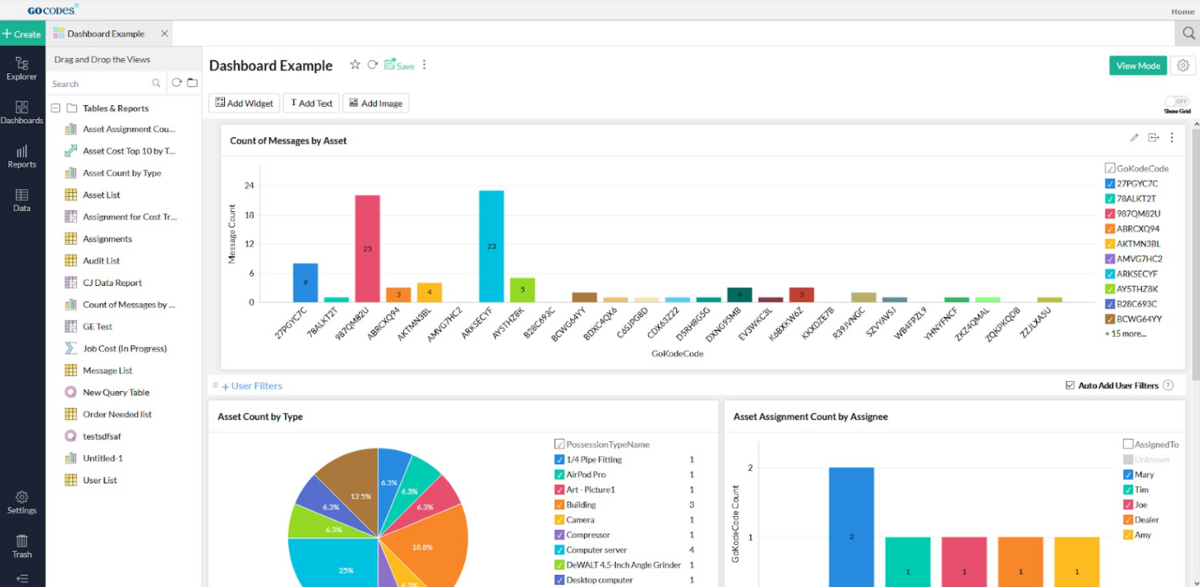

And to better detect which of your assets is being over or under-utilized, consider using your asset tracking software’s reporting feature.

The feature enables you to create customized reports on your own, set them up to be created automatically, or generate graphs and charts—all with the purpose of helping you visualize crucial data better, share it with your team, and make better-informed decisions about your asset allocation in the future.

Forgetting to Track Asset Maintenance Schedules

Besides establishing proper asset utilization, maintaining your assets is another great way to ensure a return on investment.

However, not all maintenance is good maintenance.

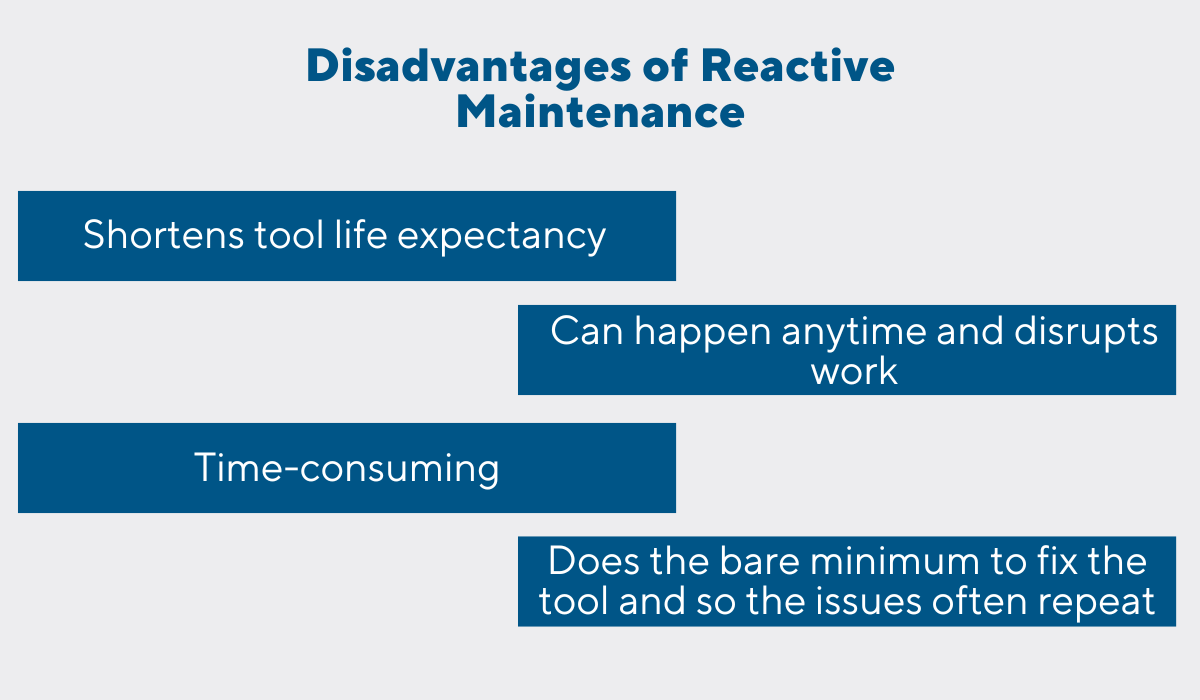

In fact, if you’re looking to avoid shortening your assets’ lifespan, along with many other harmful downsides, try refraining from reactive maintenance, i.e., only fixing your equipment when it’s already broken.

Instead, prioritize preventive maintenance that is scheduled during planned downtime and doesn’t interrupt your ongoing projects.

Naturally, unlike reactive maintenance, this kind of maintenance requires sticking to a schedule.

In order to make sure that preventive maintenance is carried out on time (or at all), don’t shy away from relying on your asset tracking software.

It will take your maintenance to a whole new level and send you scheduled service notifications via email so you or your team members never miss another planned maintenance!

Conclusion

To sum everything up, the key to successful asset tracking is consistency.

Once asset tagging and proper tracking of all relevant asset data become a habit for you and your team, you’ll have a constant influx of accurate information that’ll improve your decision-making and help you with the implementation of both short-term and long-term business plans.