Key Takeaways:

- Fleet managers’ responsibilities continue to expand, driven by evolving regulations.

- Organization, communication, and adaptability lie at the heart of fleet management.

- Modern tools provide the data and insights to navigate operational challenges.

As technologies evolve and processes improve, the role of a fleet manager has become increasingly complex and dynamic.

Today’s fleet managers must master a wide range of technical and people skills.

They have to be great organizers, strong communicators, and adept multi-taskers capable of navigating technology, regulations, finances, safety protocols, and environmental standards.

In this article, we’ll explore eight key qualities that define a great fleet manager.

In this article...

Great Organizational Abilities

Excellent organizational skills are the primary trait of successful fleet managers across many industries.

However, this is even more pronounced in the construction industry, where schedules and workflows are often complex and interdependent.

A fleet manager must coordinate multiple moving parts to ensure that one or several parallel projects stay on track.

To illustrate, consider just some of their core organizational responsibilities in a construction setting:

- coordinating with project managers to align fleet availability with construction timelines,

- scheduling vehicle and equipment usage, and assigning qualified drivers and operators,

- planning preventive maintenance while managing unexpected breakdowns.

And that’s just the beginning.

The job description and top five responsibilities for a fleet manager at an offshore wind equipment company, shown below, highlight the breadth of this role.

While fleet management in the offshore wind sector comes with unique challenges, so do many construction projects.

This is why the listed responsibilities closely align with the organizational tasks typically handled by construction fleet managers.

It all underscores the importance of strong organizational skills for success in this role.

Without a fleet manager’s meticulous planning and the ability to coordinate resources in real time, downtime, project delays, and cost overruns could quickly spiral out of control.

Conversely, their effective organization ensures seamless fleet operation, minimizing disruptions and maintaining productivity on construction sites.

Some individuals may naturally excel at organizing, but a great fleet manager can also hone these skills by leveraging the right combination of methods and tools.

As we’ll see next, this also applies to their communication.

Strong Communication Skills

Clear and effective communication is the hallmark of a successful fleet manager.

Why?

Because they must excel at conveying their thoughts clearly to a wide range of stakeholders, including:

- top managers, from the owner or CEO to CFO and COO,

- departments like operations, finance, safety, legal, HR, and IT,

- drivers, equipment operators, service technicians, and site managers,

- suppliers, subcontractors, external inspectors, and regulatory officials.

Each group requires tailored communication, from offering suggestions to issuing requirements and instructions.

Tony Eiermann, a fleet manager with over 15 years of experience, emphasizes the importance of building close relationships with internal departments.

He says his two biggest partners were the safety and finance departments.

Equally important is communication with on-the-ground staff, such as drivers and operators, who form the backbone of fleet operations.

Effective communication minimizes misunderstandings, ensures safety protocols are followed, and fosters collaboration across teams.

A big part of having strong communication skills is listening.

This is why great fleet managers actively listen to their crews and address their concerns.

This approach not only builds trust and engagement but also boosts morale, leading to safer and more efficient operations.

Michael Duda, who manages a fleet of medical service vehicles, encapsulates this key takeaway for all companies operating extensive fleets:

He adds that this engagement leads to better fleet maintenance, as people look after the company’s resources and equipment more, and treat it as their own.

Duda’s quote makes clear that, by mastering verbal and written communication and encouraging open dialogue, fleet managers can create a culture of trust and collaboration.

This includes clear reporting channels, regular team check-ins, and other appropriate methods and tools.

Next, we’ll explore the tools that can help you with that.

Proficiency in Fleet Management Technologies

A modern fleet manager’s role is inseparable from proficiency in fleet management technologies.

Tools like GPS tracking, telematics, and maintenance software empower managers to monitor vehicle performance, optimize routes, and schedule upkeep effectively.

These technologies also facilitate communication, ensuring everyone stays informed and aligned.

For instance, real-time GPS trackers on vehicles provide fleet managers with valuable insights into asset locations, movement, and condition.

Here’s an example of what GoCodes Asset Tracking’ trackers and tracking app offer:

These trackers are quick to install—whether battery-powered or connected to a vehicle’s power source—and the accompanying tracking app is easy to master and use.

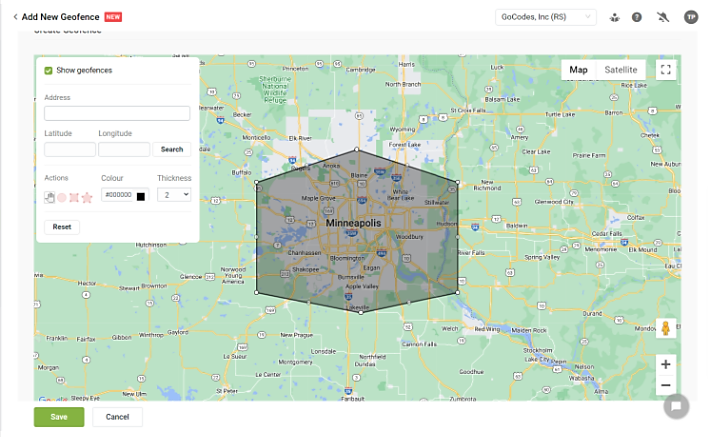

GPS tracking enables fleet managers to set up invisible fences (geofences) around job sites or storage yards to prevent theft and unauthorized use.

If a vehicle or piece of equipment leaves the designated area, the manager is immediately alerted, allowing for prompt investigation and action.

Additionally, since GPS trackers are equipped with their own sensors or can be connected to onboard vehicle/equipment sensors, this creates an integrated telematics system.

These trackers collect sensor data and transmit it to the tracking app, enabling fleet managers to monitor driver behavior and detect equipment issues.

But this requires you to become familiar with the software accompanying these trackers, so you can set up the perimeter, optimize routes, or analyze data gathered from telematics.

You should also be able to teach others how to use such solutions, check-in or out at work, thereby fostering a culture of cooperation and technological efficiency.

Another thing fleet managers need to be proficient in is financial management.

Financial Management Skills

A fleet manager in construction must budget for vehicle maintenance, fuel costs, and equipment upgrades while minimizing unnecessary expenses.

This ensures cost-effectiveness, maximizes profitability, and prevents project budget overruns due to unexpected fleet expenses.

To manage costs effectively, a manager needs to understand key concepts like budgeting, cost control, and equipment lifecycle.

One key aspect of making informed decisions about when to replace vehicles and equipment is depreciation.

Most fleet management solutions will assist managers in understanding how assets lose value over time by providing them with a depreciation calculation tool.

Fleet managers should also understand cost-benefit analysis, fuel efficiency strategies, and lifecycle cost calculations to optimize spending.

Of course, managers can address any gaps in knowledge or experience through professional development programs, mentorships, and various online and offline courses.

What is the best practice for fleet managers whose financial management skills need honing?

Regular consultations and close collaboration with the finance team.

Commitment to Safety

Someone who prioritizes cost-savings or speed over safety is exactly the opposite of what a great manager should be.

In other words, a fleet manager must always put safety first.

Legally, they are responsible for enforcing safety protocols and ensuring that vehicles and equipment comply with industry standards and safety regulations.

This proactive approach helps avoid costly legal liabilities and penalties related to both in-transport and job-site accidents and injuries.

More importantly, focusing on safety prevents accidents, protects employees, and ultimately saves lives.

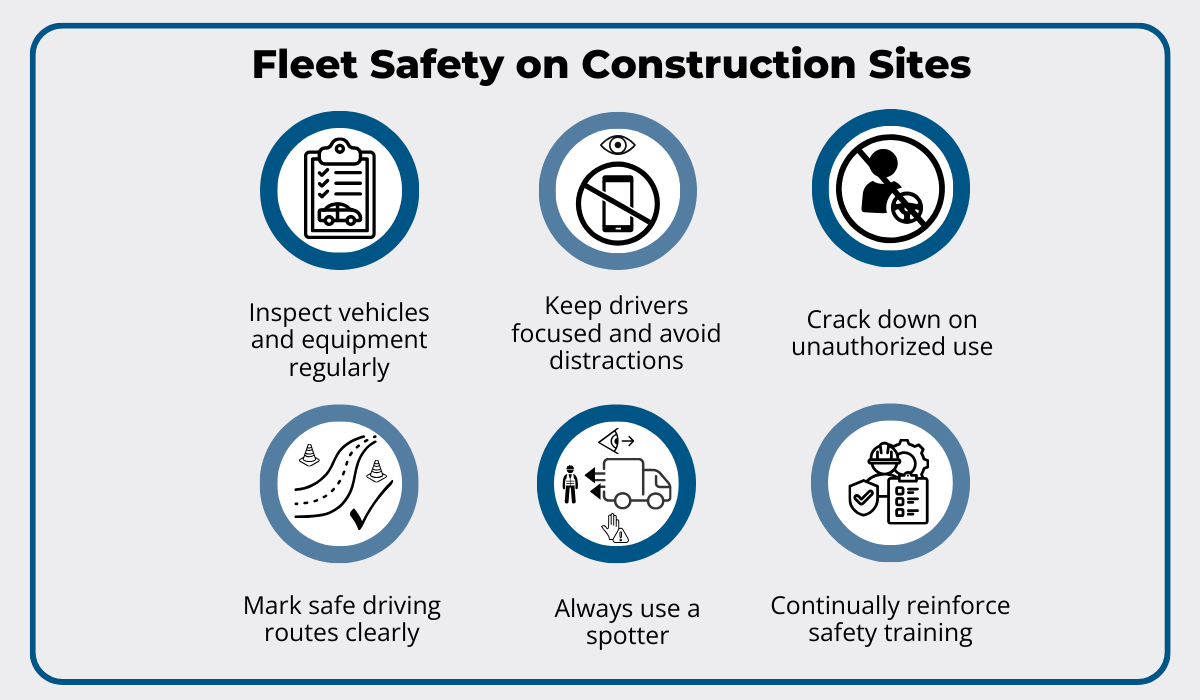

Here are some important safety tips managers whose fleets work on construction sites should keep in mind, courtesy of Weifield Contracting:

Along with these on-site tips, fleet managers must ensure that:

- drivers and operators are adequately trained and certified,

- local, state, and federal safety regulations are consistently upheld,

- a safety-first culture is actively promoted and practiced,

- safety protocols are updated regularly to reflect regulatory changes.

Given all these safety-related responsibilities, fleet management technologies prove invaluable in regard to safety as well.

So use them to your advantage and ensure your colleagues are safe and protected at work.

Analytical Skills

Regardless of their fleet size and record-keeping methods, fleet managers must be able to analyze data from fleet operations.

That’s how they can identify inefficiencies, predict maintenance needs, and optimize fleet deployment.

Say you are reviewing fuel consumption data.

You might notice that certain equipment consistently consumes more fuel than others performing similar tasks.

This could indicate maintenance issues, excessive idling, or inefficient operating habits.

From there, you can identify the root cause and address it.

Fortunately, managers no longer need to rely on spreadsheets or manual methods for data analysis.

Instead, they can use reporting features offered by their fleet management tools.

For example, in GoCodes Asset Tracking, users can create various reports customized to their specific needs, and create easy-to-understand visual dashboards, like the one you can see below.

Leveraging user-friendly tools and their automated analytics features can simplify complex data interpretation, giving managers a boost in their analytical expertise.

By extracting actionable insights from fleet data, managers can make data-driven decisions that reduce downtime, improve efficiency, and enhance overall fleet performance.

Just like with finance, gaps in analytical skills can be overcome through close collaboration with other team members and departments, training sessions, and mentorships.

Adaptability

Adaptability is a vital skill for fleet managers, enhancing organizational and communication abilities and influencing every other trait.

Why?

Because fleet managers must respond swiftly to a range of day-to-day challenges, such as:

- changing project demands,

- vehicle and equipment breakdowns, and

- unforeseen challenges on the construction site.

A tell-tale sign of a highly adaptable manager is smooth fleet operations and quick resolutions to disruptions.

This indicates that the manager has the right tools, mechanisms, and practices in place to effectively handle challenges.

If you’re a fleet manager, self-reflection and feedback can provide deeper insights into your adaptability.

Here’s what Bonnie J. Kain, maintenance planner at Nestle, recommends:

She continues by suggesting that the insights gained from this exercise can help you identify areas for improving adaptability.

This could involve embracing new technologies or being more open to different approaches.

Again, there are various strategies that can help fleet managers become more adaptable.

Along with a strong team, the right methods and tools empower a great manager to respond quickly to challenges and keep operations running smoothly.

Environmental Awareness

Lastly, a great fleet manager is keenly aware of the detrimental effects construction fleet emissions have on human health and the environment.

To promote sustainability, skilled fleet managers take measures such as:

- installing telematics sensors to monitor emissions and fuel usage,

- reducing excessive idling and other wasteful driving behaviors,

- incorporating fuel-efficient vehicles (alternative fuels, electric, hybrid).

This last point is confirmed by Abby Roberts, a sustainability program manager at Turner Construction:

She adds that they are seeing the biggest adoption in mini excavators and battery energy storage systems.

But how else can an environmentally aware manager enhance fleet efficiency and sustainability?

By utilizing tools like sensor-enabled GPS trackers we mentioned.

These telematics devices enable fleet managers to:

- monitor driver behavior, including speeding, idling, and harsh braking,

- optimize route planning to minimize unnecessary detours,

- provide real-time rerouting based on traffic conditions or as needed.

Overall, a quality fleet manager takes proactive sustainability measures, benefiting the environment, workers, and the company.

Conclusion

Naturally, every manager has strengths and weaknesses.

But you can build on your advantages and address gaps through teamwork, technologies, and continuous learning.

As technologies and processes evolve, so will the role of fleet managers, making these skills even more essential for navigating future challenges and driving success.