If you’ve landed here, chances are you want to know how your construction company can best track the movements, location, usage, and condition of various assets as they move across multiple jobsites.

These assets can include tools, equipment, heavy machinery, and vehicles, all of which need a different approach due to their varying requirements.

Secondly, if you’re struggling with lost, stolen, or poorly maintained construction assets that your company has to keep replacing, you likely want to minimize the negative financial and operational effects of such occurrences and maximize productivity.

With that in mind, we’ll explore the best ways to control the movement of your company’s assets, explain how each method works, and suggest how you can best use them to—easily, efficiently, and cost-effectively—track and manage all your construction assets.

In this article...

Using QR Codes

It could be said that good old one-dimensional, vertical-line barcodes, although still utilized by many companies that deal with storage and inventory, are becoming a thing of the past.

In contrast, quick response (QR) codes—which are similar to barcodes, but two-dimensional— have emerged as a more advanced, practical, and cost-effective asset-tracking solution.

As such, they are used by many asset-heavy companies, particularly in the construction industry.

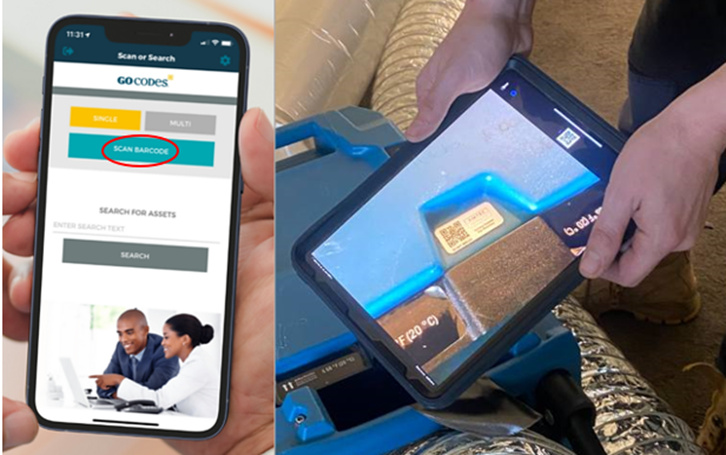

When tracking construction assets, QR codes have a major advantage over barcodes in that they can be instantly read in any size and at any angle using a smartphone, a tablet, or a handheld scanner.

Moreover, they can be scanned even when half of the QR code is missing.

That’s very practical for tools, equipment, personal protective equipment (PPE), and other assets used on jobsites under harsh conditions.

With that in mind, these QR code tags should be printed on durable, tamper-proof, robust labels that are firmly affixed to your tracked assets.

Now, let’s turn to how the asset tracking system works and how you can track and manage the movement of your assets using QR codes.

Simply put, to track where your tools and equipment are located and who is using them, you need three things, and only one of them can be considered “hardware”—the QR asset tags we just described.

The remaining two components of this tracking system—cloud software and the in-app scanner—are accessible through mobile devices you and your construction workers already use, such as smartphones and tablets.

Occasionally, dedicated QR code scanners may also be used to scan assets, while laptops and desktops are typically used to access the system’s online central database.

When these components are combined, the system will update the asset’s GPS position every time the asset tag is scanned and show it on a map.

In addition to tracking the asset’s GPS location, the software will record who scanned the tag and provide users instant access to asset information, from some general details to usage and maintenance history.

Overall, tracking construction assets using customizable, rugged QR code tags, cloud software, and in app-scanners are the simplest and most affordable tracking method described here.

The cost-effectiveness of this method stems primarily from having real-time access to the latest asset location and usage data using simple asset labels and devices you already have.

Even among just QR code/barcode-based asset tracking systems, some solutions require you to purchase on-premises software, dedicated scanners, and special label printers, all of which increase the price and complexity of company-wide implementation.

When an all-in-one, hardware-free, cloud-based tracking solution also comes with a quick system setup and minimal-to-no training requirements, launching the tracking system and onboarding employees is quick and painless.

Finally, the benefits of utilizing a QR code-based asset tracking system to control the movement of your construction assets include minimized asset loss and theft, higher employee accountability, better asset utilization at lower cost, and improved profitability.

Using Bluetooth Beacons

Bluetooth beacons are small, battery-powered devices that transmit Bluetooth signals at regular intervals.

These Bluetooth Low Energy (BLE) beacons with long-lasting batteries are attached to assets whose movements you want to track in real time.

The radio signals broadcasted by Bluetooth beacons are detected and received by Bluetooth-enabled devices, such as smartphones or tablets, equipped with the corresponding asset tracking app.

The range of your mobile device’s automatic detection of Bluetooth beacons is up to 300 feet (100 meters).

This means you can find (see their location on a map and follow the directions provided by the app) all assets on a jobsite or in storage that are within the range of your BLE-enabled device.

For example, our construction asset tracking app, GoCodes Asset Tracking, combines BLE-based asset tracking technology with the patented QR code asset tags we showed above.

By combining QR tags and Bluetooth beacons, GoCodes Asset Tracking enables you to take advantage of two affordable and easy-to-use asset-tracking solutions.

For instance, let’s say you tagged several pieces of high-value equipment, such as generators, cranes, and tower scaffolds, with BLE beacons.

These types of equipment represent just a few valuable assets often targeted by thieves due to their high cost and ease of resale.

In our example, the GoCodes Asset Tracking smartphone app will automatically detect and identify the assets and beacons when they appear in its range, and display their presence, distance, and other relevant data.

In the app, you can select any detected asset to view individual asset info, like when a smartphone or tablet scans GPS-enabled QR code tags without beacons.

Moreover, using the GoCodes Asset Tracking Guardian feature, you can instruct the app to send you text message alerts if a BLE-tagged asset leaves your phone’s Bluetooth range.

Using a single phone, this feature can act as your personal 300-feet geofence, i.e., an invisible security perimeter around the asset, that will alert you if that generator or excavator is taken out of range.

In its most affordable and practical use case, you could use one phone with the Guardian app as a stationary hub centrally positioned on the jobsite and receive alerts on another phone in your pocket.

Of course, this BLE-based real-time location tracking system and its capabilities can be scaled by workers and other on-site personnel using the app on their phones.

This turns their mobile devices into roaming BLE detection hubs, enhancing asset monitoring accuracy and coverage.

Finally, stationary BLE detection hubs can be strategically placed at key locations around the jobsite or storage space, such as entry points and large signal-blocking barriers, to extend the tracking system’s range and signal strength.

In summary, using Bluetooth-based tracking technology to control the movement of your assets is a cost-effective way to protect your high-value equipment on-site and storage with many applications and is easily scalable.

There is no manual scanning and no direct line of sight required, which increases the ease of use, allowing users to quickly and accurately locate where assets are and get real-time location updates and security alerts.

Using RFID Technology

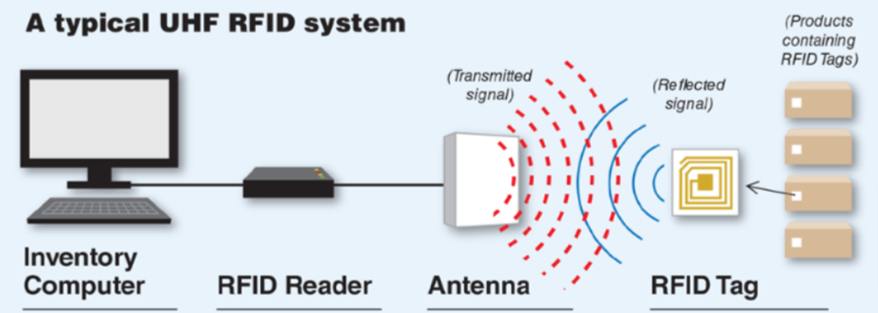

RFID (radio-frequency identification) technology can be used to control the movement of your company’s assets because RFID asset tags, once scanned, relay the location of the asset they are attached to by using radio frequencies.

That said, unlike QR codes and Bluetooth beacons (both using smartphones and tablets), this tracking technology requires handheld and/or stationary RFID readers, antennas, and network infrastructure.

For larger asset-tracking operations, RFID printers and encoders might be required.

As for its range, passive RFID tags are a close-proximity technology meaning that, although no line of sight is required, the reading device must be in close range to detect the RFID tag’s radio signal.

Conversely, battery-powered active RFID tags can be read from a distance of several hundred feet, depending on the environment in which they’re used.

That’s why RFID technology is used primarily in warehousing and inventory management operations.

Compared to QR codes, RFID tags can be placed inside an asset, thus ensuring they’re not damaged or tampered with.

Regarding scanning methods, both QR codes and RFID tags enable the simultaneous reading of multiple asset tags.

Compared to Bluetooth beacons, RFID tags are smaller and more affordable, particularly for large-scale deployments.

Overall, RFID-based asset tracking is best suited for large asset-tracking applications in controlled environments and requires more infrastructure and specialized infrastructure.

However, under these conditions, this technology can ensure accurate and real-time asset tracking, making it an efficient way to control the movement of your assets in a warehouse or on-site.

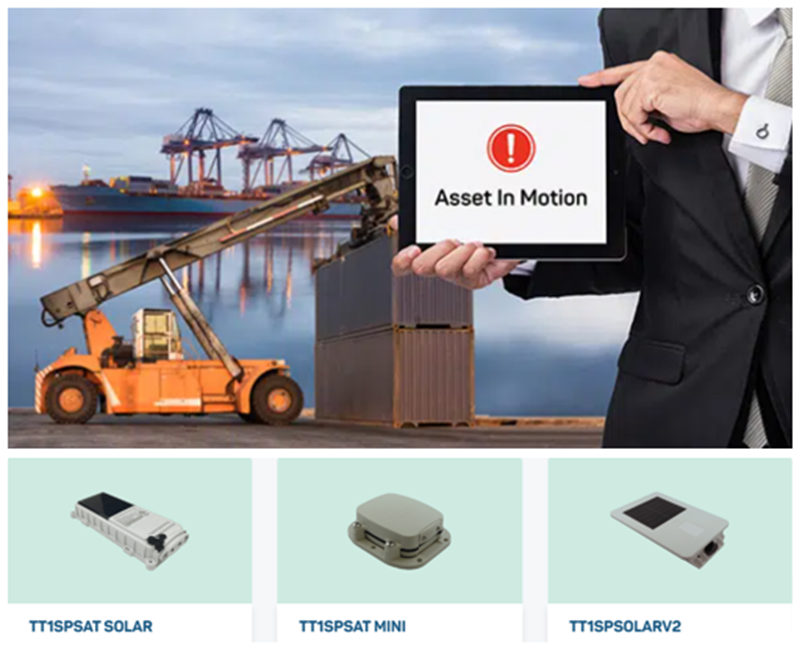

Using GPS Tracking

We’ve already mentioned GPS tracking, but that was passive GPS tracking using QR codes and the mobile device’s GPS function when an asset is scanned.

In comparison, active GPS trackers give construction companies real-time visibility into the movements of their assets anywhere in the world.

Simply put, GPS trackers (battery-powered or connected to the asset’s power source) use signals from satellites in the Earth’s orbit to determine their position and send it to the tracking app, which shows it on a map.

However, the price of active GPS trackers—and often their size—prevents them from being attached to all construction assets, so their use is usually limited to construction vehicles, heavy equipment, and other high-value items.

As the Global Positioning System (GPS) covers the globe, construction companies can track their equipment across multiple jobsites and any distance, making GPS a perfect navigation system available in many vehicles.

The benefits of active GPS tracking far exceed theft protection because it allows companies to collect valuable data leading to optimized route planning, reduced fuel consumption, and improved driver/operator accountability.

As said, some potential downsides are the price of trackers and the fact that the satellite signal can’t reach the GPS tracker indoors or underground.

In summary, GPS tracking gives you real-time control over the movement of your company’s assets, and active trackers are ideal for tracking vehicles, heavy machinery, and other valuable construction equipment.

Using Software to Check Your Assets in and Out

Now that we covered four different asset tracking methods—QR codes, Bluetooth beacons, RFID tags, and GPS trackers—let’s turn to two features of asset tracking software that enable you to control the movement of your assets.

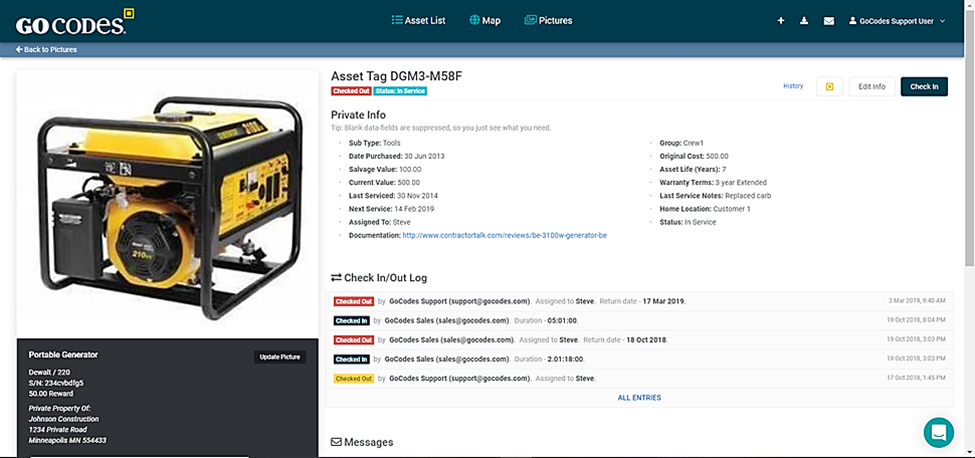

The first is asset check-in and check-out, which allows you to track who is responsible for an asset at any given time, whether the asset is in use or not, and if it has been returned on time.

This is achieved by requiring the company’s employees to check an asset out when they want to use it and check it back in when they no longer need it.

As such, this feature automates the process of workers taking and returning tools, equipment, and other items from the tool room or equipment yard.

The check-in/check-out function increases worker accountability and minimizes theft, misplacement, and careless handling of construction assets.

As for how the check-in/check-out system works, this feature is enabled when scannable QR codes or RFID tags are used to track assets, while Bluetooth beacons and GPS trackers would need to have additional QR code tags to be included in the system.

In any case, workers can check assets in and out in the tool room (either supervised or via self-service) or when they exchange them between themselves while on-site.

Managers can set due-back dates, so the asset’s user would receive overdue reminders if they fail to return the asset on time.

All in all, the asset check-in/check-out feature enabled by your tracking software helps you control your assets, assuring accountability and transparency and improving asset allocation, utilization, and maintenance.

Kitting Your Assets

The second feature that should be enabled by your asset tracking system is asset kitting.

This functionality helps you control the movement of your company’s assets by keeping track of grouped asset “kits” and their movement instead of tracking every individual asset separately.

In other words, you can prepare a group of tagged tools and equipment and put them in a container that is also labeled.

Now the whole container with the tools and equipment inside can be treated and tracked in the system as a single unit, which helps with asset allocation, transport, and scheduling as part of wider construction operations.

When creating a kit in the tracking software, keep in mind that the kitted assets (i.e., their tags) will no longer be treated as individual assets until they’re removed from the “digital kit.”

To sum up, asset kitting is a practical feature of your tracking software that allows you to control the movement of company assets that are frequently stored, transported, and used together by enabling you to group them and track their movement as a single unit.

The benefits of asset kiting are reflected in improved asset allocation and scheduling and easier asset check-out and transport to the construction site.

Conclusion

Having covered the six best ways to control the movement of your company’s assets, it’s evident that, depending on your specific needs and budget, you should find the right tracking combination that helps you address your biggest asset management pain points.

Secondly, you should consider using an optimal mix of low-cost asset tracking methods (QR codes), mid-priced remote tracking solutions (Bluetooth beacons or RFID), or higher-cost global GPS tracking.

At the same time, you should utilize the two tracking software features that allow you to strengthen control over who is using your company’s assets and when.