Key Takeaways:

- Truck fleet telematics makes it possible to enhance driver safety, optimize fleet operations, and reduce costs.

- It minimizes fuel wastage by encouraging fuel-efficient driving habits.

- The data provided by truck fleet telematics helps prevent unexpected breakdowns and costly repairs.

We can all agree that construction is an industry where time, resources, and safety are paramount.

A big part of this pertains to the fleet of trucks, vehicles, and heavy equipment constantly moving between storage yards and often multiple worksites at once.

To handle the complexities related to fleet management, construction companies are increasingly turning to advanced tracking technologies, i.e., telematics.

This sophisticated integration of telecommunications and informatics offers numerous advantages that translate into improved efficiency, cost savings, and enhanced safety.

In this article, we’ll delve into five key benefits of truck fleet telematics and explore how your business can profit from them.

In this article...

Increases Operational Efficiency

Before we go into how telematics can lead to increased efficiency in fleet scheduling, routing, and utilization, let’s quickly explain what telematics is.

To do that, we’ll break telematics down into three levels while noting that the line between them is becoming more blurry as technology advances and more features become standard even on lower-cost devices.

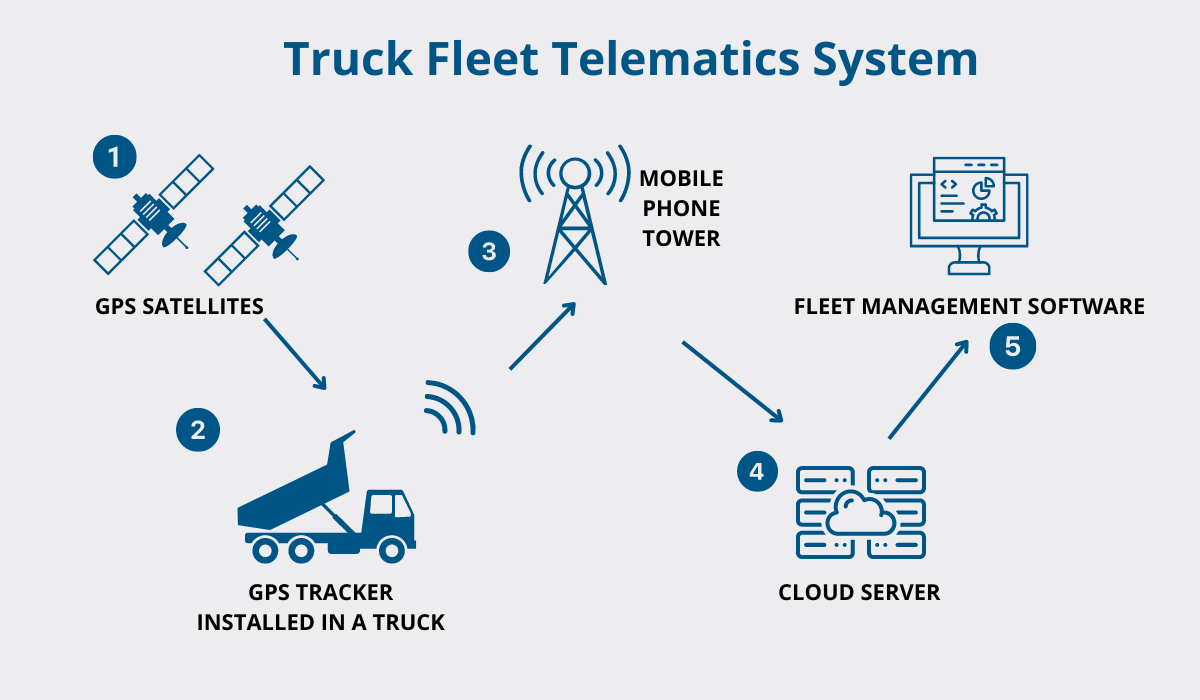

The first, simplest level is when GPS trackers are installed in your vehicles.

These telematics devices use satellite signals to pinpoint in real time where a vehicle is and in which direction it’s going.

Here’s a simplified scheme of how this—and other telematics sophistication levels—works.

The second level is when that GPS tracking device has its own internal sensors (like an accelerometer), which enable it to also tell you, for example:

- the truck’s speed,

- how long the engine is turned on, and

- whether the truck was exposed to sudden accelerations or harsh braking.

The third, most sophisticated level is when the GPS tracker is connected to your truck’s on-board diagnostics (OBD) and/or its external sensors (installed separately), allowing it to monitor almost any parameter like engine performance, fuel consumption, and tire pressure.

While each of these levels can help optimize fleet operations and increase efficiency, they will differ in price, complexity of installation, and how detailed the provided tracking data is.

That said, even the “simplest” GPS tracker will do the job when it comes to improving your fleet scheduling and routing.

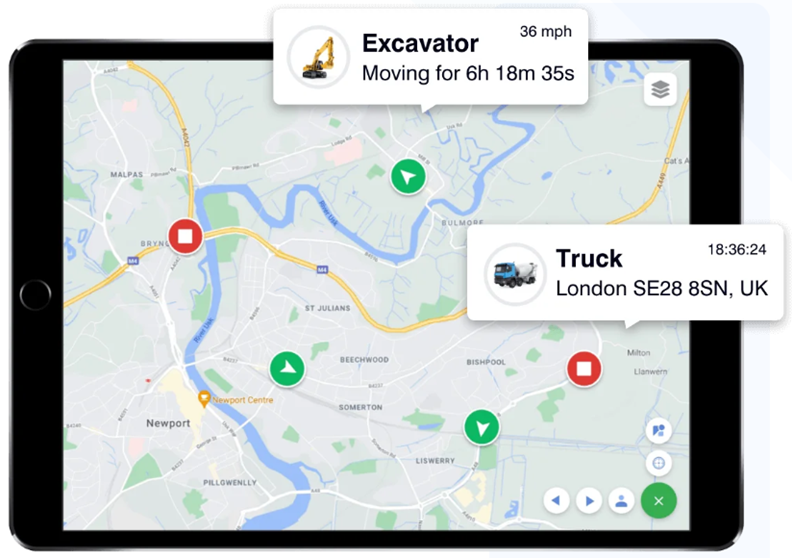

For instance, just the fact that you can see where all your vehicles are at any time allows you to quickly reroute one closest to the place where a previously unscheduled delivery of materials needs to be picked up.

Naturally, since you don’t need to dispatch another truck for that pick-up, this saves time and fuel (i.e. money), as well as increases operational efficiency.

Furthermore, by utilizing GPS trackers linked to route optimization software, dispatchers can optimize driving routes for maximum efficiency.

To do that, they can take into account the current traffic conditions (e.g., road closed due to works, weather conditions) and historical routing data in the software’s database.

They can also notify drivers in real-time to change their route if they’re heading towards, for example, a traffic jam.

Overall, when real-time data provided by telematics is combined with insights provided by fleet tracking software, this opens up a whole range of possibilities to increase operational efficiency, from improved scheduling and utilization to dynamic routing.

Helps Monitor Driver Performance

By utilizing telematics to track various aspects of driver performance, construction companies can not only enhance safety but also optimize fleet operations and reduce costs.

One of the benefits of monitoring driver behavior is the ability to identify and address risky driving habits.

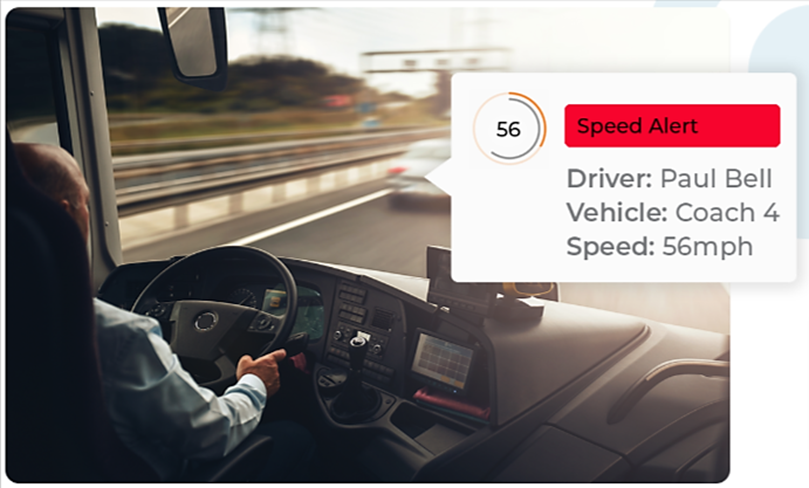

For example, a telematics system can detect instances of speeding, harsh braking, aggressive acceleration, and other unsafe behaviors in real time.

Depending on the system, such driver actions can be recorded automatically, so the fleet manager can analyze them and, in case of a driver’s consistently risky behavior, provide instructions or coaching to improve driving habits.

Some systems can also provide real-time alerts to drivers when they engage in unsafe behavior.

This proactive approach helps mitigate the risk of accidents and reduces liability for your company.

Likewise, road-facing dashcams (RFDs) can also be used to alert drivers of impending risks, such as:

- tailgating (driving too close to another vehicle),

- sudden lane departures,

- pedestrians on road, and

- upcoming stop signs.

In a similar fashion, driver-facing dashcams (DFDs) can alert the driver about seat belt usage, and detect their fatigue or distracted driving actions, such as using their phone.

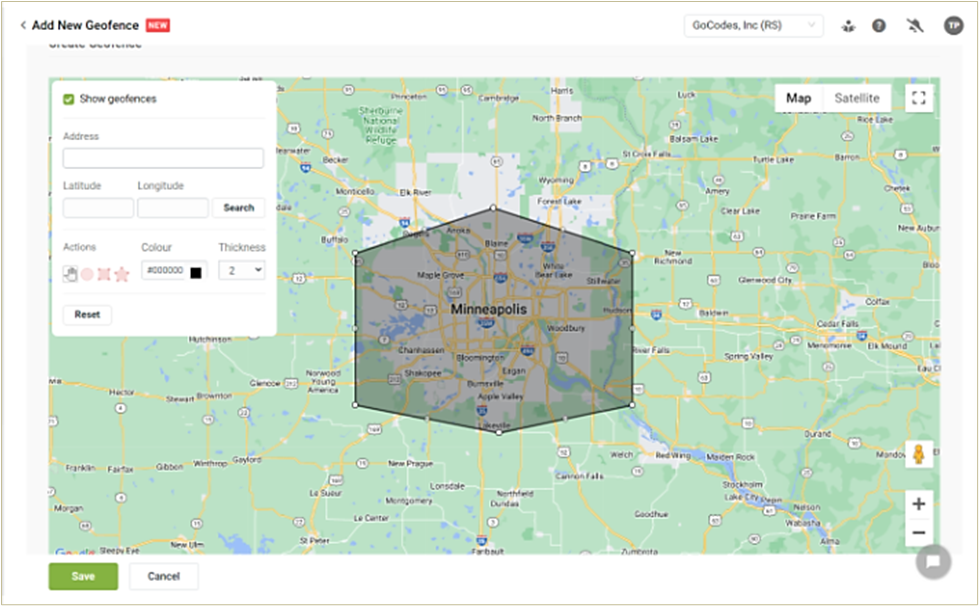

Another useful telematics technology is geofencing, which fleet managers can use to get alerts if a truck deviates from the designated route or enters a hazardous jobsite area.

For instance, you can use our real-time GPS tracking system, GoCodes Asset Tracking, to set up virtual boundaries alongside a truck route or a specific geographic area.

This ensures your drivers are adhering to their route or staying out of construction site areas designated as off-limits for trucks.

Additionally, geofencing can also be used as an effective security measure, alerting you if a vehicle leaves the predefined area, whether because it’s stolen or a driver intends to use it without authorization.

To recap, telematics tracking provides valuable insights into driver habits, efficiency, and productivity.

By analyzing factors such as risky driving behavior, idle time, route adherence, and time spent at each jobsite, fleet managers can identify opportunities to improve driver performance, making operations safer and more efficient.

Minimizes Fuel Wastage

Another major benefit of telematics is that it allows you to monitor fuel consumption and minimize its wastage by encouraging fuel-efficient driving habits.

With as much as 60% of a construction fleet’s budget typically spent on fuel, this is probably the area where effective measures can yield the highest cost-savings for construction companies.

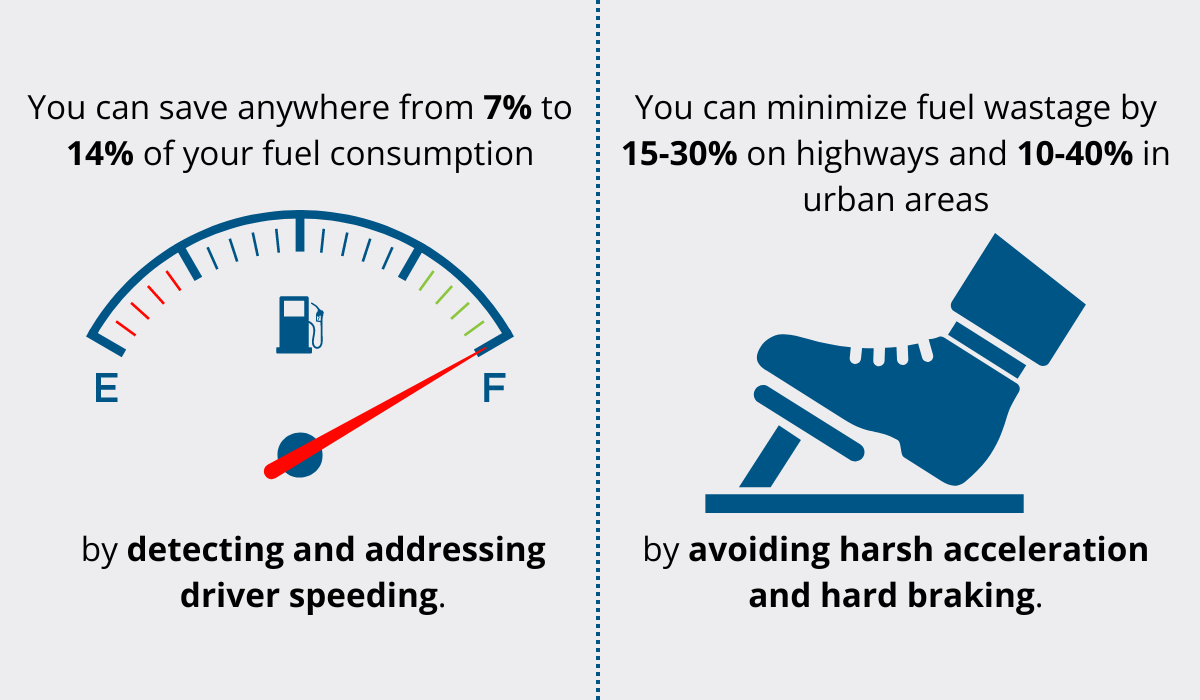

For instance, by detecting and addressing driver speeding, i.e., encouraging them to reduce their speed by 5 to 10 mph, you can save anywhere from 7% to 14% of your fuel consumption, as calculated by the U.S. Department of Energy.

The same source states that, by avoiding harsh acceleration and hard braking, you can further minimize fuel wastage by 15-30% on highways and 10-40% in urban areas.

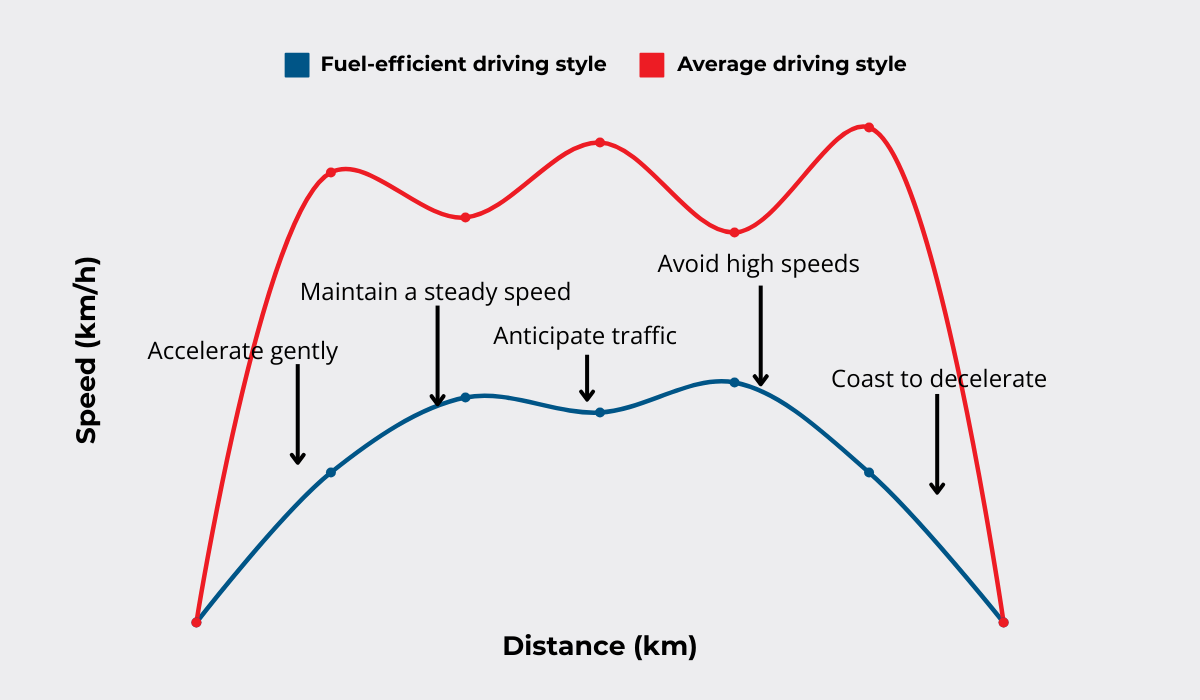

On that note, here is how fuel-saving driving techniques can affect fuel wastage compared to less mindful driving styles.

Another major fuel wastage area where telematics can help lower consumption is idle time detection.

In other words, internal or external engine sensors can identify when your trucks are idling unnecessarily—as opposed to instances where idling is required.

Armed with these insights, you can take appropriate measures (i.e., provide mindful driving instructions or training) to minimize wasteful idling and combat rising fuel costs.

For example, West Coast Sand and Gravel, which specializes in delivering construction materials in bulk and hauling off construction waste, utilized telematics to cut their fleet’s idling time by 37%.

This allowed them to save 5,205 gallons of fuel or about $18,000 in just three months.

To recap, telematics-enabled fuel consumption tracking and analysis can assist you in identifying inefficiencies and wasteful practices, ultimately leading to minimized fuel consumption and maximized fuel cost savings.

Assists with Preventive Maintenance

Telematics data enables proactive maintenance scheduling based on vehicle health and usage metrics, helping to prevent unexpected breakdowns and costly repairs.

By continuously monitoring various components and systems of construction vehicles, telematics provides valuable insights that enable fleet managers to stay ahead of maintenance needs.

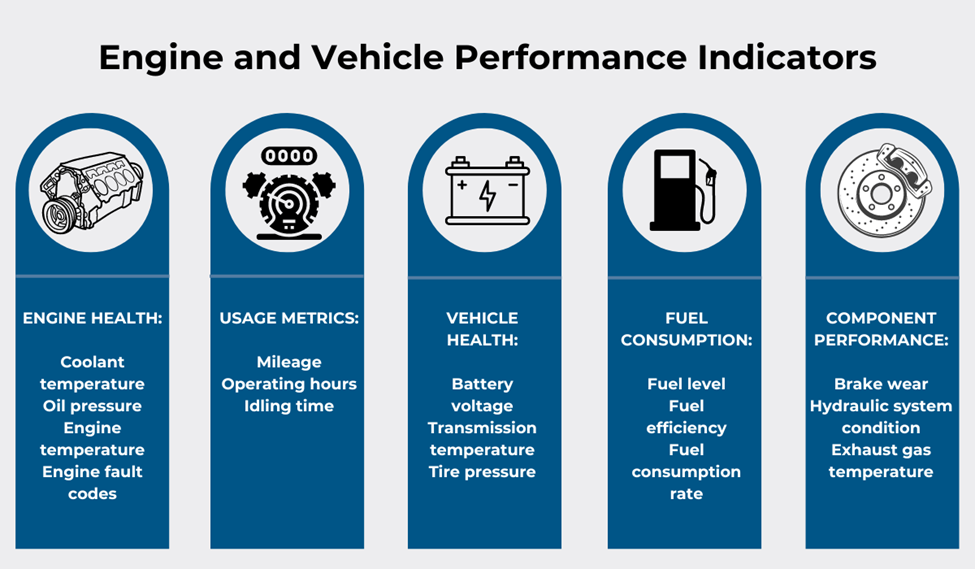

One critical aspect is the telematics ability to track various engine and vehicle performance indicators. This is done via internal on-board diagnostics or external sensors.

Here’s just a glimpse of what telematics can monitor:

By analyzing these parameters in real-time, fleet managers can identify potential issues before they escalate into major problems, allowing for timely maintenance interventions.

For example, if a telematics system detects a drop in oil pressure or an abnormal increase in engine temperature, it can trigger an alert prompting immediate inspection and maintenance to prevent engine damage or failure.

Moreover, tracking these metrics allows you to establish customized maintenance schedules tailored to the specific needs of each vehicle.

When mileage and engine hours are monitored, you can set up timely maintenance intervals to ensure optimal performance and reliability of high-usage vehicles.

This extends to the condition of critical components, such as brakes and hydraulic systems.

By detecting signs of wear and tear or abnormal operating conditions, telematics enables you to proactively schedule brake pad replacements or hydraulic fluid changes.

All this helps fleet managers minimize downtime, reduce maintenance costs, and extend the lifespan of construction vehicles.

Overall, preventive maintenance strategies supported by telematics empower fleet managers to maximize the uptime and efficiency of their vehicles while minimizing the risk of unexpected equipment failures and costly repairs.

Streamlines Communication

Telematics platforms often include communication features such as messaging and task assignment, which helps streamline communication between drivers, dispatchers, and fleet managers.

Such communication tools enable real-time collaboration and information exchange, enhancing operational transparency and responsiveness within the construction fleet.

Before the rise of telematics systems, contractors had to resort to less efficient and more time-consuming communication methods.

Brad Zimmer, manager at West Coast Sand and Gravel from our successful idle time reduction example, summed it up nicely:

After implementing a GPS tracking system with communication features, they were able to utilize messaging to communicate with their drivers more efficiently throughout the day.

More precisely, centralized communication within a telematics platform enabled them to streamline the conveying of important instructions, updates on job statuses, and any encountered issues or concerns.

For instance, dispatchers can now prioritize urgent tasks based on the vehicle’s proximity to the task’s location, thereby optimizing resource allocation and response times.

Additionally, since drivers can access their task assignments through a telematics system at any time, this reduces the risk of miscommunication or delays.

In summary, communication-enabled telematics allows construction companies to streamline workflows, minimize time lost on less efficient communication, and improve overall operational efficiency.

Conclusion

We’ll close by reiterating that the integration of telematics technology into construction fleet management offers a multitude of benefits that can significantly enhance your fleet’s productivity, safety, and cost-effectiveness.

From optimizing fleet routing and monitoring driver performance to minimizing fuel consumption and facilitating proactive maintenance scheduling, telematics empowers your company to streamline operations on all levels.

Therefore, embracing telematics represents a strategic investment in the future of construction fleet management, opening opportunities for increased efficiency and, ultimately, improved profitability.