Key Takeaways:

- Serial numbers help identify assets, but aren’t enough on their own.

- Barcodes and QR codes make tracking easier with scannability.

- RFID, NFC, and Bluetooth automate tracking—no scanning required.

- GPS provides real-time location visibility for your most valuable assets.

For many construction businesses, keeping track of what assets they have and how they’re used is a time-consuming job often fraught with inefficiencies.

Tools go missing, equipment gets misplaced, and time gets wasted chasing things down.

The good news?

There are now plenty of ways to identify and track your assets, each with its own pros, cons, and ideal use cases.

In this article, we’ll break down the most common methods used in construction so you can choose what works best for your business.

In this article...

Asset Serial Numbers

Most construction assets come with their own serial number, usually etched or printed on a nameplate.

So, it often feels natural to use these as unique identifiers in a company’s asset tracking system.

This approach has several advantages:

- No need for extra tags, devices, or infrastructure

- No need to create or assign your own ID system

- No special technology required

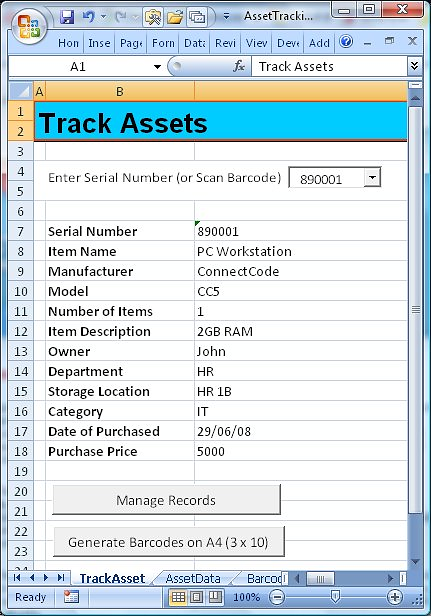

Serial numbers can be entered into asset tracking software, but a simple shared document or spreadsheet is often enough.

Here’s an example of a serial number-based Excel spreadsheet setup:

Source: Spreadsheet ML

The main benefits of using serial numbers for asset tracking come down to cost-efficiency and simplicity: no extra tools, no added hassle.

However, relying on serial numbers as your only asset ID method typically leads to several issues, starting with uniqueness.

While a manufacturer may assign unique numbers, there’s no guarantee another manufacturer hasn’t used the same format, leading to possible duplication and confusion.

Also, serial numbers are often small, hard to locate, and rarely barcoded.

This not only slows down field identification but can sometimes prevent it altogether.

As one Reddit user put it when asked why asset tags are still needed if serial numbers exist:

Illustration: GoCodes Asset Tracking / Quote: Reddit

While serial numbers may be the least suitable option for asset identification and tracking, they still play an important role.

It’s essential to record them in your system for warranty claims, insurance documentation, and theft reporting.

That said, serial numbers should be treated as secondary, not primary, identifiers.

Barcodes, on the other hand, can be a reliable primary identifier and have the added benefit of being easily scannable.

Barcodes

Barcodes are everywhere: retail, logistics, healthcare, and yes, construction.

They’re simple in principle: a barcode is generated along with an item ID, then printed and physically attached to the item.

To identify or track the item, users just scan the code.

That can be done with a handheld scanner or, more commonly these days, a smartphone or tablet.

The scan pulls up a digital record. Users can instantly retrieve or update asset information from the connected database.

In construction, barcodes are typically used for tracking materials and consumables.

But they’re also found on tools, equipment, and components that require regular compliance checks.

Source: GoCodes Asset Tracking

Since barcodes require you to manually—or automatically, depending on your setup—assign unique asset IDs, they eliminate the serial number issues we mentioned earlier.

Scannability is another obvious benefit.

When paired with software, it allows for fully digitized and partially automated asset tracking.

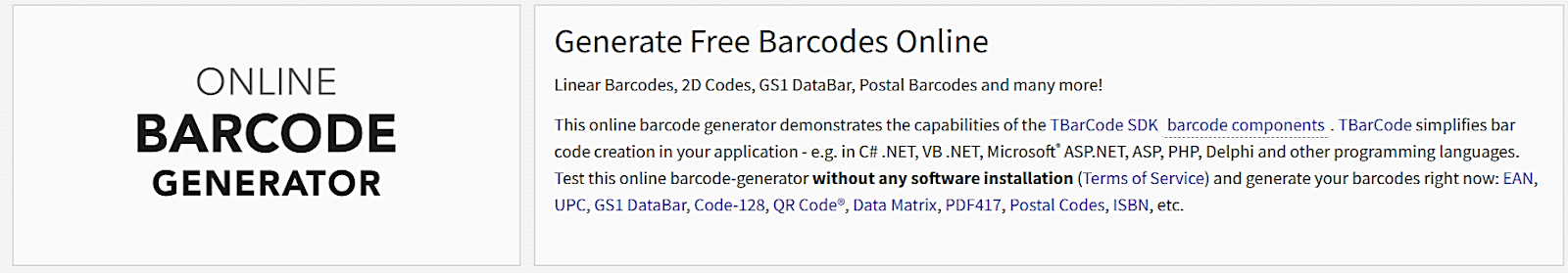

Barcodes are also easy to generate and print, which makes them both low-cost and highly scalable.

That means anything from a small tool or spare part to heavy equipment can be tracked.

Here’s one example of a free barcode generator available online:

Source: Barcode Tec

So, what are the downsides?

For starters, many barcode tracking systems still require you to purchase separate scanners and special printers, which increases upfront costs.

Another drawback is that the scanner must be precisely aligned with the barcode, which can be tricky and frustrating in the field.

Lastly, unless printed on durable, wear-resistant labels or tags, barcodes are prone to damage and can quickly become unreadable.

Despite these limitations, barcodes remain a practical and affordable step toward more efficient asset tracking.

QR Codes

Quick Response (QR) codes work similarly to barcodes but come with distinct advantages that make them especially useful for asset tracking.

Like barcodes, QR codes are widely used across industries—but they offer more flexibility and functionality.

Compared to barcodes, QR codes have several notable benefits:

- They can be scanned from any angle

- They store more data in a smaller space

- They remain readable even when damaged

- They don’t require dedicated handheld scanners

Instead, QR codes can be scanned with smartphones or tablets.

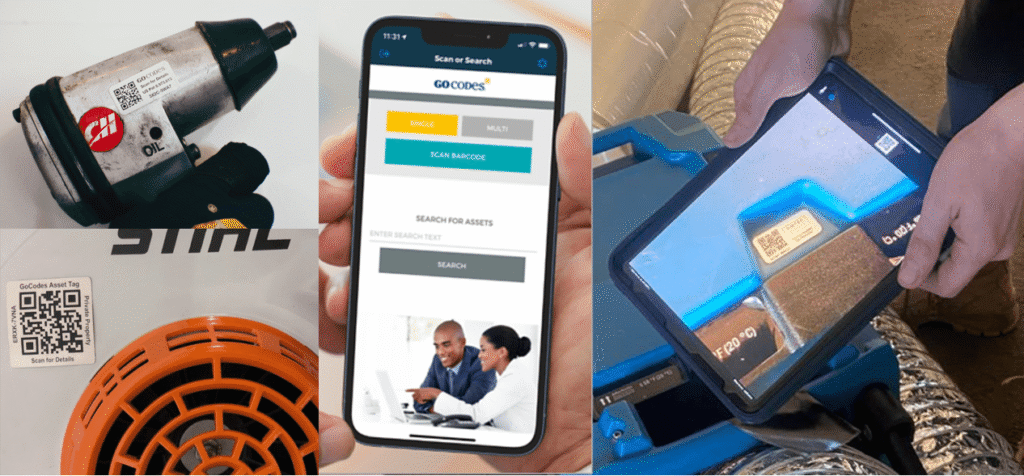

The images below highlight several key aspects of QR code-based asset tracking.

Source: GoCodes Asset Tracking

They show that QR codes, just like barcodes, are most effective when printed on durable tags that can withstand tough construction environments.

As noted earlier, the major difference is that QR codes can remain scannable even when partially damaged.

The next image shows that, to effectively use QR codes for tracking, they must be paired with a mobile asset tracking app.

The final image illustrates the scanning process in action, which instantly pulls up an asset’s info page, allowing users to view and update asset details.

Source: GoCodes Asset Tracking

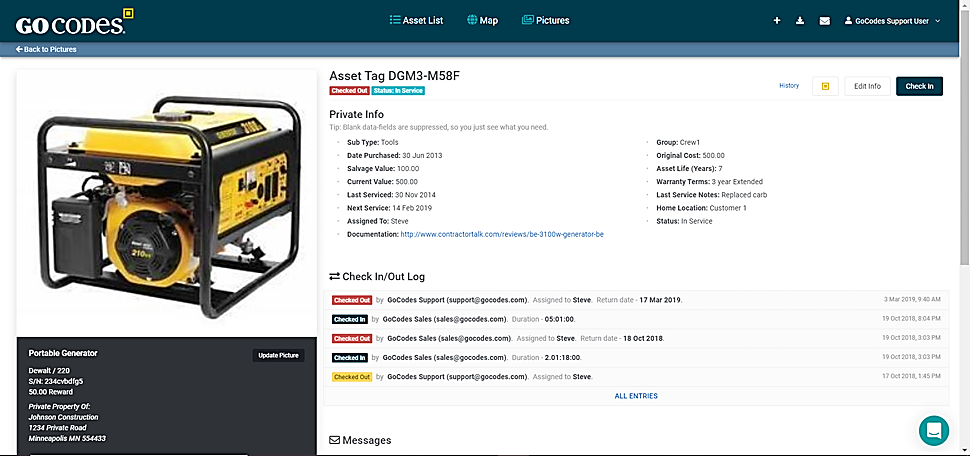

The described features of a QR code-based tracking system streamline key asset management tasks, such as allocation, usage monitoring, maintenance scheduling, and more.

Workers can quickly check tools and equipment in and out by scanning asset tags, creating a clear digital trail that improves accountability and reduces theft.

Next, most asset tracking apps allow users to update asset locations manually, whether using serial numbers, barcodes, or QR codes.

However, GoCodes Asset Tracking—our end-to-end asset tracking solution—adds a layer of automation.

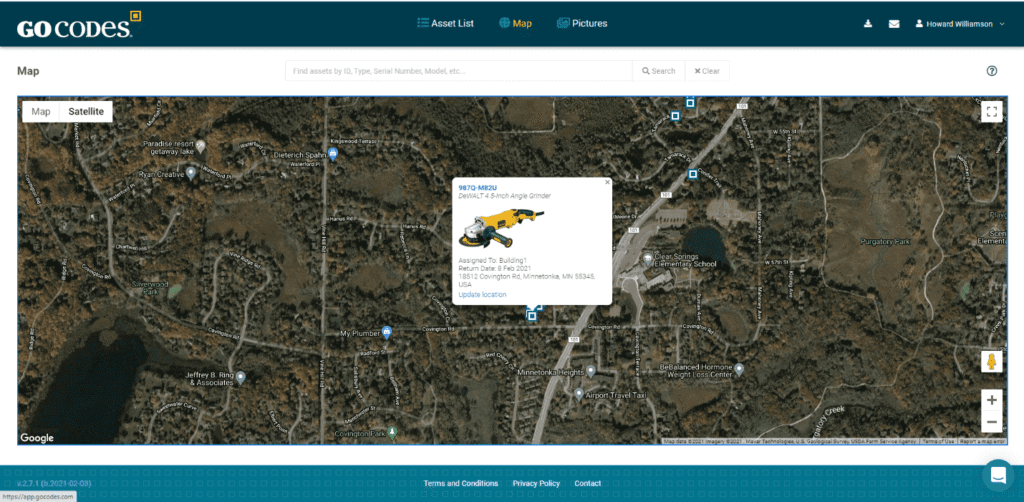

Each time a worker scans a QR code, the GoCodes Asset Tracking app automatically records the asset’s GPS location and displays it on a map.

Source: GoCodes Asset Tracking

This scan-based GPS tracking is powered by the device’s built-in location services, removing the need for manual input and reducing the risk of human error or manipulation.

The benefits are clear: both workers and managers can instantly see where an asset was last scanned, making it easier to find.

This makes GPS-enabled QR codes especially useful for tracking smaller, lower-value assets that often go missing.

So, what’s the downside?

Even with GPS and mobile integration, QR codes still require someone to scan the tag for data access and location updates.

That brings us to the next method: the first that doesn’t rely on scanning at all.

RFID Trackers

RFID, or Radio Frequency Identification, is a wireless tracking method that uses radio waves to identify and locate assets.

Unlike barcodes or QR codes, RFID doesn’t require direct line of sight, making it faster and more flexible in busy or hard-to-reach environments.

There are several types of RFID trackers, operating at different frequencies:

- Low Frequency (LF)

- High Frequency (HF)

- Ultra-High Frequency (UHF)

It’s useful to know that most smartphones can read certain HF RFID tags, but not LF or UHF tags, which require specialized hardware.

Another key distinction is between passive and active RFID trackers.

As shown below, each comes with its own range, cost, and setup considerations.

| Passive RFID | Active RFID | |

|---|---|---|

| Power source | No battery; powered by the reader | Internal battery |

| Read range | 4 inches to 33 feet (varies by type) | Up to 300 feet and more |

| Smartphone compatible | Yes, but only with certain tag types | Usually no |

| Cost | Lower | Higher |

| Typical use | Inventory, access control | Real-time asset monitoring in limited zones |

Beyond eliminating the need for line of sight and manual scanning, RFID systems can read multiple tags at once, making them ideal for audits or tool dispatch.

QR code-based apps offer multi-scanning, too, but still require manual scans.

Another advantage is size: RFID trackers are tiny and can be embedded in labels or even inside assets, like the ultra-small UHF RFID tag shown below.

Source: Sparkfun

That said, RFID has its downsides.

For starters, costs are higher, especially for active tags and dedicated readers.

Setup can be complex, requiring specialized hardware and user training.

Additionally, environmental factors like metal, liquid, or poor antenna placement can interfere with signal accuracy.

Compared to RFID, the next method—NFC—offers a simpler, smartphone-friendly alternative.

NFC Trackers

NFC (Near Field Communication) is a subtype of HF RFID that enables short-range, contactless communication, typically within 1 to 4 inches (2–10 cm).

Most smartphones come with built-in NFC readers, making the technology a practical solution for construction teams looking to track assets without additional hardware.

NFC tags, like some RFID types, are compact and often embedded in cards, stickers, or key fobs.

Users can access or update asset information simply by tapping their phone to an NFC tag.

As our banner shows, tag programming is just as easy: tap to set, tap to update.

Source: GoCodes Asset Tracking

Naturally, NFC comes with a few limitations. Its very short reading range means it can’t be used to read multiple tags at once.

And while scanning is replaced with tapping, NFC tags tend to be more expensive than QR code labels.

Also, NFC doesn’t support live location tracking—unlike some longer-range RFID systems—and remains limited to tap-based data access and updates.

The next method, however, offers a simpler alternative to these short-range RFID solutions.

Bluetooth Trackers

Bluetooth Low Energy (BLE) asset trackers—often called Bluetooth or BLE beacons—use radio signals to automatically broadcast their presence to nearby compatible devices, such as smartphones.

Their signal range typically falls between 30 and 300 feet, depending on the environment.

This range can be extended by adding fixed gateway hubs at strategic points around the jobsite or warehouse.

While this adds some cost, it greatly increases both coverage and security, as gateways can be configured to send regular location updates automatically.

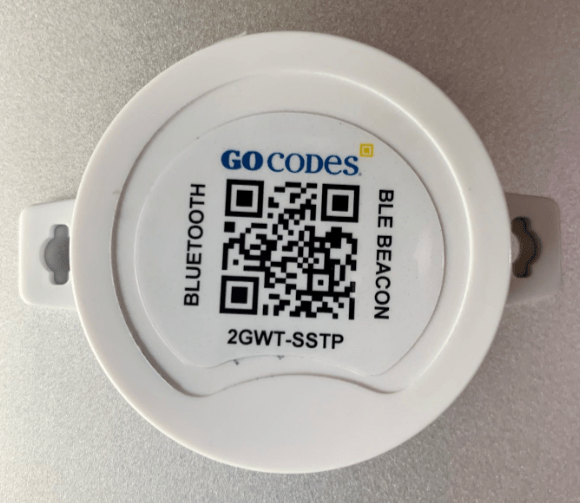

Here’s what a small, battery-powered BLE beacon looks like:

Source: GoCodes Asset Tracking

As shown above, a QR code or barcode is often printed on the beacon.

This allows workers to manually identify an asset if needed—or, in the case of GPS-enabled QR codes, to continue tracking the asset even outside Bluetooth range.

When paired with gateways, BLE trackers can send automatic location updates to the asset tracking app, making them ideal for remote monitoring of on-site equipment.

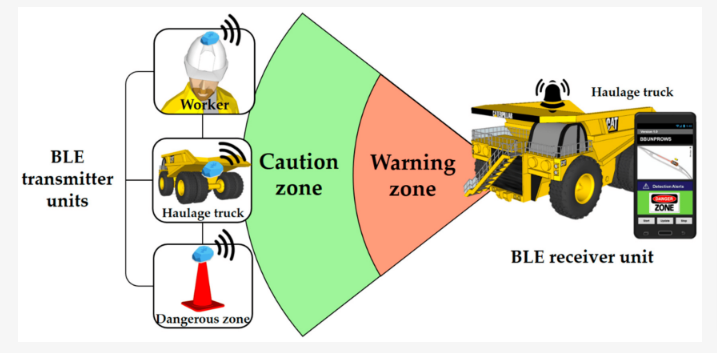

Another key advantage is that BLE systems can trigger alerts when an asset leaves the range of connected devices.

This feature is useful not only for asset security, though.

It’s also useful for broader safety applications, like access control or proximity warnings in active construction zones.

Source: MDPI

As for the downsides, limited range and signal interference from walls, metal, or electronics are the main concerns.

Strategically placed gateways can help overcome these challenges, but they do increase setup costs.

Overall, Bluetooth trackers are more expensive than QR codes, but still more affordable than the real-time GPS tracking solutions we’ll cover next.

GPS Trackers

For construction companies that need real-time location data, GPS (Global Positioning System) trackers offer unmatched visibility.

These devices use satellites—and sometimes Wi-Fi or cell tower triangulation—to pinpoint the location of vehicles, heavy machinery, and other high-value, moving equipment.

Unlike RFID and Bluetooth, GPS tracking works globally, providing continuous updates even across job sites, cities, or regions.

With the right hardware and software, you can monitor asset locations in real time, capture driving or engine behavior data, and more.

Source: GoCodes Asset Tracking

The main advantage of GPS tracking is real-time location visibility, which streamlines route navigation and helps prevent asset loss or theft.

Advanced trackers can also capture data such as speed, braking, idling, and engine hours, which are valuable for both compliance and maintenance planning.

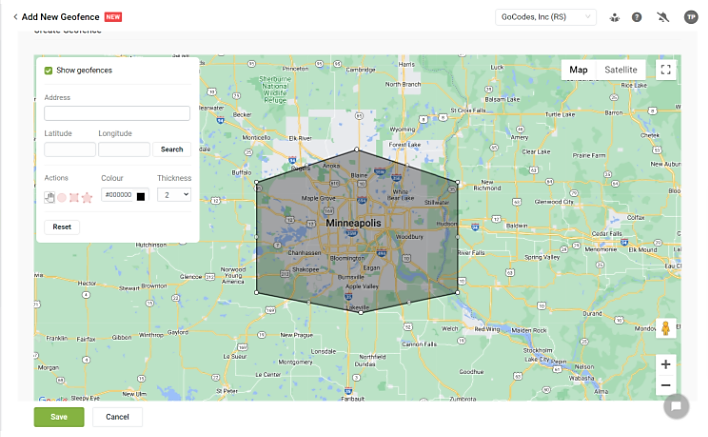

GPS tracking also enables geofencing, allowing teams to define virtual boundaries of any size—unlike Bluetooth-enabled geofencing—and receive alerts when assets move outside those zones.

Source: GoCodes Asset Tracking

Of course, GPS tracking does have some limitations.

Signal interference from mountains, tall buildings, or enclosed spaces like tunnels can affect accuracy.

It’s also worth mentioning that setup costs are higher than with Bluetooth or QR-based solutions, especially when tracking a large fleet.

And while GPS trackers provide location data, they’re often paired with QR code labels to support asset identification.

Still, for high-value or mobile assets, GPS remains the go-to solution for reliable, real-time location tracking.

Conclusion

So, which of these asset tracking methods is the best?

The truth is, no single method is best for all assets.

Instead, many construction businesses combine multiple technologies to balance cost, coverage, and functionality.

Ultimately, your decision should be guided by clearly identifying your tracking needs and then choosing a cost-effective provider that can ensure seamless integration across your chosen methods.