In construction, just like in any business, there are only 2 ways to increase profits: charge more or spend less.

As raising prices in a competitive market is tough and usually just offsets rising material and labor costs, cutting costs becomes the smarter choice. And, since equipment is one of your biggest expenses, it makes sense to start there.

But how?

By reducing the total cost of ownership of your construction equipment.

In this article, we’ll walk you through our top tips for doing just that.

Ready to lower costs and increase profits?

Let’s get into it.

In this article...

Buy Quality Used Equipment from Reliable Vendors

When we talk about the total cost of ownership, we’re looking at everything that goes into the lifetime cost of a machine: acquisition, operation, upkeep, downtime and productivity loss, and eventually, resale or disposal.

| Cost | Description |

|---|---|

| Acquisition Costs | This includes the initial purchase price, taxes, financing fees, and any delivery or setup expenses related to getting the equipment ready for use. |

| Operational Costs | All expenses needed to run the equipment, such as fuel, labor, insurance, and any required training for operators. |

| Upkeep | Regular maintenance tasks like servicing, parts replacement, and repairs. |

| Downtime and productivity loss | The costs associated with equipment being out of service. This could be due to lost work time, renting substitutes, or delays in project timelines. |

| Disposal | Costs or potential gains when selling or disposing of the equipment. Depreciation affects resale value, while disposal may involve recycling or decommissioning fees. |

While many people focus on the maintenance and operating expenses that come later, it’s important to realize that TCO begins the moment you decide what to buy.

So, one of the first and easiest ways to lower your TCO is to spend less when buying.

Now, don’t get us wrong, new equipment is fantastic.

You get the latest features, no wear and tear, and it’s nice to know everything is under warranty.

But the price tag can be hard to swallow, especially when you’re trying to keep costs low.

That’s why buying used construction equipment is a much better choice.

In fact, purchasing well-maintained, used equipment can cost you 20% to 40% less than a brand-new one.

This is a huge difference, especially when it comes to heavy machinery.

Take a bulldozer, for example.

A new model could easily cost $500,000.

However, a used one in excellent condition might run you around $350,000.

That’s $150,000 saved right off the bat!

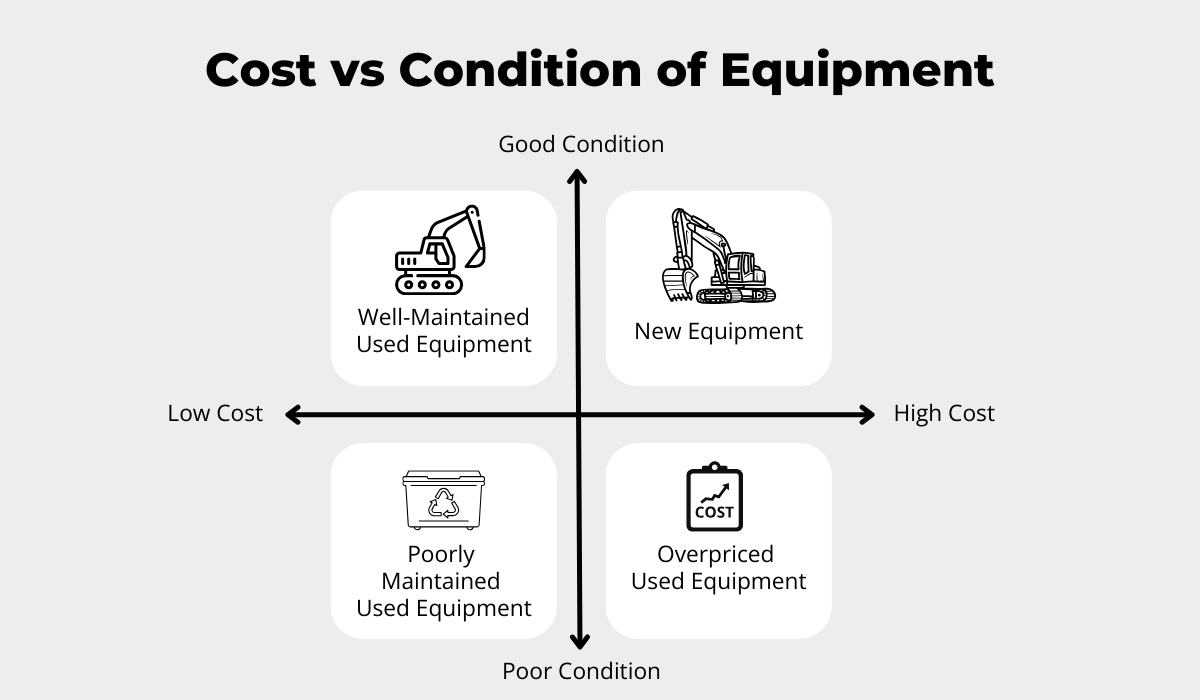

But, saving money by buying used construction equipment only works if the equipment you buy is in good shape.

Otherwise, savings on the purchase price could be easily eaten up by higher maintenance and repair costs.

So, to make sure you’re not throwing money away on a machine that will cost you more in repairs and downtime than you would spend on buying a new one, here are two tips to keep in mind:

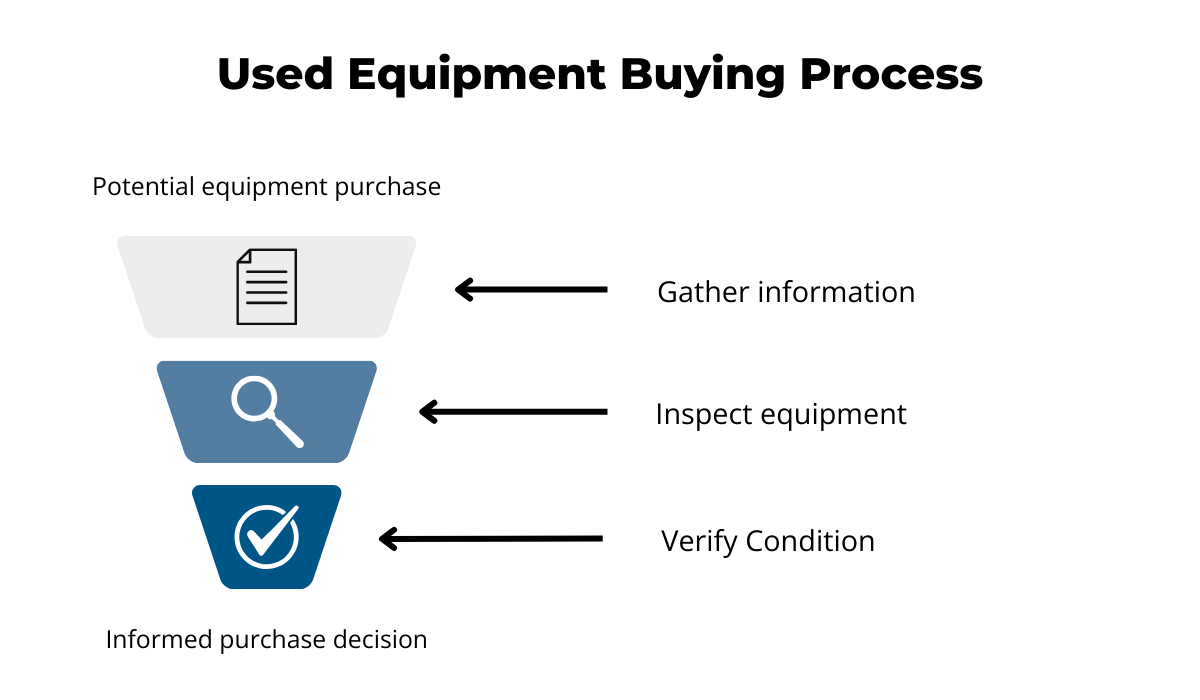

First, buy from vendors with transparent maintenance programs and equipment documentation.

When buying used equipment, look for reliable vendors that provide complete maintenance records and a full equipment history.

You want documentation that proves the machine has been properly maintained and hasn’t suffered heavy damage or neglect.

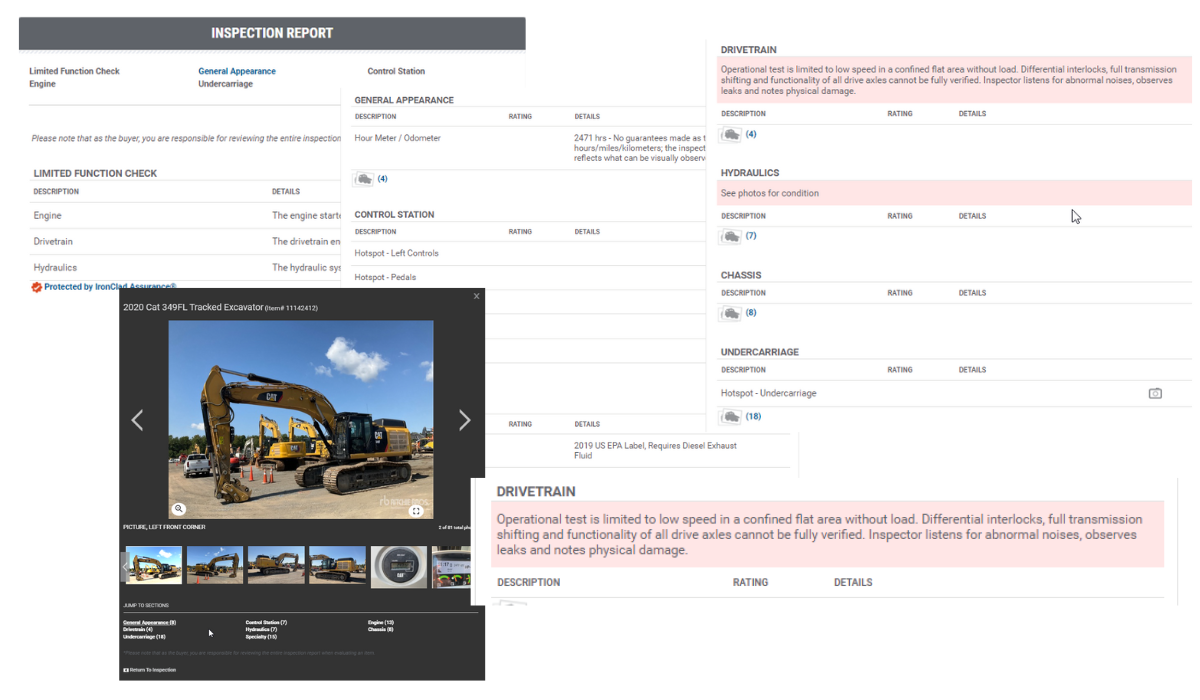

For example, reputable dealers like IronPlanet or Cat Used are known for their transparency in maintenance programs and detailed equipment documentation.

These companies often provide inspection reports and offer guarantees that give you peace of mind.

Some vendors even allow third-party inspections, so you can be sure of what you’re getting.

Speaking of which, the second thing is to do a thorough inspection.

When buying used equipment, you need to be as informed as possible and while reputable buyers will provide all the information about the machine, it’s always good to take the time to inspect used equipment and verify the condition of it.

This will prevent you from racking up massive repair bills down the road. It also helps you avoid the headaches of dealing with unreliable equipment that breaks down more often than it works.

The bottom line is that spending less upfront is great, but only if you’re sure the equipment will last.

Track Equipment Utilization

As most of you reading this already have equipment in place and lowering your total cost of ownership by spending less upfront isn’t an option, let’s focus on what is – getting the most out of the equipment you already have.

Here’s the reality: equipment that sits idle doesn’t make you money.

Even worse, it’s quietly adding to your costs.

It takes up space, requires upkeep, and loses value over time – all while not contributing to your bottom line.

This is the opposite of what your equipment is supposed to do. It’s supposed to help you make more money, not less.

To get a handle on this, you need to track equipment utilization, that is, how often each piece of equipment is being used, for how long, and on which projects.

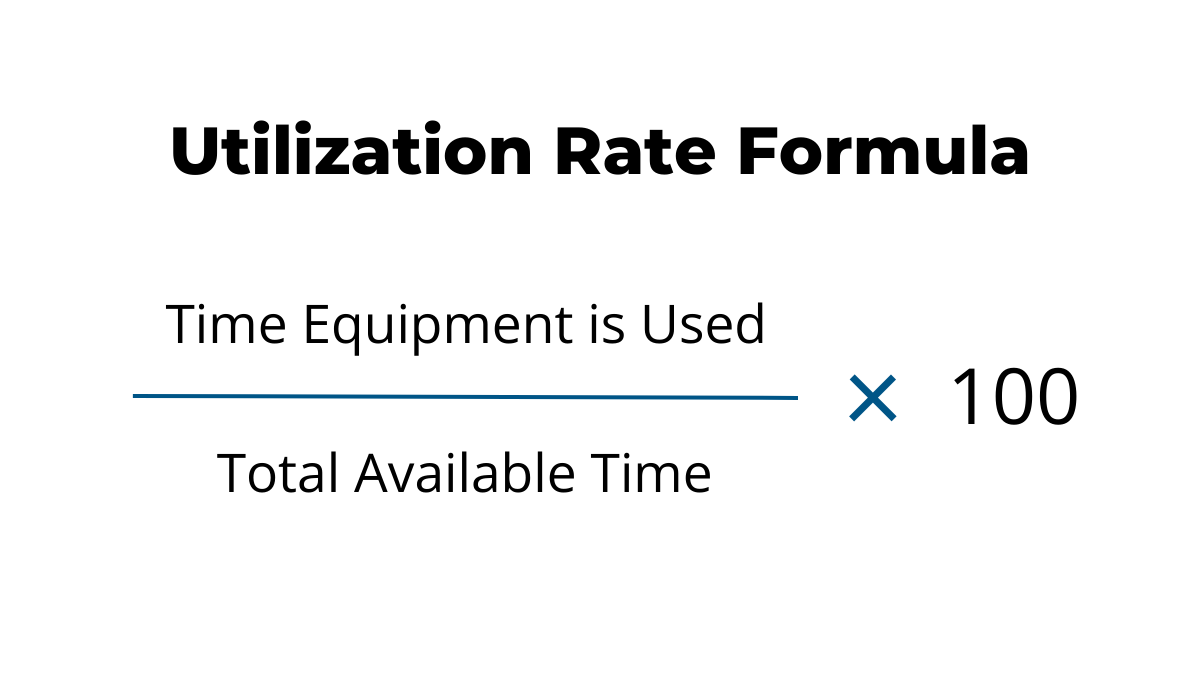

Calculating the equipment utilization rate (EUR) is straightforward:

For example, if a bulldozer is available 100 hours a week and only gets used 40 hours, your utilization rate is 40%.

By tracking these rates, you can identify underutilized equipment and make informed decisions.

If you notice certain equipment isn’t being used enough, there are usually two possible reasons:

- You’re not using it efficiently.

- You don’t need it.

If the issue is efficiency, you can work on improving equipment utilization by redistributing the equipment across projects or reducing downtime.

But if you find you don’t need it, it might be smarter to sell or rent the machine to offset some of the costs.

Now, while calculating EUR is pretty simple, acquiring reliable equipment usage data on how, where, and when your equipment is used can be tricky.

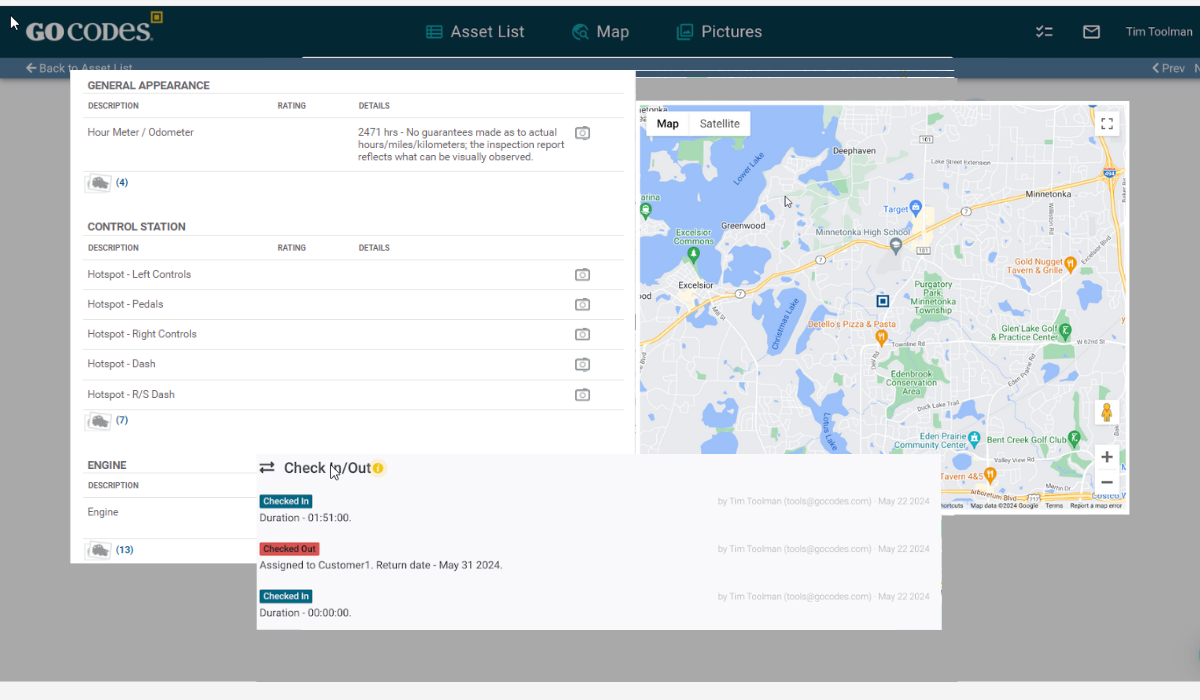

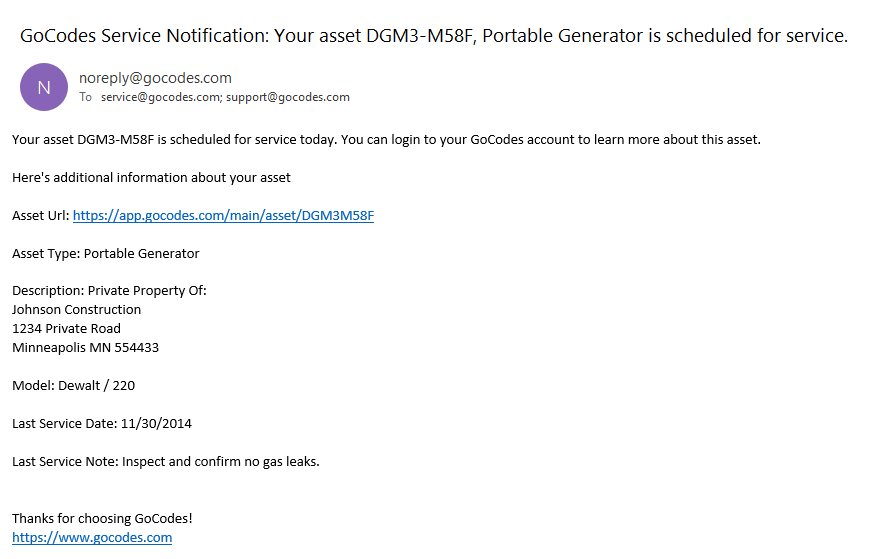

However, with equipment tracking systems like GoCodes Asset Tracking, this becomes simple too.

GoCodes Asset Tracking allows you to monitor your entire fleet in real-time, ensuring you know exactly which machines are in use, where they are, their usage rate, check-in and check-out times, and many other important metrics.

With this information at your fingertips, you can take quick action, whether that means scheduling equipment for more work, renting it out, or selling it altogether.

At the end of the day, you must make sure that every piece of equipment you have is an asset, not a liability.

Train Your Equipment Operators

The way operators use machinery has a direct impact on:

- Wear and tear

- Maintenance costs

- Fuel consumption

- Idle time

- Equipment downtime

- Overall productivity

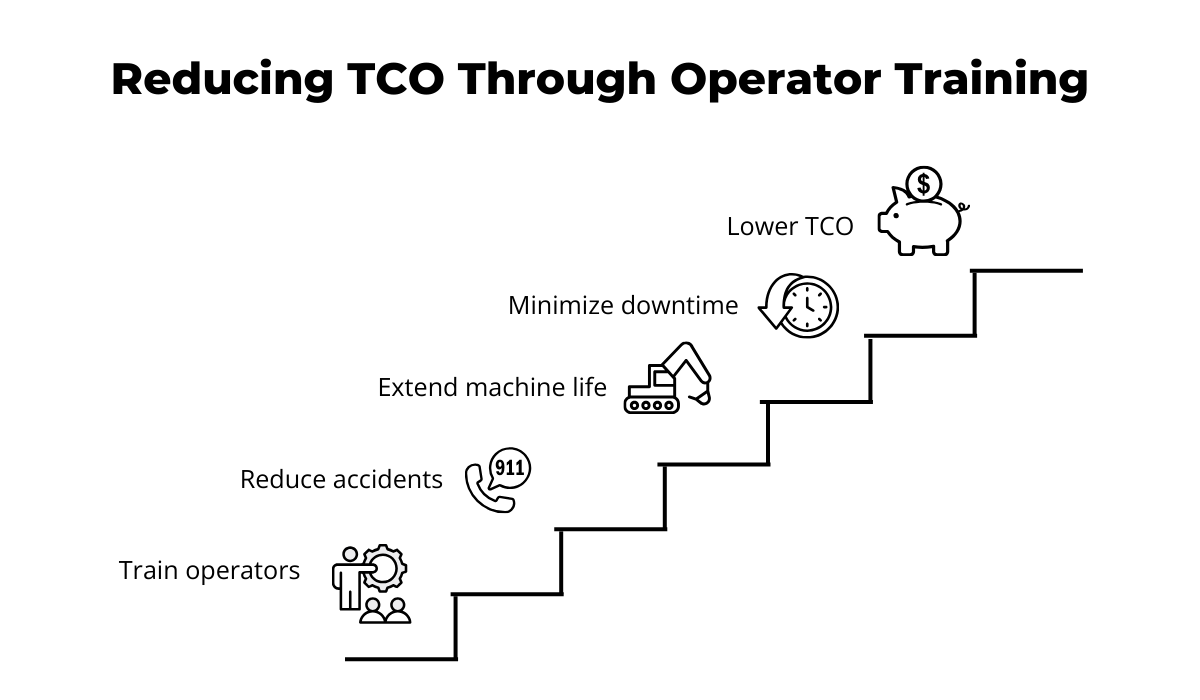

As each of these factors directly affects the total cost of ownership, it’s easy to see why properly training your equipment is one of the most important investments you can make.

First off, misuse or improper handling leads to avoidable wear and tear, accidents, and expensive repairs.

For example, one small mistake with a hydraulic excavator can result in thousands of dollars in repairs.

That’s a serious hit to your total cost of ownership (TCO).

Now, think about that happening multiple times across different machines. It adds up fast. Your maintenance budget could balloon, and the downtime needed for repairs will eat into your project timelines.

Proper training, however, can prevent many of these issues.

When your operators understand how to handle equipment correctly, they reduce the risk of accidents and extend the life of the machine.

And, the longer your machines last and the less downtime there is, the lower your overall TCO.

It’s simple math.

Not only does this protect your equipment, but it also maintains its resale value.

A machine that’s been handled with care will always fetch a higher price than one that’s been beaten up.

On top of that, well-trained operators can also significantly reduce fuel consumption and idle time – two factors that heavily influence your TCO.

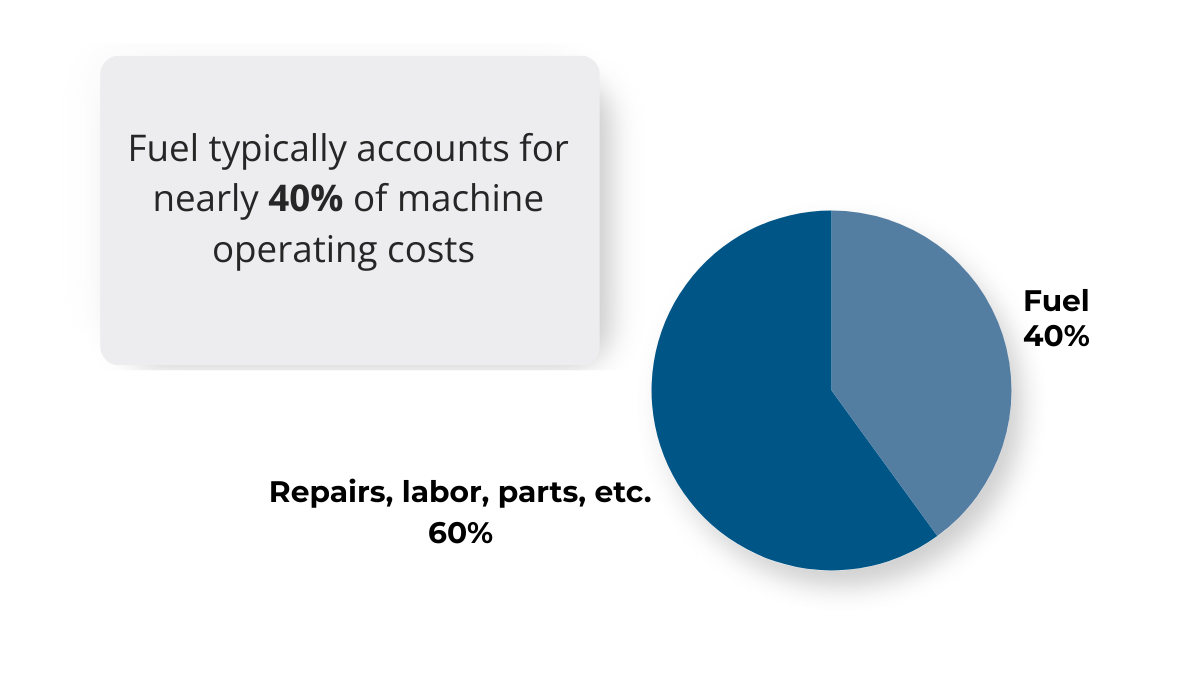

In most construction companies, fuel consumption makes up a significant portion of operating expenses.

In fact, according to an analysis by EquipmentWatch, fuel accounts for more than 40% of machine operating costs – more than repairs, parts, or labor.

Now, that study was done in 2022 when fuel prices were at an all-time high, so while the percentage might be slightly lower today as fuel prices have leveled out since then, it’s still a major cost driver and often close to that 40% mark.

Mike Vorster, a well-known construction company advisor, has seen this firsthand.

Vorster also points out that fuel is one of the most mismanaged expenses:

“Take a worker who costs $30 per hour—you know exactly what they’re doing. But when I ask for the fuel consumption of a machine that costs $30 per hour in fuel, people have no idea. It’s a very big, very poorly managed, and highly volatile cost component.”

Clearly, fuel consumption is not something you can afford to overlook.

Luckily, operator training can significantly reduce this expense.

Operators who know how to use equipment correctly tend to reduce fuel consumption by avoiding excessive idle time and operating the machine at optimal levels.

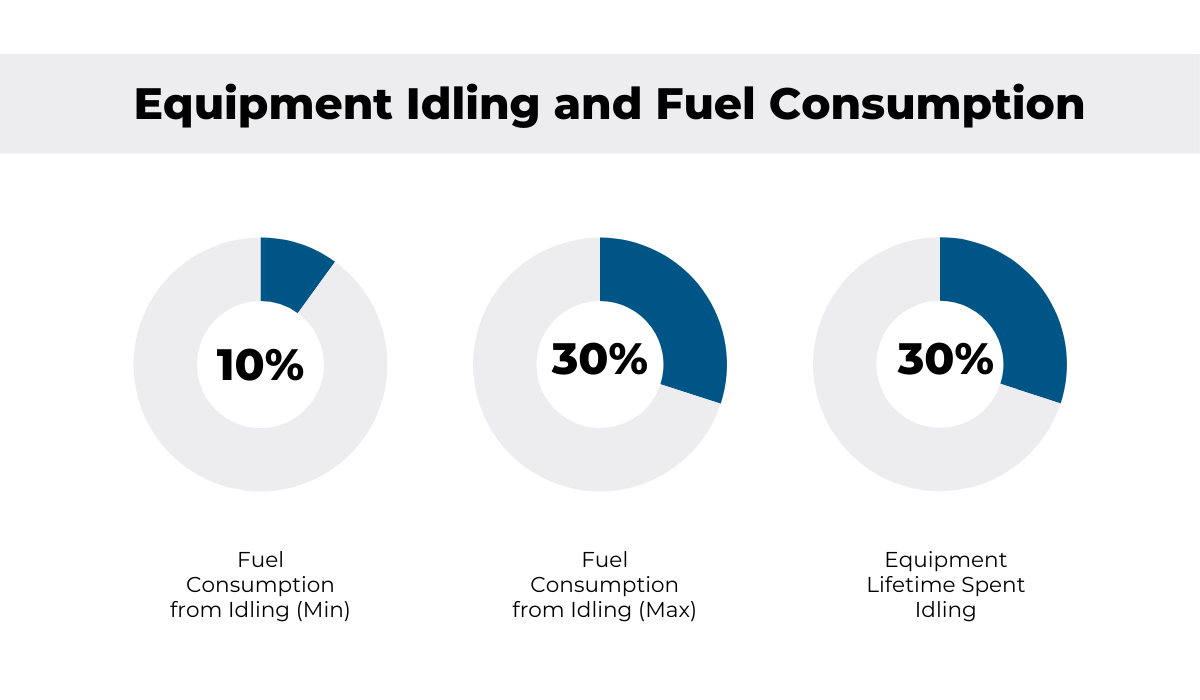

This is especially important given that 10-30% of the fuel consumed by construction machinery comes from nonproductive idling.

In other words, a large portion of your fuel budget is going up in smoke (quite literally) while your machines are doing nothing.

And considering that construction equipment is often semi-stationary and spends at least 30% of its lifetime idling, it’s clear that reducing idle time can lead to substantial savings.

You’ll spend less on fuel, reduce engine wear, and extend the life of your equipment – all of which contribute to a lower total cost of ownership.

Reduce Maintenance Costs

Maintenance is an unavoidable part of owning construction equipment.

If you want your machines to stay productive, perform well, and have a long life, regular upkeep is mandatory.

However, just because maintenance is necessary doesn’t mean you should throw money at it without a plan.

The goal is to ensure that every dollar you invest in maintenance has a cash-positive return on investment (ROI).

In other words, every dollar you spend on maintenance should ultimately save you more in repairs, downtime, or replacements.

So how can you reduce equipment maintenance costs while still taking care of your fleet?

The answer lies in proactive maintenance.

Unlike reactive maintenance – where you’re stuck fixing things only after they break, often leading to larger repairs and longer downtime – proactive maintenance focuses on preventing issues before they become expensive problems.

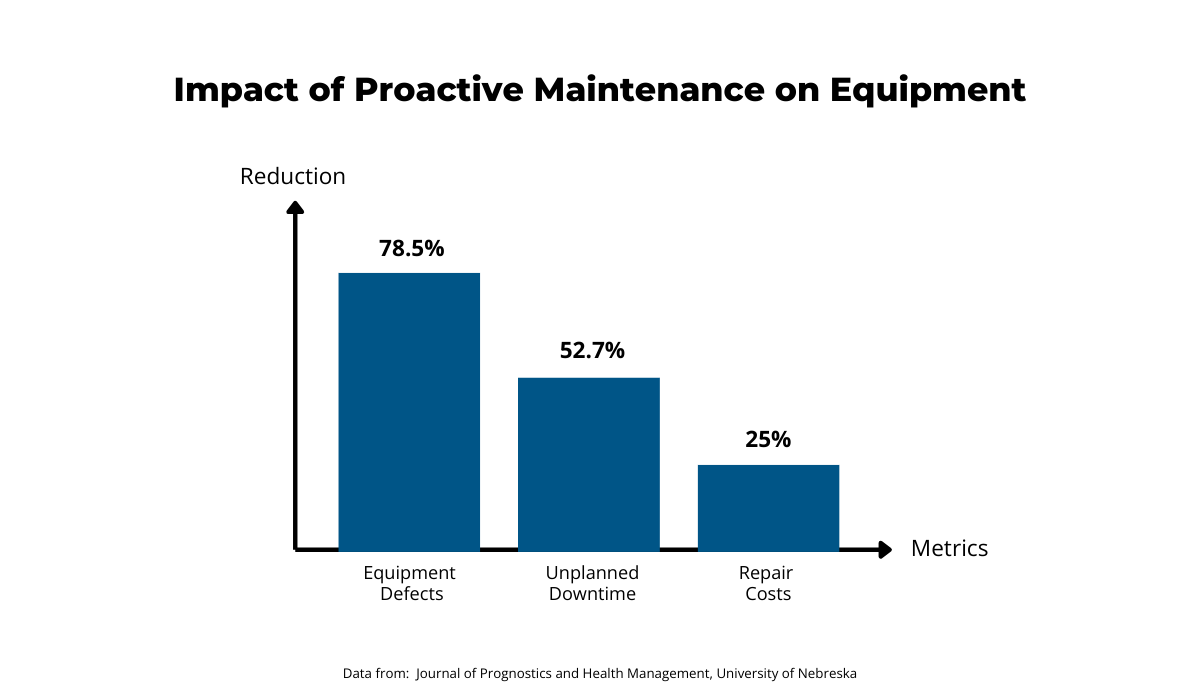

In fact, research shows that proactive measures can reduce equipment defects by nearly 80% and cut unplanned downtime by over 50%.

Additionally, a study by the University of Nebraska found that improving preventive maintenance procedures can lower heavy machinery repair costs by up to 25%.

But how do you put proactive maintenance into practice?

Firstly, it’s crucial to have a solid maintenance schedule in place.

This schedule should be tailored to each piece of equipment based on its usage, manufacturer recommendations, and historical performance.

Sticking to this schedule ensures that you’re keeping up with necessary maintenance without overdoing it or neglecting anything critical.

Along with an adequate maintenance schedule, daily equipment inspections are essential.

Pre-operation and post-operation inspections should be a daily routine for your operators.

These checks typically cover vital areas like fluid levels, tire or track conditions, and any visible signs of wear or damage.

This small investment in time can save you from much bigger expenses down the road.

Next, keep detailed maintenance records.

Tracking the maintenance history of your fleet allows you to stay on top of what’s been done and what’s coming up.

These records help you avoid missing critical maintenance tasks and ensure that each machine is being properly cared for.

Plus, detailed records can increase the resale value of your equipment, as buyers will appreciate the proof of consistent maintenance.

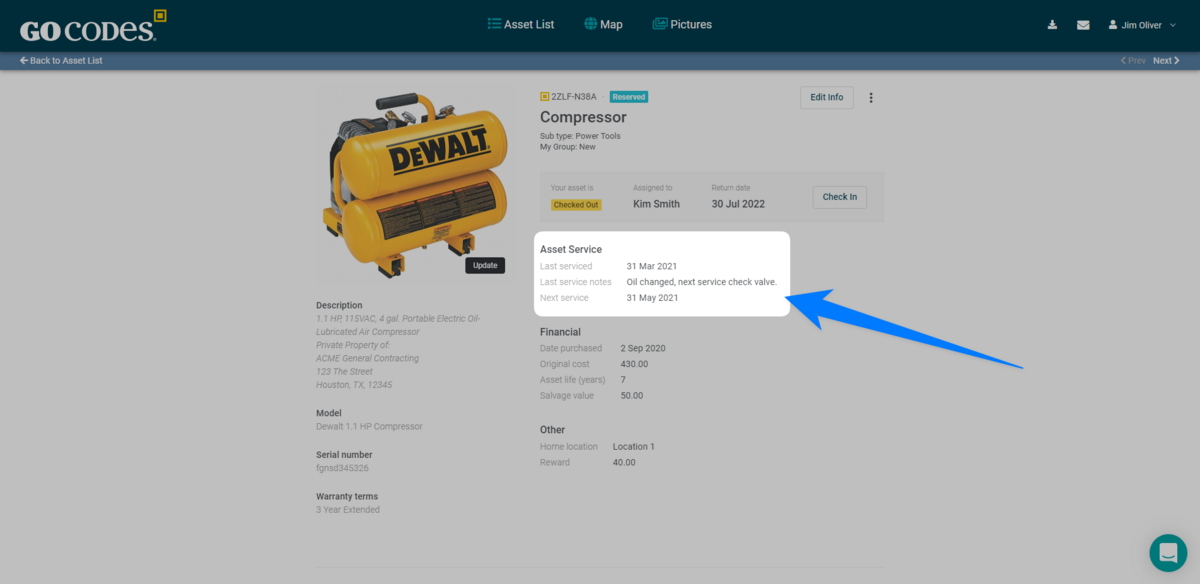

Finally, leverage technology to streamline maintenance.

Whether you use specialized maintenance management software (CMMS) or a complete equipment management solution like our GoCodes Asset Tracking, these tools allow you to streamline maintenance activities.

You will be able to schedule maintenance, keep track of inspections, and receive alerts when inspections or repairs are due.

This not only reduces manual work but also ensures that no machine falls through the cracks.

By implementing these proactive measures and committing to proactive maintenance, you’ll keep your equipment in top shape while reducing overall costs.

This not only ensures a longer life for your machinery but also leads to fewer breakdowns, less downtime, and ultimately, a lower total cost of ownership.

Implement an Equipment Sharing Program

Owning every piece of equipment your company needs may seem ideal, however, it’s rarely the most cost-effective option.

As you already know, full ownership comes with significant expenses that quickly add up, especially for heavy machinery that isn’t used regularly.

So, one very smart way to reduce these costs and lower your total cost of ownership (TCO) is partnering with other construction companies or using equipment-sharing services.

Instead of buying expensive machinery that might sit idle between projects, you can access the equipment you need when you need it, without the long-term financial commitment.

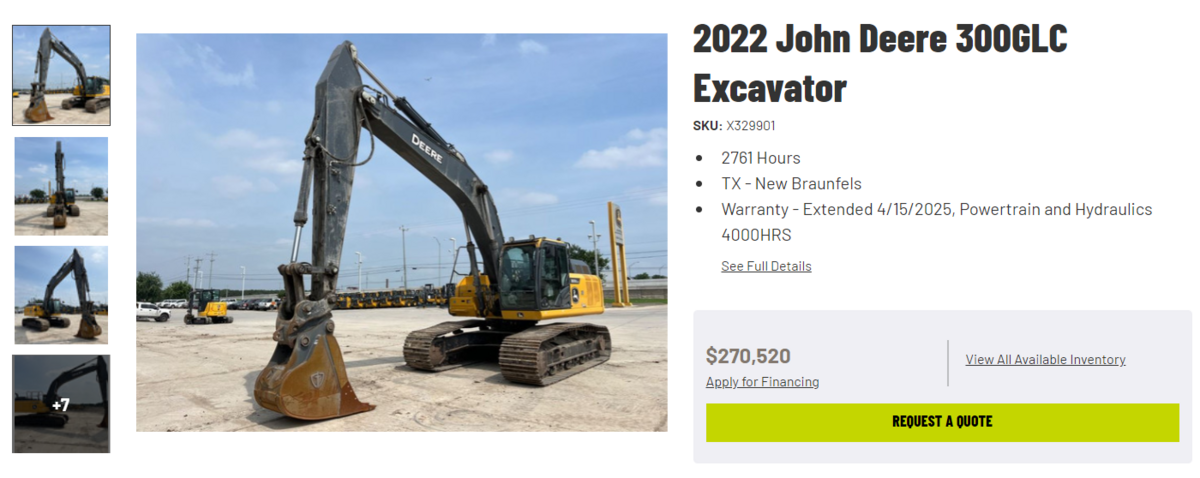

Let’s say you only need a high-capacity crane, for a few projects throughout the year.

Instead of purchasing it outright, which could cost upwards of $400,000, you can partner with a nearby construction company that owns a crane and only needs it occasionally.

By splitting the cost or creating a rental agreement, you both benefit from access to the equipment without the hefty price tag and are avoiding unnecessary costs when the machine isn’t in use.

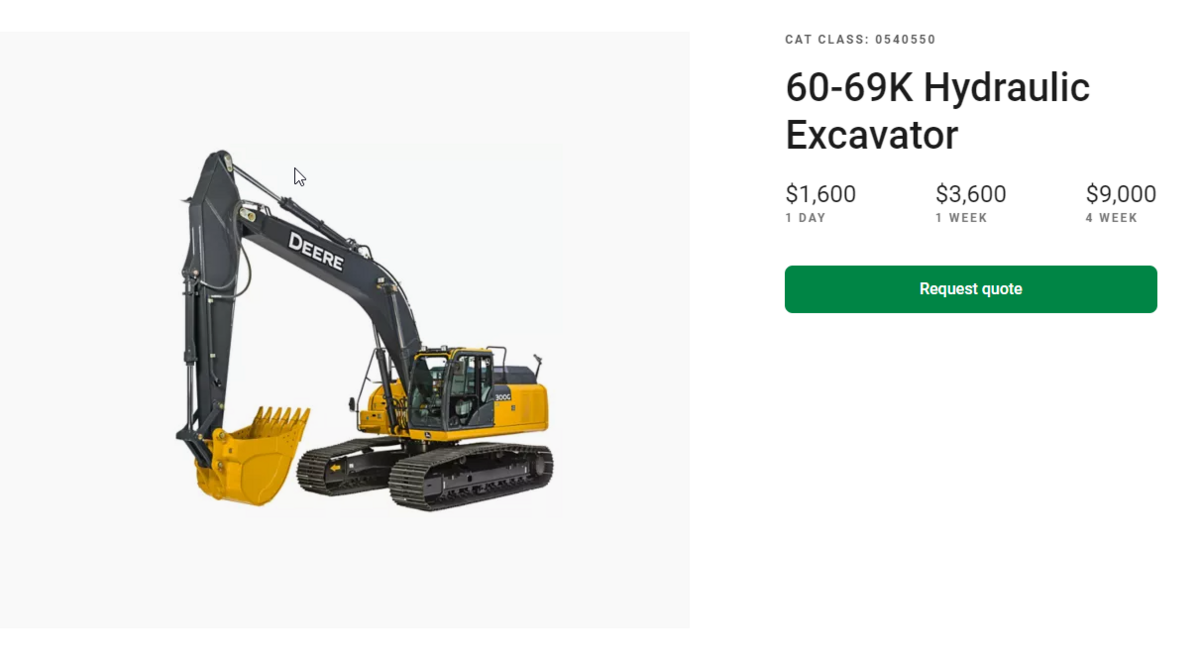

If partnering with other construction companies isn’t possible for some reason, another, much simpler option is to use established equipment-sharing services such as:

These services help streamline the process of finding, renting, and even sharing equipment with other businesses.

In terms of cost, renting or sharing equipment is often far more affordable than purchasing machines. The savings come not only from lower upfront costs but also from reduced maintenance, storage, and depreciation expenses.

Purchasing an excavator, for example, could cost you upwards of $300,000, along with the ongoing costs of storage, insurance, and maintenance.

By contrast, renting or sharing that same excavator could cost as little as $3,000 to $4,000 per week, depending on the region and rental service.

For businesses that only need certain equipment occasionally, the cost difference can be significant.

By taking advantage of equipment-sharing programs, you reduce the financial burden of owning a lot of equipment while still ensuring you have access to everything you need to complete your projects.

This approach helps streamline operations, reduce idle time, increase productivity, and ultimately lower your total cost of ownership.

Conclusion

When it comes to boosting profit, one strategy is always at your disposal: cutting operational costs.

Now, you have a deeper understanding of one specific area—reducing the cost of equipment ownership.

Start by implementing just one of the strategies outlined in this article.

Even small changes can have a significant impact on your bottom line, and as your costs shrink, you’ll see your profits grow.

Don’t wait—take that first step toward more efficient and profitable equipment management today.