Whether you work in construction or not, you’re well aware that diesel and gasoline prices are much higher than they were a year ago.

And fuel is one of the key costs for any business operating a fleet of vehicles and equipment, not only in the construction industry.

As a result, companies across the U.S. and the globe are rethinking their fuel management practices and implementing different measures to combat rising fuel prices.

Here are eight tips that can help your construction business do the same.

In this article...

Add Fuel Surcharges to Construction Contracts

One way to protect your business from rising fuel prices is to offset higher fuel costs through additional fees in your construction contracts—but it’s important to be transparent about it.

With diesel fuel prices going up by 55% and gasoline prices by 49% in the first half of 2022, more and more companies are forced to transfer these price increases to their clients.

The main reason is that, in addition to the obvious higher transportation and operating costs, rising fuel prices also affect other aspects of construction operations, such as the price of construction materials and labor.

In a situation like this, companies have a few options: they can reduce their profit, raise their overall contract price, or pass along additional fuel costs to customers.

They can do the latter in the form of a fuel surcharge, i.e., an additional fee added to the current contract rate when the cost of fuel exceeds a defined amount.

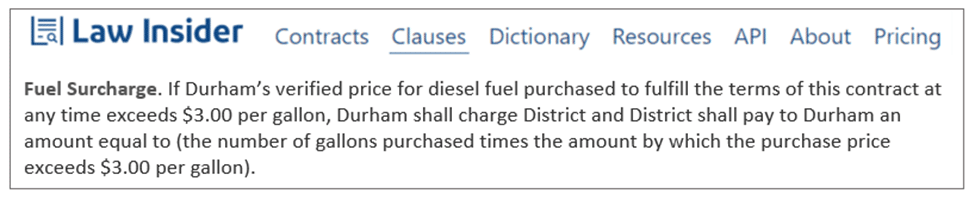

For example, this is how a fuel surcharge clause can be formulated, courtesy of LawInsider:

As you can see, if the price of fuel exceeds the specified amount, the client will be required to pay the difference.

Mind you, this is an example from a few years ago when a gallon of diesel fuel was around $3, whereas, in October 2022, the cost was significantly higher.

When fuel surcharges are compared to the overall increase in contract prices, some companies see them as a fairer and more transparent option for their clients, especially when a surcharge is based on clear criteria and publicly available data.

In summary, adding some form of a fuel surcharge to your construction contracts can help protect your business from rising fuel prices.

Search for the Best Fuel Prices

Even when contractors have an established business relationship with their fuel supplier, there is still nothing wrong with window shopping, comparing prices, and taking advantage of cost-saving opportunities.

For example, finding out that another fuel supplier offers lower fuel prices enables you to raise this issue with your current supplier and discuss whether they have some additional costs the other supplier might have omitted in their offer (but may still charge you for them).

Following that, you can ask your supplier for a loyalty discount that would get you the same or lower fuel price as the competition. Or you might even consider switching to a new fuel supplier.

On the other hand, if you’re a small contractor with no particular fuel supplier who is buying fuel at retail prices, there are mobile apps such as GasBuddy, that can help you identify the lowest price in your local area.

Although this and similar apps can save costs when fueling at retail, most construction businesses will prefer to take advantage of discounted prices as well as other perks offered by their contracted fuel supplier.

When searching for a fuel supplier, contractors should consider factors other than just the offered price per gallon.

These factors include fuel quality, efficient delivery and jobsite fueling, and potential quantity and loyalty discounts.

Overall, regardless of whether you’re considering switching suppliers or just want to keep your current one on their toes, searching for the best prices is always a good way to combat the rising fuel prices.

Plan the Most Efficient Driving Route

Planning the most efficient driving route can also generate fuel savings for contractors.

The most efficient driving route should be the shortest one that avoids rough terrain and traffic congestion, both of which result in higher fuel consumption.

For example, dispatchers or drivers usually avoid hilly routes when transporting heavy equipment from site to site to save fuel, but the same can apply to medium and light-duty vehicles if the detour is not too long.

Of course, when planning driving routes, there are many parameters to consider that can change in real-time, such as a traffic jam caused by a traffic accident or an unexpected detour to pick up workers or materials.

So, to improve their planning, construction businesses can use route optimization software with real-time GPS tracking, like RoadWarrior.

This and other similar apps enable contractors to calculate the shortest driving route and combine trips, provide alerts to drivers and dispatchers about traffic congestion, and allow them to make adjustments based on traffic information.

Naturally, all these features let you plan the most efficient driving routes and modify them in real time, thus lowering fuel consumption and generating significant cost savings.

Encourage Mindful Driving

Another way for construction companies to combat the rising fuel prices is to encourage their drivers to be mindful of the way they’re driving to minimize fuel-wasting behaviors.

For example, the U.S. Department of Energy states that reducing vehicle speed by 5 to 10 mph can lower fuel consumption by 7%-14%.

Moreover, when keeping the speed limit is combined with gradual acceleration to avoid high torque and anticipating traffic to avoid harsh braking, fuel consumption can be reduced even further.

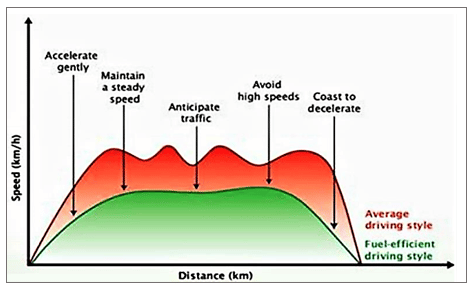

So, to encourage mindful driving, here are some fuel-efficient driving techniques and their effects on fuel economy when compared to the average driving style:

For instance, when drivers go 12 mph over the 60 mph speed limit, they’re not only jeopardizing road safety and risking a speeding ticket, but also increasing fuel consumption by about 20%.

Moreover, fuel economy will decrease by the same percentage if a driver frequently varies the vehicle speed.

Drivers should also be conscious about using the AC, as it can increase fuel usage by as much as 25%.

However, driving with the windows rolled down (to avoid turning on the AC), especially on highways, also reduces fuel economy due to drag and increased resistance.

Thus, drivers should be advised to use the AC (recirculate option is more economical) with the windows up when on highways and to roll down the windows without the AC when in the city.

Overall, contractors can achieve significant fuel savings by instructing their drivers on how to minimize fuel-wasting behaviors and implement a fuel-efficient driving style.

Reduce Vehicle Idle Time

Another mindful driving method that deserves its own section is aimed at reducing vehicle idle time.

An engine that is left running for no productive reason wastes fuel.

This goes against the persisting myth that idling is better for the engine than restarting it, which may have been true for older vehicles.

However, the starters and batteries of today’s vehicles are more durable, so they don’t suffer damage when turned on and off.

Moreover, over 10 seconds of idling for personal vehicles (15 seconds for medium and heavy-duty vehicles) will spend more fuel than turning the engine off and restarting it, as evidenced by a report from the U.S. Department of Energy.

Another common myth is that when a vehicle is turned on, it should idle for a while to warm up.

Again, modern vehicles (and their fuel consumption) are better off if the driver starts the engine and drives at a slow speed to warm it up when temperatures are low.

Hence, instructing drivers on how to reduce idle time whenever possible is another mindful driving method that can help you achieve fuel savings.

Track Fuel Spending With Fleet Management Software

Tracking fuel spending with the help of fleet management software that uses in-vehicle telematics devices to monitor vehicles and heavy equipment is a very efficient way to optimize fuel usage across your construction fleet.

We should first explain that telematics systems use in-vehicle sensors (which can come preinstalled with a vehicle/equipment or be installed later) to track and collect a range of data, such as vehicle location, speed, engine performance, driver behavior and, of course, fuel consumption.

Conversely, fleet management software aggregates and analyzes all of this data to provide contractors with insights into how they can manage their fleet more efficiently.

Here’s how Teletrac Navman presents its fleet management software in a short video.

Users of such software can use the insights gained to develop driver training plans, i.e., encourage mindful driving we covered above, and to improve fleet maintenance, which we will cover below, both of which can generate fuel savings.

Therefore, investing in this or similar fleet management software enables construction companies to track fuel spending and understand how their vehicles and heavy equipment are used to make fuel-saving improvements.

Keep Your Fleet Properly Maintained

The next tip for combatting the rising fuel prices focuses on keeping your fleet properly maintained to retain optimal fuel usage.

That’s because poorly maintained vehicles and heavy equipment tend to spend more fuel.

For instance, bad spark plugs can raise fuel consumption by as much as 30%, while under-inflated tires can add another 4% to fuel costs.

This means that contractors can improve fuel economy by regularly changing oil, performing other preventive maintenance, and keeping engines tuned.

As mentioned in the previous section, fleet management software can also improve the maintenance of your fleet by tracking various vehicle, driver, and engine parameters.

However, there are other simple and affordable cloud-based apps that can help you track, schedule, and manage fleet maintenance, automate field service requests, and even track the inventory of consumable items such as engine oil or spare parts, like GoCodes Asset Tracking does.

Thus, it’s clear that different software solutions used by contractors to improve other aspects of their operations can also be utilized to help keep your fleet properly maintained.

Regardless of what solutions you opt for, remember that regular vehicle and heavy equipment maintenance can discover problems that could cause higher fuel consumption and allow contractors to address them on time.

Upgrade to Vehicles With Better Fuel Efficiency

Finally, construction companies with an older fleet might find it more profitable to upgrade their vehicles and heavy equipment to save on fuel.

Naturally, as technology progresses and environmental and sustainability issues increasingly come into focus, manufacturers are producing vehicles and construction equipment with better fuel efficiency.

Likewise, the same factors led to the development of electric-powered vehicles and equipment that are more energy-efficient and eco-friendly than their fuel-guzzling counterparts, so contractors should also consider them when upgrading their fleet.

However, there are other avenues they can explore to cut fuel costs, such as hybrid vehicles and alternative fuels such as compressed natural gas (CNG).

For example, as SkyCNG advertises, you can save on fuel and reduce your emissions by converting your vehicles and trucks to run on clean-burning and more affordable CNG.

So, other than replacing their older vehicles with newer fuel-powered or electric vehicles, contractors should consider converting them to CNG, whose price is currently more than 50% cheaper than diesel.

Thus, contractors with an older fleet who want to cut fuel costs can upgrade their vehicles and heavy equipment to newer, more energy-efficient models, including electric-powered ones, or convert them to use less expensive alternative fuels.

Conclusion

In the end, even though fuel prices have gone up and might continue to do so as the world faces an uncertain future, there are plenty of things you can do to combat the rising fuel prices.

We hope this article inspires you to apply one or more of these tips to benefit your construction business.